The global electrical cords and plugs market is experiencing steady expansion, driven by rising demand across residential, commercial, and industrial sectors. According to Grand View Research, the global power cord market size was valued at USD 29.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing electrification, the proliferation of consumer electronics, and stricter safety standards requiring high-quality, durable power cords. Additionally, rapid urbanization and infrastructure development in emerging economies are amplifying the need for reliable electrical connectivity solutions. As demand intensifies, manufacturers are focusing on innovation, compliance with international standards (such as UL, CE, and RoHS), and sustainability. In this evolving landscape, identifying leading electrical cord with plug manufacturers becomes critical for sourcing high-performance, safe, and efficient products. Based on production capacity, global reach, certification standards, and market reputation, here are the top 9 manufacturers shaping the industry today.

Top 9 Electrical Cord With Plug Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Meltric

Domain Est. 1997

Website: meltric.com

Key Highlights: MELTRIC offers a full line of industrial plugs and receptacles, including our signature brand of UL-listed Switch-Rated devices with DECONTACTOR™ ……

#2 Power Cord Sets, Power Cords and Jumper Cords

Domain Est. 1993

Website: volex.com

Key Highlights: Volex is a leading global manufacturer and supplier of power cord sets, power cords and jumper cords….

#3 Power Cord & Electrical Cords

Domain Est. 1999

Website: americord.com

Key Highlights: Free delivery 30-day returnsWe offer a wide variety of power cords online, ranging from electronics power cords to cords for industrial machinery and everything in between….

#4 AC power cord, plugs, sockets and wire harness manufacturer Phino …

Domain Est. 1999

Website: phino.com

Key Highlights: Phino Electric is certified for sales of AC power cords, plugs, sockets, connectors around the world….

#5 Power Cord Manufacturers

Domain Est. 2001

Website: cordsets.org

Key Highlights: Instantly view the leading power cord manufacturers and suppliers in the United States who offer an assortment of power cords with varying lengths and uses ……

#6 Power Cord Manufacturers

Domain Est. 2019

Website: powercordmanufacturers.com

Key Highlights: Some specialized cord sets include business machine cords, heavy duty cords, hospital plugs, NEMA power cords, right angle power cord sets, power strips and ……

#7 Southwire

Domain Est. 1994

Website: southwire.com

Key Highlights: Choose Southwire for your wire and cable needs – we offer high-performance products that are built to last….

#8 Power Cords and Adapters

Domain Est. 1996

Website: tripplite.eaton.com

Key Highlights: We offer AC power cords, extension cords, splitters and adapters for computers, servers and PDUs. Our cords have innovative features like coiled cords and ……

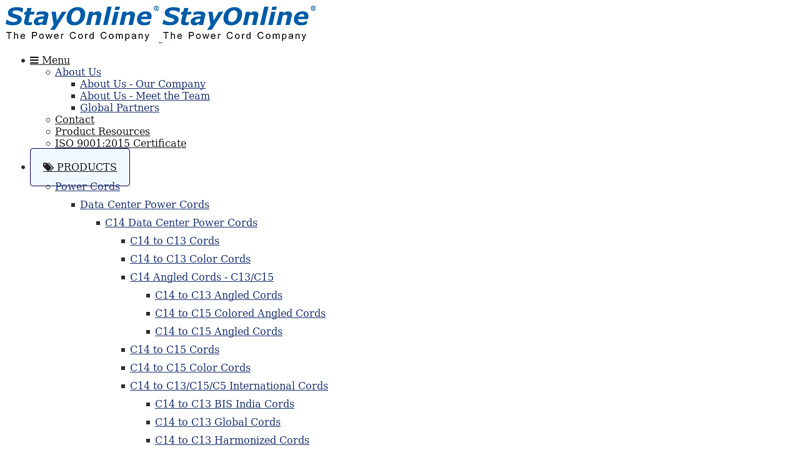

#9 StayOnline

Domain Est. 1996

Website: stayonline.com

Key Highlights: 4-day delivery 30-day returnsStay connected and stay online with the largest selection of in-stock and made-to-order power cords in the industry!…

Expert Sourcing Insights for Electrical Cord With Plug

H2: 2026 Market Trends for Electrical Cord with Plug

The global market for electrical cords with plugs is poised for notable transformation by 2026, driven by technological advancements, regulatory changes, and shifting consumer demands. This analysis highlights key trends shaping the industry landscape over the next few years.

-

Increased Demand for Smart and Energy-Efficient Cords

By 2026, there will be a growing preference for intelligent electrical cords equipped with overload protection, surge suppression, and energy monitoring capabilities. Integration with smart home ecosystems—such as compatibility with voice assistants and mobile apps—will become a key differentiator. Consumers and businesses alike will prioritize cords that contribute to energy efficiency and provide real-time usage data. -

Stricter Safety and Regulatory Standards

Regulatory bodies worldwide are expected to enforce more rigorous safety standards for electrical cords and plugs, especially in response to fire hazards and electrical accidents. Markets in Europe and North America will likely mandate compliance with updated versions of IEC, UL, and CE certifications. This will drive innovation in materials (e.g., flame-retardant insulation) and design (e.g., child-safe outlets and tamper-resistant plugs). -

Rise of Sustainable and Eco-Friendly Products

Environmental concerns will push manufacturers toward sustainable production. By 2026, cords made from recycled materials, bioplastics, or low-halogen compounds will gain market share. Companies will emphasize recyclability, reduced packaging, and carbon-neutral manufacturing to appeal to environmentally conscious consumers and comply with ESG (Environmental, Social, and Governance) standards. -

Growth in E-Commerce and Direct-to-Consumer Sales

Online retail platforms will continue to dominate the distribution of electrical cords with plugs. Enhanced product descriptions, customer reviews, and fast delivery options will influence purchasing decisions. Brands will invest in DTC (Direct-to-Consumer) models, offering customizable cord lengths, colors, and plug types to meet niche or regional requirements. -

Expansion in Emerging Markets

Developing economies in Asia-Pacific, Africa, and Latin America will witness rising demand due to urbanization, infrastructure development, and increased access to electricity. Affordable, durable cords tailored to local voltage standards and plug types (e.g., Type C, D, M) will be critical. Localized manufacturing and partnerships with regional distributors will help companies capture market share. -

Innovation in Cord Design and Durability

There will be a shift toward tangle-free, retractable, and reinforced cords designed for frequent use in industrial, commercial, and consumer applications. Kevlar-reinforced jackets, anti-kink technology, and 360-degree swivel plugs will enhance user experience and product lifespan, especially in high-demand environments like data centers and healthcare facilities. -

Integration with Renewable Energy Systems

As solar and home battery systems become more widespread, specialized cords with plugs compatible with inverters, EV chargers, and portable power stations will see increased demand. These products will need to support higher wattages and feature weather-resistant designs for outdoor use.

In conclusion, the 2026 market for electrical cords with plugs will be defined by innovation, safety, sustainability, and adaptability to regional and technological shifts. Companies that anticipate these trends and invest in R&D, compliance, and customer-centric design will be best positioned for growth.

Common Pitfalls Sourcing Electrical Cords with Plug

Poor Build Quality and Material Selection

Many low-cost electrical cords use substandard materials such as thin insulation, undersized conductors, or brittle outer jackets. These can lead to overheating, short circuits, or premature failure. Always verify the conductor gauge (AWG), insulation type (e.g., PVC, rubber), and jacket durability to ensure they meet safety standards and application requirements.

Misrepresentation of Ingress Protection (IP) Rating

Suppliers may falsely claim high IP ratings (e.g., IP67, IP68) without proper certification. In reality, the cord or plug may only be splash-resistant (IPX4) or not rated at all. Always request test reports or certification documents (e.g., from UL, TÜV, or CE) to validate the stated IP rating, especially for outdoor, industrial, or wet environment use.

Lack of Compliance with Regional Safety Standards

Electrical cords must comply with regional regulations (e.g., UL in North America, CE in Europe, CCC in China). Sourcing non-compliant cords risks rejection at customs, legal liability, or safety hazards. Confirm that the product meets the target market’s regulatory requirements before placing bulk orders.

Inconsistent Plug Type and Voltage Compatibility

Suppliers may provide incorrect plug configurations or fail to match voltage and current ratings to the intended region or device. This can result in incompatibility, unsafe operation, or damage to equipment. Clearly specify plug type (e.g., NEMA 5-15P, Schuko, BS 1363), voltage (e.g., 120V, 230V), and amperage (e.g., 10A, 15A) during sourcing.

Inadequate Strain Relief and Connector Durability

Poorly designed cords often lack robust strain relief at the plug and connector junctions, leading to internal wire breakage from repeated bending or pulling. Inspect samples for molded strain relief, secure wire anchoring, and connector robustness to ensure long-term reliability.

Omission of Certifications and Test Documentation

Reputable suppliers provide product certifications (e.g., UL, CSA, RoHS, REACH) and test reports. Avoid vendors who cannot produce documentation, as this increases the risk of receiving unsafe or non-compliant products. Always request and verify certification authenticity.

Overlooking Environmental and Temperature Ratings

Standard cords may not perform reliably in extreme temperatures, UV exposure, or oily/chemical environments. Ensure the cord is rated for the intended operating conditions—check temperature range (e.g., -20°C to +60°C), UV resistance, and oil/chemical resistance when necessary.

Logistics & Compliance Guide for Electrical Cord With Plug

Product Classification and HS Code

Electrical cords with plugs are typically classified under the Harmonized System (HS) code based on their construction, voltage rating, and intended use. A common HS code for such products is:

- 8544.42 – Insulated wire, cable (including coaxial cable), and other types of cable, for a voltage ≤ 1,000 V, with connectors.

Note: Final HS code assignment should be verified with local customs authorities, as classification may vary by country and specific product features (e.g., shielding, conductor material, plug type).

Regulatory Compliance Requirements

1. Electrical Safety Standards

Electrical cords with plugs must comply with safety standards in the destination market. Key standards include:

- USA: UL 817 – Standard for Power Supply Cords and Cord Sets (certified by UL or ETL)

- Canada: CSA C22.2 No. 21 – Power Supply Cords (recognized by CSA or cETL)

- European Union: EN 50525 series (harmonized under the Low Voltage Directive 2014/35/EU), requiring CE marking

- UK: UKCA marking required; follows similar requirements to CE

- Australia/New Zealand: AS/NZS 3191 and AS/NZS 3112 (SAA approval required)

- China: CCC (China Compulsory Certification) for certain cord types

2. Plug Type and Voltage Compatibility

Ensure the plug design matches the destination country’s:

- Plug configuration (e.g., Type A/B in North America, Type G in the UK, Type C/F in Europe)

- Voltage and frequency (e.g., 120V/60Hz in the US, 230V/50Hz in EU)

Plugs must be permanently and correctly attached per safety standards.

Packaging and Labeling Requirements

Product Labeling

Each cord must include permanent, legible markings that include:

- Manufacturer or brand name

- Model or type number

- Voltage and current rating (e.g., 125V 10A)

- Wire gauge (e.g., 16 AWG)

- Standards compliance (e.g., “UL Listed”, “CE”)

- Manufacturing date or lot number (recommended for traceability)

Retail and Shipping Packaging

- Use packaging that prevents tangling and physical damage

- Include compliance marks and safety warnings on packaging

- Multilingual labeling may be required in regions like the EU or Canada

- Avoid misleading claims (e.g., “universal” unless technically accurate)

Import Documentation

Standard documentation required for international shipping includes:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Compliance or Test Report (e.g., from UL, TÜV)

- Safety Certification (e.g., Declaration of Conformity for CE)

- Import Declaration (as required by destination country)

Environmental and Chemical Compliance

RoHS Compliance (EU, UK, China, etc.)

Electrical cords must comply with restrictions on hazardous substances such as:

- Lead, Mercury, Cadmium

- Hexavalent Chromium

- PBB and PBDE flame retardants

Ensure suppliers provide RoHS compliance documentation.

REACH (EU)

Ensure no restricted substances (e.g., SVHCs – Substances of Very High Concern) are present above threshold levels.

California Proposition 65 (USA)

If sold in California, cords containing listed chemicals (e.g., phthalates in PVC insulation) require a warning label.

Logistics Considerations

Storage and Handling

- Store in dry, temperature-controlled environments

- Avoid prolonged exposure to sunlight or extreme temperatures

- Prevent kinking or crushing during transport

Shipping Methods

- Air freight: Suitable for small volumes; ensure no restricted battery components are included

- Ocean freight: Cost-effective for bulk shipments; use moisture-resistant packaging

- Consider dimensional weight for cords that are lightweight but bulky

Country-Specific Import Duties and Taxes

- Duty rates vary by HS code and country

- Use Free Trade Agreements (e.g., USMCA, RCEP) if applicable to reduce tariffs

- VAT or GST typically applies upon import

Recalls and Product Liability

- Maintain records of compliance testing and certifications

- Register products with relevant safety bodies if required

- Have a recall response plan in place for non-compliant or defective units

Summary Checklist

✅ Verify correct HS code

✅ Obtain required safety certifications

✅ Use locally compliant plug type and ratings

✅ Label product and packaging per regulations

✅ Prepare full import documentation

✅ Ensure RoHS, REACH, and Prop 65 compliance

✅ Use appropriate packaging and shipping methods

Following this guide ensures safe, legal, and efficient global distribution of electrical cords with plugs.

In conclusion, sourcing an electrical cord with a plug requires careful consideration of several key factors including voltage and current ratings, plug type and compatibility with local standards, cord length, insulation material, and safety certifications (such as UL, CE, or ETL). It is essential to match the cord specifications to the intended application to ensure safe and reliable operation. Additionally, sourcing from reputable suppliers or manufacturers helps guarantee product quality and compliance with regulatory requirements. By evaluating these aspects thoroughly, you can select the right electrical cord with a plug that meets both performance needs and safety standards.