The global heat exchanger market is experiencing robust growth, driven by increasing energy efficiency demands and expanding industrial applications. According to Grand View Research, the global heat exchanger market size was valued at USD 23.0 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.4% from 2024 to 2030. A rising focus on sustainable HVAC solutions and waste heat recovery systems has further intensified demand for specialized components such as dryer vent heat exchangers—particularly in residential, commercial, and industrial laundry operations. As energy costs climb and regulatory standards tighten, manufacturers are innovating to improve thermal efficiency and reduce environmental impact. This data-driven landscape sets the stage for identifying the top 10 dryer vent heat exchanger manufacturers leading the charge in performance, reliability, and technological advancement.

Top 10 Dryer Vent Heat Exchanger Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

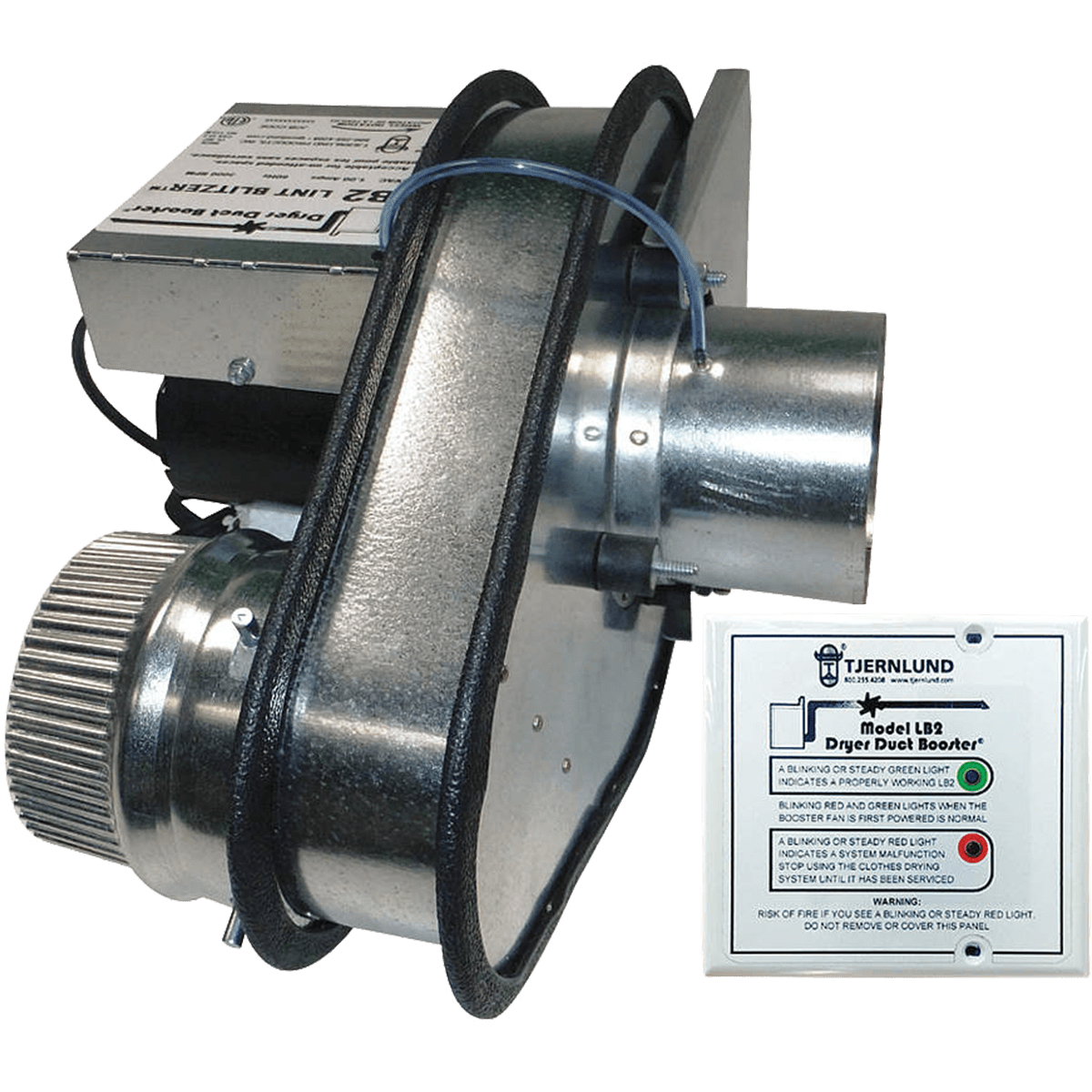

#1 Tjernlund Products, Inc.

Domain Est. 1997

Website: tjernlund.com

Key Highlights: Tjernlund Products is a premier manufacturer of mechanical ventilation and exhaust solutions tailored for both residential and commercial applications….

#2 Industrial Extruders & Dryers

Domain Est. 1995

Website: wenger.com

Key Highlights: Global Leader in Extrusion Cooking Systems. Complete process solutions for plant-based proteins, pet foods, and aquatic feed….

#3 Industrial drying solutions

Domain Est. 1997

Website: ventilex.com

Key Highlights: Ventilex is specialized in designing and manufacturing most energy efficient industrial drying solutions for food, feed and minerals….

#4 Kelvion

Domain Est. 2005

Website: kelvion.com

Key Highlights: Kelvion, your manufacturer for heat exchangers & cooling & heating solutions: plate heat exchangers, cooling heat exchangers & more!…

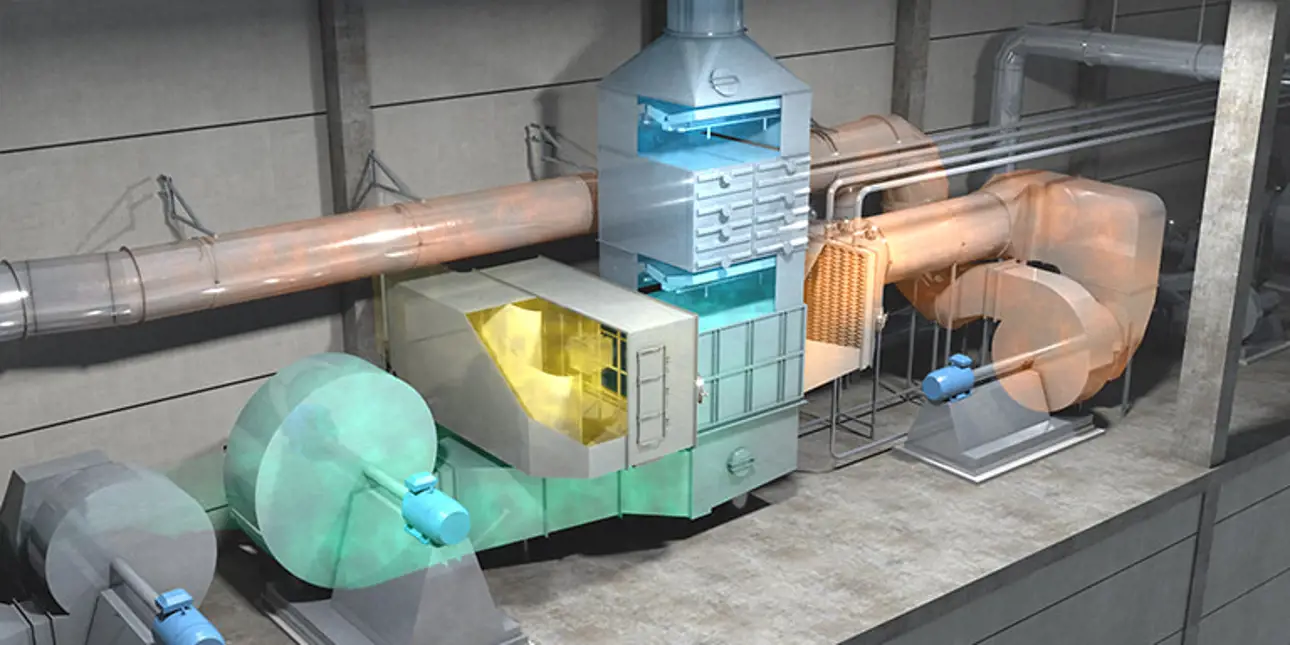

#5 OptiAir Recovery for energy-efficient heat recovery

Domain Est. 1991

Website: valmet.com

Key Highlights: OptiAir Recovery is a part of Valmet’s OptiAir family which is designed for optimal and controlled drying conditions and working environment for paper and ……

#6 Products

Domain Est. 1995

Website: greenheck.com

Key Highlights: Greenheck offers the most comprehensive line of ventilation equipment available including fans, dampers, louvers, kitchen ventilation systems, energy recovery, ……

#7 Heat Exchangers – Boyd

Domain Est. 1996

Website: boydcorp.com

Key Highlights: Efficiently reject heat from liquid cooling systems with Boyd’s custom-designed heat exchangers in aluminum and copper. Choose from tube fin, plate fin, ……

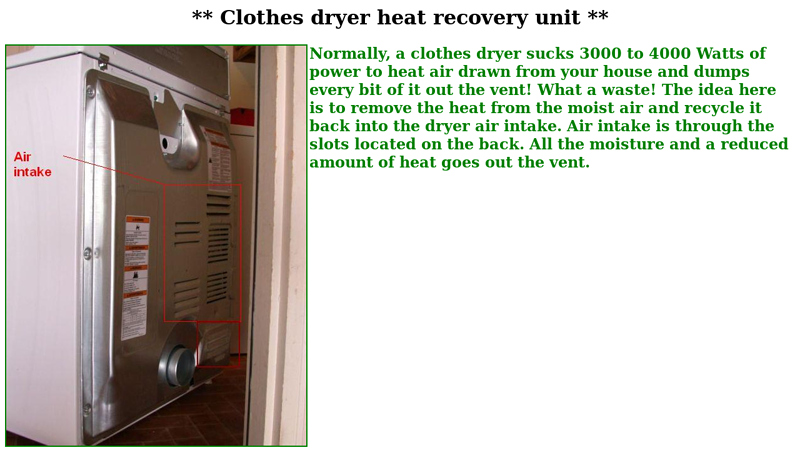

#8 Dryer heat exchanger

Domain Est. 2001

Website: alkeng.com

Key Highlights: The idea here is to remove the heat from the moist air and recycle it back into the dryer air intake. Air intake is through the slots located on the back….

#9 We simplify ventilation solutions · Fantech

Domain Est. 2002

Website: fantech.net

Key Highlights: Supplying energy-efficient ventilation products and solutions is what drives us, as does simplifying the installers’ job….

#10 ENERVEX

Domain Est. 2010

Website: enervex.com

Key Highlights: ENERVEX has developed, manufactured and sold chimney fans, mechanical draft systems, chimney and heat recovery for 30+ years…….

Expert Sourcing Insights for Dryer Vent Heat Exchanger

H2: 2026 Market Trends for Dryer Vent Heat Exchangers

The global market for dryer vent heat exchangers is poised for significant transformation by 2026, driven by rising energy efficiency standards, growing environmental awareness, and advancements in residential and commercial HVAC integration. These devices, which recover waste heat from clothes dryer exhaust to preheat air or water, are gaining traction as cost-effective solutions for reducing energy consumption and carbon emissions.

Key Trends Shaping the 2026 Market:

-

Increased Energy Efficiency Regulations

Governments worldwide are tightening building energy codes, particularly in North America and the European Union. By 2026, regulatory frameworks such as the U.S. Department of Energy’s (DOE) efficiency mandates and the EU’s Energy Performance of Buildings Directive (EPBD) are expected to incentivize or require heat recovery systems in new and retrofitted buildings. Dryer vent heat exchangers will benefit from these policies as part of broader energy recovery ventilation (ERV) strategies. -

Integration with Smart Home and Building Systems

The rise of smart HVAC and home energy management systems (HEMS) will enable dryer vent heat exchangers to communicate with thermostats, ventilation controls, and renewable energy systems. By 2026, manufacturers are expected to offer IoT-enabled models that optimize heat recovery based on real-time energy demand, occupancy patterns, and utility pricing. -

Growing Adoption in Multi-Family and Commercial Housing

With urbanization and the expansion of apartment complexes, laundromats, and dormitories, there is a scalable opportunity for centralized dryer systems equipped with heat recovery. Dryer vent heat exchangers will see increased deployment in multi-unit dwellings where cumulative energy savings are substantial, improving return on investment. -

Technological Improvements and Cost Reduction

Ongoing R&D is focused on enhancing heat transfer efficiency, reducing pressure drop in duct systems, and minimizing maintenance requirements (e.g., automated lint cleaning systems). By 2026, economies of scale and modular designs are expected to lower upfront costs, making these systems more accessible to homeowners and small businesses. -

Sustainability and Carbon Reduction Goals

As both corporations and municipalities pursue net-zero emissions targets, waste heat recovery from appliances like clothes dryers will become a strategic component of energy conservation plans. Dryer vent heat exchangers align with green building certifications (e.g., LEED, Passive House), further boosting demand in eco-conscious construction markets. -

Consumer Awareness and Incentive Programs

Energy utility rebates, tax credits (e.g., U.S. Inflation Reduction Act provisions), and public education campaigns are expected to increase consumer awareness of dryer heat recovery benefits. By 2026, these incentives will likely drive residential adoption, particularly in colder climates where space heating costs are high. -

Competitive Landscape and Market Expansion

The market will see entry from HVAC equipment manufacturers and startups specializing in energy recovery. Partnerships between appliance makers (e.g., LG, Whirlpool) and heat exchanger developers may lead to integrated dryer-heat recovery units, accelerating market penetration.

Conclusion:

By 2026, the dryer vent heat exchanger market is projected to experience robust growth, supported by regulatory tailwinds, technological innovation, and a shift toward sustainable living. While still a niche segment, increasing recognition of the energy waste associated with conventional dryers—estimated at 60–70% of input energy being expelled as hot, moist air—will solidify the role of heat recovery systems in the broader energy efficiency ecosystem.

Common Pitfalls Sourcing Dryer Vent Heat Exchanger (Quality, IP)

Sourcing a Dryer Vent Heat Exchanger (DVHE) requires careful attention to both quality and intellectual property (IP) concerns. Overlooking these aspects can lead to significant performance, safety, and legal risks.

Quality Pitfalls

- Inadequate Material Specifications: Selecting materials (e.g., aluminum, stainless steel) unsuitable for the humid, lint-laden, and potentially corrosive environment of dryer exhaust. This leads to rapid degradation, corrosion, and shortened lifespan.

- Poor Construction and Welding: Substandard manufacturing processes result in weak joints, leaks, or internal blockages. This reduces heat transfer efficiency, creates fire hazards from lint accumulation in gaps, and increases pressure drop, straining the dryer.

- Insufficient Heat Transfer Design: Units with inadequate surface area, poor fin design, or incorrect flow path geometry fail to capture sufficient heat, diminishing the energy recovery benefit and making the investment ineffective.

- Inadequate Filtration and Maintenance Access: Lack of effective lint filters or difficult access for cleaning leads to rapid clogging, drastically reducing efficiency and creating a major fire hazard. Units requiring disassembly for basic cleaning are impractical.

- Excessive Airflow Resistance: Poorly designed internal channels create high static pressure, forcing dryers to work harder, increasing energy consumption, extending drying times, and potentially voiding dryer warranties.

- Lack of Certifications and Testing: Sourcing units without independent testing data (e.g., thermal efficiency, pressure drop) or relevant safety certifications (e.g., UL, CE) introduces unknown performance and safety risks.

Intellectual Property (IP) Pitfalls

- Infringing on Patented Designs: Sourcing or manufacturing a DVHE that replicates a protected core design (e.g., specific heat exchanger geometry, unique filtration system, proprietary mounting mechanism) without a license exposes the buyer or manufacturer to costly patent infringement lawsuits.

- Using Copycat Products (“Knock-offs”): Purchasing products that are blatant copies of established, branded DVHEs often involves stolen IP. This carries legal liability, potential supply chain disruption if the copycat is shut down, and usually correlates with the quality pitfalls listed above.

- Unprotected Design Development: Failing to secure patents or maintain trade secrets on a newly developed DVHE design leaves it vulnerable to being copied by competitors immediately upon market entry.

- Unclear IP Ownership in Custom Development: When working with a manufacturer to create a custom DVHE, failing to establish clear contractual ownership of the resulting design and tooling can lead to disputes and prevent future sourcing or modification.

- Sourcing from Suppliers with Questionable IP Practices: Engaging suppliers known for reverse engineering or copying designs increases the risk that the supplied component itself infringes on third-party IP, potentially implicating the downstream buyer.

Avoiding these pitfalls requires due diligence in vetting suppliers, demanding material and performance specifications, verifying certifications, and conducting thorough IP landscape searches or securing proper legal advice before procurement or development.

Logistics & Compliance Guide for Dryer Vent Heat Exchanger

Product Overview

A Dryer Vent Heat Exchanger is a device designed to capture waste heat from clothes dryer exhaust and transfer it to incoming fresh air or water, improving energy efficiency in residential or commercial buildings. While highly beneficial for reducing energy costs and environmental impact, proper logistics handling and compliance with regulations are essential for safe and legal operation.

Shipping & Handling

- Packaging: Units should be shipped in sturdy, damage-resistant packaging with internal bracing to prevent movement during transit. Include moisture barriers if shipping to humid climates.

- Labeling: Clearly label packages as “Fragile,” “This Side Up,” and include handling instructions (e.g., “Do Not Stack”). Include product identification, model number, and weight.

- Transportation: Use freight carriers experienced in handling HVAC or mechanical equipment. Secure units to prevent shifting in transit. Avoid extreme temperature exposure during transport.

- Receiving & Inspection: Upon delivery, inspect packaging for damage. Unpack carefully and verify contents against packing slip. Report discrepancies or damage immediately to the carrier and supplier.

Storage Requirements

- Environment: Store in a dry, temperature-controlled indoor area. Avoid exposure to moisture, direct sunlight, or freezing conditions.

- Positioning: Keep units on pallets or raised surfaces to prevent floor moisture absorption. Store vertically as recommended by the manufacturer.

- Duration: Limit storage time; prolonged storage may degrade seals or insulation. Follow manufacturer guidelines for maximum storage duration.

Installation & Placement

- Clearances: Adhere to manufacturer-specified clearance requirements from walls, ceilings, and combustible materials. Typically, maintain 6–12 inches of clearance around the unit.

- Venting: Use UL-listed, rigid or semi-rigid metal ducting for all dryer vent connections. Avoid plastic or foil ducts. Ensure minimal bends and shortest possible run length (<25 ft recommended).

- Drainage (if applicable): For condensing models, provide a proper condensate drain line with a P-trap to prevent backdrafts and ensure gravity flow.

- Electrical: Connect only to a properly grounded outlet or hardwired circuit per local electrical codes. Use a dedicated circuit if specified.

Regulatory Compliance

- Building Codes: Installation must comply with the International Residential Code (IRC) and International Mechanical Code (IMC), particularly Section M1502 on dryer exhaust systems.

- Fire Safety: Follow NFPA 54 (National Fuel Gas Code) and NFPA 96 (Standard for Ventilation Control and Fire Protection) where applicable. Ensure fire dampers are installed if required.

- Energy Standards: Confirm product meets ENERGY STAR or DOE efficiency guidelines if marketed as energy-saving.

- Local Permits: Obtain necessary mechanical, electrical, or building permits prior to installation. Arrange for inspections as required by local authorities.

Environmental & Safety Regulations

- Emissions: Dryer exhaust may contain lint, moisture, and trace volatile organic compounds (VOCs). Ensure the heat exchanger does not impede proper venting or create condensation hazards.

- Material Compliance: Verify that construction materials (e.g., aluminum, stainless steel) meet RoHS (Restriction of Hazardous Substances) and REACH standards, especially for units sold in the EU.

- Disposal: At end-of-life, recycle metal components through certified e-waste or scrap metal facilities. Follow EPA guidelines for proper disposal of any insulating or electronic components.

Documentation & Certification

- User Manuals: Provide comprehensive installation, operation, and maintenance manuals in local language(s). Include safety warnings and troubleshooting guides.

- Certifications: Ensure the product carries relevant certification marks such as UL 181 (for air ducts), CSA B275 (for heat recovery ventilators), or ETL listing.

- Warranty & Support: Register product with manufacturer and retain proof of purchase. Offer customer support for compliance-related inquiries.

Maintenance & Inspection

- Schedule: Recommend biannual inspections and cleaning to prevent lint buildup in the heat exchanger core and ductwork.

- Compliance Audits: For commercial installations, conduct annual compliance checks with local code enforcement or fire safety officers.

- Recordkeeping: Maintain logs of installation, inspections, repairs, and compliance certifications for audit purposes.

Conclusion

Proper logistics, installation, and adherence to compliance standards are critical for the safe and efficient operation of Dryer Vent Heat Exchangers. By following this guide, installers, distributors, and building managers can ensure regulatory compliance, maximize energy savings, and minimize fire or operational risks. Always consult the manufacturer’s specifications and local authorities having jurisdiction (AHJs) for project-specific requirements.

Conclusion for Sourcing a Dryer Vent Heat Exchanger

In conclusion, sourcing a dryer vent heat exchanger presents a valuable opportunity to improve energy efficiency, reduce utility costs, and contribute to more sustainable household or commercial operations. By capturing and repurposing waste heat from dryer exhaust, these systems can preheat incoming air or water, thereby lowering the overall energy demand for space heating or domestic hot water.

When evaluating potential sources, it is essential to consider factors such as compatibility with existing dryer models, material durability (e.g., aluminum or stainless steel for corrosion resistance), ease of installation, and local building or ventilation codes. While commercially available heat exchangers are limited and can be relatively expensive, custom or DIY solutions offer cost-effective alternatives—provided they are designed and installed safely to avoid lint buildup, fire hazards, or reduced dryer performance.

Ultimately, successful sourcing and implementation of a dryer vent heat exchanger require a balance between practicality, safety, and efficiency. With careful selection and proper maintenance, integrating this technology can yield meaningful energy savings and support long-term environmental and economic goals.