The global hydroponics market is experiencing robust growth, driven by rising demand for sustainable agriculture, controlled environment farming, and increasing urbanization. According to Grand View Research, the global hydroponics market size was valued at USD 30.2 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 12.1% from 2024 to 2030. This surge is largely attributed to advancements in soilless cultivation techniques, particularly deep water culture (DWC) systems, which offer efficient nutrient delivery and faster plant growth. With commercial growers and hobbyists alike adopting DWC hydroponics for their scalability and ease of use, demand for reliable manufacturing partners has intensified. Based on market trends, production capabilities, and technological innovation, here’s a data-driven look at the top 10 DWC hydroponics manufacturers shaping the future of modern agriculture.

Top 10 Dwc Hydroponics Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hydroponic Bucket System

Domain Est. 2002

#2 DWC (Deep Water Culture) Hydroponics Systems

Domain Est. 2010

Website: hydrobuilder.com

Key Highlights: Free delivery over $49 · 30-day returnsShop deep water culture (DWC) hydroponic systems and parts at Hydrobuilder. Find reservoirs, air pumps, net pots, and complete DWC kits ……

#3 DWC (Deep Water Culture)

Domain Est. 2010

#4 DWC Hydroponic System with Gorilla

Domain Est. 2012

Website: gorillagrowtent.com

Key Highlights: 8-day delivery · 30-day returnsDeep Water Culture (DWC) is a simple yet highly effective hydroponic growing system where plant roots are suspended in oxygenated, nutrient-rich wat…

#5 Deep Water Culture (DWC) Kit

Domain Est. 2015

#6 Hydroponic Growing Systems

Domain Est. 2016

Website: growrillahydroponics.com

Key Highlights: 14-day returnsGrowrilla Hydroponics is a 100% Italian brand of hydroponic growing systems, designed and manufactured in Italy by growers for growers….

#7 Spider Farmer DWC Hydroponics Grow System with Top Drip Kit 7 …

Domain Est. 2019

#8 DWC Hydroponic System Sale

Domain Est. 2021

Website: hydroponicschina.com

Key Highlights: The DWC pot system is used to grow large plants because they have bigger roots, need more growing space and air. This system is very convenient to manage….

#9 DWC Grow System

Website: spiderfarmer.eu

Key Highlights: 30-day returnsSpider Farmer DWC Hydroponic Growing System with Top Drip Kit, 7-Gallon Deep Water Culture, 4-Bucket Setup, and GGS AC5 Power Strip Kit for Smart Watering ……

#10 Deep Water Culture Systems (DWC) for Hydroponic Growing

Website: viscongroup.eu

Key Highlights: Automatic deep water culture systems (DWC) for hydroponic growing & farming. Perfect for short cycle crops like lettuce, cabbage & microgreen….

Expert Sourcing Insights for Dwc Hydroponics

H2: 2026 Market Trends for DWC Hydroponics

The Deep Water Culture (DWC) hydroponics sector is poised for significant transformation by 2026, driven by technological advancements, growing demand for sustainable agriculture, and shifting consumer preferences. Below is an analysis of key market trends expected to shape the DWC hydroponics industry in 2026:

1. Increased Adoption in Urban and Vertical Farming

By 2026, urbanization and land scarcity will continue to push agricultural innovation toward space-efficient solutions. DWC systems, known for their simplicity and high yield potential, are increasingly being integrated into vertical and indoor farming operations. Urban farms in major metropolitan areas are leveraging DWC to grow leafy greens, herbs, and microgreens close to consumers, reducing transportation costs and carbon emissions.

2. Technological Integration and Automation

The integration of smart technologies—such as IoT sensors, AI-driven climate controls, and automated nutrient dosing—will become standard in commercial DWC setups by 2026. These technologies improve crop monitoring, optimize water and nutrient usage, and enhance yield consistency. Automated pH and EC monitoring systems will reduce labor costs and minimize human error, making large-scale DWC operations more viable.

3. Sustainability and Water Efficiency

As global water scarcity intensifies, DWC hydroponics will be increasingly recognized for its water efficiency—using up to 90% less water than traditional soil farming. By 2026, regulatory incentives and consumer demand for eco-friendly food production will drive wider adoption of DWC systems, especially in drought-prone regions. Closed-loop DWC systems with recirculating reservoirs will gain popularity for their minimal environmental impact.

4. Expansion into New Crop Varieties

While DWC has traditionally been used for fast-growing greens like lettuce and basil, ongoing research and system optimization are enabling the cultivation of fruiting crops such as tomatoes, cucumbers, and even strawberries in DWC by 2026. Improved root zone oxygenation and nutrient delivery systems will expand the crop range, opening new revenue streams for hydroponic farmers.

5. Growth in Home and Hobbyist Markets

The DIY and home gardening segment for DWC systems is expected to grow significantly by 2026. Consumer interest in food security, organic produce, and sustainable living will fuel demand for affordable, modular DWC kits. E-commerce platforms and educational content will make it easier for beginners to adopt DWC at home, further expanding the market.

6. Regional Market Expansion

North America and Europe will remain key markets, but significant growth is expected in Asia-Pacific, the Middle East, and Africa. Countries investing in food security—such as Singapore, the UAE, and Saudi Arabia—are heavily supporting controlled environment agriculture, including DWC hydroponics. Government subsidies and public-private partnerships will accelerate infrastructure development in these regions.

7. Consolidation and Investment in Agri-Tech

By 2026, increased venture capital and institutional investment in agritech will lead to market consolidation. Established hydroponic equipment manufacturers may acquire innovative startups specializing in DWC optimization, data analytics, or sustainable materials. This trend will drive innovation while raising industry standards.

Conclusion

The DWC hydroponics market in 2026 will be characterized by technological sophistication, sustainability focus, and broadening applications across commercial, urban, and home farming. As global food systems adapt to climate change and population growth, DWC is expected to play a critical role in building resilient and efficient agricultural models worldwide.

Common Pitfalls When Sourcing DWC Hydroponics Systems (Quality & IP)

When sourcing Deep Water Culture (DWC) hydroponics systems—especially from international suppliers or lesser-known manufacturers—buyers often encounter significant challenges related to product quality and intellectual property (IP) risks. Being aware of these pitfalls can help avoid costly mistakes and ensure a reliable, legally sound supply chain.

Poor Build Quality and Material Deficiencies

One of the most frequent issues is substandard construction. Many low-cost DWC systems use thin, brittle plastics that degrade quickly under UV light or constant water exposure, leading to leaks and structural failures. Components such as air pumps, air stones, and net pots may also be undersized or poorly made, compromising plant health and system efficiency. Always verify material specifications (e.g., food-grade, UV-resistant plastics) and request product samples before bulk ordering.

Inconsistent System Performance

Low-quality DWC systems often suffer from inconsistent oxygenation and nutrient delivery. This can stem from inadequate air pump capacity or poorly designed aeration systems. Without proper oxygen levels, roots suffocate, leading to root rot and crop failure. Ensure suppliers provide performance data and conduct independent testing to confirm that systems maintain dissolved oxygen levels above 5 ppm.

Lack of Standardization and Compatibility

Many sourced DWC units do not adhere to industry-standard dimensions or connections, making it difficult to integrate with existing infrastructure or replace parts. Net pot sizes, lid hole diameters, and reservoir depths may vary significantly between batches. This lack of standardization increases operational complexity and long-term maintenance costs.

Intellectual Property Infringement Risks

Sourcing from manufacturers in regions with lax IP enforcement raises the risk of purchasing counterfeit or cloned designs. Some suppliers replicate patented DWC systems—such as those with proprietary aeration manifolds or modular stacking features—without licensing. Buyers risk legal liability, product seizure, or reputational damage if they unknowingly distribute infringing products. Always vet suppliers for design originality and request IP documentation or disclaimers.

Inadequate Technical Support and Documentation

Many overseas or budget suppliers provide minimal technical support, incomplete assembly instructions, or no warranty. This becomes a major issue when troubleshooting system failures or training staff. Ensure suppliers offer comprehensive user manuals, English-language support, and accessible after-sales service before finalizing procurement.

Hidden Costs from Short Product Lifespan

While initial pricing may appear attractive, low-quality DWC systems often require frequent replacement due to material fatigue or component failure. This increases total cost of ownership and disrupts crop cycles. Calculate lifecycle costs—not just upfront price—when evaluating suppliers.

By addressing these quality and IP-related pitfalls proactively, businesses can secure reliable, compliant DWC hydroponic systems that support sustainable and scalable operations.

Logistics & Compliance Guide for DWC Hydroponics

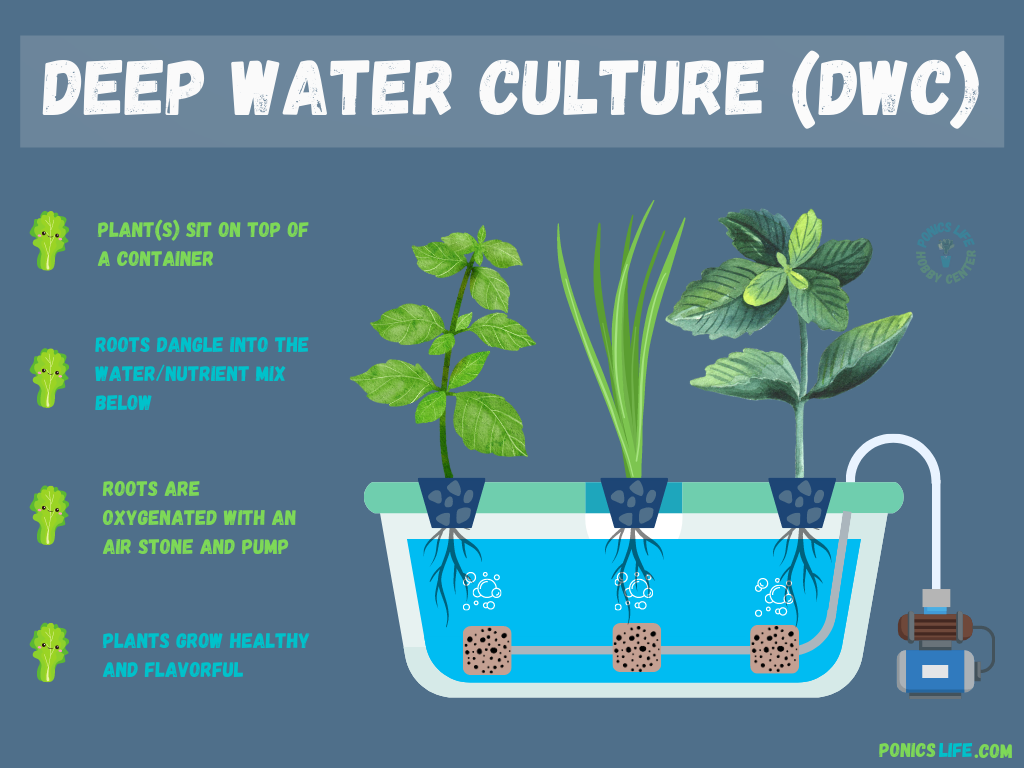

Overview of Deep Water Culture (DWC) Hydroponics

Deep Water Culture (DWC) is a hydroponic method where plant roots are suspended directly in oxygenated, nutrient-rich water. This technique is widely used in commercial and home growing operations due to its efficiency, scalability, and ability to accelerate plant growth. However, operating a DWC system—especially at scale—requires careful attention to logistics and regulatory compliance.

This guide outlines key considerations for managing logistics and ensuring legal and safety compliance when operating a DWC hydroponic system.

Facility and System Logistics

Site Selection and Layout Planning

Choose a location with reliable access to electricity, clean water, and climate control. Indoor facilities should allow for proper ventilation, lighting, and temperature regulation. Design the layout to optimize workflow, including seedling propagation areas, main grow zones, harvesting stations, and storage for nutrients and equipment.

Ensure adequate space for DWC reservoirs, pumps, airstones, and associated plumbing. Plan for easy access to all system components for maintenance and monitoring.

Water and Nutrient Supply Chain

Establish a dependable supply chain for reverse osmosis (RO) water or purified water, pH-adjusted nutrient solutions, and essential mineral supplements. Partner with reputable suppliers to ensure consistency in quality and delivery schedules.

Maintain an inventory management system to track nutrient stock levels, prevent shortages, and reduce waste due to expiration.

Equipment Procurement and Maintenance

Procure high-quality, food-safe DWC components such as reservoirs, submersible pumps, air stones, and tubing. Use materials that resist algae growth and chemical degradation (e.g., food-grade HDPE or PVC).

Develop a preventive maintenance schedule for pumps, air stones, and sensors to ensure continuous oxygenation and nutrient delivery. Keep spare parts on hand to minimize downtime.

Environmental Control

Temperature and Oxygenation Management

Root zone temperature should be maintained between 65°F and 75°F (18°C–24°C) to prevent pathogen growth and support optimal oxygen solubility. Use water chillers or heaters as needed.

Ensure proper aeration using air pumps and diffusers to maintain dissolved oxygen (DO) levels above 6 ppm. Monitor DO levels regularly, especially during peak growth phases.

Lighting and Climate Regulation

Provide appropriate light spectrums and photoperiods based on plant species and growth stage. LED grow lights are energy-efficient and produce less heat.

Control ambient humidity (40–60%) and temperature (70–80°F / 21–27°C) to prevent mold, mildew, and pest infestations. Use exhaust fans, dehumidifiers, and CO₂ supplementation as needed.

Regulatory Compliance

Agricultural and Environmental Regulations

Comply with local, state, and federal regulations related to agricultural operations, water usage, and waste disposal. In many jurisdictions, hydroponic operations are subject to environmental protection standards, especially regarding wastewater discharge.

Obtain necessary permits for water extraction, chemical storage, and facility operation. Follow guidelines for handling and disposing of spent nutrient solutions to prevent contamination of water sources.

Food Safety and Organic Certification (if applicable)

Adhere to Good Agricultural Practices (GAP) and, if producing for human consumption, consider third-party food safety certifications such as USDA GAP or GlobalG.A.P.

If marketing produce as “organic,” ensure compliance with the USDA National Organic Program (NOP) standards. Note that only certain inputs and additives are permitted in organic hydroponic production.

Chemical and Input Safety

Label and store nutrient solutions, pH adjusters, and cleaning agents according to Occupational Safety and Health Administration (OSHA) requirements. Provide Safety Data Sheets (SDS) and train staff in safe handling procedures.

Use only approved, food-grade nutrients and avoid restricted or hazardous substances.

Labor and Operational Compliance

Staff Training and Safety Protocols

Train personnel on system operation, sanitation practices, and emergency procedures. Emphasize electrical safety around water-based systems and proper use of personal protective equipment (PPE).

Implement hygiene protocols such as handwashing, boot sanitation, and restricted access to grow areas to prevent contamination.

Recordkeeping and Traceability

Maintain detailed logs of nutrient batches, pH/EC readings, equipment maintenance, harvest yields, and staff training. These records support compliance audits and help optimize system performance.

Use a traceability system to track produce from seed to sale, especially if supplying commercial markets or regulated industries.

Waste Management and Sustainability

Disposal of Spent Nutrient Solutions

Neutralize and safely dispose of used nutrient solutions in accordance with local environmental regulations. Consider recycling or reusing water through filtration systems where permitted.

Avoid dumping nutrient-rich runoff into storm drains or natural waterways due to the risk of algal blooms and pollution.

Energy Efficiency and Resource Conservation

Optimize energy use by scheduling lighting and pumps during off-peak hours, using energy-efficient equipment, and insulating reservoirs.

Implement water-saving practices such as recirculating systems and RO reject water recovery.

Conclusion

Operating a DWC hydroponic system efficiently and legally requires a strategic approach to logistics and compliance. By planning facility operations carefully, adhering to regulatory standards, and maintaining rigorous safety and environmental practices, growers can ensure sustainable, high-yield production while minimizing risks. Regular audits and staff training will further support long-term success in the evolving landscape of controlled environment agriculture.

In conclusion, sourcing DWC (Deep Water Culture) hydroponics systems presents a promising opportunity for efficient, scalable, and sustainable plant cultivation. The advantages of DWC—such as rapid plant growth, reduced water usage, and simplified nutrient management—make it an attractive choice for both commercial growers and hobbyists. When sourcing DWC components, it is essential to prioritize quality, durability, and compatibility of materials such as food-grade reservoirs, reliable air pumps, and net pots. Selecting reputable suppliers and considering cost-effective bulk options can enhance long-term viability. Additionally, integrating locally available or eco-friendly materials can further improve sustainability. With the right sourcing strategy, DWC hydroponics can deliver consistent yields, operational efficiency, and a strong return on investment, supporting the growing demand for local and sustainable food production.