The global electrical conduit market is experiencing steady growth, driven by rising infrastructure development, increased construction activities, and stringent safety regulations mandating the use of protective cabling systems. According to a report by Mordor Intelligence, the electrical conduit market was valued at USD 10.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This expansion is further fueled by the surge in smart city projects, renewable energy installations, and industrial automation, all of which require durable and code-compliant wiring protection solutions.

As demand escalates, manufacturers are focusing on innovation, material efficiency, and compliance with international standards such as UL, NEC, and IEC. From galvanized steel to flexible non-metallic conduits, product diversification is a key competitive differentiator. In this evolving landscape, a select group of manufacturers have emerged as leaders, setting benchmarks in size range, product durability, and global distribution. Below are the top 9 electrical conduit size manufacturers shaping the industry’s future through scale, technological advancement, and market reach.

Top 9 Electrical Conduit Size Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Scepter Rigid PVC Conduit

Domain Est. 2009

Website: ipexna.com

Key Highlights: Scepter FT-4 rated rigid PVC electrical conduit for indoor and outdoor use. Whether exposed, concealed in walls, encased in concrete, or directly buried….

#2 How to Determine the Right Size of Electrical Conduit

Domain Est. 2023

Website: pvcconduitmanufacturer.com

Key Highlights: -Manufacturer Websites: Many conduit manufacturers offer online resources, including sizing guides and calculators based on their products….

#3 3TM Conduit Fill Calculator

Domain Est. 1994

Website: southwire.com

Key Highlights: The app will calculate the conduit fill percentages and jam probability for multiple conductors per NEC® Guidelines. Simply enter the conduit type and size….

#4 Condulet

Domain Est. 1996

Website: eaton.com

Key Highlights: Eaton Crouse-Hinds series Condulet™ fittings are commonly available in hub trade sizes ranging from ½” to 4”. Female hub threads are tapered, NPT-style and ……

#5 Conduit Fill Table

Domain Est. 1996

Website: stateelectric.com

Key Highlights: Find the right conduit size with our Conduit Fill Table. Easily calculate NEC-compliant fill limits for safe, efficient wiring. Perfect for electricians and ……

#6 How to size conduit for cable

Domain Est. 2012

Website: essentracomponents.com

Key Highlights: In our guide, we cover the steps you need to take to correctly calculate conduit fill, including a comprehensive conduit fill chart….

#7 American Fittings Corporation

Domain Est. 2012

Website: amftgs.com

Key Highlights: Manufacturing USA specification grade Steel Rigid Conduit … AC MC Conduit Fittings. Size Range: 3/8″ to 2″ Steel For Use With MC…

#8 The Complete Guide to Cable Conduits

Domain Est. 2010

Website: aerosusa.com

Key Highlights: Electrical conduit is a plastic or metal tube that holds electrical wires or cables. It can be flexible or rigid and protects wires in a range of settings….

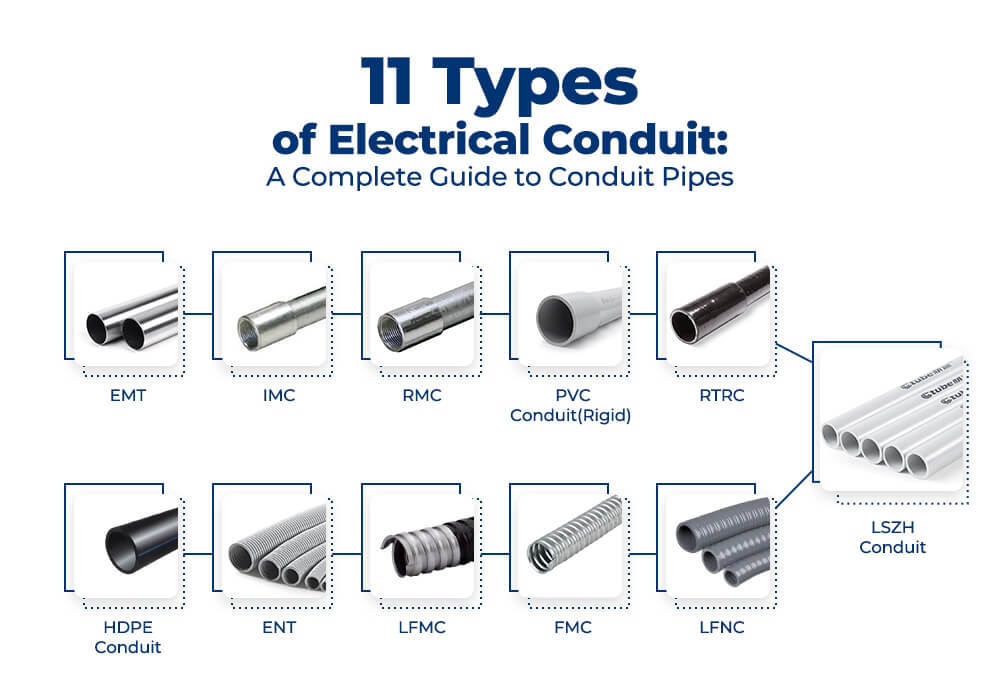

#9 11 Types of Electrical Conduit

Domain Est. 2020

Website: ctube-gr.com

Key Highlights: In this article, we’ll explore the different types of conduit pipes, their materials, sizes, and accessories like conduit bends, elbows, bodies, and boxes….

Expert Sourcing Insights for Electrical Conduit Size

Market Trends for Electrical Conduit Size in 2026

The electrical conduit market is poised for significant evolution by 2026, driven by construction growth, technological advancements, and regulatory shifts. Analysis of conduit size trends reveals distinct patterns influenced by application sectors, material preferences, and regional standards.

Dominance of Mid-Range Sizes in Commercial and Industrial Sectors

By 2026, conduit sizes ranging from ½ inch to 2 inches (15 mm to 50 mm) are projected to maintain the largest market share, particularly in commercial buildings and industrial facilities. This trend is fueled by the global surge in smart office construction, data centers, and manufacturing plants requiring robust yet manageable routing for power, data, and control cables. The ¾ inch and 1 inch sizes are especially prevalent due to their optimal balance of cable capacity, bending radius, and ease of installation in standard wall and ceiling cavities.

Growth in Larger Conduit Sizes for Infrastructure and Renewable Energy

Demand for larger conduit sizes—2½ inches and above (63 mm+)—is expected to accelerate through 2026, primarily driven by infrastructure modernization and renewable energy projects. Solar farms, electric vehicle (EV) charging stations, and utility-scale battery storage systems require high-capacity conduits to house multiple feeders and communication lines. Additionally, urban underground electrical upgrades and transit projects are boosting the need for 3-inch and 4-inch conduits, particularly in high-density polyethylene (HDPE) and reinforced thermoset resin (RTRC) materials.

Miniaturization and High-Density Wiring in Residential and Smart Buildings

In contrast, the residential and smart home sectors are seeing increased use of smaller conduit sizes, particularly ½ inch and 3/8 inch (12 mm), as wiring systems become more compact and efficient. The proliferation of low-voltage systems—such as structured cabling, security, and home automation—favors smaller conduits that allow for discreet installation while still complying with fire and safety codes. This trend is supported by advancements in bendable non-metallic tubing (e.g., ENT and FMC), which simplify routing in tight spaces.

Regional Variations and Standardization Pressures

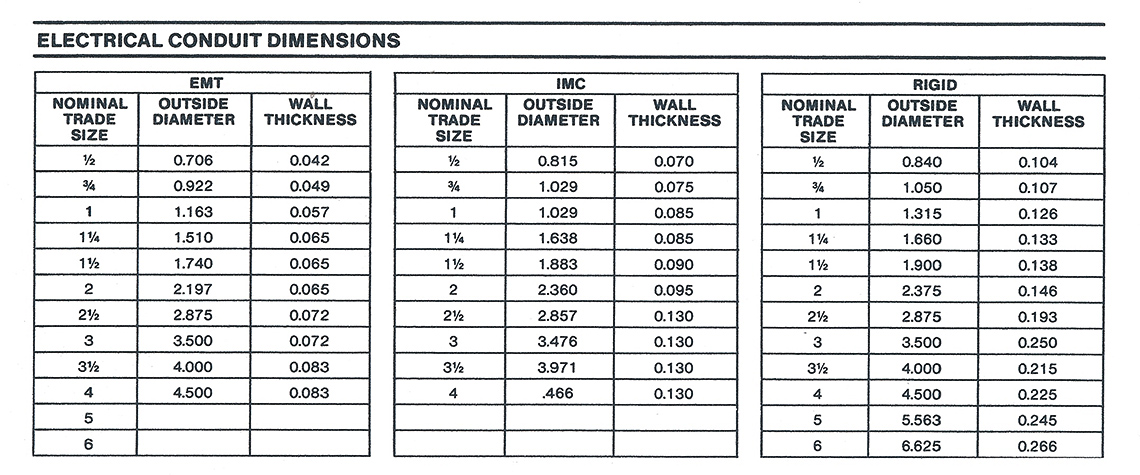

Regional construction practices continue to influence size preferences. North America remains heavily reliant on NEMA-standard sizes with a strong preference for EMT and RMC in the ½” to 1½” range. In contrast, European and Asian markets show growing adoption of metric-sized conduits (e.g., 16 mm, 20 mm, 25 mm), driven by IEC standards and modular building designs. Harmonization efforts and multinational construction projects are expected to encourage greater interoperability, potentially leading to hybrid sizing strategies by 2026.

Material-Driven Size Optimization

Material innovation is also shaping conduit size trends. Lightweight materials like PVC and HDPE enable the use of larger diameters without significant increases in labor or structural load, making them ideal for trenchless installations and retrofit projects. Meanwhile, aluminum and stainless steel conduits are being optimized for corrosion resistance in critical applications, with standard sizes being engineered for faster assembly and reduced connector complexity.

In summary, the 2026 electrical conduit size landscape will be characterized by a three-tiered demand: mid-sizes for general commercial use, larger diameters for energy and infrastructure, and smaller conduits for smart residential systems. Manufacturers and contractors must adapt to these diverging trends by offering versatile product lines and staying aligned with evolving regional codes and sustainability goals.

Common Pitfalls When Sourcing Electrical Conduit Size (Quality, IP Rating)

When sourcing electrical conduit, selecting the correct size is just one part of the equation. Overlooking quality and Ingress Protection (IP) ratings can lead to safety hazards, compliance issues, and costly failures. Below are common pitfalls related to quality and IP ratings that buyers often encounter:

Choosing Conduit Based Solely on Size Without Verifying Material Quality

Many buyers focus only on diameter and wall thickness while ignoring the actual material composition and manufacturing standards. Low-quality conduit may use substandard metals or plastics that degrade quickly under environmental stress. Always verify compliance with recognized standards such as UL, IEC, or EN, and request material certifications to ensure durability and fire resistance.

Assuming All Conduits Meet Required IP Ratings

Not all conduits are created equal when it comes to protection against dust and water. A common mistake is assuming that standard conduit offers high IP protection. For example, using non-threaded or poorly sealed conduit in wet or dusty environments may result in an effective IP rating lower than required. Always confirm the IP rating (e.g., IP55, IP66) matches the installation environment, especially in outdoor, industrial, or washdown areas.

Ignoring Thread Quality and Coupling Compatibility

Even if the conduit size and IP rating are correct, poor thread quality or incompatible couplings can compromise the entire system. Damaged threads or mismatched fittings create gaps that reduce the effective IP protection and mechanical strength. Inspect sample fittings and ensure compatibility with connectors and boxes from the same or approved manufacturers.

Overlooking UV and Corrosion Resistance in Outdoor Applications

In outdoor installations, conduit must resist UV degradation and corrosion. Using standard steel or non-UV-stabilized PVC conduit in sunlight leads to brittleness, cracking, and eventual failure. Always specify conduit with appropriate coatings (e.g., galvanized, PVC-coated) or materials (e.g., stainless steel, UV-resistant polymer) and verify compliance for outdoor use.

Failing to Verify Third-Party Certifications

Some suppliers claim high IP ratings or quality standards without certification. Relying solely on datasheets without independent verification (e.g., UL, CE, TÜV) is risky. Request test reports or certification documents to confirm that the conduit has been independently tested for both IP rating and mechanical/electrical performance.

Underestimating Installation Conditions on IP Performance

Even high-IP-rated conduit can fail if installed incorrectly. Poor sealing at entry points, improper bending, or using undersized grommets compromises protection. Ensure that the entire system—including fittings, terminations, and bends—maintains the required IP rating. Specify complete kits or systems designed to work together.

By addressing these pitfalls during procurement, you ensure that the electrical conduit not only fits physically but also performs reliably under real-world conditions, maintaining safety and compliance over its service life.

Electrical Conduit Size: Logistics & Compliance Guide

Selecting the correct electrical conduit size is critical for ensuring safety, regulatory compliance, and efficient installation and maintenance. This guide outlines key logistics and compliance considerations related to electrical conduit sizing in accordance with widely accepted standards, primarily the National Electrical Code (NEC) in the United States.

Understanding Conduit Fill Requirements

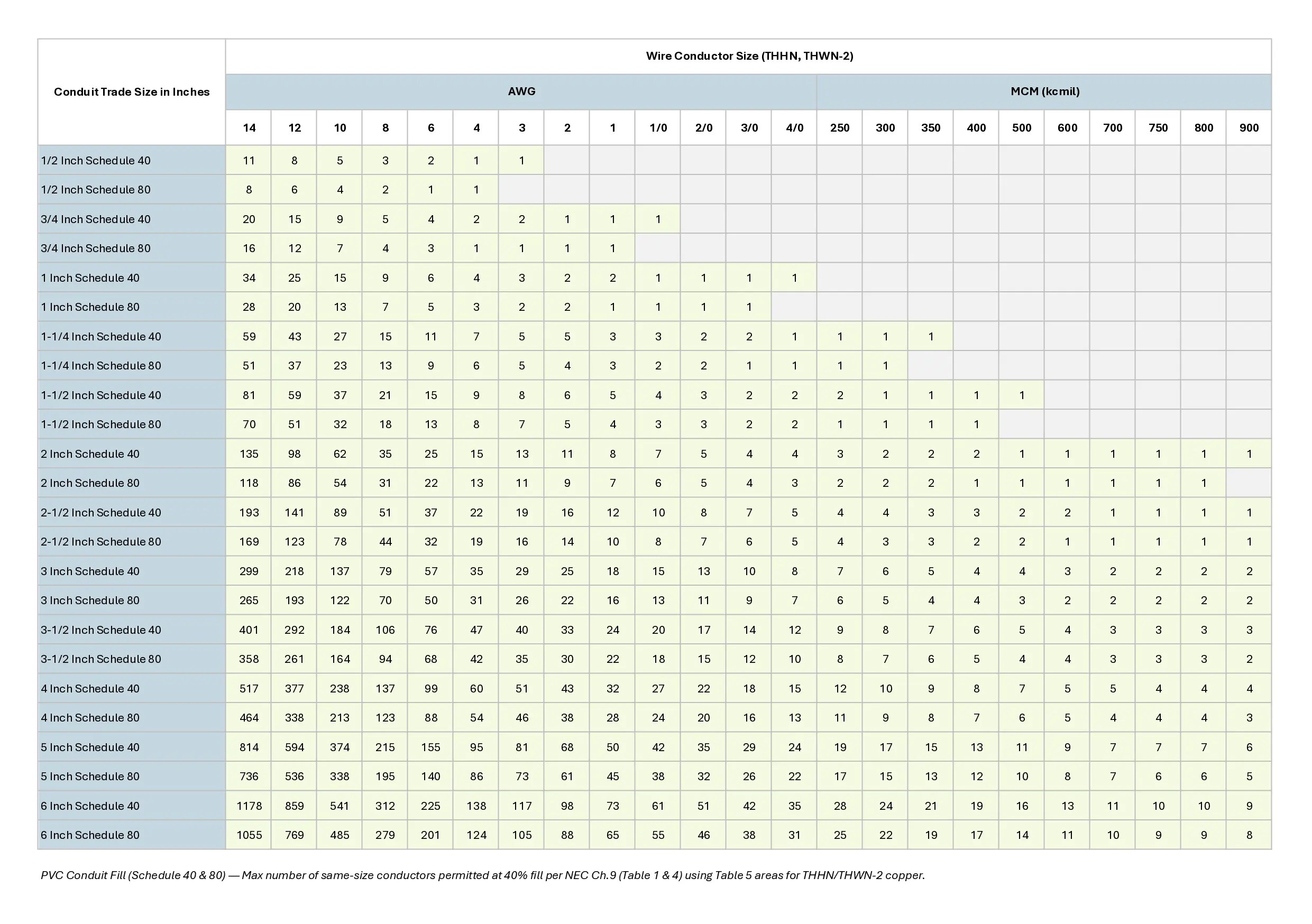

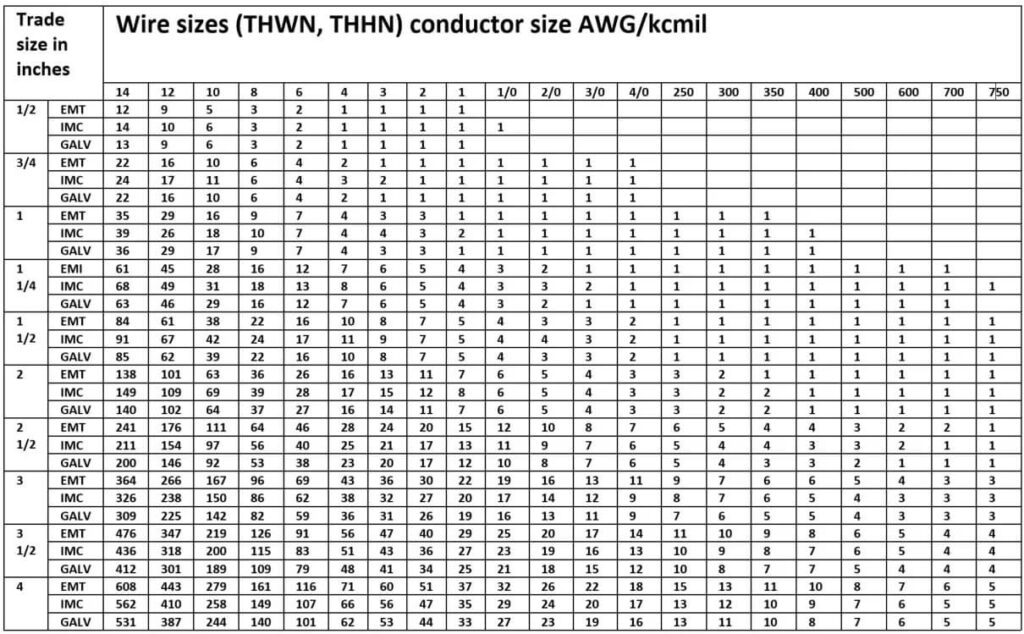

Conduit fill refers to the percentage of the conduit’s cross-sectional area occupied by conductors. Overfilling can lead to overheating, difficulty in pulling wires, and non-compliance. The NEC (NFPA 70), Article 300.17 and Chapter 9, Table 1, specifies maximum fill percentages:

- One conductor: Maximum 53% fill

- Two conductors: Maximum 31% fill

- Three or more conductors: Maximum 40% fill

These limits ensure adequate heat dissipation and ease of installation. Always calculate total conductor area using the largest wire size and insulation type (e.g., THHN, THWN).

Determining Conduit Size: Step-by-Step Process

- List all conductors – Include all current-carrying conductors, equipment grounding conductors, and bonding jumpers.

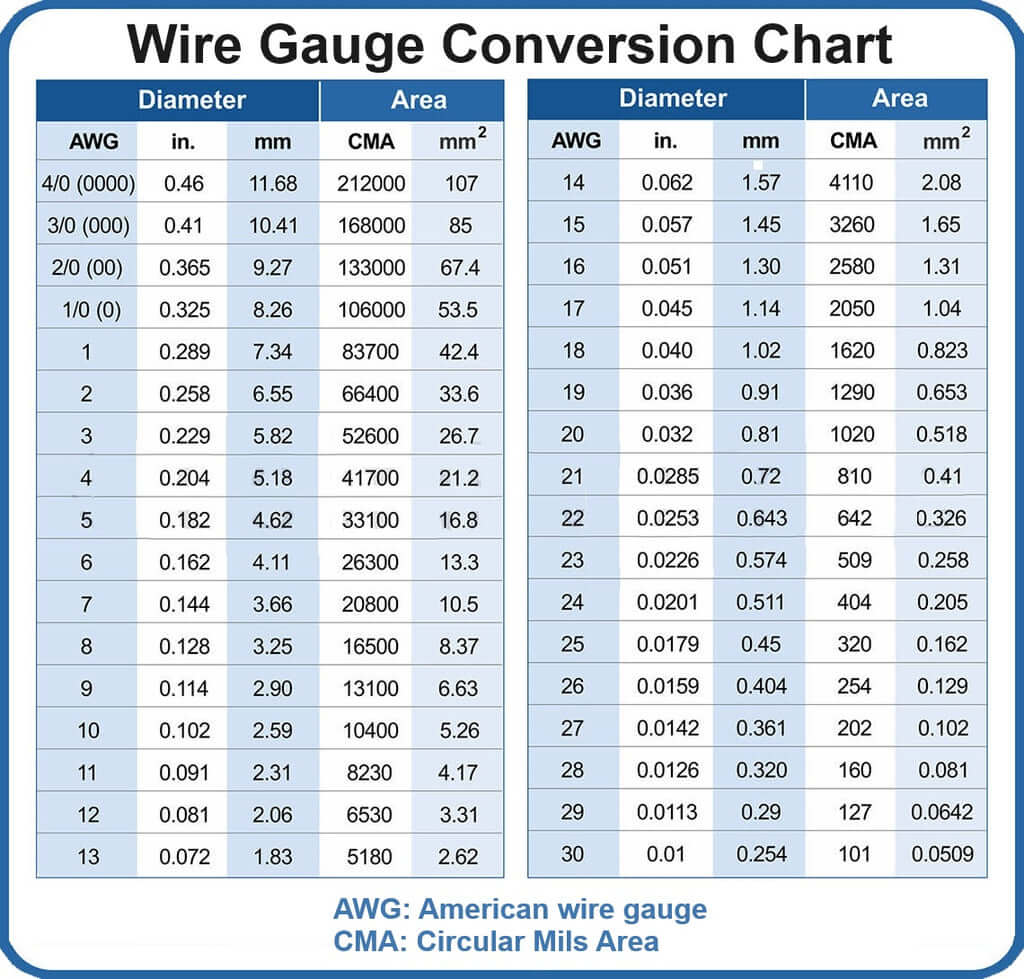

- Determine conductor cross-sectional area – Use NEC Chapter 9, Table 5 (for insulated conductors) to find the area in square inches or mm².

- Sum the total conductor area – Add the areas of all conductors to be installed.

- Select conduit type – Different materials (EMT, PVC, Rigid Metal) have varying internal diameters and fill capacities.

- Consult NEC Chapter 9, Table 4 – Match the total conductor area to the conduit size, ensuring it does not exceed the allowable fill percentage.

Example: Running three 12 AWG THHN wires (each ≈ 0.0133 sq. in.) totals 0.0399 sq. in. According to Table 4, ½” EMT (available area: 0.161 sq. in. at 40% fill) is sufficient.

Compliance with National and Local Codes

- NEC (NFPA 70) is the primary standard in the U.S. Always adhere to the latest adopted edition.

- Local Amendments may impose stricter requirements. Verify with local authorities having jurisdiction (AHJ).

- International Projects: For non-U.S. installations, refer to IEC 60364 or local electrical codes (e.g., BS 7671 in the UK, CEC in Canada).

- Occupancy-Specific Rules: Healthcare, industrial, and hazardous locations (Class I, Div 1) may require larger conduit or specialized types.

Logistics & Installation Best Practices

- Allow for Future Expansion – Use conduit one size larger if future circuit additions are anticipated.

- Minimize Bends – NEC limits total bends between pull points to 360°. Plan routes to reduce friction and pulling tension.

- Use Proper Pulling Lubricants – Lubricants reduce drag and prevent insulation damage during installation.

- Label Conduits at Termination Points – Improves maintenance and ensures compliance with identification requirements.

- Verify Environmental Compatibility – Outdoor, corrosive, or high-temperature areas may require specific conduit types (e.g., PVC for moisture resistance, rigid aluminum for corrosion).

Special Considerations

- Derating for Ambient Temperature or Multiple Circuits – Conduit size may need to increase if conductors require derating due to bundling or high ambient temperatures (NEC Table 310.15(C)(1)).

- Grounding and Bonding – Equipment grounding conductors count toward conduit fill and must be properly sized per NEC Table 250.122.

- Firestopping and Sealing – In fire-rated assemblies or hazardous locations, conduits must be sealed per NEC Articles 300.7 and 501.15.

Inspection and Documentation

- Pre-Inspection Verification – Confirm conduit size, fill, and routing matches approved plans.

- Maintain Installation Records – Include conduit schedules, wire types, and fill calculations for compliance audits.

- Third-Party Inspections – Required in most jurisdictions; ensure all work meets code before energizing.

By following these logistics and compliance guidelines, electrical professionals can ensure safe, code-compliant, and serviceable conduit installations that support long-term system reliability.

Conclusion on Sourcing Electrical Conduit Size:

Selecting the appropriate electrical conduit size is a critical step in ensuring the safety, efficiency, and compliance of an electrical installation. Proper conduit sizing depends on several key factors, including the number and size of conductors, allowable fill capacity as defined by the National Electrical Code (NEC) or local regulations, ambient temperature, and future expansion needs. Undersized conduits can lead to overheating, difficulty in pulling wires, and code violations, while oversized conduents may result in unnecessary material and labor costs.

When sourcing conduit, it is essential to perform accurate load calculations, account for voltage drop where applicable, and consider the type of conduit material (e.g., EMT, PVC, RMC) based on environmental and mechanical requirements. Collaboration with electrical engineers, adherence to local codes, and the use of conduit fill charts are vital to determining the correct size.

In summary, sourcing the right electrical conduit size is a balance between technical requirements, regulatory compliance, and cost-effectiveness. A well-planned conduit system supports reliable electrical performance, eases maintenance, and accommodates future upgrades, making it a fundamental aspect of quality electrical design and installation.