The global electric heater tent market is gaining momentum, driven by rising demand for portable and energy-efficient heating solutions across recreational, industrial, and emergency response sectors. According to a 2023 report by Mordor Intelligence, the global electric heating equipment market is projected to grow at a CAGR of 4.6% from 2023 to 2028, with increasing adoption of innovative heating technologies and expanding outdoor recreational activities fueling demand for specialized products like electric heater tents. Additionally, Grand View Research valued the global space heaters market at USD 5.3 billion in 2022, expecting it to expand at a CAGR of 4.8% through 2030, underscoring sustained growth in heating solutions tailored for enclosed and semi-enclosed environments. As consumers and organizations prioritize comfort, safety, and sustainability, manufacturers are responding with advanced, energy-efficient electric heater tents designed for diverse climates and applications. This growing market landscape has given rise to key players distinguished by innovation, reliability, and performance—here are the top 7 electric heater tent manufacturers leading the charge.

Top 7 Electric Heater Tent Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 L.B. White

Domain Est. 1996

Website: lbwhite.com

Key Highlights: L.B. White Company, a subsidiary of Modine, is a leading global manufacturer of forced air heaters, electric heaters, brooders, tube heaters, handheld gas ……

#2 Products

Domain Est. 2009

Website: drheaterusa.com

Key Highlights: The infrared heaters and industrial heaters we supply are manufactured by the very same factory that supplies to Sears and Home Depot. Therefore, these heaters ……

#3 Powerblanket

Domain Est. 2005

Website: powerblanket.com

Key Highlights: Powerblanket’s unique technology allows our containers of coatings and materials to heat evenly and quickly, opposed to band heaters….

#4 Heating solutions for camping vehicles from Webasto

Domain Est. 1997

Website: webasto.com

Key Highlights: Webasto heating solutions for motorhomes, caravans and camper vans reliably ensure warm interiors, hot water and ice-free windows….

#5 HeatStar® by Enerco

Domain Est. 2005

Website: heatstarbyenerco.com

Key Highlights: HeatStar® sets the standard for REAL.TOUGH. HEAT.™ At the core of our brand is a focus on durability, function and innovation for the contractor and worker….

#6 Portable Space Heaters

Domain Est. 2006

#7 Event & Party Tent Heaters

Domain Est. 2014

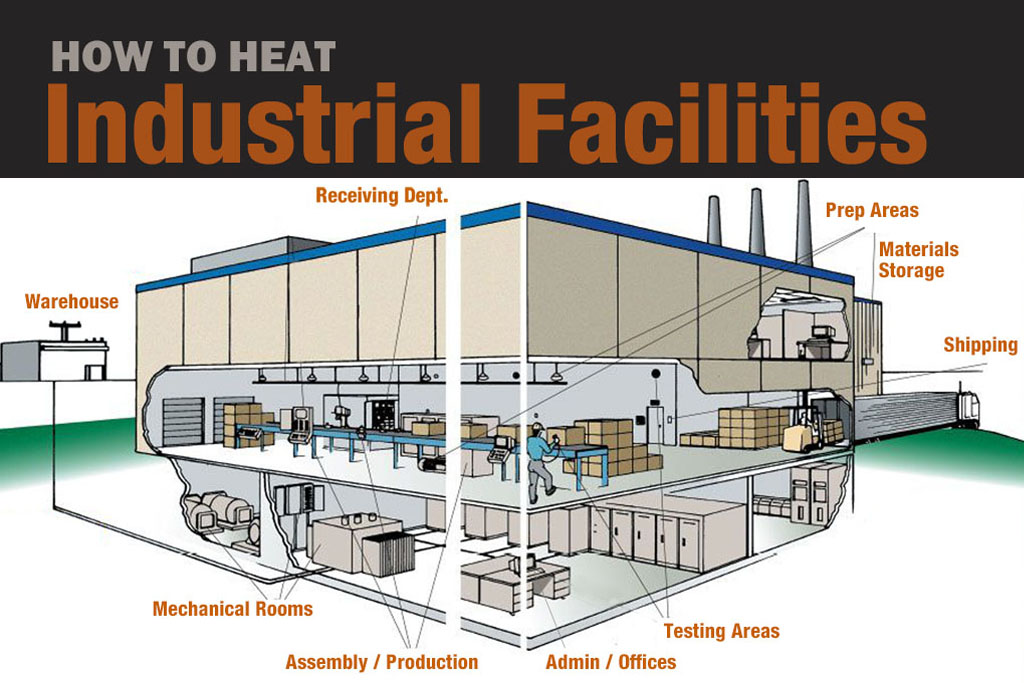

Expert Sourcing Insights for Electric Heater Tent

2026 Market Trends for Electric Heater Tents

As the demand for versatile, energy-efficient, and climate-resilient shelter solutions grows, electric heater tents are poised to become a pivotal segment within the broader outdoor, emergency, and temporary housing markets. By 2026, several key trends are expected to shape the electric heater tent industry, driven by technological advancements, environmental concerns, and shifting consumer behaviors.

Increasing Demand in Recreational and Outdoor Markets

The outdoor recreation industry continues to expand, with more consumers engaging in camping, glamping, and cold-weather adventures. Electric heater tents offer a comfortable alternative to traditional camping gear, especially in colder climates. By 2026, the integration of lightweight, high-efficiency heating systems powered by portable batteries or renewable energy sources is expected to make electric heater tents more accessible and appealing to a broader audience. Glamping (glamorous camping) operators are increasingly investing in heated tents to enhance guest comfort, further fueling market growth.

Advancements in Energy Efficiency and Smart Technology

Technological innovation is a major driver in the electric heater tent market. By 2026, expect wider adoption of smart thermostats, app-based climate control, and energy monitoring features. These smart capabilities allow users to regulate temperature remotely, optimize energy consumption, and integrate with solar power systems. Improved insulation materials and low-wattage heating elements will enhance energy efficiency, reducing reliance on grid power and making electric heater tents viable for off-grid use.

Growth in Emergency and Temporary Housing Applications

Natural disasters, humanitarian crises, and extreme weather events are on the rise globally, increasing the need for rapidly deployable, climate-controlled shelters. Governments and NGOs are turning to electric heater tents for emergency response due to their portability and ability to maintain safe indoor temperatures. By 2026, partnerships between manufacturers and relief organizations are expected to expand, with customized models designed for durability, quick setup, and compatibility with alternative power sources like solar generators.

Sustainability and Eco-Friendly Design

Environmental concerns are influencing product development across industries, including outdoor gear. By 2026, manufacturers of electric heater tents will increasingly prioritize sustainable materials, recyclable components, and low-carbon manufacturing processes. The shift toward renewable energy integration—such as solar-compatible heating systems—will align with global decarbonization goals and appeal to environmentally conscious consumers.

Regulatory and Safety Standards Evolution

As the market grows, so does the need for standardized safety regulations. By 2026, stricter safety certifications related to fire resistance, electrical safety, and ventilation are anticipated, particularly in North America and Europe. Manufacturers will need to comply with updated codes to ensure product reliability and consumer trust. This regulatory push will encourage innovation in fail-safe heating mechanisms and automatic shut-off features.

Regional Market Expansion

While North America and Europe currently dominate the electric heater tent market, emerging economies in Asia-Pacific and Latin America are expected to see accelerated growth by 2026. Increasing disposable income, urbanization, and interest in outdoor lifestyles will drive demand in these regions. Additionally, cold-weather events in traditionally warmer areas due to climate volatility may expand the geographic relevance of heated tents.

Conclusion

By 2026, the electric heater tent market will be shaped by innovation, sustainability, and expanding use cases—from recreation to disaster relief. As technology improves and consumer expectations evolve, electric heater tents will transition from niche products to mainstream solutions for comfort, safety, and resilience in diverse environments.

Common Pitfalls When Sourcing Electric Heater Tents (Quality, IP)

Sourcing electric heater tents involves navigating several critical challenges, particularly concerning product quality and Ingress Protection (IP) ratings. Overlooking these aspects can lead to safety hazards, poor performance, and costly replacements. Below are the most common pitfalls to avoid:

Overlooking IP Rating Suitability for Environment

Many buyers assume a basic “water-resistant” claim is sufficient, but fail to verify the specific IP rating. Electric heater tents used outdoors or in high-moisture environments require a minimum of IP65 (dust-tight and protected against water jets). Choosing a tent with a lower rating (e.g., IP54) risks water ingress, electrical faults, or corrosion, especially in rain, snow, or humid conditions.

Prioritizing Price Over Build Quality

Low-cost electric heater tents often use substandard materials such as thin PVC fabric, weak zippers, or undersized heating elements. These compromises lead to shorter lifespan, poor insulation, and inconsistent heating. A cheaper tent may save money upfront but results in frequent replacements and higher total cost of ownership.

Inadequate Heating Capacity for Intended Use

Selecting a heater tent based solely on size without considering wattage and insulation quality leads to inefficient heating. Underpowered units struggle to maintain temperature in cold environments, increasing energy consumption and failing to meet operational needs. Always match the heater’s output (watts) to the tent’s volume and expected ambient temperatures.

Ignoring Certifications and Safety Standards

Reputable electric heater tents should carry recognized safety certifications such as CE, UL, or ETL. Sourcing from suppliers who cannot provide proof of compliance increases the risk of using non-compliant, potentially hazardous equipment. Lack of certification also complicates insurance claims in case of fire or electrical incidents.

Poor Sealing and Entry Design

Even with a high IP rating, poor design—such as unsealed cable entries, flimsy door closures, or gaps around zippers—can compromise protection. Ensure that all access points are properly sealed and that the tent maintains its integrity when doors are opened or cables are routed.

Assuming All “Industrial” Tents Are Equal

Suppliers may market tents as “industrial grade” without substantiating claims. Verify construction details: double-stitched seams, reinforced corners, robust frame materials, and reflector-backed insulation. Request material specifications and test reports to confirm durability claims.

Neglecting Supplier Reliability and After-Sales Support

Choosing an unknown supplier to cut costs often results in delayed deliveries, missing documentation, or lack of technical support. A reliable supplier should offer clear specifications, responsive customer service, and warranty coverage—critical for addressing quality issues or IP rating failures post-purchase.

Avoiding these pitfalls requires due diligence in vetting suppliers, verifying technical specifications, and prioritizing long-term performance and safety over initial cost savings.

Logistics & Compliance Guide for Electric Heater Tents

Product Classification and Regulatory Overview

Electric heater tents fall under the category of portable electric heating devices and temporary shelter structures. Compliance involves adherence to electrical safety standards, fire safety regulations, and product certification requirements depending on the target market. Key regulatory bodies include UL (Underwriters Laboratories) in the U.S., CE marking directives in the EU (including LVD, EMC, and RED if applicable), and other regional authorities such as IEC, CSA, and PSE. Manufacturers and distributors must ensure the product meets all relevant safety and performance standards before market entry.

Electrical Safety Standards

All electric heater tents must comply with electrical safety regulations to prevent fire, electric shock, and overheating hazards. In North America, compliance with UL 1278 (Movable and Stationary Electric Heaters) or UL 2021 (Electric Heating Appliances) is typically required. In the EU, adherence to EN 60335-1 (General Safety) and EN 60335-2-30 (Particular Requirements for Room Heaters) is mandatory. The heating elements, power cords, thermostats, and control systems must be evaluated and certified by an accredited laboratory. Grounding, insulation, and overheat protection features must be integrated into the design.

Fire Safety and Material Compliance

The tent fabric and internal components must be constructed from flame-retardant, non-toxic materials to reduce fire risk. Compliance with fire resistance standards such as CPAI-84 (Canvas Products Association International) for tent materials or NFPA 701 (Small Scale Flame Test for Textiles) is essential. Additionally, the product should incorporate automatic shut-off mechanisms triggered by tipping, overheating, or timer expiration. Packaging and user manuals must include clear fire safety warnings and safe operating distances from combustible materials.

Electromagnetic Compatibility (EMC)

Electric heater tents with electronic controls, thermostats, or digital displays must comply with EMC regulations to ensure they do not interfere with other electronic devices and are immune to external interference. In the EU, compliance with the EMC Directive 2014/30/EU is required, involving testing per EN 55014 (emissions) and EN 61000 (immunity). In the U.S., FCC Part 15 Subpart B governs unintentional radiators. Shielding, filtering, and proper circuit layout are critical for passing EMC tests.

Packaging, Labeling, and Marking Requirements

Proper labeling is mandatory for market compliance. The product must display certification marks (e.g., UL, CE, CSA), voltage and wattage ratings, manufacturer information, and warning symbols. Labels must be durable and permanently affixed. Packaging should include multilingual safety instructions, installation guides, and compliance statements. In Canada, bilingual (English/French) labeling is required. Additionally, QR codes linking to digital manuals may be used to meet space constraints while ensuring regulatory accessibility.

Import and Export Documentation

International shipping requires accurate classification under the Harmonized System (HS Code). Electric heater tents typically fall under HS Code 8516.29 (other electric space heating appliances). Required documentation includes commercial invoices, packing lists, certificates of origin, and test reports from accredited labs (e.g., CB Scheme reports). Importers must verify country-specific requirements, such as China’s CCC mark, South Korea’s KC mark, or Australia’s RCM. Failure to provide correct documentation can result in customs delays or product seizure.

Transportation and Storage Guidelines

Due to the presence of electrical components and heating elements, electric heater tents must be packed securely to prevent damage during transit. Use of anti-static and moisture-resistant packaging is recommended. Avoid stacking heavy items on top of packaged units. During storage, maintain a dry, temperature-controlled environment to prevent degradation of insulation materials or electronics. Lithium batteries, if included (e.g., for controls), must comply with IATA/IMDG regulations for air or sea transport if shipped internationally.

End-of-Life and Environmental Compliance

Electric heater tents are subject to environmental regulations such as the EU’s WEEE (Waste Electrical and Electronic Equipment) Directive, which mandates proper recycling and disposal. Producers must register with national WEEE authorities and provide take-back options. RoHS (Restriction of Hazardous Substances) compliance is required to limit the use of lead, mercury, cadmium, and other harmful materials in electrical components. In the U.S., adherence to state-level e-waste laws such as California’s Electronic Waste Recycling Act may apply.

User Instruction and Safety Warnings

Comprehensive user manuals must be provided in the local language(s) of the target market. Instructions should cover assembly, safe operation, maintenance, and emergency shutdown procedures. Mandatory safety warnings include risks of fire, burns, and electric shock, along with guidance on avoiding use in wet environments, near flammable materials, or unattended operation. Include diagrams showing minimum clearance distances and correct power source usage (e.g., no extension cords unless rated for high wattage).

Audit and Certification Maintenance

Compliance is an ongoing requirement. Manufacturers must maintain production consistency through regular factory audits and periodic retesting of samples. Changes in design, materials, or components may require new certifications. Keep records of all test reports, certifications, and correspondence with notified bodies or accreditation agencies for a minimum of 10 years. Non-compliance discovered post-market can lead to recalls, fines, or legal liability.

Conclusion: Sourcing an Electric Heater Tent

Sourcing an electric heater tent requires a careful evaluation of safety, energy efficiency, durability, and compliance with local electrical standards. These specialized tents offer a practical solution for temporary heating in cold environments, commonly used in construction, outdoor events, emergency shelters, and seasonal workspaces. When selecting a supplier, it is essential to prioritize products that incorporate high-quality insulation, reliable heating systems, and safety features such as overheat protection and flame-retardant materials.

Additionally, consider the ease of installation, portability, and scalability to meet specific operational needs. Partnering with reputable manufacturers or suppliers who provide certifications, warranties, and technical support ensures long-term reliability and performance. Overall, a well-sourced electric heater tent not only enhances comfort and productivity in cold conditions but also represents a cost-effective and energy-efficient alternative to permanent heating solutions. Proper due diligence in the sourcing process will lead to a safe, durable, and efficient heating solution tailored to your requirements.