Introduction: Navigating the Global Market for Edge Banding Laminate

Edge banding is where a laminate project lives or dies in the buyer’s eyes. It protects the core, completes the aesthetic, and determines service life. In North America and Europe, the market spans PVC, wood veneer, and metallic facings, with multiple backing options and a broad design library that matches major sheet brands. The challenge isn’t shortage of supply—it’s precision in specification, reliable color matching, and predictable lead times.

This guide moves from supplier landscape to shop-floor execution: choose the right material and backing, match codes across Wilsonart, FENIX, and Formica catalogs, set finishes and thicknesses, and apply with repeatable quality. You’ll also get a practical sourcing view—non-glued, pre-glued, and peel‑n‑stick availability, special order lead times (typically 1–2 business days), and cancellation restrictions on made‑to‑order materials—so procurement, project management, and fabricators align on risk and timelines.

A quick overview of options:

– Materials: PVC (standard), Metallic PVC (premium look), Wood Veneer (premium feel).

– Backings: Non-glued, Pre-glued, Peel‑N‑Stick (often special order).

– Matches: PVC designs align with Wilsonart, FENIX, and Formica HPL; availability varies by brand.

Core Options at a Glance

| Material | Backing | Best For | Notes |

|—|—|—|—|

| PVC | Non-glued | High-volume edges; hot-melt application | Most economical; broad match to HPL |

| PVC | Pre-glued | Small runs; ease of use | Adhesive limits rework; special order |

| PVC | Peel‑N‑Stick | Temporary panels; quick fixes | Adhesive strength varies; special order |

| Wood Veneer | Non-glued | Premium edges; sand/finish on-site | High-end look; veneer handling required |

| Metallic PVC | Non-glued | Accent edges; design-led projects | Aesthetic value; verify wear performance |

Use this guide as your operating system: specify confidently, match precisely, and apply with control—delivering consistent results across regions and brands.

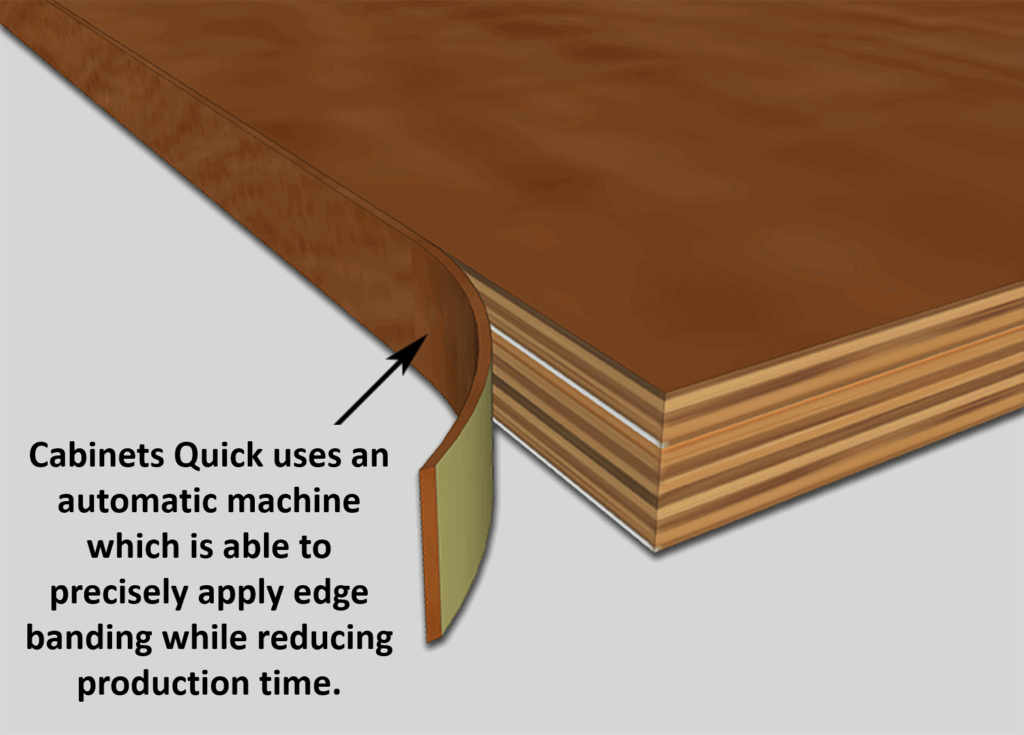

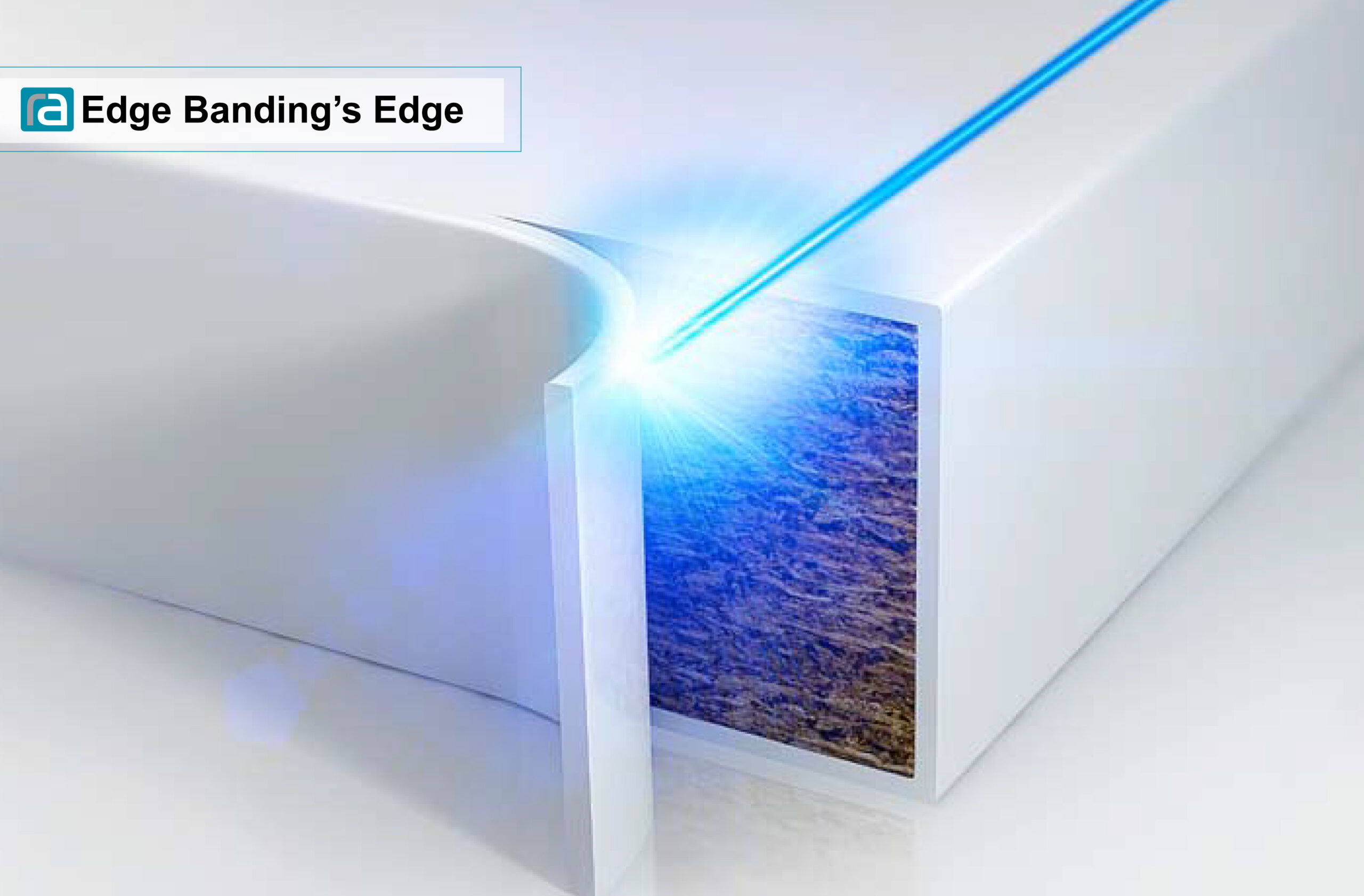

Illustrative Image (Source: Google Search)

Article Navigation

- Top 10 Edge Banding Laminate Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for edge banding laminate

- Understanding edge banding laminate Types and Variations

- Key Industrial Applications of edge banding laminate

- 3 Common User Pain Points for ‘edge banding laminate’ & Their Solutions

- Strategic Material Selection Guide for edge banding laminate

- In-depth Look: Manufacturing Processes and Quality Assurance for edge banding laminate

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘edge banding laminate’

- Comprehensive Cost and Pricing Analysis for edge banding laminate Sourcing

- Alternatives Analysis: Comparing edge banding laminate With Other Solutions

- Essential Technical Properties and Trade Terminology for edge banding laminate

- Navigating Market Dynamics and Sourcing Trends in the edge banding laminate Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of edge banding laminate

- Strategic Sourcing Conclusion and Outlook for edge banding laminate

- Important Disclaimer & Terms of Use

Top 10 Edge Banding Laminate Manufacturers & Suppliers List

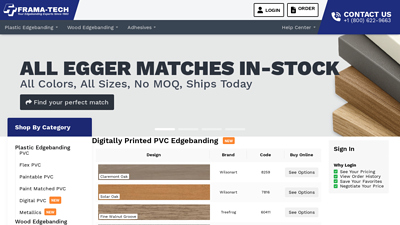

1. High-Quality Edge Banding Solutions I Frama-Tech

Domain: framatech.com

Registered: 2012 (13 years)

Introduction: Largest selection of edgebanding in North America. Over 5,000 matches, 100,000 in-stock skus and 7-14 day made-to-order customs. Pain-free edgebanding….

2. Laminate Edge Banding | ABS & PVC Edge Banding | KML Corp

Domain: kmldesignerfinishes.com

Registered: 2014 (11 years)

Introduction: We offer a range of edge banding options for curved surfaces and straight edges alike, giving a finished touch to any number of unique laminate shapes….

3. Edge Banding Suppliers – Thomasnet

Domain: thomasnet.com

Registered: 1996 (29 years)

Introduction: Custom manufacturer of edge banding. Aluminum, stainless steel, gold, chrome, pewter, zinc, bronze, copper, veneer, ABS, and PVC edge bandings are offered….

4. SSI North America: Specialty Film & Laminate Suppliers | Best …

Domain: ssinorthamerica.com

Registered: 2004 (21 years)

Introduction: SSI North America is a laminate supplier of PVC, PET, & PP films for office products, cabinetry, furniture, media storage, packaging & more!…

Illustrative Image (Source: Google Search)

5. Formica ® Laminate Matched Edgebanding

Domain: formica.com

Registered: 1997 (28 years)

Introduction: Formica Corporation partners with the leading suppliers of edgebanding in North America to offer you the most current trends….

6. PVC Edge Banding – ledgeband

Domain: ledgeband.com

Registered: 2023 (2 years)

Introduction: 3-day deliveryWe stock color match edge banding for all laminate brands including: Formica, Wilsonart, Nevamar, Panolam, Finsa, Funder, Egger, AGT, Lab Designs, Uniboard, ……

7. Top 10 PVC Edge Banding Manufacturers In Global Market

Domain: pvcdecorativefilm.com

Registered: 2019 (6 years)

Introduction: Top 10 PVC Edge Banding Manufacturers In Global Market · 1. KAISHENG XINXIN · 3. Mobelkant · 4. Panefri Industrial Co., Ltd. · 5. Shirdi Industries ……

8. Edgebanding – Cabinetmaker Warehouse

Domain: cabinetmakerwarehouse.com

Registered: 2013 (12 years)

Introduction: Free delivery over $500 · 30-day returnsCabinetmaker Warehouse offers a comprehensive selection of Edgebanding, available in PVC, Metallic PVC, and Wood Veneer facings….

Illustrative Image (Source: Google Search)

9. Professional Edge Banding Strips | PVC & ABS | Factory Direct

Domain: edgebandct.com

Registered: 2025 (0 years)

Introduction: Premium edge banding for furniture manufacturers. PVC & ABS strips, custom colors, fast delivery. Get factory prices – Request quote today!…

10. Edgebanding Products

Domain: edgebanding-services.com

Registered: 1997 (28 years)

Introduction: ESI is North America’s leading distributor of PVC Edgebanding with 8 branches in 7 states holding the largest inventory in the continent….

Understanding edge banding laminate Types and Variations

Understanding Edge Banding Laminate Types and Variations

Edge banding for laminate projects is commonly available in PVC, Metallic PVC, and Wood Veneer facings, with finishes and designs that match major brands such as FENIX, Formica, and Wilsonart. Selection is driven by application, aesthetic, and installation requirements. Non-glued, Peel-N-Stick, and Pre-Glued backings are offered; Peel-N-Stick and Pre-Glued are special-order with 1–2 business day lead time. Made-to-order materials cannot be cancelled or refunded once purchased.

Comparative overview

| Type | Features | Applications | Pros/Cons |

|---|---|---|---|

| PVC Standard Edgeband | Solids, woodgrains, patterns, stones; Gloss or Matte finishes; Non-glued, Pre-Glued, Peel-N-Stick; matches FENIX/Formica/Wilsonart | Casework edges, tabletops, drawer fronts | Pros: versatile, cost-effective, durable, easy to form; Cons: limited high-heat performance, lower premium feel |

| Metallic PVC Edgeband | Metallic appearance in PVC; Limited palettes; Non-glued | Accent trim, contemporary casework | Pros: distinctive look, no rust/corrosion risk; Cons: more limited SKUs, visible seams possible |

| Wood Veneer Edgeband | Real wood; Can be prefinished or unfinished; Non-glued (and some special-order PSA on request) | High-end cabinetry, office, hospitality, retail | Pros: premium look, stain/finishable, tactile; Cons: more sensitive to moisture/handling, premium price |

PVC Standard Edgeband

- Features

- Facings: Solids, patterns, stones, woodgrains; Gloss, Matte finishes (per catalog).

- Backings: Non-glued (industrial hot-melt/PUR at machine), Pre-Glued, Peel-N-Stick (PSA).

- Matches leading laminate brands (FENIX, Formica, Wilsonart).

- Applications

- Standard casework, countertops, panels, and drawer edges where durability and cost-efficiency are priorities.

- Pros/Cons

- Pros: Broad design and finish coverage; resilient; easy to route and shape.

- Cons: Withstands typical service temps; premium tactile feel is limited compared to wood veneer.

Metallic PVC Edgeband

- Features

- Metallic appearance using PVC; supplied in limited finishes; non-glued backing is common.

- Applications

- Decorative accents on contemporary cabinetry, fixtures, and retail displays requiring a metallic effect without metal-related corrosion concerns.

- Pros/Cons

- Pros: Striking visual, no rusting or pitting; maintains PVC workability.

- Cons: Fewer SKUs than PVC; joints can show on high-reflectivity finishes.

Wood Veneer Edgeband

- Features

- Real wood faces; prefinished or unfinished options; commonly non-glued; select SKUs may be available with PSA.

- Applications

- High-end casework, commercial interiors, hospitality, and offices where tactile authenticity and finish continuity are desired.

- Pros/Cons

- Pros: Natural appearance; can be sanded/repaired; stain/finishable.

- Cons: More susceptible to moisture and handling marks; typically higher cost and lead time.

Backing/Attachment options

- Non-glued

- Applied with industrial adhesives (hot-melt or PUR) at an edgebander; highest reliability and throughput.

- Pre-Glued

- Factory-applied hot-melt; suitable for hand-held or bench tools; special order, 1–2 business day lead time.

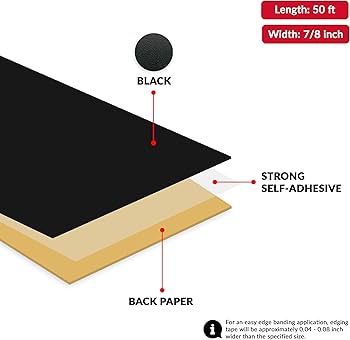

- Peel-N-Stick (PSA)

- Pressure-sensitive adhesive; fast field application; special order, 1–2 business day lead time.

- Note

- Special-order backings are non-cancellable/non-refundable once purchased.

Key Industrial Applications of edge banding laminate

Key Industrial Applications of Edgebanding Laminate

Edgebanding laminate—available in PVC, metallic PVC, and wood veneer facings—delivers durable, finished edges across commercial interiors. Options include non-glued, peel-n-stick (PSA), and pre-glued backings to support varied installation workflows. Designs (solids, woodgrains, stones, patterns) and finishes (gloss, matte) match leading laminate brands, ensuring visual continuity and robust performance.

Illustrative Image (Source: Google Search)

| Industry | Typical Applications | Benefits Relevant to Edgebanding Laminate |

|---|---|---|

| Office Furniture | Worktops, desks, storage units, conference tables | Durable edges resist daily abrasion; wide design/finish selection matches HPL surfaces; choice of non-glued, peel-n-stick, or pre-glued backing aligns with production processes |

| Retail Fixtures & Displays | Counters, gondolas, product stands, shelving | Color/pattern continuity elevates brand visuals; PVC edgeband provides abrasion resistance; quick installation supports turnover and reconfiguration |

| Hospitality | Hotel vanities, tables, bar tops, casegoods | High-wear edges benefit from robust PVC construction; premium wood veneer option adds aesthetic value; moisture resistance supports humid environments |

| Healthcare | Reception desks, nurse stations, cabinets, exam tables | Easy-to-clean laminate edges with durable PVC; finish matching improves cohesive aesthetics across facilities; compatible with non-glued workflows for shop efficiency |

| Kitchens & Foodservice | Counters, tables, prep surfaces, cafeteria furniture | Edgeband protects core materials from moisture and impact; broad design selection blends with laminate surfaces; reliable adhesion supports frequent cleaning routines |

| Education | Student tables, library furniture, lab benches, lockers | HPL with edgeband extends lifespan in high-traffic settings; non-glued backing speeds school-cycle installations; matching finishes minimize visual seams |

| Marine & Transportation Interiors | Wall panels, countertops, storage units | Edgebanding provides impact resistance; PVC option adapts to tight tolerances; consistent finish selection supports uniformity across fleets or boats |

| Casegoods & Millwork | Cabinets, built-ins, wall units, trim | PVC and wood veneer options suit different price/finish needs; non-glued and pre-glued backings match automated or manual application methods |

| Laboratory & Cleanrooms | Work surfaces, cabinets, fixtures | Durable, easy-to-clean edges help maintain sanitation; finish consistency supports controlled environments; adhesion options support varied fabrication practices |

| Recreational Facilities | Poolside furniture, sports venue counters, locker rooms | Edgeband resists moisture and wear; design selection matches laminate aesthetics; reliable installation supports fast deployment |

3 Common User Pain Points for ‘edge banding laminate’ & Their Solutions

3 Common User Pain Points for Edge Banding Laminate & Their Solutions

1) Color/finish mismatch with HPL panels

- Scenario: You spec a Wilsonart or Formica woodgrain for a corporate fit‑out and source edgeband from a different batch or alternative brand. Finish sheen differences and grain alignment issues make edges visibly different from the sheets.

- Problem: Perceived “low quality” finish, rework of components, and schedule slip.

- Solution:

- Match brand, pattern code, and finish sheen explicitly (e.g., Wilsonart 7012 woodgrain vs. Formica 7012 solid).

- Place one purchase order for sheet laminates and edgebanding to minimize batch variance.

- Use PVC edgeband for consistent look across brands; reserve wood veneer for premium exposed edges.

- Confirm finish grade (matte vs. gloss) across SKUs before fabrication.

- Validate appearance on a sample mockup before running production.

2) Edge adhesion and durability failures

- Scenario: In a busy shop or humid climates, pre‑glued or peel‑and‑stick edgeband lifts, curls, or chips during handling.

- Problem: Rejection, rework, and compromised edge protection.

- Solution:

- Select the right backing for the application:

- Non‑glued with contact cement for high‑stress edges (cabinet doors, worktops).

- Pre‑glued for lighter‑duty edges; ensure heat and activation per manufacturer spec.

- Peel‑and‑stick for temporary or low‑load uses only.

- Control application: clean substrate, correct temperature, firm pressure, and adequate activation.

- Post‑process: trim flush with a quality tool and break or chamfer sharp edges.

- Use PVC edgeband (vs. wood veneer) where impact and abrasion resistance are critical.

- Note: special‑order pre‑glued/peel‑and‑stick items cannot be cancelled or refunded once purchased—plan accordingly.

3) Lead‑time delays and SKU selection errors

- Scenario: Project timelines compress; pre‑glued/peel‑and‑stick edgeband is listed as special order with 1–2 business day lead time, and mismatched SKUs are ordered in error.

- Problem: Missed milestones and material substitutions.

- Solution:

- Procure a full SKU kit (edgeband + sheet laminate) early; confirm backing type and finish match before PO.

- Use PVC edgeband for fast availability; metallic PVC for decorative accents; wood veneer for exposed premium edges.

- Keep a buffer of fast‑moving designs (e.g., common Wilsonart/Formica woodgrains and solids).

- Lock supplier lead times for special‑order SKUs and communicate to production; avoid late‑stage changes.

At‑a‑glance summary

| Pain Point | Underlying Causes | Immediate Fixes | Longer‑Term Fixes |

|---|---|---|---|

| Color/finish mismatch | Cross‑brand mismatches; batch variance; gloss vs. matte differences | Replace with same brand/pattern/finish; place combined orders for sheets + edge | Establish “finish spec + brand + code” in BOMs; pre‑approve samples |

| Edge adhesion failures | Wrong backing type; poor surface prep; insufficient activation/pressure | Switch to non‑glued + contact cement for critical edges; improve heat/pressure; trim flush | Standardize process cards by backing type; use PVC for durability; train on correct activation |

| Lead‑time/SKU errors | Special‑order delays; incomplete BOM; late changes | Lock SKUs and backing type; order full kit early; use fast‑lead PVC | Maintain buffer stock; maintain internal spec checklist; align with supplier lead times |

Practical product notes

– Backings available: Non‑glued, Peel‑N‑Stick, Pre‑Glued. Peel‑N‑Stick and Pre‑Glued are special order (1–2 business day lead time) and are non‑refundable/cancellable once ordered.

– Facings: PVC (most common), Metallic PVC (decor accents), Wood Veneer (premium exposed edges).

– Brand alignment: FENIX, Formica, and Wilsonart edgebanding align with corresponding sheet laminates; match brand and pattern code to reduce variance.

Strategic Material Selection Guide for edge banding laminate

Strategic Material Selection Guide for Edge Banding Laminate

Selecting the right edge banding material is a direct lever on installed quality, cycle time, and lifecycle cost. For USA and Europe installations, base your choice on three variables: material type (substrate and facing), backing (glue system), and finish compatibility with your laminate line. The rest is execution.

1) Material Types and When to Use Them

- PVC (Polyvinyl chloride) edgeband

- Best for: High-volume casework, retail fixtures, lab benches, tabletops, high-traffic schools/hospitals.

- Strengths: Best durability for impact/abrasion (vs. veneer), moisture resistance, broad pattern and brand matches, predictable handling. 0.5–2.0 mm typical.

-

Watch-outs: Avoid prolonged UV; ensure adequate adhesive setup and cooling to prevent tunneling/bridging; match thickness to substrate/balance tolerance.

-

Metallic PVC edgeband

- Best for: Accents and signage edges, feature plinths, contemporary fronts where a metallic look is required.

- Strengths: Distinct visual; compatible with PVC installation methods.

-

Watch-outs: Scratch visibility is higher; control heat and roller pressure to avoid burn-through or marring.

-

Wood veneer edgeband

- Best for: Premium furniture lines, interiors, museum/office casework, touch-heavy edges that benefit from a repairable surface.

- Strengths: True wood appearance; easier to patch/repair dents.

- Watch-outs: Less abrasion resistance than PVC; higher moisture sensitivity and glue-line risk; may require different finishing and a more compliant roller system.

2) Backing (Glue System) Selection

PVC and Metallic PVC are offered with Non-Glued, Peel‑N‑Stick, and Pre‑Glued backings. Match glue system to your equipment, throughput, and tolerance for quality variance.

- Pre-Glued (heat‑activated)

- Use when: You have a contour edgebander or edgebander with reliable pre-glue activation and consistent feed/pressure. Lower setup time; limited repositioning once activated.

- Typical adhesives: EVA/Hot‑melt for fast cycles; PUR for high humidity or demanding shear/peel performance.

-

Notes: Ensure temperature profiling and roller force are controlled. Allow full cure before buffing/polishing to avoid telegraphing.

Illustrative Image (Source: Google Search)

-

Peel‑N‑Stick (self‑adhesive PSA/contact)

- Use when: Prototyping, small runs, or curved edges with hand tooling. Excellent control and repositionability during application.

-

Notes: Surface energy and cleanliness are critical. Many inventory programs treat Peel‑N‑Stick and Pre‑Glued as Special Order with 1–2 business day lead time; made‑to‑order items cannot be cancelled or refunded once purchased.

-

Non‑Glued (raw)

- Use when: You require a specific adhesive system (e.g., contact cement, EVA, APAO, PUR) tailored to end-use (e.g., food prep counters, high humidity labs).

- Notes: Enables choice of glue to meet shear/creep and moisture requirements; requires more process control and cure monitoring.

3) Finish and Brand Compatibility

Cabinetmaker Warehouse’s edgeband line matches high-volume laminate brands: FENIX, Formica, and Wilsonart. To avoid noticeable shadow lines at edges:

– Use edgeband whose finish, gloss level, and texture/pattern ID align with the panel finish.

– Where possible, co‑source from the same brand to minimize finish mismatch and color drift across SKUs.

Illustrative Image (Source: Google Search)

4) Performance and Compliance Priorities

- Durability: PVC vs. wood veneer—PVC typically outperforms for abrasion and impact; veneer offers premium look and repairability.

- Moisture/hygiene: PVC’s moisture resistance supports kitchen, lab, and healthcare environments. If using veneer or non‑glued systems, ensure appropriate glue and sealing.

- Consistency: Pre‑glued vs. non‑glued influences repeatability—non‑glued allows you to engineer glue-line performance to specification; pre‑glued trades flexibility for speed.

- Cost control: Standard PVC from major brands provides a predictable cost curve; exotic finishes/metallics may carry a premium and longer lead.

5) Application‑Based Quick Picks

- Kitchen cabinet doors/boxes and retail fixtures: PVC edgeband, finish matched to brand; pre‑glued for speed or non‑glued with PUR where long-term moisture resistance matters.

- Food service or lab countertops: PVC non‑glued + PUR; verify adhesive’s moisture/steam resistance; consider thicker 1.5–2.0 mm for edge robustness.

- Premium office interiors: Wood veneer edgeband for authenticity; seal adequately and plan for periodic touch‑ups.

- Accent/feature elements: Metallic PVC for visual effect; manage scratch risk and heat/pressure during application.

6) Sourcing and Logistics Notes

- PVC is the core SKU range; Metallic PVC and Wood Veneer are limited options.

- Peel‑N‑Stick and Pre‑Glued edgeband are typically Special Order with 1–2 business day lead time. Made‑to‑order materials cannot be cancelled or refunded once purchased—validate production schedule and dimensional specifications up front.

7) Process Tips That Prevent Calls-Backs

- Confirm pattern/ID and finish gloss across edgeband and panel before loading.

- For pre‑glued, tune pre‑heat and post‑heat; use compliant rollers and adequate pressure to prevent telegraphing or bridging.

- Allow adhesives to reach full cure before edge trimming/buffing.

- Maintain clean, prepared substrate surfaces for PSA/contact systems.

- Store edgeband flat, clean, and sealed to avoid edge curl and contamination.

8) Specification Quick‑Win

- If speed and consistency dominate: Use PVC edgeband, pre‑glued, and match brand/finish ID with your HPL panels.

- If durability in wet/hot environments dominates: Use PVC edgeband, non‑glued, bonded with PUR adhesive; include glue line shear/peel requirements in your submittals.

Summary Comparison: PVC vs. Metallic PVC vs. Wood Veneer

| Attribute | PVC | Metallic PVC | Wood Veneer |

|---|---|---|---|

| Finish/pattern availability | Broad solids, woodgrains, stones; brands FENIX, Formica, Wilsonart | Limited metallic finishes | True wood faces; varies by species/finish |

| Typical backing options | Non-Glued, Peel-N-Stick, Pre-Glued (Special Order with 1–2 day lead time) | Non-Glued, Peel-N-Stick, Pre-Glued (Special Order with 1–2 day lead time) | Non-Glued, Peel-N-Stick, Pre-Glued (Special Order with 1–2 day lead time) |

| Durability (abrasion/impact) | High; suitable for heavy commercial use | High base PVC durability; scratch visibility can be higher due to finish | Lower abrasion resistance vs. PVC; dent/scratch repairable |

| Moisture resistance | High | High | Moderate; depends on finish/sealant |

| Installation complexity | Low to moderate; robust with pre‑glued | Low to moderate; careful heat/pressure to avoid burn‑through | Moderate; may require different rollers/finishing steps |

| Typical adhesives | Pre‑glued (EVA/PUR), or hot‑melt; Non‑glued: EVA/APAO/PUR/contact | Same as PVC | PSA/contact, EVA, or PUR depending on spec |

| Typical applications | Casework, retail, labs, schools, desktops | Accent edges, signage, feature fronts | Premium interiors, office casework, furniture |

| Cost tier (relative) | Baseline; broad SKU coverage | Higher visual cost | Variable; premium SKUs |

| Compliance focus | Moisture and hygiene compatibility via glue selection | Visual performance; adhesive same as PVC | Finish/seal strategy; glue selection for edge stability |

| Lead time notes | Core SKUs; Special Orders (PNS/PG) 1–2 business day; MTO non‑refundable/cancellable | Same as PVC | Same as PVC |

In-depth Look: Manufacturing Processes and Quality Assurance for edge banding laminate

In‑Depth Look: Manufacturing Processes and Quality Assurance for Edge Banding Laminate

Purpose and scope

– This section outlines the typical production pathway for PVC, metallic PVC, and wood veneer edgeband, which are available as non‑glued (raw), pre‑glued, and peel‑and‑stick (special order) products; it also summarizes the quality assurance measures that align with recognized ISO‑based management systems and relevant product/adhesive standards across the USA and Europe. While the details vary by substrate and adhesive system, the manufacturing logic follows consistent steps—material preparation, forming/coating, finishing/converting, and quality control—since these formats interface with laminate facings from leading brands (e.g., FENIX, Formica, Wilsonart).

Materials and inputs

– Decorative facings: PVC films (solid colors, stones, woods) and wood veneers are selected to match laminate decors; metallic PVC offers specular finishes for premium aesthetics.

– Substrate/carrier: PVC carrier or equivalent backing; thickness is specified to provide durable edge integrity and reliable application on particleboard, MDF, plywood, and HDF.

– Adhesive systems: pre‑glued and peel‑and‑stick products include either hot‑melt/PSA adhesives with release films or pre‑applied glue lines; these are special‑order items with defined lead times and are non‑cancellable/refundable once ordered (as per standard trade terms).

Manufacturing process (representative flow)

1) Prep (material sourcing and conditioning)

– Decorative rolls or sheets (PVC, veneer) are inspected for visual defects, colorway verification, and batch traceability; adhesive and release films are staged and stored under controlled temperature and humidity to avoid condensation and off‑gassing.

– Dimensional verification is performed to confirm substrate thickness, width tolerance, and roll weights, ensuring compatibility with downstream edgebanding equipment; color batch matching to sheet laminates (Formica/Wilsonart/FENIX) is confirmed before extrusion or lamination.

2) Forming (coextrusion or lamination) and coating

– PVC/Metallic PVC edgeband: Extrusion or coextrusion aligns the decorative film with the carrier; coating stations apply pre‑glued hot‑melt/PSA adhesives under controlled line speed and temperature, followed by a cooling or calendaring section that sets the adhesive bond and ensures flatness and uniform glue line thickness.

– Wood veneer edgeband: Veneer is bonded to the carrier using adhesives meeting regional compliance (e.g., EN 1396, ECA/ECA‑compliant systems, CARB/TSCA Title VI for low formaldehyde emissions where applicable) and is calendared to thickness; surface finishing may include sanding, sealers, and UV-curable topcoats to improve scuff and moisture resistance.

– Peel‑and‑stick: Pressure‑sensitive adhesives are applied and covered with release paper or film; the adhesive must retain tack and cohesion over time, with controlled peel force during activation on site.

Illustrative Image (Source: Google Search)

3) Assembly and packaging

– Slitting converts the web to specified widths; roll winding or cut‑to‑length operations are executed to produce standard lengths or custom sizes.

– Packaging is implemented using protective wraps, end caps, or boxes to prevent edge abrasion and to maintain tape flatness; special‑order formats (pre‑glued, peel‑and‑stick) are processed under defined lead times and are subject to non‑cancellation/non‑refund policy once ordered.

– Optional pre‑cutting or pre‑forming for CNC/routers can be provided when specified by the fabricator to reduce on‑site waste and increase throughput.

Quality assurance framework (ISO‑aligned standards and product standards)

– Management systems (used by edgeband manufacturers and end‑users):

– ISO 9001 (Quality Management Systems) is commonly used to govern process control, traceability, calibration, and continuous improvement.

– ISO 14001 (Environmental Management Systems) may be used by suppliers to monitor VOC emissions, energy, waste, and compliance with environmental directives such as RoHS and REACH.

– ISO 45001 (Occupational Health and Safety) helps manage workplace risks associated with extrusion, laminating, solvents, and adhesives.

– Product and adhesive standards:

– PVC edgeband performance aligns with ISO 9001 quality practices; laminate‑matching standards for decor alignment and specification are commonly reference points in procurement.

– Wood veneer edgeband specifications follow regional wood‑based materials standards for adhesive emissions and dimensional behavior; veneer handling and moisture control follow best practices derived from ISO‑aligned management systems.

– Pre‑glued and peel‑and‑stick adhesives typically reference EN 1396 for constructional adhesives and EN 301/302 for polychloroprene adhesives in building applications, with compliance to CARB/TSCA Title VI for low formaldehyde if relevant to the carrier or veneer adhesives; VOC content and restricted substances are monitored to satisfy US/EU regulatory requirements.

– Dimensional tolerances and visual acceptance criteria are verified against ISO 9001 procedures, including thickness tolerance, color consistency, and gloss/finish match to specified finishes (Gloss, Matte).

Testing and inspection (typical QA checks)

– Dimensional checks: thickness across the width, straightness of edges, roll width and length conformity, and absence of camber or curl; tolerance bands are established per buyer specification and verified using calibrated gauges.

– Adhesion and cohesion: pre‑glued/PSA systems are tested for bond strength under typical service conditions, including 90° peel at room and elevated temperatures; wood veneer systems undergo bond integrity checks after environmental conditioning.

– Visual matching: color, pattern, and finish (gloss/matte) alignment to sheet laminates is evaluated under controlled lighting; batch‑to‑batch color matching is recorded for traceability.

– Surface tests: scuff and scratch resistance, stain resistance, and heat tolerance (dry heat and steam exposure for kitchen environments) are evaluated to ensure durability; metallic PVC products are checked for clear coat integrity to prevent flaking or haze.

– Physical stability: dimensional behavior under humidity and temperature variations (shrinkage, curl, warpage) is assessed; moisture content in veneer products is monitored and controlled.

– Length/roll integrity: core integrity, winding uniformity, and label accuracy are verified prior to shipment.

– Regulatory compliance: adhesive emissions and VOC content are verified for compliance with applicable US and EU standards; restricted substances lists are reviewed to satisfy REACH and RoHS requirements where applicable.

Packaging, storage, and handling

– Products are packed to minimize abrasion and to preserve adhesive performance; rolls should be stored flat and clean, protected from moisture and direct sunlight, and conditioned to ambient fabricator temperatures before use.

– Handling instructions for pre‑glued and peel‑and‑stick systems specify cleaning of substrates, activation temperatures, application pressure, and trimming procedures, all of which are critical to achieving durable, seamless edges.

Illustrative Image (Source: Google Search)

Special order considerations

– Pre‑glued and peel‑and‑stick formats are special‑order with a typical 1–2 business day lead time; once processed, made‑to‑order materials cannot be cancelled or refunded, reflecting standard trade conditions; ordering teams should therefore confirm specifications, finish, and adhesive compatibility early in the schedule.

Summary

– The manufacturing pathway—prep, forming/coating, assembly/packaging, and ISO‑aligned QA—ensures that PVC, metallic PVC, and wood veneer edgeband consistently match laminate facings from major brands while meeting dimensional, visual, and adhesion performance criteria expected by professional fabricators in the USA and Europe; because pre‑glued and peel‑and‑stick formats are produced to order under defined lead‑times and non‑refundable conditions, procurement should pair early specification confirmation with rigorous incoming inspection against ISO‑based acceptance criteria, thereby reducing rework risk and maintaining throughput across cabinetry, countertops, and built‑in applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘edge banding laminate’

Practical Sourcing Guide: A Step-by-Step Checklist for Edge Banding Laminate (USA & Europe)

Use this checklist to source edge banding laminate that matches your laminate brand and finish, aligns with your production method, and meets USA and EU compliance and lead-time requirements.

1) Define Requirements

- Create a written specification for each application:

- Material: PVC, Metallic PVC, or Wood Veneer

- Width: e.g., 19 mm (3/4 in)

- Thickness: e.g., 0.5 mm (0.020 in)

- Finish: Gloss, Matte (or equivalent)

- Pattern/Code: exact brand and item code

- Backing: Non-glued, Pre-glued, or Peel-N-Stick

- Quantity per SKU and total

- Confirm match with brand and code for primary laminates you use.

2) Select Backing Type

- Pre-glued: best for low-volume and non-continuous operations. Use a hot-melt profile applicator; ensure film thickness suits material and line speed. Note: many pre-glued options are special-order with lead-time (1–2 business day) and cannot be cancelled or refunded.

- Peel-N-Stick (PSA): for light-duty or low-volume on flat edges. Requires pressure and time for full adhesion. Note: usually special-order with 1–2 business day lead-time and no cancellation.

- Non-glued: for production lines with automatic applicators and solvent-based contact cement or hot-melt systems. Highest process control and throughput.

3) Match Brand, Finish, and Code

- Align with your primary laminate brand to minimize mismatch risk.

Table — Backing type matrix

| Backing type | Typical production fit | Pros | Cons / considerations | Notes (US/EU) |

|---|---|---|---|---|

| Pre-glued | Low to mid-volume; profile banding | Simple start; minimal tooling | Requires heat/pressure; lead-time; non-cancellable | Verify EVA/polyamide hot-melt; follow line temp guidance |

| Peel-N-Stick | Low-volume; flat edges; prototypes | No equipment needed | Adhesion sensitive to surface prep/pressure; special-order | Ensure PSA compliance and cleaning before bonding |

| Non-glued | High-volume; continuous lines | Fastest setup; best bond with contact | Requires applicator and adhesive management | Confirm solvent VOC and labeling in your region |

Table — Brand and finish overview

| Brand | Core materials offered (sourcing context) | Finish notes (sourcing context) |

|---|---|---|

| Wilsonart | PVC (with metallic option), Wood Veneer | Solids, Woodgrains; Gloss/Matte |

| Formica | PVC (with metallic option), Wood Veneer | Solids, Woodgrains, Stones; Gloss/Matte |

| Fenix | High-performance decorative surfaces; check edge options | Premium matte/low-gloss surfaces |

Ensure the brand and finish category on the edgeband match your laminate.

4) Confirm Product Availability and Lead Times

- Many PVC edgebands are in stock. Peel-N-Stick and Pre-glued are typically special-order.

- Typical lead-time: 1–2 business days after order placement.

- Note: Made-to-order materials cannot be cancelled or refunded once purchased.

5) Price and Terms Check

- Verify pricing is per roll/coil or per linear foot/meter; confirm unit of measure and discounts.

- Confirm minimum order quantity (MOQ) and production lead-time.

- Align Incoterms for USA and EU deliveries (e.g., FOB for US, DAP or DDP for EU).

6) Sampling and Approval

- Sample request:

- Provide brand, item code, finish, width, thickness, and backing type.

- Approval criteria:

- Visual match under daylight and task lighting.

- Physical tests: adhesion (cross-cut/scratch), heat stability at application temperature, edge radius fit, and color consistency.

- Approve with written sign-off.

7) QC and Receiving

- Incoming inspection (batch level):

- Verify brand and code; measure width and thickness.

- Surface quality: color uniformity, finish, and absence of defects.

- Adhesion performance (pre-glued/PSA): 24–72 h peel/shear test; check for cold creep.

- UV and heat stability (if exposed): verify no bubbling or discoloration at expected exposure.

- Packaging:

- Rolls coiled correctly; protective wrapping; labeled with code, width, thickness, batch.

- Storage: avoid high heat and direct sunlight; keep adhesive-protected materials dust-free.

8) Logistics: Shipping and Duties (US/EU)

- USA:

- Confirm HS code for classification; typically 3926.30 (articles of plastics) for PVC edgebanding.

- Provide freight dimensions for accurate LTL/FTL cost.

- Verify carrier accessorials (liftgate, inside delivery).

- EU:

- Check EORI; ensure VAT compliance for business-to-business shipments.

- Align Incoterms; provide HS code for customs.

- Note regional carrier compliance for ADR where applicable.

- Delivery SLA:

- Confirm order-to-ship lead-time and tracking.

Table — Simple logistics summary

| Region | HS code (typical) | Notes |

|---|---|---|

| USA | 3926.30 | Verify classification with your broker |

| EU | 3926.30 | Provide EORI and VAT details |

9) Compliance & Documentation (USA & Europe)

- Material and VOC:

- For PVC/PSA products: obtain supplier declarations or REACH SVHC information (EU).

- For adhesives: request SDS and labeling; verify VOC content vs. local regulations.

- USA:

- Check RoHS compliance for any metallic facings; verify California Proposition 65 labeling if applicable.

- Keep certificates and SDS on file per procurement policy.

- EU:

- Request REACH and SVHC statements for adhesives and coatings.

- Obtain CE/DoC if applicable; follow WEEE on packaging.

- Note: Many edgeband products in this category are standard PVC with limited formaldehyde concerns; request documentation as required.

10) Change Control and Supplier Management

- Document approved code, batch, and specification for repeat orders.

- Track performance: lead-time adherence, defect rate, color variance.

- For any change of brand, code, or backing, trigger a new sample approval cycle.

11) Risk Management

- Special-order vs. stock: stock backings reduce lead-time risk; plan buffer inventory.

- No cancellation/refund on made-to-order: align production schedules with order placement.

- Adhesive compatibility: define and qualify adhesives for your line; document set and open time.

- Color consistency: qualify by lot; require batch-controlled color matching.

- Logistics: confirm packaging size for warehouse handling; verify carrier restrictions.

12) Quick Reference: Materials and Finishes

Table — Material vs. properties

| Material | Pros | Cons / considerations | Typical uses |

|---|---|---|---|

| PVC | Durable; broad color/finish selection; cost-effective | Edgebanding; matches brand codes; limited premium tactile | Standard casework; tabletops |

| Metallic PVC | Unique metallic look; visual interest | Surface polish sensitivity; price premium | Accents; design features |

| Wood Veneer | Premium tactile finish; natural look | Thicker stock; different tooling; more fragile | Designer finishes; premium edges |

Finish overview (based on available inventory): Gloss and Matte available; additional Prefinished/Unfinished may be offered. Use matching finish to your laminate to minimize sheen mismatch.

Checklist format (copy/paste):

– [ ] Spec approved (brand, code, finish, width, thickness, backing)

– [ ] Backing type selected (Pre-glued / Peel-N-Stick / Non-glued)

– [ ] Samples ordered and approved (visual + physical tests)

– [ ] Price and lead-time confirmed; Incoterms and MOQ agreed

– [ ] Special-order lead-time documented; no-cancellation policy noted

– [ ] Incoming QC checklist created (dimensionals, finish, adhesion)

– [ ] Compliance documents collected (SDS, REACH, VOC notes, HS codes)

– [ ] Logistics alignment complete (USA/EU broker details; delivery SLA)

– [ ] Change control and repeat order instructions set (lot tracking)

This approach balances brand/finish match, production fit, lead-time reliability, and compliance for USA and Europe, minimizing downstream quality issues and supply risk.

Comprehensive Cost and Pricing Analysis for edge banding laminate Sourcing

Comprehensive Cost and Pricing Analysis for Edge Banding Laminate Sourcing (USA, Europe)

Purpose: Provide a transparent cost model and sourcing strategy that balances quality, lead-time, and total cost of ownership for USA and European buyers.

Illustrative Image (Source: Google Search)

Notes on references:

– Cabinetmaker Warehouse offers PVC, Metallic PVC, and Wood Veneer edgeband with Non-Glued, Peel-N-Stick, and Pre-Glued backings.

– Example observed PVC prices in the USA: from $87.69 to $103.23 per roll depending on finish.

– Peel-N-Stick and Pre-Glued are special-order with 1–2 business day lead-time. Made-to-order items cannot be cancelled or refunded once purchased.

1) Materials pricing overview (USD; EUR for Europe)

- Prices vary by width, thickness, finish (solid, woodgrain, stone, metallic), and backing.

- Peel-N-Stick and Pre-Glued typically add cost vs Non-Glued.

Table 1. Representative materials price view (illustrative, based on observed ranges)

| Material/Facing | Backing | Typical roll size | USA observed price range | Europe indicative price range | Notes |

|---|---|---|---|---|---|

| PVC | Non-Glued | 19 mm × 0.5 mm × 100 m | $87.69–$103.23 / roll | €8–€16 / roll | Special-order backings may add premium; special-order = 1–2 day lead-time |

| PVC | Pre-Glued | 19 mm × 0.5 mm × 100 m | Premium over Non-Glued | Premium over Non-Glued | Pre-glue enables hot-melt application; ensure activation tools/process |

| PVC | Peel-N-Stick | 19 mm × 0.5 mm × 100 m | Premium over Non-Glued | Premium over Non-Glued | Simplest application; consider quality of adhesive and bonding strength |

| Metallic PVC | Non-Glued | 19 mm × 0.5 mm × 100 m | Premium over PVC | Premium over PVC | Aesthetic accent; typically higher cost than standard PVC |

| Wood Veneer | Non-Glued | 19 mm × 0.5 mm × 100 m | Premium over PVC | Premium over PVC | Natural grain finish; handle carefully to avoid tear |

Key takeaway: For USA procurement, a baseline PVC roll typically lands between $87.69 and $103.23 depending on finish and brand. Expect similar relative tiering in Europe, with variability by country, VAT, freight, and supplier.

2) Total cost-of-ownership (TCO) model

Structure your per-linear-foot and per-project cost as follows.

Illustrative Image (Source: Google Search)

Table 2. Cost component model and formulas

| Component | What it covers | Typical inputs | Formula |

|---|---|---|---|

| Materials | Edgeband rolls, adhesives, protective film | Roll price, roll yield (LF/roll), width/thickness | Material LF cost = Roll price ÷ Roll yield |

| Labor | Loading, trimming, applying, activating, buffing | LF per hour, operator and setup hours, scrap rate | Labor cost per LF = (On-machine time per LF × operator hourly rate) ÷ (1 − Scrap rate) |

| Machine/overhead | Rental or depreciation, power, maintenance | Hourly rate, machine utilization | Overhead per LF = Machine hourly rate ÷ LF per hour |

| Logistics | Freight, handling, duties, VAT, brokerage, insurance | Carrier quotes, customs/VAT, packaging | Logistics cost per unit = (Shipment cost + duties + taxes + handling) ÷ Units shipped |

| Total cost | End-to-end | All above | Total per LF = Materials + Labor + Overhead + Logistics |

How to assemble practical numbers:

– Roll yield example: 100 m per roll ≈ 328 LF. With PVC at $87.69/roll, material cost per LF ≈ $0.27 (without adhesive).

– Labor example: If your cell produces 650 LF per hour and operator + benefits cost is $25/hour, labor per LF ≈ $0.04; at 325 LF/hour, ≈ $0.08; at 160 LF/hour, ≈ $0.16.

– Overhead example: If the machine’s all-in rate is $12/hour, at 650 LF/hour overhead ≈ $0.018/LF; at 160 LF/hour ≈ $0.075/LF.

– Logistics example: If you ship 500 rolls at $6,000 freight, duties + taxes are $2,000, handling $500, then shipment total is $8,500. Logistics per roll ≈ $17; per LF (328 LF/roll) ≈ $0.052/LF.

3) Labor cost levers (speed and scrap drive the unit economics)

- Faster lines drive labor and overhead down. The impact is linear: doubling throughput roughly halves labor and overhead per LF.

- Scrap cuts both revenue and throughput. Reducing scrap from 3% to 1% improves effective yield by ~2%.

- Backings:

- Pre-Glued: Faster application using hot-melt activation; requires consistent temperature, activation time, and compaction.

- Peel-N-Stick: Lowest skill threshold; good for prototyping or low-volume. Check adhesive quality and shelf life.

- Non-Glued: Lowest material cost but slower setup if using separate glue application (solvent or hot-melt).

Table 3. Representative throughput and labor scenarios (illustrative)

| Backing type | Typical throughput (LF/hour) | Labor + Overhead per LF at $25/hr + $12/hr | Notes |

|---|---|---|---|

| Peel-N-Stick (manual) | 325 | ~$0.11 | Requires clean substrates; watch peel strength |

| Pre-Glued (hot-melt) | 650 | ~$0.06 | Consistent activation temp; high compaction |

| Non-Glued + hot-melt | 650 | ~$0.06 | Material cost lowest; setup complexity varies |

4) Logistics and regional differences

- USA:

- Domestic freight for full-pallet shipments; avoid LTL surcharges for low-density loads.

- Special orders (Pre-Glued, Peel-N-Stick) have 1–2 business day lead-time; plan buffer inventory for critical SKUs.

- Made-to-order materials cannot be cancelled or refunded once purchased—commit only after design freeze.

- Europe:

- Cross-border logistics, VAT, and country-specific brokerage fees impact landed cost.

- Packaging and palletization standards vary; ensure stable packaging for metallic finishes to avoid scuffing.

- Consider regional stocking in DE, PL, or UK to reduce lead-times and customs friction.

Table 4. Logistics cost scenarios (illustrative)

| Scenario | Shipment size | Freight | Duties/Taxes | Handling/Admin | Logistics per roll | Logistics per LF (328 LF) |

|---|---|---|---|---|---|---|

| Domestic USA pallet | 500 rolls | $6,000 | $2,000 | $500 | ~$17.00 | ~$0.052 |

| Domestic USA LTL (single roll) | 1 roll | $120 | $0 | $15 | $135.00 | ~$0.41 |

| Cross-border EU | 300 rolls | €6,000 | €2,000 | €500 | ~€28.30 | ~€0.086 |

5) Savings and sourcing levers

- Materials and finish:

- Prefer PVC for cost unless wood veneer or metallic finish is required for brand/customer aesthetics.

- Match sheet laminates (FENIX, Formica, Wilsonart) to minimize dye-lot variance and waste.

- Standard widths (e.g., 19 mm) reduce tooling complexity and inventory SKUs.

- Backings and adhesives:

- Use Non-Glued if you have high-volume hot-melt application lines to capture material savings.

- Use Pre-Glued for higher speed and consistent activation; avoid adhesive dry-out with climate control.

- Use Peel-N-Stick for low-volume, design samples, or field repairs.

- Labor and throughput:

- Increase compaction and activation consistency; maintain activation temperature profiles and dwell time.

- Reduce setup time with quick-change tooling and standardized widths.

- Implement quality gates to catch mismatches before application.

- Procurement and inventory:

- Consolidate purchases into full pallets to avoid LTL freight penalties.

- Lock critical SKUs under blanket orders; hold buffer for special-order backings (1–2 day lead-time).

- Avoid changeovers once made-to-order items are placed (non-refundable).

- Regional strategy:

- USA buyers: use domestic distributors; confirm special-order lead-times; plan for price steps by finish.

- Europe buyers: consider regional stocking hubs; factor VAT/duties into SKU-level landed cost.

Table 5. Savings levers and typical impact (illustrative)

| Lever | Cost impact | Notes |

|---|---|---|

| Choose PVC vs wood veneer/metallic | Lower material cost | 10–40% savings depending on region |

| Non-Glued + hot-melt in high-volume | Lower material + faster line | Requires investment in consistent activation |

| Eliminate LTL freight | Large logistics savings | Target full-pallet shipments |

| Reduce scrap 3% → 1% | ~2% yield gain | Impacts materials, labor, overhead |

| Standardize widths | Lower tooling and changeover cost | Fewer SKUs, faster setup |

6) Action plan for USA and Europe

- Define a baseline: material cost per LF (PVC, your width), throughput (LF/hour), and scrap rate.

- Compute TCO per LF using the model; isolate the single largest driver (materials or labor/overhead) and attack it first.

- Supplier shortlist:

- PVC edgeband from brands including Wilsonart and Formica via a distributor with special-order backings.

- Validate finish match to sheet laminates you stock (solid, woodgrain, stone).

- Pilot and scale:

- Run a 10–20 roll pilot on the chosen backing to confirm activation and scrap metrics.

- Lock logistics contracts for full-pallet shipments; set buffer inventory for special-order items.

Bottom line: With PVC PVC from $87.69 to $103.23/roll in the USA and a modest labor/overhead structure, material cost often sets the baseline; however, throughput and freight frequently dominate TCO per LF. A disciplined finish-and-backing decision, standardized widths, and logistics optimization deliver the fastest, most reliable savings on either side of the Atlantic.

Alternatives Analysis: Comparing edge banding laminate With Other Solutions

Alternatives Analysis: Edge Banding vs. Wood Veneer and Solid Wood Edge

Selecting the right edge solution involves balancing finish fidelity, durability, moisture resistance, and total installed cost. Below is a pragmatic comparison anchored in commonly used edge banding materials and a widely used solid edge alternative.

Comparison at a glance

| Criteria | Edge Banding: PVC (prefabricated strip) | Edge Banding: Wood Veneer (thin real wood) | Solid Wood Edge (e.g., solid maple/cherry) |

|---|---|---|---|

| Aesthetics | High color/pattern match to laminates (FENIX, Formica, Wilsonart) | Natural wood look; more tactile authenticity | Premium; wood appearance dominates (edge dominates panel aesthetics) |

| Finish options | Solids, patterns, stones, woodgrains; gloss/matte; metallic looks available | Natural wood species, stains/clear coats | Clear or tinted coatings; can be routed for profile |

| Durability & impact | Good general impact resistance; may scuff; can chip at corners if impacted | Softer surface; susceptible to denting/splintering; more finish touch-ups | Highest impact tolerance and repairability; can be re-profiled |

| Moisture resistance | Excellent water resistance; seams require adhesive seal for wet-duty | Sensitive to moisture; glue lines can telegraph; finishing critical | Solid; sealed finish resists spills; more dimensional change risk |

| Color/pattern matching | Very high (coordinated with major laminate lines) | Requires separate stain/finish strategy to match; exact matching is hard | No laminate matching needed; contrasts with panel face |

| Installation complexity | Fast and repeatable; non-glued, pre-glued, or peel‑n‑stick | More labor/time; edge trimming, sanding, finishing required | Highest labor; planing/sanding/routing and finishing |

| Typical edge thickness | Common 1–3 mm | ~0.4–1.5 mm (species dependent) | Typically 10–20 mm visible thickness |

| Total installed cost (relative) | Low to moderate | Moderate | High |

| Lead times & availability | Broad market availability; branded match lines | Specialty items; fewer coordinated match options | In-house or local shop; project-specific lead time |

| Sustainability notes | PVC is durable; recycling/reuse depends on local programs | Natural wood; look for FSC/PEFC and low‑VOC finishes | Natural wood; depends on forestry and finishing chemicals |

| Repairability | Difficult to patch; replacement/removal needed | Can be patched/repaired more easily with wood filler/stain | Most repairable: sanding, filling, re-finishing, re-profiling |

Sources for options and backing types reflect common industry offerings (PVC and wood veneer edgeband; non‑glued, pre‑glued, and peel‑n‑stick configurations; coordination with FENIX, Formica, and Wilsonart laminates).

Illustrative Image (Source: Google Search)

Wood Veneer Edgeband

- Where it fits: Projects that require a real wood visual on exposed edges with tighter budget than solid wood.

- Strengths: Natural look and feel; easier repairs compared to PVC; can be routed and finished to profile.

- Weaknesses: Moisture sensitivity; visible glue lines; higher labor for trimming/sanding/finishing; more finish maintenance.

- Best for: Retail, hospitality, and office interiors with moderate exposure and an emphasis on natural material.

Solid Wood Edge

- Where it fits: High‑durability and high‑impact areas, premium furniture, and applications requiring pronounced edge profiles.

- Strengths: Robust impact resistance; easy to refinish; can be re‑profiled or detailed.

- Weaknesses: Highest installed cost and lead time; visual contrast with laminate faces; seasonal movement/expansion risks.

- Best for: Heavy‑use casework, desks, workstations, institutional furniture, and where aesthetics prioritize wood over laminate matching.

Quick selection guidance

- Choose PVC edgeband when you need fast, consistent, high‑match aesthetics at the lowest installed cost and robust moisture resistance. It is the default for production shops standardizing on laminate sheets from major brands.

- Choose wood veneer when you want a real wood edge visual with moderate durability and accept the added finishing steps and maintenance.

- Choose solid wood when impact resistance, long‑term refinishing options, and prominent edge detailing are prioritized over matching laminate patterns and when budget allows for higher labor.

Essential Technical Properties and Trade Terminology for edge banding laminate

Essential Technical Properties and Trade Terminology for Edge Banding Laminate

Material and Core Build

- Facings available: PVC, Metallic PVC, and Wood Veneer.

- Backings (application category): Non-Glued, Peel‑N‑Stick (PSA), Pre‑Glued (PSA).

- Finish options: Gloss, Matte; offered as both Prefinished and Unfinished.

- Substrate/core: PVC-based edgeband with laminate-facing for durability and color alignment.

Compatibility

- Matched to leading laminate brands: FENIX, Formica, and Wilsonart.

- Use to finish tabletops, cabinets, and drawer edges in high-wear environments.

Backing Definitions and Availability

- Non‑Glued (no adhesive): ready for shop-applied adhesive; generally in stock.

- Peel‑N‑Stick (PSA): factory-applied pressure-sensitive adhesive; Special Order, 1–2 business day lead time.

- Pre‑Glued (PSA): factory-applied pressure-sensitive adhesive; Special Order, 1–2 business day lead time.

- Note: Peel‑N‑Stick and Pre‑Glued options are Special Order; Made‑to‑Order materials cannot be cancelled or refunded once purchased.

Finish and Color System

- Finish definitions:

- Gloss: high-sheen surface for modern or formal designs.

- Matte: low-sheen, low-glare finish; often preferred for modern interiors.

- Prefinished: ready for installation (most SKUs).

- Unfinished: requires post-application finishing in shop (where applicable).

- Pattern and Color Matching:

- Colorways align to recognized brand codes and pattern numbering systems (e.g., Formica, Wilsonart, FENIX).

- Example SKU structure: Brand + Pattern Code (e.g., 7966) + Product Type (PVC Edgeband).

Availability and Ordering Basics

- Catalog: extensive SKU set with multiple design categories (Solids, Woodgrains, Stones, Metallics).

- Special Order policy:

- Peel‑N‑Stick and Pre‑Glued backed bands: Special Order with 1–2 business day lead time.

- Made‑to‑Order materials: non-cancellable and non-refundable after purchase.

Trade Terminology (B2B Reference)

| Term | Definition | Implications for Ordering / Specs |

|---|---|---|

| MOQ (Minimum Order Quantity) | Minimum units or footage per SKU to fulfill an order. | Varies by SKU; confirm with supplier. |

| Lead Time | Time to ship after order confirmation. | Stock (Non‑Glued): typically short; Special Order (Peel‑N‑Stick, Pre‑Glued): 1–2 business days. |

| Special Order | Non-stock configuration made on request. | Longer lead time; stricter returns/cancellations. |

| Made‑to‑Order (MTO) | Produced specifically for the order. | Non-cancellable and non-refundable after purchase. |

| SKU (Stock Keeping Unit) | Unique identifier for each product. | Track inventory, pricing, and replacement. |

| Pattern Number | Brand-specific color/pattern code. | Ensures accurate color/finish matching across laminates and edgeband. |

| Backing Type | Adhesive application category on the band’s reverse. | Dictates installation method and lead time. |

| PSA (Pressure‑Sensitive Adhesive) | Factory-applied adhesive layer for peel‑and‑apply. | Consistent bond; available on Special Order. |

| Non‑Glued | No factory adhesive; shop applies adhesive. | Flexible adhesive choice; commonly stocked. |

| Prefinished / Unfinished | Surface readiness of the edgeband. | Prefinished = install-ready; Unfinished = shop finishing required. |

| Roll Length / Footage | Linear footage supplied per roll. | Confirm per SKU to optimize cutting plans. |

| Roll Width | Width of the band (e.g., for thickness of the panel edge). | Select to match substrate thickness. |

| Price Unit | The unit used for pricing (per roll, per foot). | Compare pricing across SKUs/widths. |

| Warranty / Returns | Policy coverage and conditions. | Note MTO restrictions; verify warranty terms per product line. |

Quick Reference: Backing Type at a Glance

- Non‑Glued:

- Typical stock availability.

- Shop applies adhesive (e.g., hot melt or contact cement).

- Flexibility in adhesive chemistry.

- Peel‑N‑Stick (PSA):

- Special Order; 1–2 business day lead time.

- Install with pressure; clean application recommended.

- Pre‑Glued (PSA):

- Special Order; 1–2 business day lead time.

- Install with heat/pressure activation if specified by manufacturer.

Notes

– Exact thicknesses, widths, and roll lengths vary by SKU and are not specified here.

– Always confirm compatibility between edgeband backing, adhesive, and panel materials prior to specification.

Navigating Market Dynamics and Sourcing Trends in the edge banding laminate Sector

Navigating Market Dynamics and Sourcing Trends in the Edge Banding Laminate Sector

** The North American and European edge banding laminate market is currently dominated by PVC facings that mirror Wilsonart, Formica, and Fenix laminates, with wood veneer edgebanding positioned as a premium, specialized option. PVC’s material flexibility, broad thickness/window options, and wide color match across pattern families (woodgrains, solids, stones) drive adoption; wood veneer plays a specific role for premium feel, repairability, and premium aesthetic. The supply base features a consolidated mix of big-name laminate brands and mid-tier distributors, with consistent availability concentrated in PVC; wood veneer edgeband is largely made-to-order. Buyers see lead-time and policy sensitivity for pre-glued and peel-and-stick backings, and must plan adhesive and coater compatibility to avoid call-backs. Sustainability pressures are rising across regions, accelerating demand for PVC content with recycled content, VOC-compliant hot-melts, and circular packaging, with regulatory scrutiny stronger in the EU than in the U.S. To reduce risk and cost volatility, buyers should qualify multiple sources, enforce color match standards, specify adhesive performance by substrate, confirm thickness/window standards to simplify inventory, and adopt sustainability clauses where applicable. **

Materials and Formats: What the Data Says

- Leading material: PVC edgeband is the default choice for laminates in North America and Europe, with metallic PVC variants and wood veneer edgebanding as specialized options.

- Matching requirement: The majority of orders require color and finish match to specified laminate brands (Wilsonart, Formica, Fenix).

- Backings and lead-time: Non-glued PVC is generally in stock; pre-glued and peel-and-stick are common as special order with short lead-time (commonly 1–2 business days) and strict no-cancellation/no-refund policies for made-to-order items.

Table 1: Material Type Overview (from category and product-level references)

| Attribute | PVC Edgeband | Metallic PVC Edgeband | Wood Veneer Edgeband |

|---|---|---|---|

| Volume vs Premium | High-volume, default | Specialty; decorative accents | Premium/niche |

| Typical Thickness | 0.8–2.0 mm bands commonly specified | Similar ranges to PVC | Varies by profile; matches laminate windows |

| Typical Width (Window) | 19 mm (3/4″), 25–30 mm (1″) common | Same as PVC | 19 mm typical; can be custom |

| Finishes | Matte, Gloss, Prefinished | Metallic effects | Veneer finishes vary; often pre-finished or oiled |

| Adhesive Options | Non-glued, Pre-glued, Peel-and-stick | Non-glued, Pre-glued, Peel-and-stick | Usually pre-glued or non-glued; specialty adhesives |

| Typical Availability | Broad; multiple brands and widths | Limited options | Made-to-order; select SKUs |

| Sustainability Levers | Recycled content options; VOC hot-melts | Limited options | Wood supply certification; solvent-free adhesives |

Table 2: Finish and Pattern Mix (from category listings)

Illustrative Image (Source: Google Search)

| Finish | Notes | Count (representative assortment) |

|---|---|---|

| Gloss | High-sheen, limited items | 7 |

| Matte | Low-sheen; durable | 8 |

| Prefinished | Ready-to-use after cutting | 1 |

| Unfinished | Requires coating/finishing | 1 |

Pattern families (representative counts from assortment):

| Pattern Family | Approx. Count | Notes |

|---|---|---|

| Patterns | 48 | Decorative textures/abstracts |

| Solids | 108 | Neutral/functional finishes |

| Stones | 15 | Marble/granite looks |

| Woodgrains | 177 | Dominant category; broad matching |

Table 3: Adhesive Backings—Operational Implications

| Adhesive Backing | Core Features | Pros | Operational Notes |

|---|---|---|---|

| Non-glued | Band without adhesive | Fast thermal processing; low lead-time | Requires own coater; match substrate; VOC control |

| Pre-glued | Adhesive applied at factory; activation needed | Speed-to-installation; reduced equipment | Activation window/time critical; lead-time on special order |

| Peel-and-stick | PSA backing with protective film | Rapid installation; minimal setup | Temperature sensitivity; substrate prep critical |

Supply Chain and Pricing Dynamics

- Product mix: Inventory and pricing are driven by brand availability and matching requirements; PVC dominates both.

- Availability and lead-times: PVC edgeband tends to be more available across widths and finishes; pre-glued and peel-and-stick are commonly special order with short lead-time (e.g., 1–2 business day lead-time) and policy restrictions for cancellations/refunds on made-to-order items.

- Price signaling: The market exhibits common list prices and tiers by brand and material. For example, many PVC edgeband SKUs from leading brands are priced at a consistent list level (e.g., $87.69 per unit) in one catalog, with select SKUs at higher list levels ($103.23). These observed price anchors, along with special-order status, create predictable decision points for buyers balancing speed and cost.

Sustainability Landscape and Buyer Implications

- Material-level pressures: PVC edgeband programs increasingly incorporate recycled content (PCR) claims; buyers should specify recycled content targets where available and verify supplier documentation.

- Adhesives and emissions: Hot-melt adhesives can be solvent-free and VOC-compliant; specifications should include substrate bonding strength, service temperature activation ranges, and emissions standards (e.g., compliant low-VOC profiles) for interiors. Pre-glued backings may entail different emission profiles; insist on activation guidance and certification documentation.

- Wood veneer options: Veneer edgeband supports repairability and premium aesthetics; sustainable sourcing may involve asking for wood certification status and specifying solvent-free finishes to minimize VOCs.

- Circularity: Packaging reductions, PCR content in plastics, and take-back programs are becoming common discussion points in larger accounts; EU buyers typically face stricter expectations than U.S. buyers on chemical labeling, REACh compliance, and emissions.

Sourcing Strategy: Practical Steps for USA and Europe

- Qualify by requirement:

- Material: Specify PVC for cost-effective durability; wood veneer for premium aesthetic and reparability; metallic PVC for select decorative lines.

- Thickness/window: Standardize commonly used thicknesses and window widths (e.g., 0.8–2.0 mm bands; 19 mm and 1″ widths) to reduce SKU complexity and lead-time.

- Adhesive: Match backing to your production line and substrate. Non-glued supports thermal processing; pre-glued and peel-and-stick increase speed but have short lead-times and policy constraints.

- Enforce brand matching:

- Require cross-check of brand and code for color/finish match across Wilsonart, Formica, and Fenix series to minimize visible joints and rework.

- Manage lead-times and risk:

- Treat pre-glued and peel-and-stick as special order with short lead-time; plan buffer inventory and avoid cancellations.

- Qualify at least two sources per category (PVC and wood veneer) to mitigate single-source delays.

- Supplier policies:

- Align procurement with catalog-based lead-time and no-cancellation policies for made-to-order items; ensure purchase orders reflect these constraints.

- Contract language:

- Include warranty on color match, batch tracking, and adhesive activation parameters.

- Add sustainability clauses specifying PCR content targets, VOC compliance, and material disclosure where applicable (stronger emphasis for EU customers).

Risk Management and Compliance

- Inventory and SKU discipline: Standardize finishes and widths to limit stock-outs; maintain a small buffer of non-glued PVC for quick-turn jobs.

- Activation and environment: For pre-glued and PSA backings, document activation temperature windows, dwell time, and climate controls; poor bonding often drives callbacks.

- Regional differences: Expect stricter documentation in the EU for adhesives and material claims; ensure suppliers can provide compliance and emissions data on request.

Summary

The current edge banding laminate market is anchored by PVC face materials that mirror the major laminate brands, with wood veneer edgeband serving premium segments and repairability needs; adhesive options drive operational decisions, and special-order backings require careful lead-time planning. Buyers should standardize thickness and width profiles, qualify multiple sources, and enforce color match by brand while integrating sustainability requirements into specifications—especially in the EU. These practices reduce cost volatility and minimize on-site risks, ensuring projects deliver consistent appearance and performance.

Frequently Asked Questions (FAQs) for B2B Buyers of edge banding laminate

Frequently Asked Questions (FAQs) for B2B Buyers of Edge Banding Laminate

What types and materials are available?

- Product types: Edgeband (facings)

- Facings/materials: PVC, Metallic PVC, Wood Veneer

- Design options: Solids (108), Patterns (48), Stones (15), Woodgrains (177)

- Finishes: Gloss (7), Matte (8), Prefinished (1), Unfinished (1)

- Brands: CMW (11), Fenix (4), Formica (127), Wilsonart (216)

What backing options exist and how are they used?

| Backing type | Description | Notes |

|---|---|---|

| Non-glued | Dry, unglued tape | Requires adhesive application; suitable for high-throughput adhesive processes |

| Peel-N-Stick | Pressure-sensitive adhesive | Special order; 1–2 business day lead-time |

| Pre-Glued | Heat-activated adhesive | Special order; 1–2 business day lead-time |

Typical thicknesses are available across PVC offerings. Select PVC when durability, moisture resistance, and cost-effectiveness are key; consider wood veneer for high-end aesthetics where hardwood edges are preferred.

Illustrative Image (Source: Google Search)

How do I ensure matching with my laminate sheets?

Edgebands are designed to match FENIX, Formica, and Wilsonart laminates. To ensure accurate color and finish alignment:

– Match by brand and pattern code (e.g., 7008, 7011, 7966).

– Validate color and finish on a sample before batch production.

– Reference the design category (solid, woodgrain, stone) for initial filtering.

Note: Some finish/color references are limited (e.g., limited Gloss/Matte/Unfinished selections).

What are the current product counts and indicative price range?

- Total SKUs: 358 edgeband products

- Material counts: PVC (342), Metallic PVC (4), Wood Veneer (7)

- Indicative PVC pricing: commonly “from $87.69” per unit (price floors vary by SKU)

Contact sales for current pricing, reel/coil availability, and bulk tiers.

What are lead times and availability?

- Core range: Typically in stock; purchase directly online

- Peel-N-Stick and Pre-Glued: Special order items

- Lead-time: 1–2 business days

- Wood Veneer and Metallic PVC: Smaller counts; confirm availability per SKU

Request cut-to-length, reel packaging, or bulk quantities to plan your production calendar.

Are special orders cancellable or refundable?

No. Peel-N-Stick and Pre-Glued options are made-to-order once purchased and cannot be cancelled or refunded. Verify specifications (brand, pattern, finish, backing, thickness, width, length) before ordering.

What should procurement teams consider when placing large orders?

- Match strategy: Align edgeband brand/pattern codes with sheet laminates

- Adhesive process: Select backing type (non-glued vs. pre-glued/peel-and-stick) to match your finishing workflow

- Reel vs. coil: Choose continuous lengths to reduce joints and waste

- Tolerances: Verify thickness, width, and finish performance for your CNC/router setups

- Quality control: Validate a sample on your line (e.g., routing, trimming, finishing) before full release

- Documentation: Maintain pattern/finish references in your bill of materials (BOM) to avoid mismatches

How is this product range categorized for easy sourcing?

Cabinetmaker Warehouse catalogs edgebanding by:

– Facings/materials (PVC, Metallic PVC, Wood Veneer)

– Backing (Non-glued, Peel-N-Stick, Pre-Glued)

– Design category (Solids, Woodgrains, Stones, Patterns)

– Brand (FENIX, Formica, Wilsonart, CMW)

Use filters (category, brand, pattern/finish, backing) to quickly target SKUs that match your sheet laminate program.

Strategic Sourcing Conclusion and Outlook for edge banding laminate

Conclusion and Outlook

Edge banding laminate remains a quiet lever for margin and productivity. A coordinated strategy across PVC, Metallic PVC, and Wood Veneer—backed by Non‑Glued, Peel‑N‑Stick, and Pre‑Glued options—enables faster trim times, lower rework, and consistent finishes. Matching to FENIX, Formica, and Wilsonart streamlines color validation and reduces claims.

Illustrative Image (Source: Google Search)

Prioritize SKU rationalization, dual‑sourcing by backing type, and a 4–6 week safety stock for pre‑glued/peel‑n‑stick SKUs (special order; 1–2 business day lead‑time; cancellations not permitted). Fix tolerances, adhesives, and radii in spec to standardize operations.

Outlook: expect tighter adhesive and VOC requirements (US/EU), steady adoption of low‑VOC hot melts, and continued strength in pre‑glued convenience. Wood Veneer edgeband will rise where sustainability, premium feel, and repairability matter. Maintain price discipline by calculating landed cost (band, adhesive, labor, waste) and managing special orders tightly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.