The global electronic springs market is experiencing robust growth, driven by rising demand across consumer electronics, automotive, industrial equipment, and medical devices. According to Grand View Research, the global springs market size was valued at USD 6.3 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth is fueled by advancements in miniaturization, increasing automation, and the proliferation of connected devices requiring reliable electrical interconnect solutions. Mordor Intelligence further projects steady expansion in the electronics components sector, with electronic springs playing a critical role in ensuring signal integrity, grounding, and shielding in compact high-performance systems. As innovation accelerates, manufacturers specializing in precision spring technologies are strategically positioned to meet evolving industry standards. Here are the top nine electronic springs manufacturers leading the market through technological expertise, global reach, and scalable production capabilities.

Top 9 Electronic Springs Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Spring Manufacturers

Domain Est. 2003

Website: springmanufacturer.com

Key Highlights: Connect with top spring manufacturers and industrial suppliers who offer ISO certified industrial springs at competitive prices and with fast shipping….

#2 Lee Spring

Domain Est. 1996

Website: leespring.com

Key Highlights: Lee Spring is your go-to supplier for stock and custom springs, wireforms, fourslide parts and stampings. With thousands of products in stock and engineers ……

#3 CAES

Domain Est. 1996

Website: caes.com

Key Highlights: CAES is a leading provider of mission critical electronic solutions for the United States aerospace and defense industry….

#4 Sparton DeLeon Springs, LLC

Domain Est. 1997

Website: sparton.com

Key Highlights: Solutions that shape the future. Developing, testing, and perfecting new maritime technologies. Meet our products. Sonobuoys. Packed with innovation….

#5 MGM Brakes

Domain Est. 1997

Website: mgmbrakes.com

Key Highlights: MGM Brakes designs, manufactures and distributes Spring Brakes and Electronic Brake Monitoring Systems for all your commercial vehicle needs…Worldwide….

#6 Spring City Electrical Equipment Manufacturing Company

Domain Est. 1998

Website: springcity.com

Key Highlights: Spring City manufactures ornate LED luminaries, Lamp Posts, Bollards & more. See why we’re the leader in street lighting products across America….

#7 WEG

Domain Est. 2004

Website: weg.net

Key Highlights: WEG provides global solutions for electric motors, variable frequency drives, soft starters, controls, panels, transformers, and generators….

#8 Frontgrade: Your Partner in High

Domain Est. 2011

Website: frontgrade.com

Key Highlights: Frontgrade offers innovative radiation-hardened and high-reliability solutions for aerospace, defense, and industry, driven by quality and expertise….

#9 Electronic Springs

Domain Est. 2024

Website: tfsprings.com

Key Highlights: TING FENG utilizes advanced testing instruments and multi-axis servo machinery for precision and efficiency. Through production modularization ……

Expert Sourcing Insights for Electronic Springs

H2: 2026 Market Trends for Electronic Springs

As the global electronics industry continues to evolve, the demand for precision components such as electronic springs is expected to grow significantly by 2026. Key trends shaping the electronic springs market include advancements in miniaturization, the proliferation of wearable technology, increased adoption of electric vehicles (EVs), and the expansion of industrial automation. These developments are driving innovation in materials, design, and manufacturing techniques for electronic springs.

One of the dominant trends is the shift toward smaller, high-performance components. With electronic devices becoming increasingly compact—especially in consumer electronics, medical devices, and IoT sensors—there is a growing need for micro springs that maintain reliability under repeated stress. This has led to increased R&D investments in materials such as beryllium copper and phosphor bronze, which offer high conductivity, durability, and resistance to corrosion.

The rise of electric vehicles is another major driver. Electronic springs are critical in EV battery management systems, connectors, and charging interfaces, where they ensure stable electrical contact and thermal resilience. As global EV production accelerates in response to environmental regulations and consumer demand, the electronic springs market is poised for robust growth, particularly in regions like North America, Europe, and Asia-Pacific.

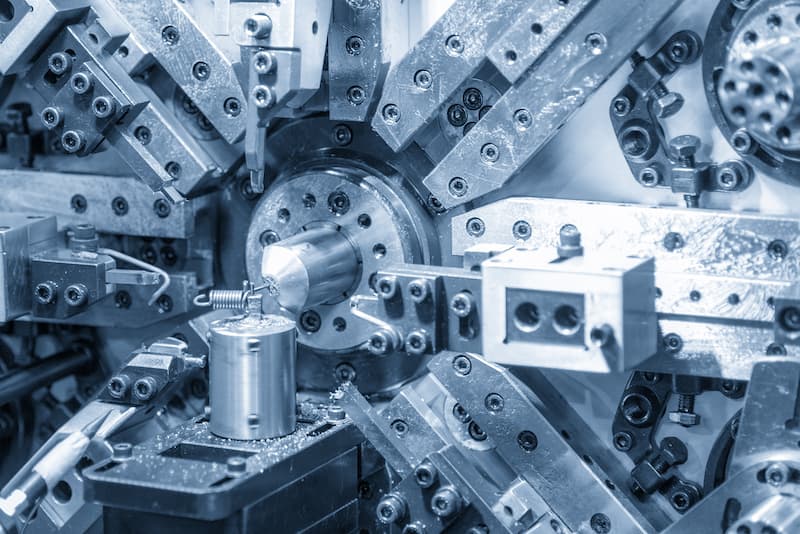

Additionally, the expansion of 5G infrastructure and smart manufacturing is creating new applications for electronic springs in high-frequency connectors and automated assembly systems. These applications require springs with precise tolerances and consistent performance under dynamic conditions, further pushing suppliers to adopt advanced manufacturing technologies such as precision stamping and automated inspection systems.

Sustainability is also emerging as a key consideration. By 2026, manufacturers are expected to prioritize eco-friendly materials and recyclable designs to meet tightening environmental regulations and corporate sustainability goals. This includes reducing hazardous substances and optimizing production processes to minimize waste.

In summary, the 2026 outlook for electronic springs is characterized by technological innovation, rising demand across high-growth sectors, and a focus on sustainability. Companies that invest in R&D, adapt to evolving industry standards, and align with global electrification and digitalization trends are likely to gain a competitive advantage in this dynamic market.

Common Pitfalls Sourcing Electronic Springs (Quality, IP)

Sourcing electronic springs—such as contact springs, battery springs, and connectors—requires careful evaluation to ensure reliability and legal compliance. Overlooking key aspects can lead to product failures, recalls, or intellectual property (IP) disputes. Below are common pitfalls related to quality and IP:

Poor Material Selection and Specifications

Using substandard materials (e.g., incorrect spring alloys like low-grade stainless steel or inadequate phosphor bronze) can result in poor conductivity, reduced spring life, or corrosion. Buyers often fail to specify critical parameters such as tensile strength, resistivity, plating thickness (e.g., gold or nickel), and environmental resistance, leading to performance issues in end applications.

Inconsistent Manufacturing Tolerances

Electronic springs require tight tolerances for reliable electrical contact and mechanical fit. Suppliers from low-cost regions may lack precision tooling or quality control, resulting in dimensional variations. This inconsistency can cause intermittent connections, increased contact resistance, or assembly difficulties.

Inadequate Testing and Certification

Many suppliers provide insufficient or falsified test data. Lack of proper testing for critical parameters—such as load deflection, cycle life, temperature stability, and corrosion resistance (e.g., salt spray testing)—can result in field failures. Certifications like ISO 9001 or IATF 16949 should be verified, not assumed.

Hidden Tooling and Setup Costs

Initial prototypes or low-volume orders may come with undisclosed tooling fees. Buyers unaware of these costs can face budget overruns. Additionally, unclear ownership of custom tooling can create dependency on a single supplier and limit sourcing flexibility.

Intellectual Property Infringement Risks

Sourcing from suppliers who replicate patented spring designs—especially in connectors or proprietary contact mechanisms—exposes buyers to IP litigation. Common in markets with lax IP enforcement, using copied designs can lead to shipment seizures, legal penalties, or forced redesigns.

Lack of Design Ownership and Documentation

Suppliers may retain design rights or fail to provide complete engineering documentation (e.g., 3D models, GD&T drawings, material specs). This creates risks for future manufacturing changes, second sourcing, or product modifications.

Counterfeit or Gray Market Components

Electronic springs may be sourced through unauthorized distributors or recycled from e-waste, especially for high-demand or obsolete parts. These components can have degraded performance or inconsistent quality, compromising device reliability.

Overlooking Long-Term Supply Stability

Suppliers may discontinue materials or go out of business without notice. Failure to secure long-term supply agreements or identify alternate sources can disrupt production, particularly for custom spring designs.

To mitigate these risks, buyers should conduct thorough supplier audits, require material certifications, validate IP clearance, and establish clear contractual terms on design ownership and quality standards.

Logistics & Compliance Guide for Electronic Springs

Electronic springs, though small in size, play a critical role in the performance and reliability of electronic devices. Ensuring their safe, efficient, and compliant movement across the supply chain is essential. This guide outlines key logistics and compliance considerations specific to the handling, packaging, shipping, and regulatory requirements for electronic springs.

Product Classification and Handling Requirements

Electronic springs are typically classified as precision electromechanical components. They are often made from conductive and sometimes sensitive materials such as stainless steel, phosphor bronze, or beryllium copper. Due to their small size and susceptibility to corrosion, deformation, and electrostatic discharge (ESD), proper handling is crucial.

- ESD Protection: Use static-dissipative or anti-static packaging materials and work surfaces when handling.

- Mechanical Protection: Prevent bending, compression, or torsion during storage and transit. Use rigid containers or trays to minimize movement.

- Environmental Controls: Store in dry, temperature-controlled environments to prevent oxidation or moisture damage.

Packaging Standards

Appropriate packaging safeguards electronic springs from physical and environmental damage. Packaging must also meet international shipping requirements.

- Inner Packaging: Use ESD-safe plastic tubes, trays, or foam-lined containers. Individual spring compartments prevent tangling and mechanical stress.

- Outer Packaging: Use durable corrugated boxes with shock-absorbing materials (e.g., bubble wrap or molded pulp). Label packages with “Fragile” and “ESD-Sensitive” warnings.

- Moisture Barrier Bags (MBBs): For long-term storage or humid environments, use MBBs with desiccants and humidity indicator cards, per IPC/JEDEC J-STD-033 standards.

Transportation and Shipping Logistics

Electronic springs are commonly shipped via air, sea, or ground freight, depending on volume and urgency.

- Domestic Shipments: Use reliable courier services with tracking and signature confirmation. Ensure temperature and humidity stability during transit.

- International Shipments:

- Comply with IATA (air) or IMDG (sea) regulations if shipping hazardous materials (e.g., springs containing beryllium).

- Provide accurate commercial invoices, packing lists, and Harmonized System (HS) codes (typically under 8544.42 or 7320.20, depending on material and application).

- Declare precise weight and dimensions for volumetric pricing.

Regulatory and Compliance Standards

Manufacturers and distributors must adhere to multiple international regulations affecting the logistics of electronic springs.

- REACH (EU): Ensure compliance with SVHC (Substances of Very High Concern) regulations. Disclose chemical content if requested.

- RoHS (EU/UK): Confirm that springs are free of restricted substances (e.g., lead, cadmium, hexavalent chromium).

- Conflict Minerals (U.S. Dodd-Frank Act): If applicable, report use of tin, tantalum, tungsten, or gold sourced from conflict-affected regions.

- Customs-Trade Partnership Against Terrorism (C-TPAT): For U.S.-bound shipments, participate in supply chain security programs if required by partners.

Documentation and Traceability

Maintain detailed records for quality assurance and regulatory audits.

- Batch/LOT Tracking: Assign unique identifiers to each production batch for full traceability.

- Certificates of Compliance (CoC): Provide RoHS, REACH, and material compliance documentation with shipments.

- Shipping Documentation: Include MSDS (Material Safety Data Sheet) if materials are classified as hazardous.

Warehouse and Inventory Management

Efficient warehouse practices reduce risk and improve fulfillment.

- Storage Conditions: Maintain clean, dry storage areas with controlled humidity (<60% RH) and ambient temperatures (15–25°C).

- FIFO (First-In, First-Out): Implement FIFO to prevent aging of materials and ensure product integrity.

- Inventory Accuracy: Use barcode or RFID systems for real-time tracking and stock reconciliation.

Returns and Reverse Logistics

Establish clear procedures for handling defective or excess electronic springs.

- Inspection Protocol: Inspect returned items for damage, contamination, or ESD exposure before restocking.

- Data Logging: Record return reasons for quality improvement and compliance reporting.

- E-Waste Compliance: Recycle non-reusable springs through certified e-waste handlers, especially if containing restricted metals.

Summary

Proper logistics and compliance management for electronic springs ensures product reliability, regulatory adherence, and customer satisfaction. Attention to ESD protection, packaging integrity, international regulations, and traceability is essential throughout the supply chain. By following these guidelines, businesses can minimize risk, avoid customs delays, and maintain high standards in the delivery of electronic components.

Conclusion for Sourcing Electronic Springs

In conclusion, sourcing electronic springs requires a strategic approach that balances performance, reliability, cost, and supply chain efficiency. As critical components in many electronic devices—ranging from connectors and switches to sensors and medical equipment—electronic springs must meet stringent specifications for precision, durability, and conductivity.

Key considerations in the sourcing process include material selection (such as beryllium copper, phosphor bronze, or stainless steel), compliance with industry standards (e.g., RoHS, REACH), and the manufacturer’s capability for tight tolerances and high-volume production. Additionally, partnering with reliable suppliers who offer technical expertise, consistent quality control, and responsive support is essential to ensure seamless integration into end products.

Global sourcing offers access to competitive pricing and advanced manufacturing capabilities, particularly in regions like Asia; however, it necessitates careful risk management around logistics, lead times, intellectual property, and geopolitical factors. Nearshoring or regional sourcing may be preferable for high-mix, low-volume applications or when rapid prototyping and flexibility are priorities.

Ultimately, successful sourcing of electronic springs is achieved through a collaborative supply chain, thorough due diligence, and a long-term perspective focused on total cost of ownership rather than upfront price alone. By aligning technical requirements with strategic procurement practices, companies can ensure reliable performance, reduce downtime, and maintain a competitive edge in fast-evolving electronic markets.