The global brass manufacturing industry is experiencing steady expansion, driven by rising demand across sectors such as plumbing, electrical, automotive, and construction. According to Grand View Research, the global brass valves market alone was valued at USD 18.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. Similarly, Mordor Intelligence forecasts the overall brass market to register a CAGR of over 4.5% during the same period, underpinned by increasing urbanization, infrastructural development, and the metal’s antimicrobial properties gaining traction in hygienic applications. As competition intensifies and technological advancements reshape production standards, identifying the top nine elements that define leading brass manufacturers—from raw material sourcing and alloy composition to sustainability practices and global compliance—becomes critical for stakeholders navigating this evolving landscape.

Top 9 Elements Of Brass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mueller Industries

Domain Est. 1996

Website: muellerindustries.com

Key Highlights: Mueller Industries, Inc. is an industrial manufacturer that specializes in copper and copper alloy manufacturing while also producing goods made from aluminum, ……

#2 United Brass Works, Inc.

Domain Est. 1996

Website: ubw.com

Key Highlights: United Brass Works is a leading industrial valve manufacturer offering a range of high-quality products, including boiler, ball, globe, angle, and blowdown ……

#3 Brass Supplier

Domain Est. 1999

Website: meadmetals.com

Key Highlights: Brass is composed of copper and zinc; the proportions of zinc and copper can be varied to create a range of brasses with varying properties. Mead Metals, Inc….

#4 Brass Manufacturers in Jamnagar

Domain Est. 2009

Website: surajbrassindustries.com

Key Highlights: Leading brass components manufacturer in Jamnagar offering precision brass parts, custom fittings & global export solutions. ISO 9001:2015 certified….

#5 Brass Foundry,Brass Casting,Custom Brass Parts Manufacturer

Domain Est. 2015

Website: gatonbrass.com

Key Highlights: One-stop Solution for Brass Parts Casting. From decorative brass items to heavy duty brass pump parts, from automotive parts to marine boat parts….

#6 Aviva Metals

Domain Est. 2017

Website: avivametals.com

Key Highlights: Aviva Metals is the leading manufacturer of bronze, brass & copper alloys. We keep a ready stock of of these metals in a variety of shapes & sizes….

#7 Brass, Red Brass|Copper & Alloy Materials

Domain Est. 2020

Website: mitsubishi-copper.com

Key Highlights: Brass is an alloy of copper and zinc. It has relatively high conductivity compared with other alloys, and has strength compared with pure copper….

#8 Brass Alloys

Domain Est. 1998

Website: sequoia-brass-copper.com

Key Highlights: Sequoia Brass & Copper has been a leading domestic supplier of top-notch copper and brass alloys, serving the metal fabrication industry across North America….

#9 Introduction to Brass

Domain Est. 2018

Website: rightonblackburns.co.uk

Key Highlights: With one of the largest in-stock ranges of brass in the UK, we are able to offer a truly diverse selection of sheet, plate, bar, tube, wire, extrusion and ……

Expert Sourcing Insights for Elements Of Brass

H2: Projected Market Trends for Elements of Brass in 2026

As we approach 2026, the market for elements of brass—primarily copper and zinc, along with trace alloying components like lead, tin, aluminum, and silicon—is expected to undergo significant transformation driven by technological advancements, sustainability initiatives, and evolving industrial demands. Below are the key trends shaping the brass elements market:

1. Rising Demand in Green Technologies

The global shift toward renewable energy and energy-efficient systems is increasing the demand for copper, a core component of brass. Copper’s superior electrical conductivity makes it indispensable in electric vehicles (EVs), wind turbines, solar inverters, and smart grid infrastructure. As EV production is projected to grow at a CAGR of over 20% through 2026, demand for brass components in motors, connectors, and wiring will follow suit.

2. Zinc Market Stability and Recycling Growth

Zinc, the second primary element in brass, is expected to see stable supply dynamics in 2026 due to expanded mining operations in Australia, Canada, and Peru. However, increasing environmental regulations will drive greater reliance on recycled zinc. The recycling rate of zinc is anticipated to exceed 80% in developed markets, reducing the carbon footprint of brass production and aligning with circular economy goals.

3. Lead-Free Brass Adoption Accelerates

Regulatory pressures, particularly in North America and the European Union, are accelerating the transition to lead-free brass (e.g., EnviroBrass, silicon brass) in plumbing and potable water applications. By 2026, over 60% of new brass fittings in these regions are expected to comply with low-lead or lead-free standards, driven by legislation such as the U.S. Reduction of Lead in Drinking Water Act.

4. Expansion in Emerging Markets

Urbanization and infrastructure development in Southeast Asia, Africa, and Latin America will fuel demand for brass in construction, HVAC systems, and industrial machinery. Countries like India and Vietnam are investing heavily in smart city projects, increasing the need for durable, corrosion-resistant brass components in valves, fittings, and decorative fixtures.

5. Technological Innovation in Alloys

Advancements in metallurgy are leading to high-performance brass alloys with enhanced properties—such as improved machinability, antimicrobial surfaces, and higher thermal resistance. These innovations are particularly relevant for medical devices and HVAC systems, where hygiene and efficiency are critical. Nanotechnology applications may also emerge, enabling self-sanitizing brass surfaces in healthcare environments.

6. Supply Chain Resilience and Geopolitical Factors

Ongoing geopolitical tensions and trade policies could impact the availability and pricing of copper and zinc. China’s dominance in refining and alloy production may lead to regional diversification efforts, with North America and Europe investing in domestic processing capabilities to reduce dependency and enhance supply chain security by 2026.

7. Price Volatility and Market Speculation

Commodity markets for copper and zinc are expected to remain volatile due to fluctuating energy costs, speculative trading, and macroeconomic factors such as interest rates and inflation. However, long-term contracts and hedging strategies are likely to become more common among brass manufacturers to mitigate price risks.

In conclusion, the 2026 market for elements of brass will be shaped by sustainability, regulatory compliance, technological innovation, and growing demand from green industries. Companies that prioritize recycling, invest in R&D for advanced alloys, and adapt to regional regulatory landscapes will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Elements of Brass (Quality, IP)

Sourcing brass components—whether for industrial, architectural, or consumer applications—requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance failures, reputational damage, or legal complications. Below are key pitfalls to avoid.

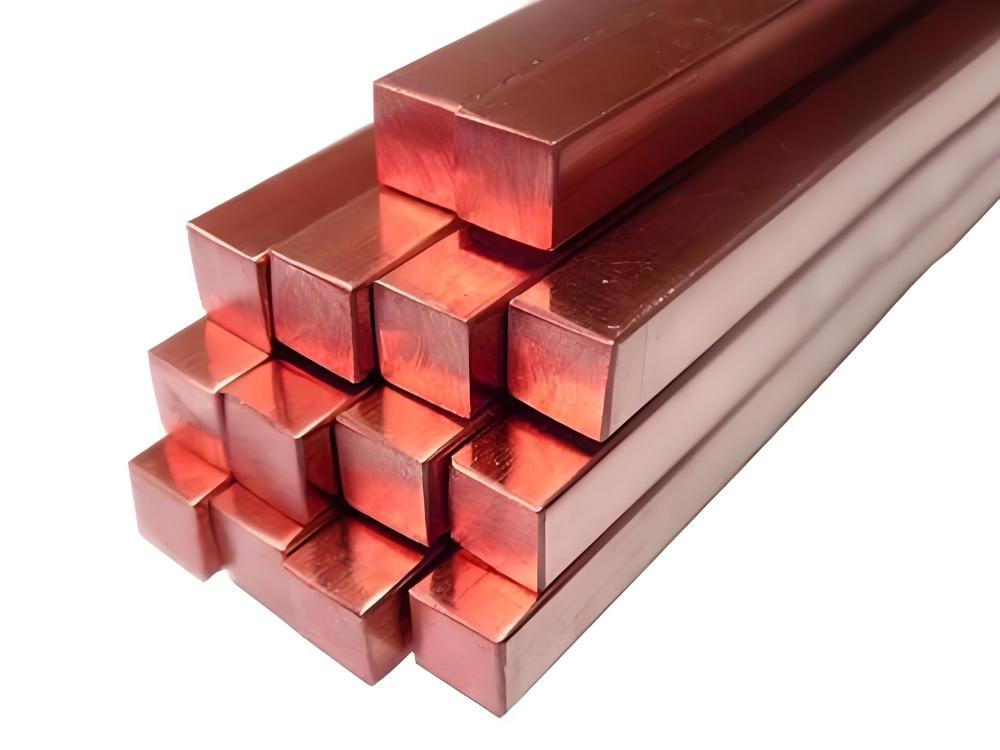

Poor Material Quality and Composition

One of the most frequent issues in sourcing brass elements is receiving materials that do not meet specified compositional standards. Brass is an alloy primarily of copper and zinc, but variations in ratios and the inclusion of lead, tin, or other additives affect mechanical properties, corrosion resistance, and machinability. Suppliers may offer substandard alloys labeled as “brass” that fail under stress or corrode prematurely. Always verify material certifications (e.g., ASTM, ISO) and conduct independent testing to confirm composition and mechanical properties.

Lack of Compliance with Environmental and Safety Regulations

Many regions enforce strict regulations on lead content in brass, especially for plumbing and potable water applications (e.g., NSF/ANSI 61, RoHS, and the U.S. Safe Drinking Water Act). Sourcing non-compliant brass elements can result in product recalls or legal penalties. Ensure suppliers provide documentation proving compliance with relevant standards and avoid vendors who cannot substantiate their claims.

Inadequate Quality Control and Manufacturing Consistency

Brass components must meet precise dimensional tolerances and surface finish requirements. Inconsistent casting, machining, or finishing can lead to fitment issues or premature failure. Sourcing from manufacturers without robust quality management systems (e.g., ISO 9001) increases the risk of receiving defective batches. Regular audits and sample inspections are essential to maintain consistency.

Intellectual Property Infringement Risks

When sourcing brass parts—especially custom-designed fittings, valves, or decorative elements—there is a risk of inadvertently purchasing counterfeit or IP-infringing products. Some suppliers may replicate patented designs without authorization, exposing the buyer to legal liability. Conduct due diligence by verifying design rights, requesting IP indemnification clauses in contracts, and sourcing from reputable manufacturers with transparent design origins.

Misrepresentation of Origin and Traceability

Brass sourced from certain regions may carry reputational or regulatory risks due to unethical mining practices or environmental concerns. Vendors might misrepresent the origin of raw materials or finished goods. Insist on full supply chain transparency and traceability documentation to ensure ethical sourcing and compliance with import regulations.

Overlooking Long-Term Supplier Reliability

Choosing suppliers solely on price can lead to disruptions in supply, inconsistent quality, or poor communication. Establish long-term relationships with suppliers who demonstrate reliability, technical expertise, and responsiveness. A dependable supplier is crucial for maintaining product integrity and continuity, especially in regulated industries.

Avoiding these pitfalls requires a proactive approach: thorough vetting of suppliers, rigorous quality assurance processes, and a clear understanding of both technical specifications and legal obligations related to brass components.

Logistics & Compliance Guide for Elements Of Brass

This guide outlines the key logistics and compliance considerations for handling, transporting, and managing products made from or containing Elements of Brass. Adherence to these guidelines ensures regulatory compliance, operational efficiency, and product integrity.

Material Classification and Handling

Brass, an alloy primarily composed of copper and zinc, is generally non-hazardous under normal conditions. However, proper handling procedures must be followed to prevent contamination, oxidation, and physical damage. Store brass components in a dry, climate-controlled environment to minimize tarnishing and corrosion. Use non-abrasive materials when handling to avoid surface scratches or deformation.

Packaging and Transportation Standards

All brass elements must be packaged to prevent mechanical damage during transit. Use protective wrappings such as anti-tarnish paper, VCI (Vapor Corrosion Inhibitor) bags, or foam inserts. Secure packaging within sturdy, labeled containers that meet international shipping standards (e.g., ISTA, ISO). Clearly label shipments with product details, weight, and handling instructions (e.g., “Fragile,” “This Side Up”).

International Trade Compliance

When exporting or importing brass components, ensure compliance with relevant trade regulations:

– HS Code Classification: Use appropriate Harmonized System (HS) codes (e.g., 7412.20 for brass tubes, 7415.39 for brass fittings) to determine tariffs and duties.

– Export Controls: Verify if brass items are subject to export restrictions, especially if used in defense, aerospace, or dual-use applications.

– Country-Specific Requirements: Comply with destination country standards, including RoHS (Restriction of Hazardous Substances), REACH (EU chemical regulation), and local environmental directives.

Environmental and Safety Regulations

Brass manufacturing and processing may generate metal dust or machining waste. Adhere to OSHA (Occupational Safety and Health Administration) and local safety standards for workplace exposure. Implement proper ventilation and use PPE (Personal Protective Equipment) when cutting, grinding, or polishing. Recycle brass scrap in accordance with EPA (Environmental Protection Agency) and local waste disposal regulations.

Documentation and Traceability

Maintain accurate records for all brass components, including:

– Material Certifications (e.g., Mill Test Reports)

– Certificate of Conformance (CoC)

– Batch or Lot Numbers for traceability

– Shipping and customs documentation

Ensure all documentation is accessible for audits and regulatory inspections.

Product Labeling and Marking

Label brass products with essential information such as:

– Alloy type (e.g., C36000, C26000)

– Dimensions and weight

– Manufacturer or supplier identification

– Compliance marks (e.g., CE, RoHS, UL)

Labels must be durable and resistant to fading or removal during handling and use.

End-of-Life and Recycling Compliance

Design brass components with end-of-life recovery in mind. Provide customers with disposal and recycling guidelines. Comply with WEEE (Waste Electrical and Electronic Equipment) directives where applicable, and support take-back programs to encourage sustainable practices.

Audit and Continuous Improvement

Conduct regular internal audits to ensure ongoing compliance with logistics and regulatory standards. Review supplier performance, update documentation, and train personnel on evolving regulations. Implement corrective actions promptly to address non-conformances.

By following this guide, organizations can ensure the safe, compliant, and efficient handling of Elements of Brass throughout the supply chain.

Conclusion for Sourcing Elements of Brass:

Brass, as an alloy primarily composed of copper and zinc, relies heavily on the responsible and sustainable sourcing of these two key elements. Copper is typically extracted from sulfide or oxide ores through mining operations, while zinc is obtained from sphalerite ore, often as a byproduct of lead or copper mining. The environmental and ethical implications of mining—such as habitat destruction, energy consumption, and labor practices—highlight the importance of sourcing from certified, responsible suppliers who adhere to environmental regulations and social standards.

Additionally, recycling plays a critical role in the brass supply chain, as scrap brass can be re-melted and repurposed with minimal loss of quality, reducing the demand for newly mined materials and lowering the carbon footprint. Advances in urban mining and closed-loop recycling systems further enhance the sustainability of brass production.

In conclusion, ensuring a stable and ethical supply of copper and zinc, combined with robust recycling practices, is essential for the long-term viability and environmental stewardship of brass as a widely used engineering and decorative material. Strategic sourcing, transparency in supply chains, and investment in circular economy models are key to meeting future demands sustainably.