The drywall sander market has experienced steady growth over the past decade, driven by rising residential and commercial construction activities, coupled with an increasing focus on dust-free and efficient surface finishing solutions. According to Grand View Research, the global drywall tools market was valued at USD 1.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion is fueled by advancements in cordless technology, growing demand for ergonomic and high-performance tools, and stricter regulations around indoor air quality during construction. As contractors and professionals seek reliable, durable, and efficient sanding solutions, manufacturers have intensified innovation in dust extraction, motor efficiency, and user comfort. Based on market presence, product innovation, and performance metrics, the following nine companies have emerged as leading drywall sander manufacturers shaping the industry’s future.

Top 9 Drywal Sander Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Canvas

Domain Est. 1995

Website: jlg.com

Key Highlights: Canvas, the world’s first robotic drywall finishing company, provides a new class of robotic tool for the drywall finishing trade….

#2 Hyde Tools

Domain Est. 1996

Website: hydetools.com

Key Highlights: Free delivery over $50Drywall & Wall Repair Tools. Drywall & Wall Repair Tools. Joint Knives · Taping Knives · Mud Pans · Mixers · Finishing trowels · Corner Tools · Self-Adhesive …

#3 Mirka® LEROS Wall & Ceiling and Drywall Sander

Domain Est. 1997

Website: mirka.com

Key Highlights: The Mirka LEROS drywall sander helps you reach the precision and smoothness you need for a job well done. Its innovative design includes a sanding head with 180 ……

#4 Sanders

Domain Est. 1999

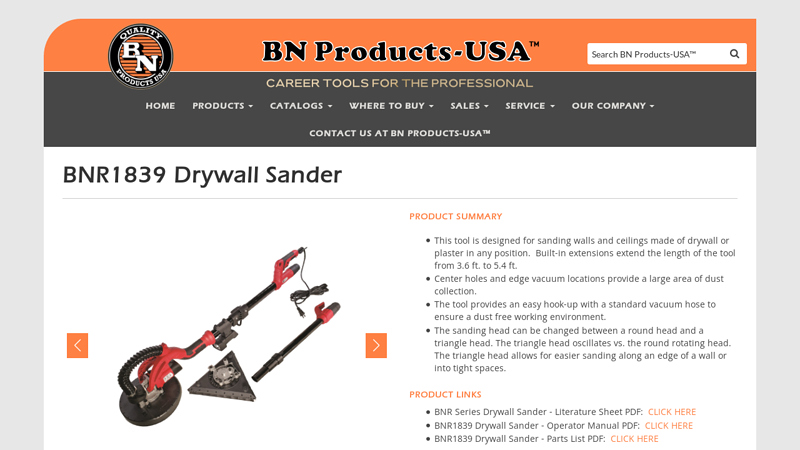

#5 BNR1839 Drywall Sander

Domain Est. 1999

Website: bnproducts.com

Key Highlights: This tool is designed for sanding walls and ceilings made of drywall or plaster in any position. Built-in extensions extend the length of the tool from 3.6 ft….

#6 Sheetrock Tools Drywall Pole Sander

Domain Est. 2001

Website: alstapingtools.com

Key Highlights: In stock Free deliverySheetrock Tools Drywall Pole Sander The drywall industries premium brand brings you an exceptionally engineered pole sander built to perform….

#7 Drywall sanders

Domain Est. 2004

Website: festoolusa.com

Key Highlights: Festool professional drywall sanders make wall and ceiling sanding fast, clean, and effortless with powerful brushless motors and nearly dust-free operation. ……

#8 Hyde Tools 09175 Dust

Domain Est. 2009

Website: hydestore.com

Key Highlights: In stock Free delivery over $30Buy Hyde Tools 09175 Dust-Free Drywall Vacuum Sander with Pole | for only $125.78 compare at Sand indoor surfaces without creating a dusty mess using…

#9 Garvee Drywall Sander 710W 800 1800RPM 6ft Handle for Ceiling …

Domain Est. 2022

Website: garvee.com

Key Highlights: Rating 4.8 (47) Discover the GARVEE Drywall Sander with a 750W motor, variable speeds, LED light, and extendable handle for flawless finishes and efficient dust collection….

Expert Sourcing Insights for Drywal Sander

H2 2026 Market Trends for Drywall Sanders

Heading into the second half of 2026, the drywall sander market is experiencing a confluence of technological innovation, sustainability demands, and evolving labor dynamics that are reshaping product development, purchasing behavior, and competitive positioning. Driven by the ongoing recovery and transformation in global construction, particularly in residential and commercial remodeling, key trends are emerging across several critical dimensions.

1. Accelerated Adoption of Smart and Connected Sanders

Smart drywall sanders equipped with IoT (Internet of Things) capabilities are moving beyond niche adoption into mainstream professional use. By H2 2026, leading manufacturers are integrating real-time dust monitoring, performance analytics, and Bluetooth connectivity into mid-to-high-end models. Contractors can now track sander efficiency, maintenance needs, and dust exposure compliance through mobile apps, improving job site safety and project management. AI-assisted sanding profiles—automatically adjusting speed and pressure based on wall condition—are becoming standard in premium rotary and pole sanders, reducing rework and enhancing finish quality. This trend is fueled by demand for data-driven workflows and improved OSHA compliance.

2. Dominance of Cordless Innovation and Battery Ecosystems

The shift toward cordless drywall sanders continues to accelerate, with major tool brands expanding their 20V and 36V brushless platforms. By H2 2026, battery life and power output have closed the performance gap with corded models, enabling professionals to complete entire drywall jobs without power cords. Interoperability within brand ecosystems (e.g., sharing batteries across sanders, drills, and lights) is a key differentiator, driving brand loyalty. Advances in lithium-ion technology have reduced weight while increasing runtime, making pole sanders more ergonomic for extended overhead work—a critical factor in reducing worker fatigue and injury.

3. Heightened Focus on Dust Containment and Health Compliance

Regulatory and health concerns are pushing dust extraction performance to the forefront. In H2 2026, drywall sanders are increasingly sold as part of integrated dust management systems, including HEPA-filtered vacuums, sealed shrouds, and real-time air quality sensors. OSHA’s silica dust regulations remain a primary driver, leading contractors to favor sanders with certified low-emission designs. Consumer demand for healthier indoor environments in residential projects is also boosting sales of sanders marketed as “low-dust” or “near-zero emission.” This trend is reinforced by green building standards like LEED and WELL, which reward clean construction practices.

4. Growth in Rental and Subscription Models

As equipment costs rise and project variability increases, rental and subscription-based access to high-end drywall sanders is gaining traction. By mid-2026, major rental chains and manufacturers offer flexible leasing programs, especially for automated or robotic sanders. Smaller contractors and DIYers benefit from access to advanced tools without large upfront investments. This model supports sustainability by extending equipment lifecycles and reducing overproduction. Additionally, some platforms include maintenance, dust bags, and training—creating value-added service ecosystems.

5. Rise of Automation and Semi-Automated Solutions

While fully autonomous drywall sanding robots remain in limited deployment, semi-automated systems are becoming more practical and affordable. In H2 2026, hybrid sanders with guided motion control and auto-leveling features are gaining adoption in large commercial projects. These systems reduce reliance on highly skilled labor and improve consistency across large wall areas. Though still a small segment, automation is seen as a strategic response to skilled labor shortages and rising labor costs, particularly in North America and Western Europe.

6. Sustainability and Circular Economy Initiatives

Environmental responsibility is influencing product design and lifecycle management. Manufacturers are increasingly using recycled plastics and recyclable components in sander housings. Refurbished and remanufactured drywall sanders are emerging as a credible alternative, supported by warranty programs and performance guarantees. Additionally, companies are introducing take-back programs for worn sanding pads and filters, aligning with broader ESG (Environmental, Social, and Governance) goals in the construction supply chain.

Conclusion

By H2 2026, the drywall sander market is defined by intelligence, connectivity, and sustainability. Professionals are prioritizing tools that enhance efficiency, ensure regulatory compliance, and integrate into digital workflows. While cordless and smart features dominate innovation, the industry’s response to labor challenges and environmental concerns will shape long-term competitiveness. Companies that combine advanced technology with holistic service models—spanning rentals, maintenance, and dust management—are best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing a Drywall Sander (Quality and Intellectual Property)

Logistics & Compliance Guide for Drywall Sander

This guide outlines the key logistics and compliance considerations for the safe and legal handling, transportation, storage, and use of drywall sanders. Adhering to these guidelines ensures operational efficiency, worker safety, and regulatory compliance.

Product Classification & Regulatory Overview

Drywall sanders are classified as power tools and fall under occupational safety and equipment regulations. Key regulatory bodies include OSHA (Occupational Safety and Health Administration) in the U.S., Health and Safety Executive (HSE) in the UK, and similar agencies internationally. These tools may also be subject to electrical safety standards (e.g., UL, CE, CSA) and noise emission regulations.

Transportation Requirements

When transporting drywall sanders:

– Secure tools to prevent movement during transit to avoid damage or injury.

– Use original packaging or protective cases where possible.

– Comply with carrier-specific rules for shipping power tools (e.g., IATA for air freight if batteries are included).

– Ensure lithium-ion battery-powered models (if applicable) meet UN 38.3 testing requirements and are shipped with proper labeling.

Storage Conditions

Store drywall sanders in a clean, dry, and temperature-controlled environment:

– Avoid exposure to moisture, extreme temperatures, or corrosive substances.

– Keep tools in their cases or on dedicated racks to prevent physical damage.

– Store away from flammable materials, especially when filters or dust bags contain combustible drywall dust.

Dust Collection & Environmental Compliance

Drywall sanding generates fine particulate matter (e.g., gypsum, silica), posing respiratory and environmental risks:

– Use sanders equipped with HEPA-filtered dust extraction systems.

– Ensure local exhaust ventilation (LEV) is used and regularly tested where applicable.

– Dispose of collected dust as non-hazardous waste, unless testing reveals hazardous components (e.g., lead-based paint residue).

– Follow EPA NESHAP (National Emission Standards for Hazardous Air Pollutants) and local air quality regulations for construction activities.

Worker Safety & PPE Requirements

Mandatory personal protective equipment (PPE) includes:

– NIOSH-approved respirator (N95 or higher, especially when silica dust is present)

– Safety goggles or face shield

– Hearing protection (drywall sanders can exceed 85 dB)

– Gloves and long-sleeve clothing to minimize skin irritation

Ensure all operators are trained on tool use, emergency procedures, and hazard recognition.

Electrical Safety & Equipment Standards

Verify that all drywall sanders:

– Bear certification marks (e.g., UL, ETL, CE) indicating compliance with electrical safety standards.

– Are used with grounded outlets and GFCI (Ground Fault Circuit Interrupter) protection, especially in damp environments.

– Undergo regular inspection for damaged cords, plugs, or housings.

Maintenance & Inspection Protocol

Implement a routine maintenance schedule:

– Inspect tools before each use for damage or wear.

– Clean dust filters and collection systems after every use.

– Replace worn sanding pads, motors, or hoses per manufacturer guidelines.

– Document inspections and repairs to demonstrate compliance.

Training & Documentation

Provide formal training for all personnel using drywall sanders, covering:

– Safe operating procedures

– Emergency shutdown

– PPE use and maintenance

– Hazard communication (e.g., SDS for associated materials)

Maintain training records, equipment logs, and compliance documentation for audits.

Disposal & End-of-Life Handling

At end-of-life:

– Recycle metal and electronic components through certified e-waste facilities.

– Dispose of plastic housings and filters according to local waste regulations.

– Remove and recycle batteries separately if applicable (following battery-specific disposal rules).

Following this guide ensures safe operations, regulatory adherence, and environmental responsibility when using drywall sanders. Always consult local regulations and manufacturer instructions for site-specific requirements.

Conclusion for Sourcing a Drywall Sander:

After evaluating various options and suppliers, sourcing a drywall sander should focus on balancing cost, quality, and long-term efficiency. Whether opting for corded or cordless models, it is essential to prioritize durability, dust extraction capabilities, ease of use, and ergonomic design to reduce operator fatigue and improve finish quality. Reputable brands offering reliable warranties and good customer support should be preferred to ensure minimal downtime and maintenance costs. Additionally, bulk purchasing or establishing a relationship with a dependable distributor can lead to cost savings and consistent supply—especially important for contractors or teams working on multiple projects. Ultimately, investing in a high-quality drywall sander enhances productivity, ensures a professional finish, and contributes to a safer, cleaner work environment, making it a worthwhile consideration in any drywall project.