Introduction: Navigating the Global Market for Drywall Screws for Metal

Selecting the right drywall screw for metal is not a commodity task; it’s a performance decision that controls installation speed, rework, and total cost on commercial sites. When metal studs and tracks enter the mix, coarse-thread drywall screws—designed for gypsum—lose holding power and risk stripping. Metal-to-metal assemblies need a specific screw system: correct thread pitch (e.g., #6–18 or #6–20), an appropriate point (sharp or self-drilling), and a finish that resists corrosion.

This guide provides a procurement-ready framework to navigate the global market and avoid project-critical surprises:

– Screw system types and where to use them.

– Thread and point selection by gauge and substrate thickness.

– Head and drive configuration trade-offs (bugle, pan, trim; Phillips vs. square).

– Coatings and finishes: black phosphate vs. zinc (CR+3).

– Corrugated metal roofing (CMR) specifics: corrosion exposure and finish selection.

– Bulk vs. collated fasteners—productivity, cost-per-fastener, and line balance.

– Standards, certifications, and compliance across the USA and Europe.

Use the tables and checklists in the sections that follow to map your substrate thickness and application to the correct screw specification, compare vendor offerings, and standardize your bill of materials. The outcome is predictable installation speed, fewer callouts, and better lifecycle performance on every metal-to-drywall or metal-to-metal task.

Article Navigation

- Top 10 Drywall Screws For Metal Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for drywall screws for metal

- Understanding drywall screws for metal Types and Variations

- Key Industrial Applications of drywall screws for metal

- 3 Common User Pain Points for ‘drywall screws for metal’ & Their Solutions

- Strategic Material Selection Guide for drywall screws for metal

- In-depth Look: Manufacturing Processes and Quality Assurance for drywall screws for metal

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘drywall screws for metal’

- Comprehensive Cost and Pricing Analysis for drywall screws for metal Sourcing

- Alternatives Analysis: Comparing drywall screws for metal With Other Solutions

- Essential Technical Properties and Trade Terminology for drywall screws for metal

- Navigating Market Dynamics and Sourcing Trends in the drywall screws for metal Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of drywall screws for metal

- Strategic Sourcing Conclusion and Outlook for drywall screws for metal

- Important Disclaimer & Terms of Use

Top 10 Drywall Screws For Metal Manufacturers & Suppliers List

1. Drywall Screw Manufacturers – Intercorp

Domain: intercorpusa.com

Registered: 1997 (28 years)

Introduction: Leading drywall screw manufacturer offering bulk supply for contractors and distributors … Fine-threaded drywall screws are designed for metal framing….

2. Drywall Screws for Metal Studs and Wood | Pro-Twist

Domain: pro-twist.com

Registered: 2003 (22 years)

Introduction: Our high-quality drywall screws are designed for durability and strength. Perfect for all your needs from wood to metal studs. Shop our selection now!…

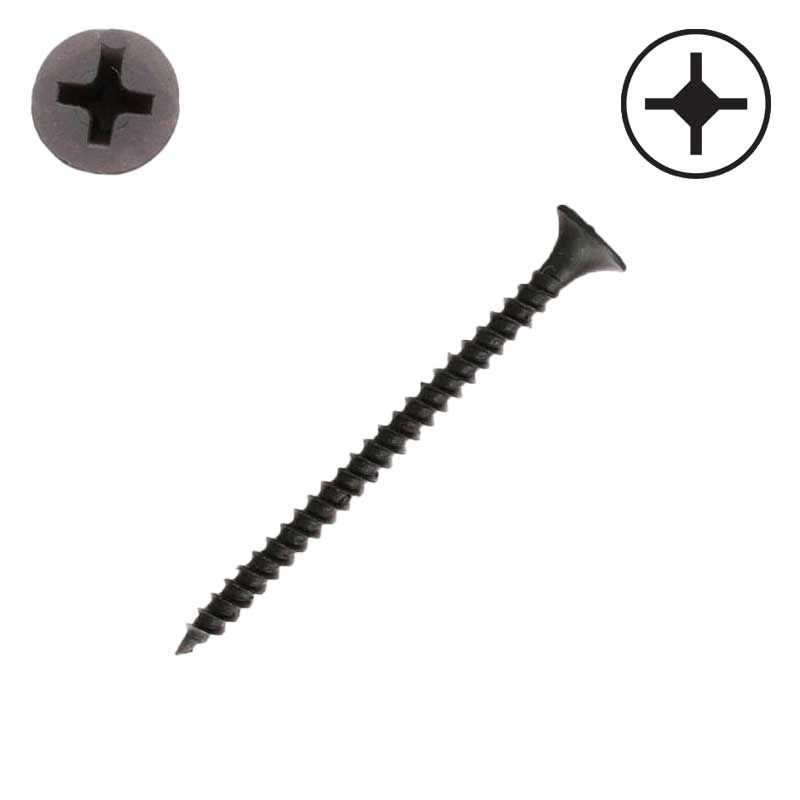

Illustrative Image (Source: Google Search)

3. Drywall Screw – Minerallac

Domain: minerallac.com

Registered: 1996 (29 years)

Introduction: Drywall Screw. Application, For attaching drywall to wood studs or to 25 gage metal studs. Material, Steel. Size, 6. Length, 1-5/8″. Thread Type, Coarse Threads….

4. Drywall Screws | Allfasteners Products

Domain: allfasteners.com

Registered: 2002 (23 years)

Introduction: 4-day delivery 30-day returnsMade specifically for securing drywall to wood or metal studs, drywall screws have become an industry standard for the building interiors sector….

5. Premium Drywall Screws for Secure & Efficient Installation

Domain: fongprean.com

Registered: 2011 (14 years)

Introduction: As a top drywall screw manufacturer, Fong Prean provides drywall screws for metal studs. Our specialized design ensures quick and stable installation….

6. What Screws to Use for Metal Studs – US Frame Factory

Domain: usframefactory.com

Registered: 2021 (4 years)

Introduction: Use 1-1/4″ long screws for a single layer of plywood or drywall and 1-5/8″ long screws for a double layer of plywood or drywall.Missing: manufacturers suppliers…

Illustrative Image (Source: Google Search)

Understanding drywall screws for metal Types and Variations

Understanding drywall screws for metal: Types and variations

Selecting the correct screw for drywall-to-metal framing reduces callbacks, prevents stripping, and controls installed cost. In the market you will encounter drywall-style fasteners in multiple head profiles, drive systems, drive formats, finishes, and thread/point designs. Use the table below to orient your specification, then refer to the details by type.

Quick‑reference matrix

| Type | Key features | Typical applications | Pros | Cons |

|---|---|---|---|---|

| Self‑drilling bugle head (drywall‑style), collated and bulk | #6‑20 and #8‑18 sizes; #2 point; self‑drilling (TEK); Phillips drive; bugle head undercuts paper to countersink; zinc CR+3 finish | Attaching drywall to 20–18 ga metal studs; general ceilings on metal track/joist; high‑volume installs (collated) | No pre‑drill; fast install; countersinks well; available in collated format; good corrosion resistance | Not suitable for very thick steel (heavy structural); limited cosmetic finish |

| Fine‑thread bugle head (drywall‑style), bulk | Coarse “drywall” name, but fine thread pattern (e.g., #6‑20); sharp point (Type S gimlet); black phosphate finish; Phillips drive | Attaching drywall to 25–26 ga metal studs or light‑gauge track; limited thickness capability vs. self‑drilling | Countersinks well; excellent holding in thin metal; cost‑effective | Not for 20 ga or thicker; point can deform on thicker steel; higher torque; slower installation vs. collated |

| Trim head self‑drilling, square drive | Trim head for clean, low‑profile appearance; #6‑20; self‑drilling #2 point; zinc CR+3; square (Robinson) drive reduces cam‑out | Finish carpentry in metal framing; cabinets on metal; soffits; fascia boards; where cosmetics matter | Clean countersink; excellent torque control; corrosion resistant | Slightly higher fastener cost; requires pre‑set driver depth |

| Coarse‑thread bugle head, collated | #6‑9 (coarse); often listed with “coarse thread drywall” naming but commonly applied with Type S points for light metal; collated for drywall‑to‑metal on thin gauge | High‑speed drywall installation on 25–26 ga track/tees; limited thickness | High installation speed (collated); lower installed cost on thin metal | Stripping risk on thicker metal; limited holding in steel; not a structural metal‑to‑metal fastener |

Detailed profiles by type

1) Self‑drilling bugle head (drywall‑style), collated and bulk

- Key specifications: Sizes #6‑20 and #8‑18; #2 point; self‑drilling (TEK) capability; zinc CR+3 (Corrosion Resistant, 3‑stage zinc plating); bugle head; Phillips drive.

- What it does: The drill point and flute remove material from the metal stud as you drive, creating its own pilot and threads. The bugle head compresses the drywall paper without tearing, yielding a clean, controlled countersink.

- Typical use: Attaching drywall to 20–18 ga metal studs and track. Bulk form suits hand or collated tools; collated format (e.g., #6‑20 collated) enables high‑speed, high‑volume installations and reduces driver fatigue.

- Why it matters: Eliminates pre‑drilling, shortens cycle time, and reduces operator variability. The corrosion‑resistant finish supports long‑term performance on interior steel.

- Notes and limits: Not intended for heavy structural steel or thick gauge; adjust clutch settings to avoid over‑driving or skipping on thin metal.

2) Fine‑thread bugle head (drywall‑style), bulk

- Key specifications: Coarse‑thread packaging notation but fine‑thread geometry; sharp (Type S) point; black phosphate finish; Phillips drive.

- What it does: The fine, dense thread pattern engages thin steel effectively without a separate pilot. The sharp point starts readily and the bugle head produces a consistent countersink.

- Typical use: Drywall to 25–26 ga metal studs and track where the steel thickness is light. Effective when self‑drilling screws are not necessary but wood‑thread drywall screws are inadequate.

- Why it matters: Optimal balance of holding power and cost for thin‑gauge steel; a proven solution for light commercial and residential interior metal framing.

- Notes and limits: Not for 20 ga or thicker; can bind, strip, or twist off in heavier steel. Use self‑drilling screws for 20 ga and thicker.

3) Trim head self‑drilling, square drive

- Key specifications: Trim head (low profile); #6‑20; self‑drilling #2 point; zinc CR+3 finish; square (Robinson) drive for superior torque transmission and reduced cam‑out.

- What it does: Combines the low‑profile, high‑visibility appearance of a trim head with self‑drilling capability. The square drive prevents cam‑out and helps maintain consistent depth, minimizing surface defect risk.

- Typical use: Finish surfaces on metal framing where countersink appearance matters (e.g., cabinets, soffits, fascia, trims). Suitable on 20–18 ga steel where controlled cosmetics are required.

- Why it matters: Provides clean lines and high torque control at the finish stage, reducing touch‑up time and rework.

- Notes and limits: Slightly higher fastener cost than bugle head; requires driver depth presetting to avoid over‑driving and surface marring.

4) Coarse‑thread bugle head, collated

- Key specifications: #6‑9 coarse thread; often Type S point; collated for high‑speed drywall tools; black phosphate or zinc finish.

- What it does: Coarse pitch pulls fast on thin metal but does not engage or remove material in heavier steel. Collated format accelerates throughput in repetitive work.

- Typical use: Ultra‑high‑speed drywall installation on 25–26 ga track/tees and similar light‑gauge steel where a finish appearance is not critical.

- Why it matters: Delivers the lowest installed cost in thin‑gauge interiors when a large volume of screws is used.

- Notes and limits: Stripping and pull‑through risk on thicker metal; holding performance is limited in steel. Not a substitute for self‑drilling screws on 20 ga and heavier.

Specification notes

- Point/threading matters more than “drywall” naming:

- Sharp point, fine thread (Type S): For 25–26 ga metal only.

- Self‑drilling (TEK) point: For 20–18 ga steel and most common drywall‑to‑metal framing.

- Drive and head:

- Phillips: Widely available and cost‑effective; cam‑out risk in high torque scenarios.

- Square (Robinson): Preferred where torque stability is critical (e.g., trim head self‑drilling).

- Bugle head: Countersinks without tearing paper; ideal for drywall.

- Trim head: Minimal, clean head exposure in visible work.

- Collated vs bulk:

- Collated: Faster installations on thin metal; ideal for framing houses, modular units, and drywall booths.

- Bulk: Better for mixed conditions, touch‑ups, and varying substrate thicknesses.

- Coatings:

- Zinc CR+3: Higher corrosion resistance for steel studs; better long‑term service in interiors with humidity variance.

- Black phosphate: Primarily for cost and appearance in drywall; adequate in dry interior conditions; use zinc in more demanding environments.

Selection guidance

- 25–26 ga metal studs/track: Use fine‑thread bugle head or #6‑9 coarse‑thread collated if speed is critical; bugle head (bulk or collated) with Type S point.

- 20–18 ga metal studs: Use self‑drilling bugle head screws (#6‑20/#8‑18) for speed and consistency; zinc CR+3 recommended.

- Visible, finish work on metal framing: Use trim head self‑drilling (#6‑20) with square drive and zinc CR+3.

- High‑volume production lines (panelized drywall, modular): Favor collated, self‑drilling bugle head for 20–18 ga metal; maintain driver clutches to avoid over‑driving on thinner sheets.

This selection framework aligns with the available market configurations (bugle/trim/pan head options, Phillips/square drives, #6–#10 sizes, fine/coarse and self‑drilling points, black phosphate and zinc CR+3 finishes, collated/bulk formats) and helps standardise procurement and installation practices across USA and Europe.

Key Industrial Applications of drywall screws for metal

Key Industrial Applications of drywall screws for metal

For drywall-to-metal framing, use fine-thread bugle-head screws (e.g., #6–20) on 20–25 ga steel; choose coarse thread for wood studs; switch to self-drilling (TEK) when fastening into ≥18 ga steel. Always verify compliance with project specs and local code.

| Industry / Sector | Typical metal-to-drywall application | Common metal substrate | Recommended drywall screw for metal | Why it works well (benefits) |

|---|---|---|---|---|

| Commercial Interior Construction | Interior partitions; corridor walls; tenant improvement (TI) fit-outs | 20–25 ga steel studs and tracks; jamb/head reinforcements | Bugle-head, fine thread, #6–20, Phillips or square drive; collated strips optional | High setting speed; low head pull-through; minimal bulging; works without pre-drilling on thin steel; collated tools boost productivity |

| Healthcare & Life Sciences | Cleanable wall systems; service corridors; equipment niches | 20–25 ga steel; occasional 18 ga reinforcements; furring channels | Fine-thread bugle head #6–20; zinc CR+3 or phosphate depending on spec | Thread geometry grips thin steel reliably; finish options support cleanliness and mild-corrosion zones |

| Hospitality & Retail | Guestroom partitions; back-of-house walls; soffits | Light-gauge steel studs; furring; door frames | Fine-thread bugle head #6–20 | Consistent drive performance on thin steel; reduced risk of spin-out; aesthetic finish with minimal countersink |

| Education | Classroom partitions; corridor walls; admin areas | Light-gauge steel; occasional thicker plates | Fine-thread bugle head #6–20; #10×1-1/2″ laminate screws for double-layer | Fast installation over steel; suitable for layered systems; longer screws for two-board assemblies |

| Industrial & Logistics | Light-duty enclosures; partition dividers; machine access panels | Steel furring; sheet-metal frames; 18–25 ga studs | Fine-thread bugle head for thin steel; self-drilling (TEK) bugle for ≥18 ga | Avoids pre-drilling on thin gauges; TEK variants drive straight into thicker steel; phosphate or zinc coating supports indoor industrial environments |

| Data Centers & Critical Facilities | Cold-aisle/hot-aisle containment; access panels; service corridors | Steel frame and furring; double-layer drywall common | Fine-thread bugle #6–20; laminate bugle #10×1-1/2″ | High-speed installation for containment; strong board engagement; longer screws for dual-layer stacks |

| Residential (Metal Framing) | Single-family and multifamily partitions; shaft enclosures | Steel studs/tracks; door frames | Fine-thread bugle #6–20 | Reliable performance on metal framing; standard head fits automated collated tools |

| Public Sector & Government | Courtrooms; civic spaces; security enclosures | Steel studs/tracks; 18 ga reinforcements | Fine-thread bugle for 20–25 ga; self-drilling bugle for ≥18 ga | Consistency across variable gauges; reliable capture in steel; supports efficient tool use |

Best-practice pairing by substrate

| Metal gauge / thickness | Recommended drywall screw | Head/drive | Drive notes |

|---|---|---|---|

| 20–25 ga steel (typ. studs/tracks) | Fine-thread bugle head #6–20 (steel, black phosphate or zinc CR+3) | Phillips or square (square reduces cam-out) | Self-drilling not required; sharp point bites through; pre-drill optional depending on alloy/hardness |

| ≥18 ga steel (e.g., door frames, stiffeners) | Fine-thread bugle head #6–20 or #8–18; or use self-drilling bugle (TEK) #6–20, #8–18 | Phillips or square | TEK point avoids predrilling; maintains straight engagement; reduces spin-out on thicker steel |

| Mixed substrates (gypsum-to-steel with wood-to-metal transitions) | Fine-thread bugle #6–20 for steel; coarse thread for wood | Phillips or square | Match thread to substrate; avoid cross-threading between materials |

Additional selection guidance

– Gauge and metal type: For 20–25 ga steel studs, fine-thread bugle heads deliver reliable engagement without TEK points. For thicker steel (≥18 ga), choose fine-thread bugle for pre-drilled holes or a self-drilling bugle to eliminate predrilling and reduce walking.

– Coating and environment: Black phosphate provides corrosion resistance for indoor environments and standard handling; zinc CR+3 offers mild corrosion resistance and a cleanable finish. Confirm specified coating for facility exposure.

– Drive system: Square-drive (e.g., #2) reduces cam-out in high-volume use; Phillips is widely available and works well with collated systems.

– Head profile: Bugle head is designed to countersink below paper face and limit tear-out; avoid pan framing or trim heads on interior surfaces unless specified.

– Collated vs. bulk: Collated drywall screws improve cycle time with auto-feed screwguns; use collated for large partitions and TEK collated for thicker steel where permitted.

Important checks

– Structural limits: Drywall screws for metal are for attaching gypsum boards to non-structural metal framing; do not use for structural or load-bearing connections.

– Fire-rated assemblies: Ensure drywall screw type, length, and spacing are compatible with UL/EN fire-rated assemblies for your project.

– Code and spec: Confirm fastener material, coating, and drive with project documents; select TEK/self-drilling only where allowed and necessary.

This section focuses on fast, consistent performance across commercial, healthcare, hospitality, education, industrial, data center, residential, and public-sector interiors where gypsum boards meet steel framing.

3 Common User Pain Points for ‘drywall screws for metal’ & Their Solutions

3 Common User Pain Points for “drywall screws for metal” & Their Solutions

1) Frequent spin-out and poor metal engagement when using coarse-thread drywall screws

- Scenario: Installers use coarse-thread drywall screws (e.g., #6-9, #6-18 coarse thread) on 20–25 ga metal studs/tracks and experience spin-out, low pull-out, and thread stripping.

- Root problem: Coarse threads and blunt/penetration points are designed for gypsum and wood, not steel. They slide and ratchet without solid engagement on metal.

- Solution:

- Switch to fine-thread, self-drilling drywall screws (#6–20) with a #2 self-drilling point. These are designed for metal and eliminate pre-drilling.

- Use #6–20 trim head (square drive) or #6–20 bugle head (Phillips) self-drillers; examples include Proferred #6-20 trim head square-drive and #6–20/#8–18 bugle head Phillips self-drilling options.

- Calibrate auto-feed screwdrivers for fine-thread metals; set proper clutch/torque to avoid cam-out and thread damage.

- Keep standard coarse-thread drywall screws for gypsum-to-gypsum only.

Why it works: Self-drilling points and fine threads cut mating threads into steel, increase thread engagement, and deliver reliable hold without predrilling.

2) Corrosion and staining when using phosphate-coated drywall screws on metal framing

- Scenario: In humid interiors, exterior edges, or buildings with moisture migration, black phosphate drywall screws rust and telegraph black stains through finish paint or joint compound.

- Root problem: Black phosphate coatings offer mild corrosion resistance and are not rated for wet or aggressive environments.

- Solution:

- Use zinc CR+3 (electrogalvanized) coated self-drilling drywall screws for better corrosion resistance. The Proferred #6–20/#8–18 bugle head Phillips self-drilling screws are representative of this specification.

- For coastal or highly humid conditions, specify stainless steel screws to ensure longevity and avoid staining.

- Avoid carbon-steel phosphate screws where moisture exposure is likely.

Why it works: Zinc CR+3 provides a uniform, sacrificial barrier that resists rust and staining compared with phosphate-only coatings. Stainless steel avoids corrosion entirely in harsh conditions.

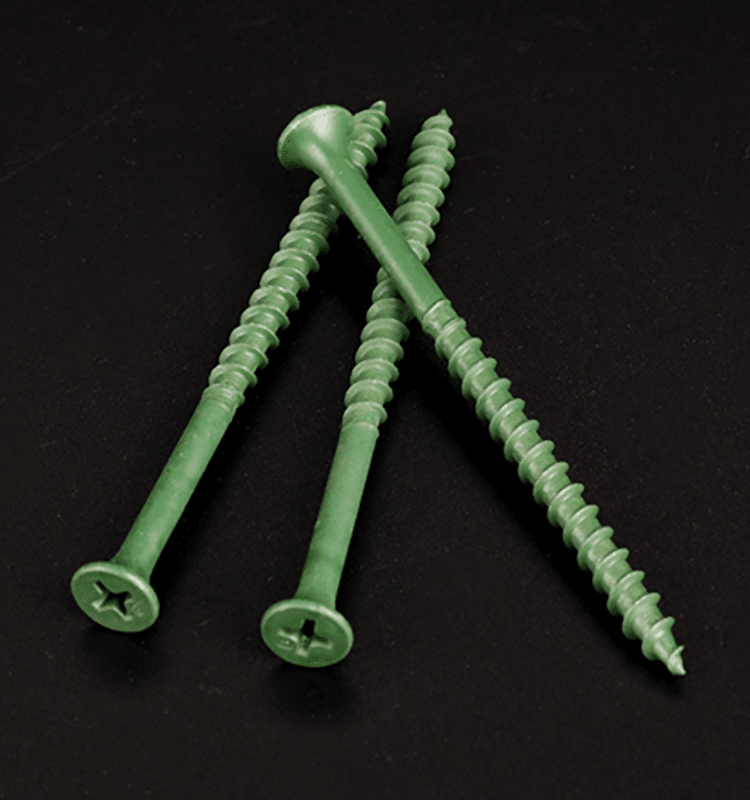

Illustrative Image (Source: Google Search)

3) Countersink control, cam-out, and finish quality issues when fastening gypsum to metal framing

- Scenario: Installers use bugle head Phillips drywall screws on metal, leading to over-driving, dimpling, Phillips cam-out, and inconsistent finishes on gypsum board.

- Root problem: Bugle heads on metal with Phillips drives increase the risk of cam-out and uncontrolled penetration, especially under auto-feed tools.

- Solution:

- Select trim head or pan framing heads (e.g., Proferred trim head square-drive or #7 x 7/16″ pan framing head Phillips) for better countersink control on metal-to-gypsum or metal-to-metal interfaces.

- Use square or hex drives to reduce cam-out and improve torque transfer.

- Tune auto-feed tool depth settings and clutch to achieve consistent countersink without dimpling.

- Reserve bugle head screws for gypsum-to-gypsum where countersinking into paper face is intended.

Why it works: Trim/pan heads provide a smaller, controlled bearing surface; square/hex drives maintain positive engagement; and properly tuned depth/force settings produce a clean, repeatable finish.

Strategic Material Selection Guide for drywall screws for metal

Strategic Material Selection Guide for Drywall Screws for Metal

1) Material and finish options: what to choose and why

Use this table to match the stud/track thickness and environment to the screw material and finish. Head, drive, and point selection should follow the stud thickness guidance further down.

| Material / finish | Key properties | Typical corrosion resistance | Magnetic | Best use-cases | Considerations |

|---|---|---|---|---|---|

| Carbon steel, zinc CR+3 | General-purpose plated finish; good hardness and drive integrity | Indoors, dry environments; light intermittent humidity | Yes | Interior non-wet drywall on metal studs/track | Do not use for exterior or high-humidity areas |

| Carbon steel, black phosphate | Economical; often paired with fine-thread drywall screws | Low; primarily for dry, indoor use | Yes | Interior gypsum-to-metal on 20–25 ga studs with fine-thread or self-piercing points | Not a corrosion-resistant finish; avoid moisture exposure |

| Stainless steel (410/305) | Superior corrosion and staining resistance | High; coastal/interior wet, chemical/food areas, exterior-grade exposures | Partially (410 magnetic, 304/316 weakly magnetic) | Exterior gypsum sheathing, humid interiors (bathrooms), coastal, corrosive atmospheres, long-life interiors | Higher cost; verify local building code acceptance for exterior gypsum-to-steel interfaces |

2) Stud/track thickness vs. screw type and head recommendation

Match the metal thickness to a suitable screw and head/drive. For metal, “drywall screws” commonly mean bugle-head or trim-head fine-thread or self-drilling screws.

| Stud/track thickness | Recommended screw | Point style | Head and drive | Notes |

|---|---|---|---|---|

| 20–25 ga (0.8–0.6 mm) | #6, fine thread (e.g., #6-18) or #6 self-drilling #2 point | Self-piercing or #2 self-drilling | Bugle head, Phillips or square drive | Use fine-thread or self-drilling for 20–25 ga metal framing |

| 16–14 ga (1.5–2.0 mm) | #6 or #8 self-drilling, #3 point (or higher) | #3 self-drilling | Bugle, trim, or pan framing head; Phillips or square | Self-drilling eliminates pre-drilling; confirm capacity for full metal thickness |

| 12 ga (2.7 mm) and thicker | #8 self-drilling #3 or #4 point | #3 or #4 self-drilling | Bugle/trim/pan framing; square or Phillips | Use self-drilling screws designed for heavy-gauge metal |

Drive and head guidance:

– Phillips and square (Roberson) drives are widely available.

– Trim head reduces visible head protrusion; pan framing head offers higher drive engagement; bugle head countersinks neatly into gypsum.

Illustrative Image (Source: Google Search)

3) Application-specific material recommendations

| Application | Recommended material/finish | Typical screw type | Rationale |

|---|---|---|---|

| Interior, dry climate | Carbon steel, zinc CR+3 or black phosphate | Bugle or trim head; fine-thread or self-drilling #2 | Cost-effective, adequate performance in dry conditions |

| Interior, high humidity (bathrooms, kitchens, spas) | Stainless steel (410/305) or, if permitted, coated carbon steel with validated corrosion resistance | Self-drilling bugle/trim head | Humidity drives corrosion; stainless or validated coatings mitigate risk |

| Coastal/interior near salt exposure | Stainless steel 305/316 preferred (410 acceptable where permitted) | Self-drilling bugle/trim head | Salt-containing moisture accelerates corrosion; stainless resists staining and pitting |

| Exterior gypsum sheathing to steel framing | Stainless steel 305/316 preferred; 410 acceptable where permitted | Self-drilling bugle or trim head; confirm local code compliance | Exterior exposure requires high corrosion resistance |

4) Practical tips for specifiers and buyers

- Verify stud/track thickness before selecting point type (#2 for light gauge, #3/#4 for medium to heavy).

- Specify the head style to suit finishing requirements (trim for minimal visibility, pan for high drive engagement, bugle for standard countersinking).

- Collated options are available for #6-20 fine-thread and #6-18 self-drilling variants; collated fasteners increase installation speed for production environments.

- Avoid mixing metals in long-term exterior applications; when dissimilar metals must be used, ensure fasteners are the more noble metal.

- Confirm local code requirements for exterior gypsum-to-metal connections; some jurisdictions mandate stainless or specific coating standards.

In-depth Look: Manufacturing Processes and Quality Assurance for drywall screws for metal

In‑depth Look: Manufacturing Processes and Quality Assurance for Drywall Screws for Metal

Drywall screws for metal are engineered for high-volume, reliable installation into steel studs, tracks, and fixtures; therefore, manufacturing must deliver tight geometric consistency, strong steel, and repeatable drive performance. The process comprises wire preparation, cold forming, thread rolling, coating, and—in collated forms—strip assembly, with each step controlled by in‑process checks and final inspection.

Manufacturing Overview: From Wire to Fastener

Drywall screws for metal typically start from low‑carbon steel wire rod, cleaned and annealed to improve formability; next, cold forging produces the head (bugle, pan framing, or trim), drives (Phillips or square) are rolled or cut, and threads are rolled to final diameter and pitch; the point is then formed (sharp or self‑drilling), followed by cleaning, surface treatment (black phosphate or zinc), lubrication where applicable, and optionally collation into strips or coils for automatic tools.

- Prep: Wire rod receipt inspection checks grade, diameter, coil condition, and documentation; cleaning removes scale and debris, annealing normalizes hardness for forming, and surface preparation ensures consistent coating adhesion.

- Forming: Cold heading presses billet segments into head geometry with precise diameter and countersink (bugle, pan framing, trim); drive recess is rolled or stamped (Phillips #2 or square #2), thread rolling then sets pitch and major/minor diameters, and the point is configured for steel (sharp point or self‑drilling with flute and edge prep).

- Assembly (collation): Strip or coil collation aligns fasteners with orientation and spacing; nails or resin strips hold bands; end‑of‑strip checks confirm spacing, orientation, and strip continuity.

- Finalization: Coatings (black phosphate or zinc CR+3) are applied with thickness control and post‑treatment; a dry film lubricant may be used to improve drive cam‑out resistance; packaging includes lot identification and product identifiers.

Thread and Point Selection for Metal

For metal framing, choose thread and point combinations aligned to steel thickness and installation method:

- Fine thread: For 20–25 gauge steel, high‑low or fine threads increase engagement and reduce push‑out; coarse thread: For thicker studs and tracks or wood to metal, coarse or high‑low threads aid initial bite; self‑drilling: For 18–20 gauge steel and heavier, self‑drilling tips (#2 point) reduce pre‑drilling and improve consistency.

- Sizes: #6, #7, #8, and #10 cover common thicknesses and lengths from 7/16″ to 1‑1/2″; verify diameter, thread count (e.g., #6‑18, #6‑20, #8‑18), and length according to steel thickness.

- Drive: Phillips #2 for general drywall use; square (#2) for higher torque and reduced cam‑out in metal framing applications.

Manufacturing Steps: What Happens and Why It Matters

- Wire Prep: Ensures clean, formable stock; consistent diameter minimizes dimensional variation during heading and rolling.

- Cold Heading: Creates full, repeatable head geometry; countsink (bugle) minimizes paper tear, pan framing offers higher head bearing for steel, trim head reduces finish‑layer penetration.

- Drive Recess: Phillips #2 is ubiquitous; square #2 increases torque transfer and reduces cam‑out; roll‑formed recess surfaces provide burr‑free, durable geometry.

- Thread Rolling: Produces stronger threads with excellent fatigue resistance; pitch control affects engagement per turn and pull‑out from steel studs.

- Point Formation: Sharp points require pilot holes in thicker steel; self‑drilling points form their own pilot and remove chips via flutes, improving speed and consistency.

- Coatings: Black phosphate offers lubrication and mild corrosion resistance; zinc CR+3 provides higher corrosion protection; thickness control avoids interference with threads and drive fit.

- Lubrication: Dry film lubricants reduce drive torque and cam‑out, especially for collated tools and high‑volume production lines.

- Collation: Accurate strip spacing and orientation ensure reliable feeding into auto‑drivers; orientation for bugle heads minimizes paper tear during drywall installation onto steel tracks and studs.

Quality Assurance: Controls and Standards

Quality management and product verification ensure that fasteners install reliably into metal.

Illustrative Image (Source: Google Search)

- Quality Management System: ISO 9001 establishes documented processes, controlled work instructions, calibration, and traceable change management across incoming inspection, in‑process controls, and final acceptance.

- Incoming Material QC: Verification of wire grade and diameter; hardness checks confirm annealed condition; visual inspection of coils and packaging prevents contamination and damage.

- Forming and Recess Controls: Dimensional checks on head diameter, height, and countsink; drive recess gauging confirms fit for #2 Phillips or square drivers; burrs and deformation are unacceptable.

- Thread Geometry: Pitch verification and major/minor diameter checks ensure consistent engagement; surface inspection confirms rolled thread integrity without laps or cracks.

- Point Verification: Self‑drilling points are measured for flute geometry, tip radius, and edge quality; pilot drill accuracy and chip evacuation are verified across multiple samples per lot.

- Hardness and Core Integrity: Hardness tests (e.g., Rockwell) in head, shank, and point verify that mechanical properties are within target ranges; over‑hardness causes brittleness, under‑hardness reduces stripping torque and pull‑out.

- Drive Torque and Fit: Torque‑to‑strip tests evaluate Phillips and square drives; cam‑out is minimized; gauge fit is verified to prevent driver slippage and installation inconsistencies.

- Pull‑out/Withdrawal from Steel: Sample tests into specified gauge steel confirm engagement values align with expected performance; over‑torque and under‑engagement are identified for corrective action.

- Corrosion Resistance: Salt fog testing to relevant standards (e.g., ASTM B117) verifies coating performance; thickness measurement (e.g., XRF or coating thickness gauges) confirms specification adherence.

- Surface Finish and Lubrication: Film thickness of lubricants is controlled; surface cleanliness and coating appearance standards are applied to ensure consistent drive performance.

- Collation Integrity: Strip spacing, orientation, and band strength are verified; collation materials are inspected for resin integrity and lack of foreign matter; end‑of‑strip failure rates are recorded.

- Packaging and Traceability: Product labeling includes size, thread, head type, drive, coating, quantity, and lot/batch information; packaging integrity prevents damage; storage conditions are specified to prevent corrosion.

- Change Control and Calibration: Equipment calibration schedules maintain measurement reliability; change management covers process parameters, tooling, and coating bath conditions.

- Compliance: Coatings follow applicable environmental and regulatory frameworks; certificates and declarations of conformity are maintained and provided to customers on request.

Practical QA Checks for Metal Framing Applications

To confirm readiness for metal framing lines, the following checks are typically performed:

- Drive fit: Verify #2 Phillips or square driver engagement with torque data; confirm no cam‑out at specified installation torque.

- Self‑drilling capability: Test drill speed and chip clearance in 18–20 gauge steel; ensure point geometry produces clean holes without burrs.

- Collation handling: Run strip through auto‑driver; confirm correct orientation, consistent spacing, and no mid‑strip misfeed.

- Head profile: Bugle head countersink must be within tolerance to avoid paper tear; pan framing head must provide adequate bearing on steel.

- Corrosion verification: Zinc CR+3 parts show specified rust‑resistance; phosphate parts meet the target film and lubrication requirements.

Notes on B2B Buyer Considerations

- Ensure thread type (fine, high‑low, coarse) matches steel thickness and application; use self‑drilling points for 18–20 gauge steel and up when speed and consistency are critical.

- Specify coating (black phosphate or zinc CR+3) and lubricant expectations; confirm packaging configuration (bulk or collated) to match tooling and lines.

- Request ISO 9001 certification of the manufacturer; obtain certificates of conformance, coating thickness reports, and hardness results for key lots.

By aligning manufacturing control points—cold forming accuracy, thread pitch integrity, drive recess quality, point performance, and coating consistency—with rigorous QA, drywall screws for metal deliver repeatable installation in steel framing environments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drywall screws for metal’

Practical Sourcing Guide: A Step-by-Step Checklist for Drywall Screws for Metal

Use this checklist to specify, qualify, and procure drywall screws for attachment to metal studs/track. It covers USA and Europe, with standards and typical specs referenced from the listed supplier data.

1) Confirm application and design inputs

- Gypsum board to metal (studs/track; typical 20–25 ga, occasionally thicker sections)

- Layer count: single-layer vs multi-layer (laminate/sublayer to metal)

- Stud material: galvanized steel (GI), stainless steel (SS), aluminum (AL)

- Project region and base materials to select finish and applicable standards

- Automation: collated vs bulk; screwgun, auto-feed, or impact/drill driver

2) Select core fastener spec

- Gauge: #6, #7, #8, #10 (typical for drywall-to-metal)

- Threads: high-low or fine thread (gypsum to metal), self-drilling for thicker steel

- Point:

- Sharp point for 20–25 ga galvanized steel

- Self-drilling (#2 point or finer) for thicker steel or stainless

- Head and drive:

- Bugle head + Phillips (most common for drywall)

- Pan framing head + Phillips (framing/fastening to track)

- Trim head + Square drive (minimal protrusion, aesthetic work)

- Length:

- 1–1/4″ typical for 1/2″ drywall to 20–25 ga

- 1–1/2″ typical for 5/8″ drywall to 20–25 ga

- Verify against total stack-up and stud depth

- Material: carbon steel (most projects), stainless steel 410/305 (corrosive or exterior envelopes; verify compatibility)

Step 2 Decision Table (when to choose which)

| If steel thickness/condition | Recommended point | Typical thread | Head/drive | Gauge(s) | Length(s) |

|---|---|---|---|---|---|

| 20–25 ga galvanized | Sharp (no pre-drill) | High-low or fine | Bugle + Phillips | #6–#8 | 1-1/4″ (1/2″), 1-1/2″ (5/8″) |

| ≥18 ga, or variable thickness | Self-drilling (#2 point) | Fine or coarse-to-fine | Pan framing + Phillips or Bugle + Phillips | #6–#8 | 1-1/2″ (match stack-up) |

| Stainless steel studs | Self-drilling (check compatibility) | Fine | Bugle + Phillips (ensure driver fit) | #6–#8 | 1-1/2″ (typical) |

| Multi-layer/laminate | Sharp or self-drill as above | As above | Bugle (laminate use #10 x 1-1/2″ listed) | #10 for laminate | 1-1/2″ |

3) Match standards and approvals (US/EU)

Standards Crosswalk

| Region | Purpose | Standard | Applies to | Notes |

|---|---|---|---|---|

| USA | Gypsum board screws | ASTM C1002 | Steel screws for attaching gypsum to wood/metal studs | Bugle/trim head, phosphate finish common |

| USA | Self-tapping screws (metal) | ASTM C1513 | Self-tapping screws for metal-to-metal | Self-drilling types for thicker steel |

| USA | Fasteners in steel | ASTM C954 | Drill screws for steel-to-steel connections | Useful for thicker stacks |

| USA | Torque-based testing | ASTM F1624 | Load/performance evaluation | Useful for design verification |

| EU | Self-tapping screws | EN 14566 | Gypsum board fasteners to metal | Common for drywall screws to metal |

Approval/Compliance Checklist

– State ASTM C1002/C1513/C954 as applicable

– For EU: EN 14566 for drywall-to-metal screws

– Confirm head/drive geometry per standard (bugle/trim, Phillips/Square)

– Ensure shank diameter, point style, and corrosion test data align with stated standard

4) Specify corrosion protection and finish

- Carbon steel, black phosphate: standard for interior, provides mild corrosion resistance; improves bit life

- Zinc CR+3 (electroplate): improved corrosion resistance; suitable where zinc compatibility with contact metals is acceptable

- Stainless steel: for high corrosion environments or stainless stud contact

Finish Crosswalk

| Finish | Base material | Corrosion class (typical) | Use case | Notes |

|---|---|---|---|---|

| Black phosphate | Carbon steel | Light–moderate (indoor) | Most interior drywall-to-metal | Check against project humidity/alkalinity |

| Zinc CR+3 | Carbon steel | Moderate | Occasional humidity, galvanic caution | Verify contact with dissimilar metals |

| Stainless 410/305 | Stainless steel | High | Coastal, chemical, exterior envelopes | Verify point/drill compatibility; cost premium |

5) Specify packaging and collation

- Bulk (bulk pack, 1,000–5,000+ ct) vs collated strips (auto-feed systems)

- Driver compatibility: collated to tool system; verify collation type and nose piece

- Sizing accuracy: confirm gauge, thread (TPI), and length on packaging labels

Packaging Overview (based on listed products)

– Head/drive types: Bugle/Phillips; Pan framing/Phillips; Trim/Square

– Thread styles: Coarse, Fine, High-low; Self-drilling (#2 point)

– Collated options: #6-18 fine thread (Bugle, Phillips); #6-9 coarse thread; #6-20 self-drilling

– Materials/finishes: Black phosphate (steel); Zinc CR+3 (steel)

– Laminate screws: #10 x 1-1/2″ Bugle, Phillips, black phosphate

– Typical sizes offered: #6–#10; lengths around 1-1/4″ and 1-1/2″

Illustrative Image (Source: Google Search)

6) Verify tooling and installation requirements

- Tooling: corded/cordless screwgun with adjustable clutch; for automation, confirm auto-feed compatibility

- Self-drilling screws: check drill point specification and recommended RPM/torque

- Bit fit: Phillips #2 (common), Square drive #2 for trim heads

- No pre-drilling for 20–25 ga with sharp-point; pre-drill or self-drill for thicker steel

- Inspect drivers and collated strips for wear to avoid cam-out or misfeeds

7) Define quality and performance verification

- Visual: correct head, drive, point; no rust, flaking, or contamination

- Dimensions: verify gauge, thread per label (e.g., #6-18, #6-20), and measured length

- Drive test: confirm positive engagement (no cam-out at spec torque)

- Penetration: neat countersink without tear-out; no breakthrough into finishing side

- Pilot testing: pull-out and shear on representative metal thickness; record results to confirm spec

Testing Matrix (create during qualification)

| Thickness (ga) | Point | Head/drive | Pass criteria (example) | Notes |

|---|---|---|---|---|

| 20 ga GI | Sharp | Bugle + Phillips | No cam-out; consistent set; no tear-out | Typical interior single-layer |

| 18 ga GI | Self-drill (#2) | Pan framing + Phillips | Clean drill; full thread engagement | Multi-layer or thicker stacks |

| 20 ga SS | Self-drill | Bugle + Phillips | Compatible driver; no slippage | Verify SS compatibility |

8) Set packaging, labeling, and storage

- Label: gauge, thread, length, head/drive, point, material/finish, standard, lot/date, country of origin

- Storage: dry indoor; avoid moisture for phosphate/zinc finishes; protect collated strips from dust/debris

- QC on delivery: random sampling for dimension and finish verification

9) Finalize procurement: TCO and logistics

- Spec sheet: include standard(s), finish, point, collation, packaging unit, lead time, MOQ

- Price: unit vs carton; compare TCO including bit life, rework, and collation benefits

- Logistics: palletize bulk and collated; confirm export (EU) compliance and documentation

10) Sign-off checklist before bulk order

- Application fit (ga, layers, stud material)

- Correct point and thread for metal thickness and type

- Head/drive correct for tool and finish requirement

- Standard compliance stated (ASTM C1002/C1513/C954; EN 14566)

- Packaging/labeling verified; collation matches tooling

- Pilot installation successful on representative material

- QC plan and documentation set

Quick Specifier Cheat Sheet (example)

– Single-layer 1/2″ drywall to 20–25 ga GI: #6–#8, high-low or fine thread, sharp point, Bugle/Phillips, black phosphate, 1-1/4″

– Single-layer 5/8″ drywall to 20–25 ga GI: same as above, length 1-1/2″

– Multi-layer to 18 ga or thicker: #6–#8, self-drilling (#2), Pan framing or Bugle/Phillips, 1-1/2″, zinc CR+3 if moisture risk

– Laminate/sublayer: #10 x 1-1/2″ Bugle/Phillips, black phosphate

This checklist ensures you specify the correct fastener, meet regional standards, and source reliably from USA and Europe suppliers offering the listed range of bugle, pan framing, trim heads; coarse/fine/high-low and self-drilling points; and common finishes like black phosphate and zinc CR+3.

Comprehensive Cost and Pricing Analysis for drywall screws for metal Sourcing

Comprehensive Cost and Pricing Analysis for drywall screws for metal Sourcing

Executive summary

- Unit prices in the dataset range from roughly $0.009–$0.016 per piece for loose bulk bugle/trim/pan framing drywall screws, and about $0.052–$0.066 per piece for collated drywall screws (≈1,000 pieces per collated strip/box).

- Materials and thread geometry are the largest drivers of cost. Labor and logistics typically represent a smaller share, but they can move meaningfully with region, duty, and mode of transport.

- In Europe, duties, VAT, and freight add material steps to landed cost; North America’s duty treatment is more favorable on many SKUs.

- For a robust quote-to-bill conversion, use a landed cost build-up and monitor material, labor, logistics, and compliance volatility monthly.

Scope and data context

- The dataset includes:

- Bugle head drywall screws: coarse thread, fine thread; black phosphate; bulk and collated

- Trim head drywall screws: black phosphate or zinc CR+3

- Pan framing head drywall screws

- Self-drilling drywall screws for metal: zinc CR+3; bulk and collated

- Typical pack sizes: bulk cartons and collated strips/boxes

- Prices are listed as “From $X”; taxes/duties not included.

Unit pricing from dataset

- Loose bulk (bugle head, black phosphate; coarse/fine; uncollated)

- Range: $63.80–$79.13 per bulk carton

- Estimated per piece: $0.012–$0.016 (assuming ~5,000 pieces/carton; indicative)

- Collated bugle head drywall screws (black phosphate; Taiwan)

- Range: $279–$280 per 5,000 pieces

- Per piece: ≈$0.0558–$0.056 (based on the dataset’s 5,000-count pricing)

- Trim head drywall screws (black phosphate; bulk)

- From $76.58 per bulk carton

- Estimated per piece: ≈$0.015 (≈5,000 pieces/carton; indicative)

- Pan framing head (#7 x 7/16”, black phosphate; bulk)

- $123.50 per bulk carton

- Estimated per piece: ≈$0.025 (≈5,000 pieces/carton; indicative)

- Self-drilling drywall screws for metal (zinc CR+3; bulk)

- From $73.92 per bulk carton

- Estimated per piece: ≈$0.0148 (≈5,000 pieces/carton; indicative)

- Self-drilling collated (zinc CR+3; collated)

- From $330.00 per collated box

- Per piece: ≈$0.066 (assuming ~5,000 pieces/box; indicative)

Note: Assumed 5,000 pieces/carton is used for estimation where count not specified. Per-piece cost must be recalculated with actual count and carton weight at the time of quoting.

Illustrative Image (Source: Google Search)

Cost breakdown methodology

- Landed cost per piece = Materials + Manufacturing + Packaging + Overhead + Logistics + Duties + Taxes/VAT + Warranty/Field Support + Target margin

- Typical ranges by cost bucket (loose bulk vs collated):

- Materials and processing: 55–70% (steel/coil, wire drawing, heading, thread rolling, point, finishing; highest for self-drilling)

- Manufacturing and QA: 8–15% (depreciation, labor, tooling, inspection; collated involves collation tooling)

- Packaging: 2–6% (bulk cartons vs collated strips/boxes + plastic/composite reels)

- Logistics and handling: 10–20% (domestic vs cross-border freight, handling; varies by INCOTERMS, mode, and region)

- Duties and VAT: 0–25% (EU often higher; NA duty varies by HS line and origin)

- Warranty/field support/margin: 5–15% (quality performance, claims, technical support)

- These are ranges for quoting and variance tracking; align with your local cost structure.

Materials and finish cost drivers

- Wire rod and cold-drawn wire: primary driver; fine/coarse thread gauge and length increase steel mass per piece.

- Head type: bugle is most efficient; trim and pan framing require more material/form energy per piece, raising unit cost.

- Thread and point: fine thread vs coarse; self-drilling points add tool life and process time cost vs standard piercing/sharp points.

- Finish/coating:

- Black phosphate: low cost, adequate for interior and general-purpose use on drywall-to-metal.

- Zinc CR+3/electroplated zinc: better corrosion performance; higher cost and stricter environmental controls.

- Packaging: bulk cartons with liners vs collated strips in plastic/composite reels; collated adds material and tooling amortization.

Labor and operations

- Heading, thread rolling, and point forming determine cycle time and yield; self-drilling adds drilling and deburring operations.

- Collation: adds labor, machine time, and consumables (adhesives, collated strip materials, reels); typically 2–4x the labor per piece vs loose bulk.

- QA: sampling (e.g., pull tests, torsion, torque-to-failure), traceability, and documentation time; critical for metal-to-metal applications.

- Overhead absorption: includes plant energy, maintenance, depreciation, and indirects; collated lines have higher fixed-cost absorption.

Logistics and landed cost

- Mode:

- Ground freight (North America): reliable, lower carbon cost; cost sensitive to diesel and linehaul density.

- Ocean + drayage (Europe/USA): lowest unit freight on high volumes; longest lead time; exposure to surcharges (e.g., BAF/CAF, peak season).

- Air: fastest but high cost; not typical for bulk screws unless urgent service-critical shipments.

- Duties/VAT and compliance:

- HS 7318.15: machine screws for metal 7318.15.00 (duty varies by origin and free-trade agreements).

- 7318.14: wood screws typically free or low duty in many markets; drywall screws are often classified under 7318.15 for metal fasteners.

- Europe: VAT due on import and domestic supply; EORI/registration and product standards conformity add overhead.

- INCOTERMS: choose FCA/FOB for buyer-controlled freight; DDP/DAP shifts logistics cost/risks to supplier; align with your cash flow and risk appetite.

Region-specific considerations

- USA

- Duty: Often favorable under trade agreements; confirm 7318.15 rate by origin.

- Logistics: Dense ground networks; strong last-mile service from national distributors.

- Packaging: Bulk cartons and collated boxes widely available; palletization and truckload utilization drive unit freight.

- Europe

- Duty/VAT: Import duty and VAT (e.g., 19–27% by member state) add to landed cost; plan EORI and customs broker setup.

- Logistics: Ocean-first with EU drayage; compliance documentation (REACH/RoHS for coatings; CE marking where required).

- Packaging: Often palletized; ensure ISPM-15 compliant pallets to avoid quarantine delays.

Cost scenarios (dataset-derived)

- Loose bulk drywall screws (bugle head, black phosphate)

- Per piece: $0.009–$0.016 (based on $63.80–$79.13/carton; indicative)

- Share: Materials/process 60–70%, packaging 2–4%, labor 8–12%, logistics 8–15%, margin 5–10%

- Collated drywall screws (bugle head, black phosphate; Taiwan)

- Per piece: ≈$0.056 (based on $279–$280/5,000)

- Share: Materials/process 55–65%, collation labor/packaging 8–12%, logistics 10–18%, margin 5–10%

- Self-drilling drywall screws for metal (zinc CR+3; bulk)

- Per piece: ≈$0.015 (based on $73.92/carton; indicative)

- Share: Materials/process (higher due to drill points) 60–70%, coating 3–6%, logistics 8–15%, margin 5–10%

- Self-drilling collated (zinc CR+3; collated)

- Per piece: ≈$0.066 (based on $330/5,000; indicative)

- Share: Collation/packaging 6–10%, materials/process 55–65%, logistics 10–18%, margin 5–10%

- Pan framing head (#7 x 7/16”, black phosphate; bulk)

- Per piece: ≈$0.025 (based on $123.50/carton; indicative)

- Share: Higher material/mass 60–70%, logistics 8–15%, margin 5–10%

Actual shares must be recalculated with your purchase order quantities, pack counts, and INCOTERMS.

Savings levers by cost bucket

- Materials

- Optimize thread/coarse vs fine per application; right-size gauge and length.

- Choose finishes by use: black phosphate for general drywall-to-metal; use zinc CR+3 only where corrosion resistance is required.

- Manufacturing

- Increase throughput per line; reduce scrap and rework; standardize head/point profiles.

- For self-drilling, lock tooling specs to control tool life and cycle time.

- Packaging

- Use bulk where installation permits; switch to collated only where labor savings offset cost.

- Right-size reels/boxes; consider reusable or recyclable packaging options to reduce waste and cost.

- Logistics

- Consolidate shipments; target FTL/LTL density; choose ocean over air unless SLA requires.

- Negotiate INCOTERMS and carrier contracts; align with duty and VAT planning.

- Commercial

- Standardize SKUs; align multi-supplier QA; negotiate MOQs and call-off schedules.

- Use indexing clauses for steel/coil and energy; set quarterly price reviews.

- Compliance and risk

- Verify HS codes and origin duties before quoting; prepare EU REACH/RoHS compliance files for coatings.

- Define field performance criteria (pull-out on metal gauge ranges) to limit warranty exposure.

Data and pricing model inputs to maintain

- Wire rod and steel price indexes

- Coating cost and availability (black phosphate, zinc CR+3)

- Energy, labor, and overhead rates

- Freight indices (truckload, ocean, air) and surcharges

- HS code, duties, and VAT rates by origin and destination

- Packaging and collation cost per piece

- Target margin and warranty reserves

Recommended next steps

- Build a per-piece landed cost calculator using the dataset’s per-piece prices as benchmarks and the cost-bucket ranges above.

- Request supplier quotes with explicit pack counts, HS codes, duties/VAT, INCOTERMS, and lead times.

- Pilot buy across two SKUs (loose bulk and collated) with field productivity measurements to confirm total installed cost.

- Set a monthly cost index and price-review cadence to manage volatility.

Alternatives Analysis: Comparing drywall screws for metal With Other Solutions

Alternatives Analysis: Comparing drywall screws for metal with other solutions

When attaching gypsum board to steel studs (typically 20–25 ga) and tracks, drywall screws engineered for metal—fine-thread, high–low or bugle head, frequently self-drilling (#6–20) or collated for auto-feed—are purpose-built. They balance pull-through resistance, countersink control, and installation speed. Two common alternatives are standard sheet metal thread-forming screws (e.g., Type A/AB) and self-drilling screws for thicker metal (TEK/SD).

- Use drywall screws engineered for metal as the default for drywall-to-metal framing.

- Consider sheet metal screws for thin gauge steel where countersink and cost control matter.

- Consider self-drilling (TEK) screws for thicker steel, aluminum, or where a single-step fastening is essential.

Pros, cons, and selection guidance

| Alternative | Best use cases | Material/Coating | Drill capacity | Head/Drive options | Cost tendencies | Pros | Cons | Corrosion guidance | Standards and approvals |

|---|---|---|---|---|---|---|---|---|---|

| Drywall screws for metal (e.g., #6–20 fine-thread self-drilling bugle or high–low; collated available) | 20–25 ga steel studs/tracks; drywall-to-metal; most gypsum board installations | Case-hardened steel; black phosphate common; corrosion-resistant zinc CR+3 available | Single-step for 20–25 ga; designed to pair with 20 ga | Bugle head Phillips/Square; trim/pan heads; collated strips for auto-feed guns | Lower material cost; collated increases unit cost but improves labor | Purpose-designed to avoid blowout, provide controlled countersink, high installation speed; good pull-through; collated options | Not for structural steel; drive cam-out can occur (choose Square/PH2); corrosion depends on coating | Zinc CR+3 for dry interiors; specify hot-dip galvanized or stainless for higher humidity/corrosion risk | ASTM C1002 (drywall screws), C954 (steel-to-steel connections where applicable); select screws that satisfy local code |

| Sheet metal screws (Type A/AB) | Thin sheet steel (≤18 ga), fixtures to metal, electrical/mechanical assemblies | Steel, often zinc-plated; stainless variants | Require pre-drilled or pilot hole; no flute | Pan head Phillips/Square/Torx common | Lower material cost | Accurate point placement; countersink control; wide availability | Slower for drywall (no flute), risk of blowout with bugle; not optimized for pull-through resistance on board | Zinc-plated or stainless for corrosion; specify per environment | ASTM C1002 not applicable; verify local approvals/requirements |

| Self-drilling (TEK/SD) screws for metal | Thicker steel (≥18 ga) or heavy gauge aluminum; metal-to-metal assemblies; structural attachments | Case-hardened steel; self-drilling points; coatings vary | Two or three flute designs; faster for thicker metal | Pan/truss heads; Square/Torx drives | Higher unit cost; fastest drive on heavy metal | One-step drilling and fastening; minimal pre-drilling | Overkill for 20–25 ga drywall; larger head may mark board; typically not collated for drywall guns | Zinc-coated, hot-dip galvanized, or stainless per exposure | ASTM C954 (steel-to-steel); some products rated for structural use; check approvals per region |

Notes:

– For drywall on 20–25 ga metal studs, a #6–20 fine-thread bugle head or high–low point (often listed as “#6–20 Bugle Head Phillips Self-Drilling, Zinc CR+3”) paired with collated strips yields the best balance of speed, pull-through, and countersink control.

– For thinner steel (<18 ga), Type AB sheet metal screws provide excellent point control; avoid tearing by controlling torque and using the proper drive.

– For steel ≥18 ga or aluminum, use self-drilling screws with the appropriate drill point number for the metal thickness; pan heads (Phillips/Square) are common.

Practical selection checklist:

– Gauge and alloy: 20–25 ga steel (use drywall screws engineered for metal); ≥18 ga or aluminum (use TEK/self-drilling).

– Head profile: Bugle countersinks gypsum cleanly; pan/truss for metal-to-metal; trim for visible finishes.

– Drive: Square/PZ2 and Torx reduce cam-out vs Phillips in high-volume use.

– Coating/corrosion: Zinc CR+3 (CR3) or zinc phosphate for dry interiors; specify hot-dip galvanized or stainless for higher humidity or exterior-adjacent work.

– Delivery: Collated strips for auto-feed drywall guns maximize speed and reduce waste; bulk for manual or mixed workflows.

– Compliance: Select screws that satisfy relevant standards (e.g., ASTM C1002/C954) and regional approvals.

Illustrative Image (Source: Google Search)

Bottom line: In North American and European drywall-on-metal projects, start with fine-thread bugle/high–low drywall screws engineered for 20–25 ga metal, often self-drilling and collated for production efficiency. Use sheet metal screws for thin steel fixtures, and TEK/self-drilling screws when fastening to thicker steel or aluminum.

Essential Technical Properties and Trade Terminology for drywall screws for metal

Essential Technical Properties and Trade Terminology for drywall screws for metal

How to decode part codes and thread/point types

Drywall-to-metal screws combine drywall head geometry (bugle/trim/pan) with metal-attachment threads and points. Common coding patterns:

-

6-9: Coarse-thread bugle-head drywall screw; 9 TPI; typically wood and 20–25 ga. steel.

-

6-20: Fine-thread bugle-head drywall screw; 20 TPI; metal studs and furring (up to ~16 ga.).

-

6-20/18 (dual marking): Same as #6-20 (20 TPI body, 18 TPI at the tip) to improve drive-in for steel; sold under Type 25 classification.

- Self-drilling drywall screws (S/D): Listed as #6-20 & #8-18, with #2 point (tear-drop/bomb point); for steel up to ~14 ga.

- Collated variants: Collation by plastic strip or wire; common for automatic screwdrivers.

Quick selector for drywall-to-metal use:

| Use-case | Screw type | Head/drive | Finish | Gauge range | Notes |

|---|---|---|---|---|---|

| Gypsum to steel studs (typ. 20–25 ga.) | #6-20 bugle (fine thread) | Phillips bugle | Black phosphate (drywall) | 20–25 ga. steel | Popular “Type 25” drywall screw for metal. |

| Gypsum to steel furring (up to ~16 ga.) | #6-20 bugle (fine thread) | Phillips bugle | Black phosphate | 18–16 ga. steel | For thicker metal, confirm performance or move to self-drilling. |

| Fastening without pre-drilling on ~20 ga. steel | #6-9 bugle (coarse thread) with piercing point | Phillips bugle | Black phosphate | ~20–25 ga. steel | Use piercing tips for quicker drive-in; limit to thinner metal. |

| Fastening to ~14 ga. or as a universal metal fastening | #6-20/#8-18 bugle self-drilling, #2 point | Phillips bugle or square | Zinc CR+3 or CR+6 | Up to ~14 ga. steel | Self-drilling eliminates pilot hole; better for repetitive use. |

| Finish-grade surfaces (laminate/furring to metal) | Trim head or pan framing | Square (trim) or Phillips (pan) | Zinc phosphate or zinc | 20–25 ga. steel | Trim/pan reduce tear-out; good for countersunk or thin metal. |

| Collated automated application | Collated fine-thread bugle (#6-18) or self-drilling (#6-20) | Phillips bugle | Black phosphate or zinc | As above | Strip or wire collation for auto-feed tools. |

Key technical properties

- Thread form:

- Fine thread (#6-20/#8-18): Best for metal; more engaged threads and reduced pull-through in metal.

- Coarse thread (#6-9): For wood and very thin metal; more aggressive start but fewer threads per inch.

-

High-low/double-lead (#6-18): Often used in fine-thread drywall screws for steel; eases drive-in into metal while maintaining bite.

Illustrative Image (Source: Google Search)

-

Point type:

- Piercing/tap point: Cuts sheet without pre-drilling; ideal for 20–25 ga. steel on drywall attachments.

-

Self-drilling, #2 point: Bores and taps in one step; suitable for up to ~14 ga. steel and repeated driving.

-

Head geometry:

- Bugle head (countersunk): Standard drywall sinking; avoids surface tearing on gypsum.

- Trim head: Smaller countersunk footprint; improved holding in thin metal; finish-friendly appearance.

-

Pan framing head (low-profile pan): Used for furring/laminating and thin metal; high clamp force, reduced pull-through.

-

Drive:

- Phillips: Broadly available and cost-effective; can cam-out at higher torque.

-

Square (Robertson): Superior torque transmission; ideal for collated and automated use; preferred in NA and increasingly in EU.

-

Material and hardness:

- Typically case-hardened, low-carbon steel for drywall screws.

- Self-drilling screws commonly zinc-plated (CR+3 or CR+6) for corrosion resistance and extended point durability.

-

Drywall bugle heads typically black phosphate to enhance drive-in friction and bit engagement; adequate corrosion protection for interior gypsum applications.

Illustrative Image (Source: Google Search)

-

Corrosion protection:

- Black phosphate: Standard on drywall bugles; sacrificial/coating protection suited to interior environments.

-

Zinc (CR+3/CR+6): Used on self-drilling and trim/pan heads; improved corrosion resistance; preferred for humid interiors or mixed-material assemblies; complies with EN 14592 definitions (fasteners—performance and corrosion protection).

-

Packaging:

- Bulk (reclosable cartons), bulk poly bags, contractor boxes.

-

Collated (plastic strip or wire) for automatic screwdrivers; improves speed and reduces bit changes.

Illustrative Image (Source: Google Search)

-

Sizing examples:

-

Lengths commonly from 1-1/4″ (for single-layer 1/2″ gypsum) to 2–3″ (laminating/furring); verify engagement into the steel member (minimum 3 threads into the metal for reliable grip).

-

Coatings overview:

- Black phosphate vs. zinc: Black phosphate (drywall bugle) emphasizes drive performance and bit engagement in gypsum; zinc plating improves corrosion resistance and suits metal-contact applications, trims/pan, and self-drilling screws.

Trade terminology and sourcing language

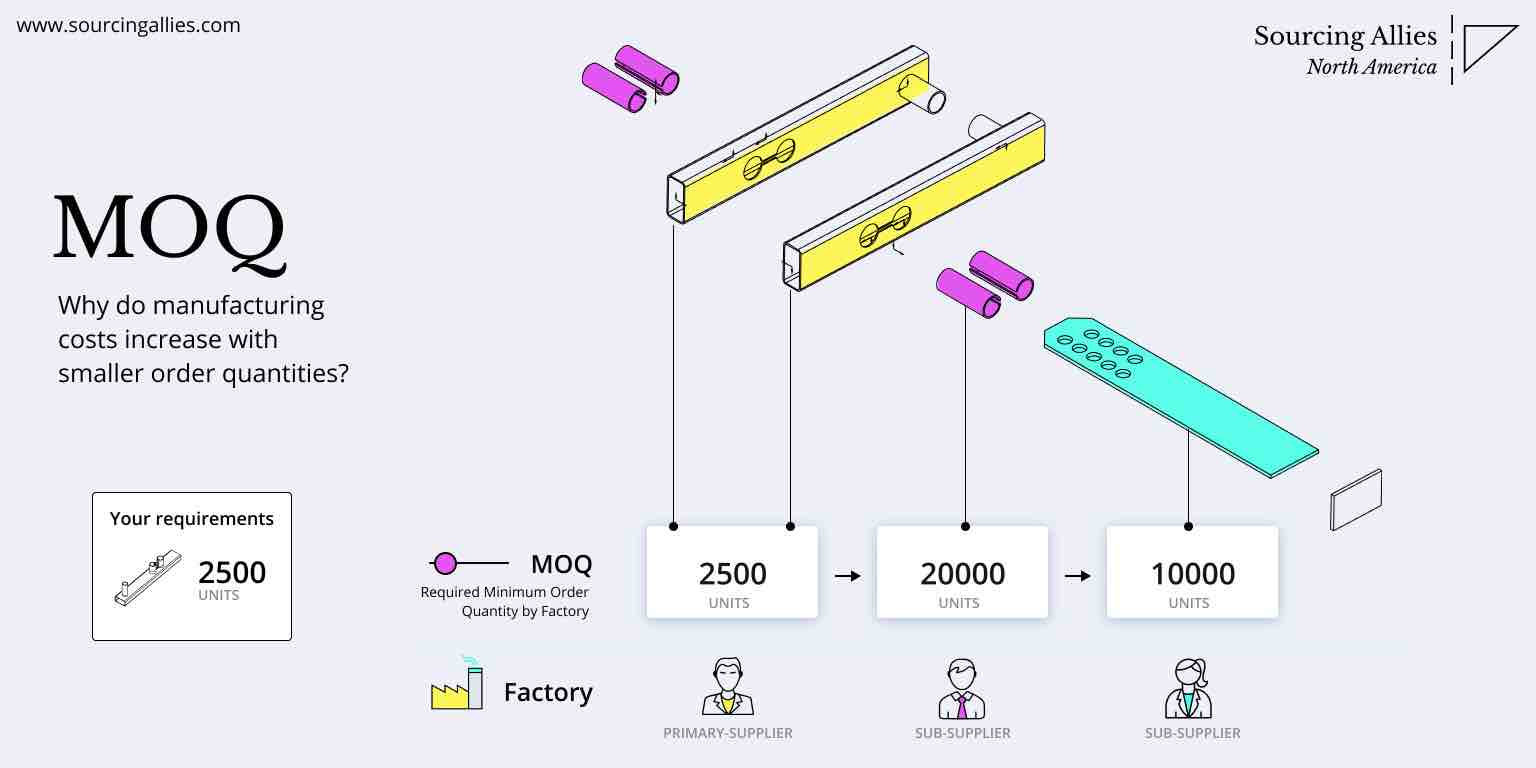

- MOQ (Minimum Order Quantity): Typically by bulk carton (e.g., 1,000–5,000 pcs) or master carton counts for collated strips; define per SKU and finish.

- Lead time: Standard production 2–4 weeks; longer for custom collations, finishes, or OEM packaging.

- OEM (Original Equipment Manufacturer) private label: Possible with supplier branding, custom packaging, and compliance labeling.

- ODM (Original Design Manufacturer): Supplier-developed packaging/specs for your SKU; may include custom head/star drives or color-matched collated strips.

- Customization options: Non-standard head styles, drives (e.g., star/torx), special coating/finish, special lubrication to reduce cam-out, collation changes.

- Certificates and testing:

- US: ASTM C1002 applies to steel drill-point screws for gypsum board (use for drywall-to-metal); confirm gauge ranges and performance where applicable.

- EU/UK: EN 14566 (self-tapping screws for gypsum board); EN 14592 (fasteners—performance and corrosion protection); CE/UKCA compliance may apply for specific construction uses.

-

Typical documentation: CoC (Certificate of Conformance), test reports for point/boring performance and corrosion coatings (e.g., salt spray on zinc), and material traceability.

Illustrative Image (Source: Google Search)

-

Logistics:

- Palletized shipments with strapping and corner protection; ESD-safe inner packs for collated tools.

- Cross-docking and regional stock points (US and EU warehouses) to reduce lead times.

-

HS codes for fasteners in the US/EU and harmonized codes for international shipments.

-

Price breaks: Volume tiers by carton/master carton; blended pricing for mixed SKUs; contract and blanket orders for stable demand.

- Incoterms: EXW or FOB for regional distribution; DDP options for US/EU hubs; specify freight carrier, insurance, and delivery windows in POs.

- Packaging standards: Master carton dimensions, unit weight, barcode labeling (ITF-14, GS1-128), pallet loads (US/EU palletization norms).

- Returns and claims: RMA process; evidence requirements (shipping damage, lot numbers, photos); defect rate expectations and corrective actions (CAPA).

Summary guidance

- For standard metal stud attachment (20–25 ga.), specify #6-20 fine-thread bugle drywall screws with a piercing or Type 25 high-low point and black phosphate finish.

- For thicker steel (~14 ga.), frequent driving, or improved corrosion resistance, specify #6-20/#8-18 self-drilling bugle screws with #2 point and zinc plating (CR+3/CR+6).

- For finish-facing applications and thin metal, use trim head (square drive) or pan framing head screws for better hold and reduced visual impact.

- If automating, select collated variants (plastic-strip or wire) to match your auto-feed tool.

- For OEM/ODM supply, align on MOQs, lead times, finish tests, packaging labels, and relevant standards (ASTM C1002; EN 14566/EN 14592) with certificates and lot traceability.

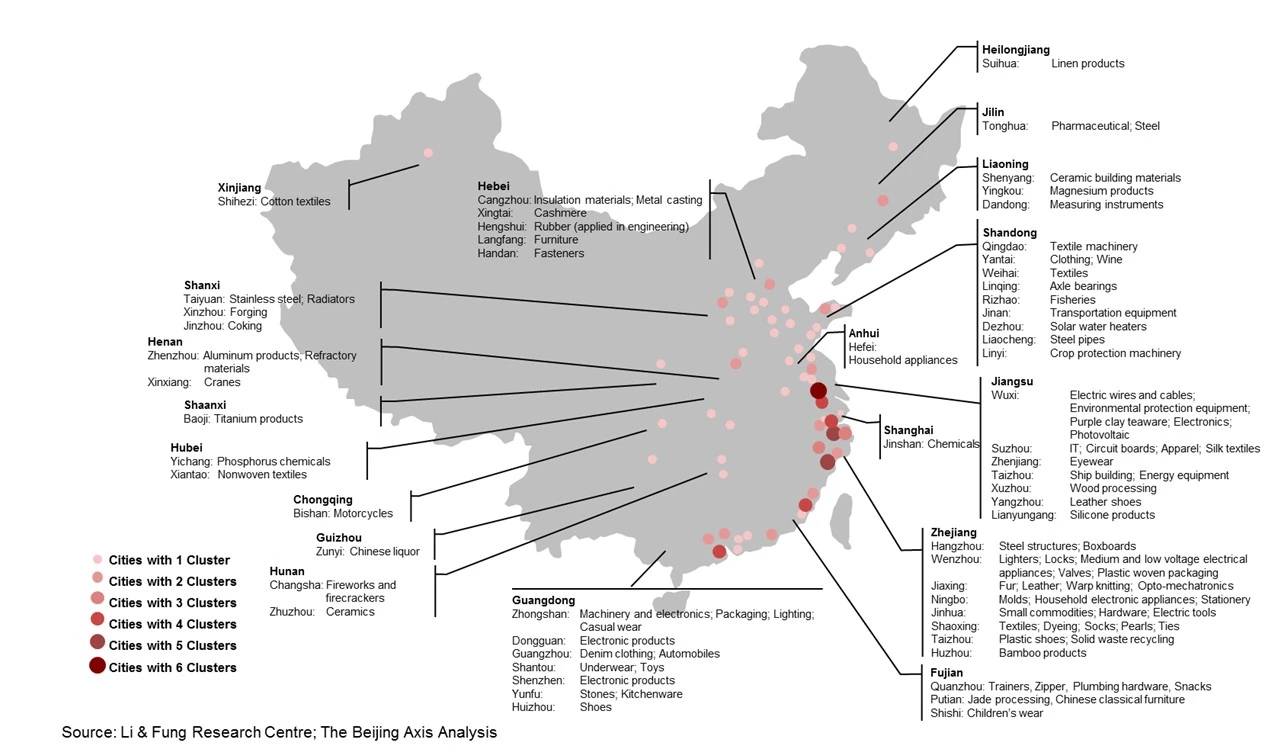

Navigating Market Dynamics and Sourcing Trends in the drywall screws for metal Sector

Navigating Market Dynamics and Sourcing Trends in the Drywall Screws for Metal Sector

History in brief

– Gypsum drywall matured mid-20th century alongside steel stud framing; standard drywall screws (bugle head, fine/coarse thread) became the default for wood framing, with metal applications requiring fine threads and, increasingly, self-drilling or sharp-point variants.

– Coatings evolved from black phosphate for corrosion protection during installation to zinc CR+3 and other zinc finishes; self-drilling points and collated formats emerged to boost speed and consistency for commercial drywall crews.

Illustrative Image (Source: Google Search)

Market dynamics (2024–2025)

– Metal framing adoption: North America and Western Europe continue to increase use of light-gauge steel studs and track due to dimensional stability, reduced callbacks, and improved fire/compliance performance.

– Format shift: Collated screws are becoming the default on commercial and high-rise projects; bulk loose fasteners remain dominant in residential retrofit and service trades.

– Point evolution: Self-drilling (#2 and higher) and sharp/standard points are expanding as crews work into thicker track and mixed substrates; standard drywall screws with sharp points fill gaps where limited drill capacity is acceptable.

– Surface finishing: Black phosphate remains a go-to for interior applications due to cost and holding; zinc and CR+3 coatings gain share where extended corrosion resistance or exterior exposure (e.g., non-cavity areas, high humidity, coastal proximity) is needed.

Buyer criteria and fit-for-purpose selection

| Criterion | Metal framing requirement | Why it matters | What to request |

|---|---|---|---|

| Thread | Fine thread for steel studs; coarse only when bridging to wood | Fine threads engage thin metal without splitting or back-out; coarse excels in wood | Fine-thread drywall screws for metal; coarse-thread only when needed |

| Point | Self-drilling #2+ for 20–14 ga metal; sharp points for 25–20 ga or mixed subs | Reduces predrilling and cam-outs; lowers cycle time | Specify #2 or higher self-drill point; sharp points for lighter gauges |

| Head | Bugle (hanging), trim (finish), pan framing (countersink alternative) | Drives countersinking for hanging; trim for finish; pan framing offers stronger head | Match head type to trade: hanging, finishing, or framing |

| Drive | Phillips, square (trim heads) | Phillips accommodates legacy tools; square reduces cam-out on collated | Match drive to applicator/collated system |

| Coating | Black phosphate (interior); zinc/CR+3 (exterior or high humidity) | Balance cost and corrosion resistance | Specify finish per exposure and QA plan |

| Format | Loose vs collated; U.S. vs metric | Collated improves speed; mixed-gauge projects may prefer loose | Align with tool availability and site logistics |

| Gauge range | 20–25 ga common; self-drilling extends to 14 ga | Ensures correct load path and drive success | Verify point/thread performance for target stud thickness |

Available product families and use cases (examples)

| Category | Typical metal use | Notes / features | Example references |

|---|---|---|---|

| Fine-thread drywall screws, bugle head | Hanging into steel studs (25–20 ga) | Phillips bugle; black phosphate; loose/bulk | Fine-thread bugle head options; #6-18 collated available |

| Coarse-thread drywall screws, bugle head | Limited in metal; preferred for wood studs | Faster engagement in wood; can deform thin metal | Coarse-thread bugle head options |

| Self-drilling drywall screws | Steel framing across 20–14 ga | #2 point; zinc CR+3 finish; loose or collated | #6-20 and #8-18 self-drilling; collated #6-20 |

| Trim head, square drive | Finish-level countersink on metal base | Trim head reduces visibility; square drive reduces cam-out | Trim head square drive options |

| Pan framing head | Optional to bugle in some framing sequences | Pan framing head; #7 x 7/16” sharp point variant | Pan framing head option |

| Laminating bugle head | Laminating gypsum/paneling to substrates | Specific laminating lengths; bugle head | #10 x 1-1/2” laminating bugle head |

Sourcing trends

– Price dispersion and availability: Fine-thread, self-drilling, and collated SKUs show tighter inventory and higher unit costs compared to standard coarse-thread bugle heads; lead times are sensitive to point tool capacity and collation tooling.

– Tool alignment: Collated systems drive the need for point standardization (e.g., #2 or higher) and drive compatibility; crews avoid cross-format mix-ups by standardizing head and drive types across the job.

– Regional preferences: North America commonly specifies #6–#8 sizes with bugle heads for hanging; Europe’s broader acceptance of collated drywall screw systems is driving more pan framing heads and higher-gauge self-drilling in commercial builds.

Illustrative Image (Source: Google Search)

Sustainability considerations

– Corrosion protection vs environmental exposure: Black phosphate is adequate for most interior conditions and reduces energy input; zinc/CR+3 extends service life in higher-corrosion environments, reducing lifecycle failure rates and rework.

– Packaging and waste: Collated systems reduce cardboard waste and improve labor productivity; buyers can request recyclable collation materials and minimized packaging to reduce site waste.

– Material and lifecycle: Steel base and zinc coatings are recyclable; specifying finishes based on actual exposure prevents premature corrosion and reduces replacement.

Practical sourcing recommendations (US/EU)

– Match thread and point to stud gauge and layout density: Use fine-thread or sharp-point for 25–20 ga; specify self-drilling for thicker sections or mixed assemblies to avoid predrill.

– Standardize on head/drive per crew to minimize tool changes and misdrives; collated lines benefit from square or Phillips that match the applicator nose.

– Align finish to exposure: Default black phosphate for interior; zinc/CR+3 where humidity, exterior envelope proximity, or coastal conditions occur.

– Size discipline: Hold #6–#8 as the core range for drywall; use #7 pan framing head where countersink strength is needed; specify laminating bugles for multilayer assemblies.

– Verify collated compatibility: Ensure coil/strip length, nose size, and driver fit the site tools to avoid downtime; lock in mixed-gauge inventory where steel/wood transitions are planned.

– Quality control and documentation: Confirm point designation (#2, etc.), thread pitch, plating type, and torque performance against stud thickness; request batch certificates where corrosion resistance is critical.

In short: Metal-framed drywall projects are increasingly powered by fine-thread or self-drilling, collated screws in zinc or phosphate finishes, with head/drive standardized to crew tools and site conditions. Disciplined sizing, point selection, and finish specification deliver speed, quality, and lifecycle performance across US and European markets.

Frequently Asked Questions (FAQs) for B2B Buyers of drywall screws for metal

Frequently Asked Questions (FAQs) for B2B Buyers of Drywall Screws for Metal

1) What is the recommended screw for attaching drywall to metal studs (20–25 ga)?

Use fine-thread drywall screws for light-gauge steel. Black phosphate (BP) coated steel is standard for indoor drywall; zinc CR+3 is preferred for higher humidity or where additional corrosion resistance is required. Coarse-thread drywall screws are not recommended for 20–25 ga metal studs—fine thread or self-drilling (TEK) performs better on steel.

Illustrative Image (Source: Google Search)

Selection guide:

– 20–25 ga metal studs: #6 fine-thread bugle-head drywall screws (e.g., #6-20)

– Overlap joints and laminating: #10 bugle-head laminating screws for added head bearing

– Attaching to thicker steel, furring, or for automated feeding: use self-drilling (TEK) bugle/trim/pan-head screws (#6-20 or #8-18)

2) Self-drilling (TEK) vs standard drywall screws—when to use each?

Standard drywall screws (bugle head) are intended for drywall-to-drywall or drywall-to-wood. When fastening to steel, the thread-forming action and point geometry are optimized for wood/gypsum and do not consistently penetrate and cut metal effectively. Self-drilling screws are purpose-built for metal: the drilling point and thread design cut into steel without pre-drilling.

When to use self-drilling on metal:

– 20–16 ga steel studs or tracks (standard drill point #2)

– Faster, more consistent penetration with less cam-out; suitable for collated auto-feed systems

– Overlap joints or attaching to thicker steel sections where standard screws will stall or break

Material/coating:

– Indoor/standard: zinc CR+3 (clear zinc)

– Exterior/soffits/high humidity: zinc CR+3 is preferred over black phosphate

Illustrative Image (Source: Google Search)

3) Head styles and drives—what works best for metal?

- Bugle head: optimal for countersinking in drywall without tearing the face paper

- Pan framing head: larger bearing surface and higher head strength—useful for wood-to-metal or high-cycle metal fastening

- Trim head: smaller head for minimal visibility; often used with self-drilling for a clean finish

- Drives: Phillips is most common for drywall guns; Square (Robertson) offers better torque control and less cam-out; both head styles are available in these drives

Head style comparison:

| Head Style | Best Use | Pros | Cons |

|—|—|—|—|

| Bugle | Drywall-to-metal and drywall-to-drywall | Optimal countersink; wide acceptance | Not ideal for heavy-duty metal-to-metal |

| Pan Framing | Wood-to-metal, high-cycle attachments | High head strength; easy engagement | Larger head may be visible on finished drywall |

| Trim | Self-drilling finish work | Smaller profile; clean look | Requires precise setup for flush driving |

4) What diameters and threads are available?

Sizes commonly stocked for drywall-to-metal include #6, #7, #8, and #10. Thread series:

– Coarse thread drywall screws: ~18 TPI (e.g., #6-9, #8-9)

– Fine thread drywall screws: ~20 TPI (e.g., #6-20)

– Self-drilling (TEK): #6-20 and #8-18 are standard for metal

Size-to-thread quick guide: