The global digital measuring tools market, including electronic tape measures, has experienced steady growth driven by advancements in laser technology, rising demand in construction and real estate, and the increasing adoption of precision tools in DIY and professional applications. According to a report by Mordor Intelligence, the global laser distance measurer market was valued at USD 712.4 million in 2023 and is projected to grow at a CAGR of 6.8% from 2024 to 2029. This expansion reflects a broader industry shift toward digitization, accuracy, and efficiency on job sites worldwide. As demand surges, a select group of manufacturers has emerged as market leaders, combining innovation, reliability, and scalability to capture significant shares across North America, Europe, and the Asia-Pacific. The following list highlights the top 10 electronic tape measure manufacturers shaping this evolving landscape, based on product performance, market presence, and technological leadership.

Top 10 Electronic Measure Tape Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Construction Measuring Tools

Domain Est. 1997

Website: keson.com

Key Highlights: Keson LLC is a professional measuring and marking tools manufacturer specializing in measuring wheels, tape measures, chalk lines, construction levels, and ……

#2 Measuring Tapes

Domain Est. 1999

Website: engineersupply.com

Key Highlights: At Engineer Supply, we have a broad selection of tape measures from some of the best manufacturers in the industry….

#3 3D Measurement, Imaging & Realization Solutions

Domain Est. 1995

Website: faro.com

Key Highlights: FARO provides the most precise 3D measurement, imaging and realization technologies for manufacturing, construction and public safety analytics industries….

#4 US Tape

Domain Est. 1997

Website: ustape.com

Key Highlights: Since 1876, US Tape has been providing unique, dependable, top-quality tools to hardworking professionals in an array of industries….

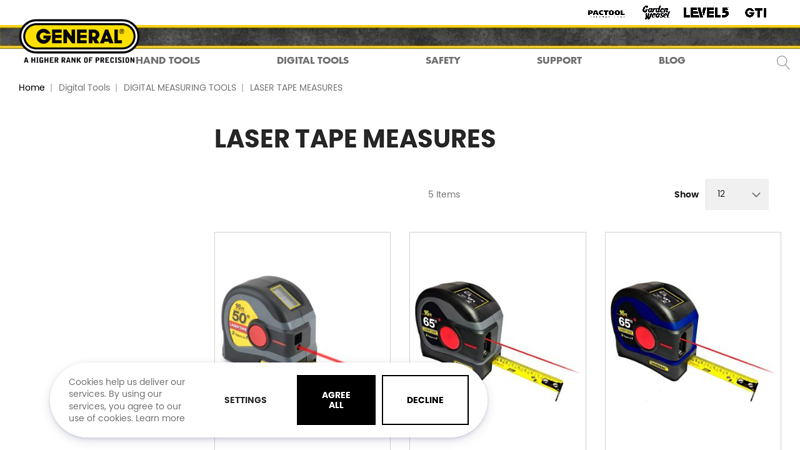

#5 LASER TAPE MEASURES

Domain Est. 1997

Website: generaltools.com

Key Highlights: 2-in-1 65 Foot Laser Tape Measure with Digital Display, Grey. ITEM #LTM2X-GY-A. 2-IN-1 65 FOOT LASER TAPE MEASURE WITH DIGITAL DISPLAY, Blue….

#6 Starrett Products

Domain Est. 1998

Website: starrett.com

Key Highlights: Discover premium precision measuring tools and cutting solutions including micrometers, calipers, band saw blades and much more. Many American-made since ……

#7 xCool 2

Domain Est. 2013

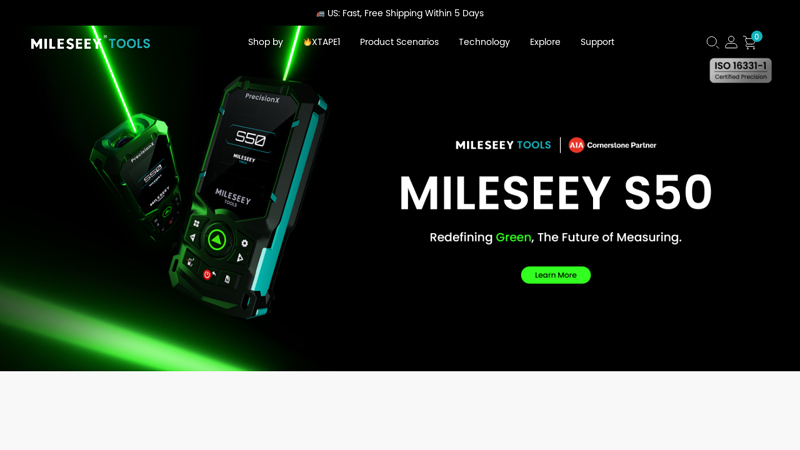

#8 MILESEEY Tools

Domain Est. 2019

Website: mileseeytools.com

Key Highlights: The XTAPE1 combines a tape measure with a laser module. lt is a versatile, easy-to-use tool for everyone, from woodworkers to DlYers….

#9 Tape Measure

Domain Est. 2021

Website: delitoolsglobal.com

Key Highlights: Explore Deli Tools’ range of Steel Measuring Tape, and more. Check Deli Tools tape measure catalog, and register to be a distributor….

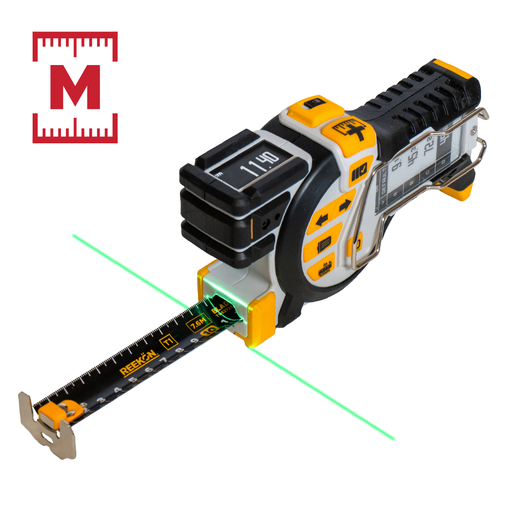

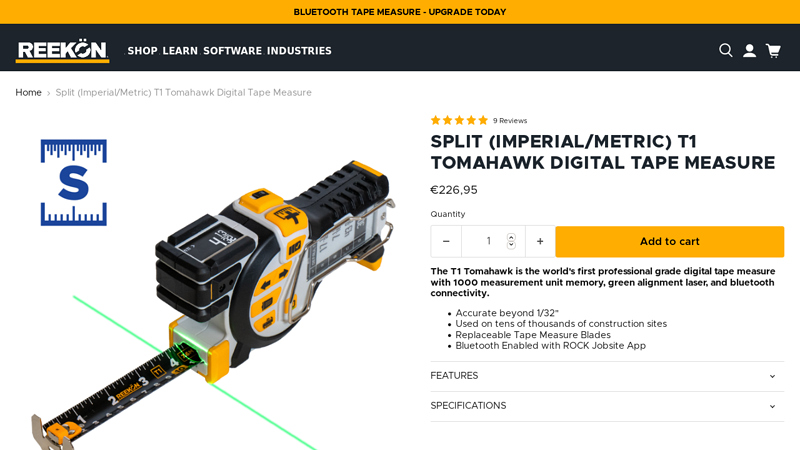

#10 Split (Imperial/Metric) T1 Tomahawk Digital Tape Measure

Expert Sourcing Insights for Electronic Measure Tape

H2: 2026 Market Trends for Electronic Measuring Tapes

The electronic measuring tape market is poised for significant evolution by 2026, driven by technological innovation, increasing demand across construction and real estate sectors, and a growing emphasis on precision and efficiency in measurement tools. As digital transformation continues to reshape traditional tools, several key trends are expected to define the market landscape in 2026.

1. Integration with Smart Devices and IoT

By 2026, electronic measuring tapes are increasingly being designed with Bluetooth and Wi-Fi connectivity, allowing seamless integration with smartphones, tablets, and cloud-based platforms. This enables real-time data transfer, automatic logging of measurements, and compatibility with CAD and BIM (Building Information Modeling) software. The integration supports professionals in architecture, interior design, and construction by streamlining workflows and reducing human error.

2. Advancements in Laser and Sensor Technology

Improvements in laser accuracy, range, and durability are enhancing the performance of electronic measuring tapes. Devices are expected to offer sub-millimeter precision over distances exceeding 100 meters, with enhanced capabilities in low-light and outdoor environments. Miniaturized sensors and improved algorithms are also enabling faster measurement processing and better surface detection, even on uneven or reflective materials.

3. Rising Demand in Residential and Commercial Construction

The global construction boom—particularly in emerging economies—along with growth in home renovation and smart home installations is fueling demand for advanced measurement tools. Electronic measuring tapes are becoming standard equipment for contractors and DIY enthusiasts alike, due to their speed, accuracy, and ease of use compared to traditional tape measures.

4. Focus on User Experience and Ergonomics

Manufacturers are prioritizing intuitive interfaces, backlit digital displays, voice-assisted measurement recording, and lightweight, rugged designs to improve usability. By 2026, many models are expected to feature voice-guided navigation, augmented reality (AR) overlays via companion apps, and longer battery life with quick-charge capabilities.

5. Sustainability and Energy Efficiency

With growing environmental awareness, companies are investing in eco-friendly materials, recyclable packaging, and energy-efficient components. Solar-assisted charging and low-power operating modes are emerging as differentiators in the competitive landscape.

6. Expansion of E-Commerce and Direct-to-Consumer Sales

Online platforms are playing a crucial role in market penetration, especially in regions with limited access to physical retail. Brands are leveraging digital marketing, customer reviews, and influencer partnerships to reach tech-savvy consumers and professionals.

7. Competitive Landscape and Market Consolidation

The market is witnessing increased competition between established players (such as Bosch, Leica, and Stanley) and innovative startups. Strategic partnerships, acquisitions, and R&D investments are expected to accelerate product differentiation and global reach by 2026.

In summary, the electronic measuring tape market in 2026 will be characterized by smart connectivity, precision engineering, user-centric design, and digital integration—positioning it as an essential tool in modern measurement ecosystems across multiple industries.

Common Pitfalls When Sourcing Electronic Measuring Tapes (Quality and IP Considerations)

Sourcing electronic measuring tapes—especially for integration into products or industrial applications—can be fraught with challenges related to both quality and intellectual property (IP). Being aware of these pitfalls helps avoid costly delays, legal issues, and substandard performance.

Poor Build Quality and Inaccurate Measurements

Many low-cost electronic measuring tapes on the market suffer from inconsistent build quality. Components such as the laser sensor, internal encoder wheel, or battery compartment may degrade quickly under regular use. This leads to inaccurate measurements, calibration drift, or complete device failure. Sourcing from unverified suppliers increases the risk of receiving units that don’t meet advertised specifications.

Lack of Environmental Durability (IP Rating Misrepresentation)

The Ingress Protection (IP) rating indicates a device’s resistance to dust and water. A common pitfall is suppliers falsely claiming high IP ratings (e.g., IP65 or IP67) without third-party certification. Devices may claim to be dustproof or water-resistant but fail under real-world conditions. Always request test reports or certifications to verify IP claims—especially if the tape will be used in harsh environments.

Inadequate Calibration and Repeatability

Electronic tapes must provide consistent and repeatable measurements across multiple uses. Poorly manufactured units may exhibit drift or inconsistent readings due to low-quality sensors or inadequate firmware calibration. This is particularly problematic in professional or industrial settings where precision is critical.

Hidden IP Infringement Risks

Many electronic measuring tapes, particularly those from generic manufacturers, may incorporate patented technologies—such as laser distance algorithms, digital display interfaces, or mechanical retraction systems—without proper licensing. Sourcing such products can expose your company to intellectual property litigation, especially when importing or reselling in regulated markets like the EU or North America.

Firmware and Software Limitations

Some devices use proprietary firmware that cannot be updated, customized, or integrated with external systems. This creates a dependency on the supplier for bug fixes or feature enhancements. Additionally, undocumented APIs or closed-source software can hinder integration into larger digital workflows or IoT ecosystems.

Inconsistent Compliance with Safety and EMC Standards

Electronic measuring tapes powered by batteries or USB often fall under electromagnetic compatibility (EMC) and electrical safety regulations (e.g., CE, FCC). Suppliers may claim compliance without proper testing, putting the buyer at risk during customs clearance or market audits. Always verify compliance documentation and insist on test reports from accredited labs.

Supply Chain and After-Sales Support Gaps

Reliability isn’t just about the product—it’s also about the supplier. Many low-cost manufacturers offer little to no after-sales support, spare parts, or technical documentation. This becomes a critical issue if units fail in the field or require firmware updates. Long lead times and communication barriers further complicate sourcing from unreliable vendors.

Conclusion

To mitigate these risks, conduct thorough due diligence: request samples, verify certifications, audit suppliers, and consult legal counsel regarding IP concerns. Investing time upfront ensures you source electronic measuring tapes that are both high-quality and legally safe for your intended use.

Logistics & Compliance Guide for Electronic Measuring Tape

Product Overview

An electronic measuring tape is a digital tool used to measure distances accurately. It typically features a retractable tape, digital display, memory functions, and may include Bluetooth connectivity or laser measurement capabilities. This guide outlines the logistics and compliance considerations for importing, distributing, and selling electronic measuring tapes internationally.

Regulatory Compliance

Electrical Safety Standards

Electronic measuring tapes powered by batteries or rechargeable circuits must comply with electrical safety standards. Key regulations include:

– IEC 61010-1: Safety requirements for electrical equipment for measurement, control, and laboratory use.

– UL 61010-1 (North America): U.S. adoption of IEC 61010-1.

– EN 61010-1 (European Union): Required for CE marking under the Low Voltage Directive (LVD).

Ensure all units pass required testing and are certified by a recognized laboratory (e.g., UL, TÜV, SGS).

Electromagnetic Compatibility (EMC)

Devices with electronic components must meet EMC standards to avoid interference with other equipment:

– FCC Part 15 (USA): Applies to digital devices; Class B for residential environments.

– CISPR 11 / EN 55011 (EU): Emissions standards for industrial, scientific, and medical (ISM) equipment.

– ICES-003 (Canada): Similar to FCC rules.

Pre-compliance testing is recommended before full certification.

Radio Frequency (RF) Compliance (if applicable)

If the device includes Bluetooth or wireless communication:

– FCC ID (USA) and ISED Certification (Canada) are required.

– RED (Radio Equipment Directive 2014/53/EU) in Europe mandates CE marking with RF compliance.

– Ensure SRRC certification if distributing in China.

Battery Safety

Most electronic measuring tapes use lithium batteries:

– Comply with UN 38.3 for lithium battery transportation safety.

– Adhere to IEC 62133 for safety of portable sealed batteries.

– Include proper battery labeling and handling instructions.

Packaging & Labeling Requirements

Product Labeling

Each unit must display:

– Manufacturer/importer name and address.

– Model number and serial number.

– Input/output voltage and battery specifications.

– Compliance marks (e.g., CE, FCC, UKCA).

– WEEE symbol (if applicable in the EU).

User Manual & Documentation

Provide multilingual user manuals including:

– Safety instructions.

– Proper usage and maintenance.

– Disposal information (especially for batteries).

– Warranty and support details.

Packaging

- Use recyclable and protective materials to prevent damage during shipping.

- Include compliance labels on outer cartons (e.g., “Fragile,” “This Side Up”).

- Ensure inner packaging secures the device and accessories.

Import & Customs Compliance

Harmonized System (HS) Code

Use the appropriate HS code for customs clearance:

– Typical classification: 9017.80 – Other drawing, measuring or mathematical instruments.

– Confirm with local customs authority based on exact specifications.

Import Duties & Taxes

- Research duty rates in the destination country.

- Provide commercial invoice, packing list, and certificate of origin.

- For the EU, ensure compliance with Import Control System (ICS2) requirements.

Product Conformity Documentation

Maintain technical documentation including:

– Declaration of Conformity (DoC).

– Test reports from accredited labs.

– Risk assessments and design specifications.

– Required for CE, FCC, and other regional certifications.

Transportation & Logistics

Shipping Classification

- Classify as non-hazardous if using standard alkaline or compliant lithium batteries.

- For lithium batteries, follow IATA Dangerous Goods Regulations (DGR) for air transport.

- Mark packages appropriately (e.g., “Lithium Battery Label” per IATA).

Storage Conditions

- Store in dry, temperature-controlled environments (typically 0°C to 40°C).

- Avoid exposure to moisture, dust, and extreme temperatures.

Supply Chain Security

- Use secure logistics partners compliant with ISO 28000 (security management).

- Implement tracking systems for inventory and shipment visibility.

Environmental & Sustainability Compliance

RoHS (Restriction of Hazardous Substances)

Ensure compliance with:

– EU RoHS Directive 2011/65/EU – Restricts lead, mercury, cadmium, etc.

– China RoHS – Applies to products sold in China.

– Provide RoHS compliance declaration and material declarations.

WEEE (Waste Electrical and Electronic Equipment)

- In the EU, register with national WEEE authorities.

- Provide take-back options and label products with the crossed-out wheelie bin symbol.

- Partner with certified e-waste recyclers.

REACH (EU)

Register and disclose substances of very high concern (SVHC) if present above threshold levels.

Market-Specific Requirements

United States

- FCC certification for digital and RF components.

- CPSC guidelines for consumer product safety.

- California Proposition 65 warning if applicable (e.g., for certain plastics or metals).

European Union

- CE marking required (LVD, EMC, RoHS, RED if applicable).

- Register in EUDR (if relevant) and comply with battery directives.

United Kingdom

- UKCA marking (post-Brexit); CE still accepted until 2025 in most cases.

- UK REACH and UK RoHS apply.

Canada

- ISED certification for RF and digital devices.

- Comply with Canadian Electrical Code and consumer safety laws.

Australia & New Zealand

- RCM (Regulatory Compliance Mark) required for electrical safety and EMC.

- AS/NZS standards alignment (e.g., AS/NZS 61010.1).

Quality Assurance & Post-Market Surveillance

Quality Control

- Implement pre-shipment inspections (AQL standards).

- Conduct periodic batch testing for safety and functionality.

Incident Reporting

- Monitor and report product defects or safety issues.

- EU: Report through RAPEX if non-compliant.

- U.S.: Report to CPSC if safety hazard is identified.

Warranty & Returns

- Define clear warranty terms (typically 1–2 years).

- Establish a returns and recycling process compliant with local e-waste rules.

Conclusion

Successfully distributing electronic measuring tapes globally requires adherence to electrical, environmental, and logistics regulations. Proactive compliance planning, accurate documentation, and collaboration with certified testing bodies ensure smooth market entry and long-term product reliability. Always consult local regulatory experts to address region-specific requirements.

In conclusion, sourcing an electronic measuring tape requires careful consideration of various factors such as accuracy, range, durability, functionality, brand reputation, and cost-effectiveness. It is essential to identify the specific needs of the intended application—whether for construction, DIY projects, or industrial use—to select a model with the right features, such as digital display, metric/imperial units, memory functions, and laser or tape-based measurement technology. Evaluating suppliers based on reliability, warranty offerings, and customer support ensures long-term satisfaction and product performance. By conducting thorough market research and comparing available options, buyers can make an informed decision that balances quality and value, ultimately enhancing efficiency and precision in measurement tasks.