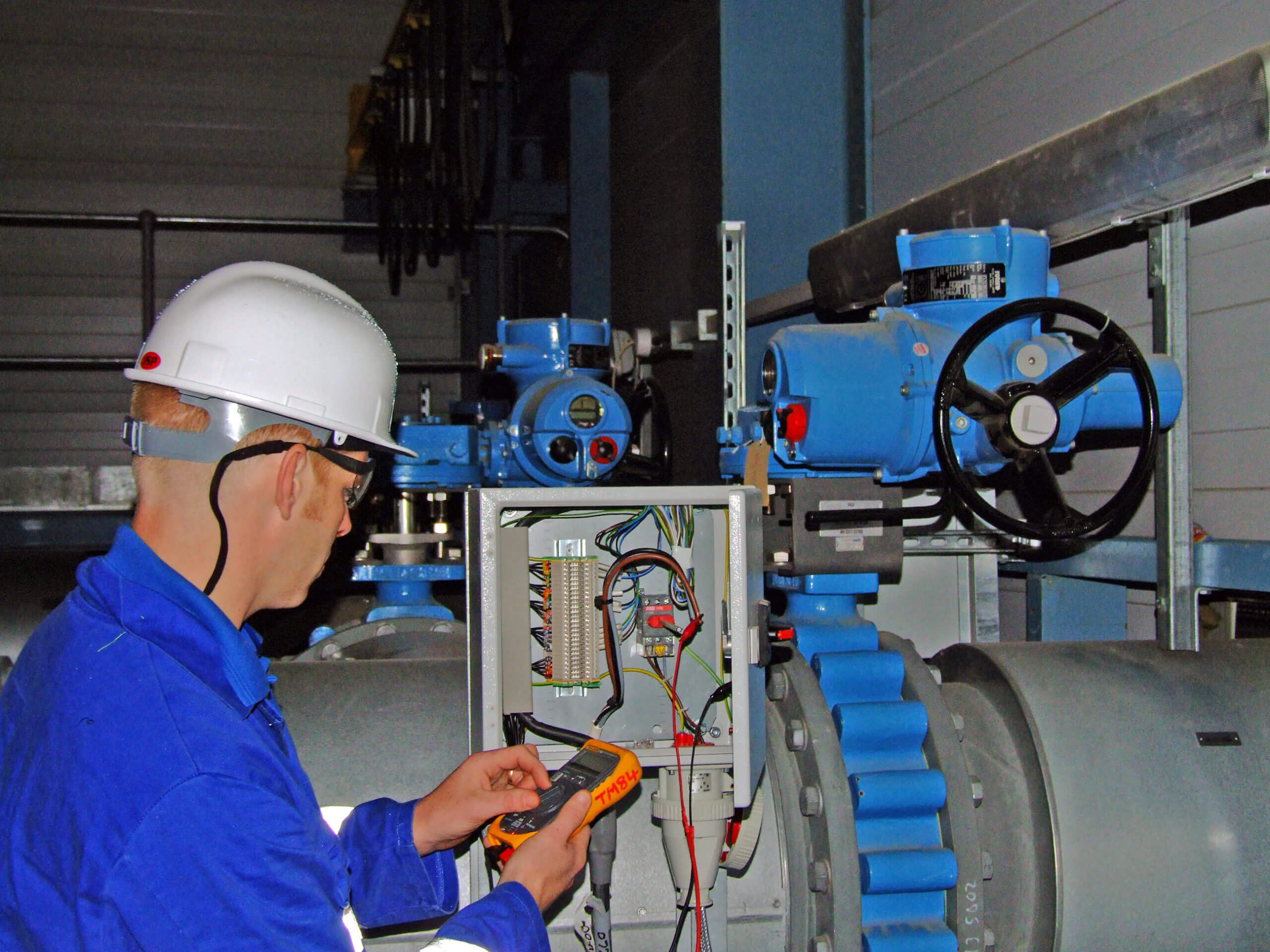

The global electric valve actuator market is experiencing robust growth, driven by rising automation across oil & gas, water treatment, power generation, and industrial manufacturing sectors. According to Mordor Intelligence, the market was valued at USD 5.3 billion in 2023 and is projected to grow at a CAGR of over 5.8% through 2029. Similarly, Grand View Research estimates a CAGR of 6.1% from 2023 to 2030, citing increased demand for energy-efficient and precision control systems in smart infrastructure and process industries. As digitalization and Industry 4.0 continue to reshape operational frameworks, electric actuators—known for their accuracy, reliability, and integration with control systems—are becoming critical components in modern fluid control applications. This expanding landscape has intensified competition among manufacturers to deliver innovative, IoT-enabled, and energy-efficient solutions. Below, we highlight the top 9 electric valve actuator manufacturers leading this transformation through technological advancement, global reach, and strong R&D investments.

Top 9 Electric Valve Actuators Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Electric Actuator Manufacturer

Domain Est. 1997

Website: haroldbeck.com

Key Highlights: Harold Beck & Sons is your premier electric actuator manufacturer. Get top precision control from our industrial linear actuator suppliers!…

#2 Biffi Actuators

Domain Est. 1998

Website: biffi.it

Key Highlights: Biffi is one of the world’s leading manufacturers of valve actuators. With an engineering pedigree of 70 years plus and a truly global presence….

#3 Electric Actuator Manufacturer

Domain Est. 2006

Website: jjbcn.com

Key Highlights: JJ BCN INTERNACIONAL is a manufacturer and international distributor of Electric Actuators. Presence in more than 66 countries….

#4 Electric Actuators

Domain Est. 1995

Website: emerson.com

Key Highlights: Electric actuators offer a zero-emission solution to your valve automation needs. With options suited for isolation valves and control valves….

#5 Rotork

Domain Est. 1995

Website: rotork.com

Key Highlights: We specialise in producing actuators and related flow control equipment for every part of the oil and gas industry, including production, processing, ……

#6 Valve Actuators

Domain Est. 1996

Website: johnsonelectric.com

Key Highlights: Johnson Electric’s Valve Actuators solutions offer reliable and efficient motor and control systems for a variety of valve control applications….

#7 Actuated Valves by Assured Automation

Domain Est. 1996

Website: assuredautomation.com

Key Highlights: We have over 25 years experience providing special order and custom valve assemblies for our customers’ new and unique applications….

#8 Valworx: Actuated Valves

Domain Est. 2007

Website: valworx.com

Key Highlights: Actuator valves and accessories for sale online. We build, test & ship your actuated valve assemblies the same day. Free shipping on orders over $99….

#9 KZ Valve

Domain Est. 2007

Website: kzvalve.com

Key Highlights: Custom valve & actuator design. We produce innovative high-performance, high-value products that meet the evolving needs of our customers….

Expert Sourcing Insights for Electric Valve Actuators

H2: 2026 Market Trends for Electric Valve Actuators

The global electric valve actuators market is poised for significant transformation by 2026, driven by technological advancements, increasing automation across industries, and a growing emphasis on energy efficiency and sustainability. Several key trends are expected to shape the market landscape in the coming years:

-

Increased Demand from Process Industries

Industries such as oil & gas, water & wastewater treatment, power generation, and chemical manufacturing are rapidly adopting electric valve actuators to improve operational efficiency and ensure precise flow control. The shift toward smart infrastructure and digitalization in these sectors is accelerating the replacement of manual and pneumatic systems with electric alternatives. -

Growth of Smart Actuators and IIoT Integration

A major trend shaping the 2026 market is the integration of Industrial Internet of Things (IIoT) technologies into electric valve actuators. Smart actuators equipped with sensors, wireless communication, and predictive maintenance capabilities are becoming standard. These devices enable real-time monitoring, remote operation, and data analytics, enhancing system reliability and reducing downtime. -

Focus on Energy Efficiency and Electrification

As industries strive to meet sustainability goals and reduce carbon emissions, there is a growing preference for electric actuators over traditional hydraulic or pneumatic systems. Electric models consume less energy, require fewer auxiliary components, and align with global decarbonization efforts. This trend is particularly strong in Europe and North America, where regulatory frameworks promote energy-efficient technologies. -

Rise of Modular and Compact Designs

Manufacturers are increasingly focusing on developing compact, modular actuators that are easier to install and maintain. These designs cater to space-constrained applications and support faster commissioning, especially in retrofitting projects within aging industrial facilities. -

Expansion in Emerging Markets

Rapid industrialization in Asia-Pacific (especially China, India, and Southeast Asia), along with infrastructure development in the Middle East and Africa, is creating new growth opportunities. Government investments in power, water, and oil & gas projects are driving demand for reliable and automated valve control systems. -

Advancements in Control Technologies

The adoption of advanced control algorithms, digital twins, and AI-driven diagnostics is enhancing actuator performance. By 2026, actuators with adaptive learning features and self-calibration capabilities are expected to gain traction, particularly in critical process environments. -

Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted manufacturers to localize production and diversify sourcing. This trend is likely to continue, with regional manufacturing hubs emerging to mitigate risks and reduce lead times—especially in North America and Europe.

In conclusion, the electric valve actuators market in 2026 will be characterized by innovation, digital integration, and sustainability. Companies that invest in smart technologies, energy-efficient designs, and global market expansion are best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Electric Valve Actuators (Quality & IP)

Sourcing electric valve actuators involves navigating technical, quality, and intellectual property (IP) challenges. Falling into common traps can lead to operational failures, safety risks, and legal exposure. Below are key pitfalls to avoid:

Poor Quality Control and Inadequate Certifications

One of the most frequent issues is selecting actuators from suppliers with weak quality assurance processes. Buyers may prioritize cost over compliance, leading to actuators that fail prematurely or under critical conditions. Lack of proper certifications—such as CE, ATEX, IECEx, or UL—can result in non-compliance with industry safety standards, especially in hazardous environments. Always verify that the manufacturer adheres to recognized quality management systems like ISO 9001 and provides test reports and material traceability.

Misalignment of Technical Specifications

Procuring actuators without fully understanding application requirements—such as torque output, duty cycle, voltage compatibility, or environmental protection (IP rating)—can lead to performance issues. For instance, specifying an IP65-rated actuator for a subsea application requiring IP68 will result in rapid failure. Ensure detailed technical alignment with process conditions, including temperature, pressure, and exposure to chemicals or moisture.

Inadequate Protection Against Counterfeit or Substandard Components

The market includes suppliers offering “compatible” or “replica” actuators that mimic branded products but use inferior materials and electronics. These counterfeit units often fail to meet performance claims and can pose safety hazards. They may also infringe on original equipment manufacturers’ (OEM) IP rights. Always source from authorized distributors or reputable manufacturers and request proof of authenticity.

Intellectual Property (IP) Infringement Risks

Using or sourcing actuators that replicate patented designs, firmware, or control algorithms without authorization exposes buyers to legal liability. Some low-cost suppliers reverse-engineer proprietary technology, violating patents or copyrights. This not only risks litigation but may also void warranties and insurance coverage. Conduct due diligence on suppliers’ IP compliance and avoid products that appear too similar to branded models without proper licensing.

Lack of Documentation and Software Access

Many electric actuators rely on proprietary configuration software or communication protocols (e.g., Modbus, Profibus). Sourcing from vendors who do not provide full documentation, software tools, or firmware updates limits maintainability and integration into control systems. Ensure access to technical manuals, diagnostic tools, and software licensing to avoid long-term operational dependencies or obsolescence.

Insufficient Warranty and After-Sales Support

Choosing suppliers with limited or ambiguous warranty terms can result in unexpected maintenance costs. Some vendors offer short warranties or exclude critical components like motors or control boards. Additionally, lack of local technical support delays troubleshooting and repairs. Prioritize suppliers with comprehensive warranties, spare parts availability, and responsive service networks.

Overlooking Cybersecurity in Smart Actuators

Modern electric actuators often include digital interfaces and remote monitoring capabilities. Sourcing connected devices without assessing cybersecurity measures—such as firmware encryption, secure boot, or access controls—can expose industrial networks to cyber threats. Ensure devices comply with relevant cybersecurity standards (e.g., IEC 62443) and that the supplier provides regular security updates.

By recognizing and addressing these pitfalls, procurement teams can ensure reliable, compliant, and legally sound sourcing of electric valve actuators.

Logistics & Compliance Guide for Electric Valve Actuators

Overview

Electric valve actuators are electro-mechanical devices used to automate the operation of industrial valves, enabling precise control of flow in systems across oil & gas, water treatment, power generation, and manufacturing. Due to their technical nature, international trade regulations, and operational risks, proper logistics and compliance planning are essential to ensure timely delivery, regulatory adherence, and safe operation.

International Shipping & Export Controls

Electric valve actuators may be subject to export control regulations based on their technical specifications and destination country.

– Export Classification: Determine the correct Export Control Classification Number (ECCN) under the U.S. Commerce Control List (CCL) or equivalent (e.g., UKML, EU Dual-Use List). Many actuators fall under ECCN 2A992 or 2B993 due to automation and control capabilities.

– Licensing Requirements: Check if a license is required for shipment to embargoed or restricted countries (e.g., Iran, North Korea, Russia). Use automated screening tools to verify end-user compliance.

– Documentation: Prepare commercial invoice, packing list, bill of lading, and export declaration. Include technical data (voltage, torque, IP rating) to support customs clearance.

Packaging & Handling Requirements

Proper packaging ensures that electric actuators arrive undamaged and ready for installation.

– Protective Packaging: Use moisture-resistant, shock-absorbent materials. Seal electronics in anti-static bags and include desiccants to prevent condensation.

– Labeling: Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture.” Include model number, serial number, and handling instructions.

– Mounting Protection: Secure moving parts and output shafts to prevent damage during transit. Avoid over-tightening during packaging to prevent mechanical stress.

Customs Clearance & Import Regulations

Compliance with destination country regulations is critical for timely customs release.

– HS Code Classification: Use the correct Harmonized System (HS) code—typically 8537.10 or 8481.80—depending on actuator integration and function.

– Conformity Markings: Ensure products meet regional standards such as CE (EU), UKCA (UK), or CRN (Canada). Include required certification marks on nameplates.

– Duties & Taxes: Calculate import duties, VAT, and any anti-dumping fees. Provide certificates of origin (e.g., EUR.1, Certificate of Origin Form A) where applicable.

Regulatory & Safety Compliance

Electric actuators must comply with electrical, safety, and environmental standards.

– Electrical Standards: Comply with IEC 60034 (rotating machinery), IEC 60529 (IP ratings), and IEC 60079 (explosive atmospheres if ATEX/IECEx certified).

– EMC & RoHS: Ensure electromagnetic compatibility (EMC Directive 2014/30/EU) and compliance with RoHS (Restriction of Hazardous Substances).

– Pressure Equipment Directive (PED): If integrated with valves in a pressure system, verify that the assembly meets PED 2014/68/EU requirements.

Installation & Environmental Considerations

Transport and storage conditions can impact performance.

– Storage Conditions: Store in a dry, temperature-controlled environment (typically -25°C to +70°C) away from corrosive agents. Avoid long-term outdoor exposure.

– Pre-Installation Checks: Verify integrity of seals, wiring, and control modules before installation. Check for condensation or moisture ingress.

– Site Compliance: Confirm that installation location meets ingress protection (IP) and hazardous zone classifications (e.g., Zone 1/2 for ATEX).

Documentation & Traceability

Maintain accurate records to support compliance audits and warranty claims.

– Technical Dossiers: Include user manuals, conformity declarations (DoC), test reports, and circuit diagrams.

– Serial Number Tracking: Log serial numbers, shipping dates, and destinations for traceability and recall management.

– Warranty & Support: Provide clear warranty terms and contact information for technical support in local languages.

Conclusion

Effective logistics and compliance for electric valve actuators require coordination between engineering, logistics, and regulatory teams. By adhering to international shipping standards, ensuring proper documentation, and maintaining product integrity, companies can reduce delays, avoid penalties, and ensure reliable field performance. Regular training and updates on regulatory changes are recommended to maintain ongoing compliance.

Conclusion for Sourcing Electric Valve Actuators

Sourcing electric valve actuators requires a comprehensive approach that balances performance, reliability, compatibility, and cost-effectiveness. After evaluating various suppliers, technical specifications, and application requirements, it is clear that selecting the right actuator involves more than just comparing price points. Key factors such as torque output, control types (on/off, modulating, or multi-point), duty cycle, environmental resilience (e.g., IP/NEMA ratings), and integration capabilities with existing control systems are critical to ensuring long-term operational efficiency.

Partnering with reputable manufacturers or suppliers who offer quality certifications, technical support, and warranty coverage helps mitigate risks associated with downtime and maintenance. Furthermore, considering total cost of ownership—factoring in energy efficiency, service life, and ease of installation—provides a more accurate picture of value.

In conclusion, a successful sourcing strategy for electric valve actuators involves thorough due diligence, alignment with specific process requirements, and collaboration with trusted suppliers. By prioritizing quality, compatibility, and support, organizations can enhance system reliability, improve process control, and achieve sustainable operational performance.