The global drilling services market is experiencing robust expansion, driven by increasing energy demand, technological advancements, and rising offshore and unconventional resource exploration. According to a 2023 report by Mordor Intelligence, the market was valued at USD 34.5 billion in 2022 and is projected to grow at a CAGR of 4.8% through 2028. This growth is further supported by Grand View Research, which highlights the expanding shale gas activities in North America and deepwater exploration in regions like the Gulf of Mexico and West Africa as key market drivers. With digitalization, automation, and environmental compliance shaping service delivery, leading manufacturers are investing heavily in innovative drilling solutions to improve efficiency and reduce operational downtime. In this evolving landscape, the following ten companies stand out as top drilling services manufacturers, combining technological leadership, global reach, and proven performance to meet the energy sector’s most demanding challenges.

Top 10 Drilling Services Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

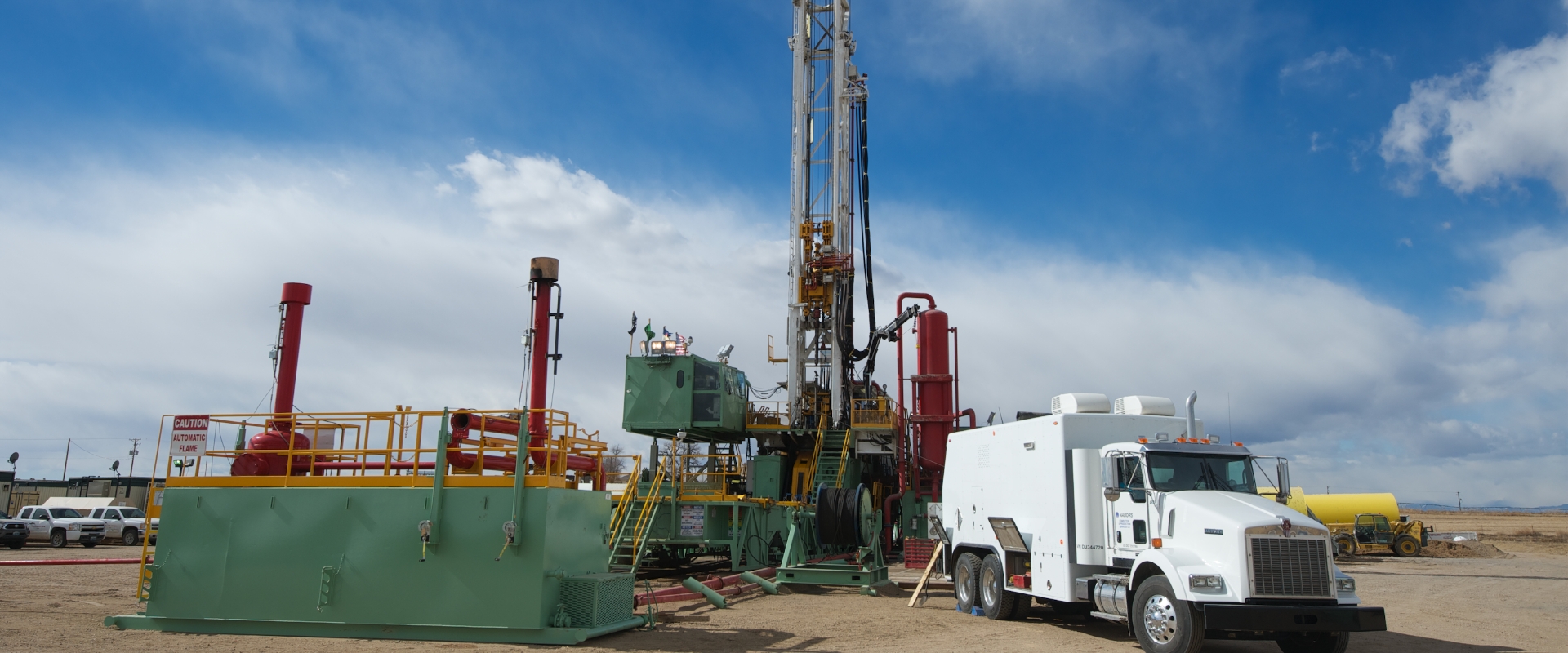

#1 Global Drilling Contractor

Domain Est. 1996

Website: hpinc.com

Key Highlights: H&P delivers innovative drilling solutions worldwide, driving safety, efficiency, & performance. Explore our drilling solutions at hpinc.com….

#2 Major Drilling Group International Inc.

Domain Est. 1996

Website: majordrilling.com

Key Highlights: Major Drilling Group International Inc. is the world’s leading provider of specialized drilling services in the metals and mining industry….

#3 Precision Drilling

Domain Est. 1997

Website: precisiondrilling.com

Key Highlights: Services · North American Drilling · International Drilling · Well Servicing · Oilfield Equipment Rentals · Camp & Catering Services….

#4 Halliburton

Domain Est. 1995

Website: halliburton.com

Key Highlights: Halliburton delivers advanced products and services to meet the evolving needs of the global energy industry, driving innovation, reliability, ……

#5 Boart Longyear

Domain Est. 1995

Website: boartlongyear.com

Key Highlights: Established in 1890, Boart Longyear is the world’s leading provider of drilling services, drilling equipment and performance tooling for mining and drilling ……

#6 Scientific Drilling

Domain Est. 1996

Website: scientificdrilling.com

Key Highlights: Our Logging While Drilling (LWD) technologies offer a comprehensive array of solutions tailored to address the challenges of your most intricate operations….

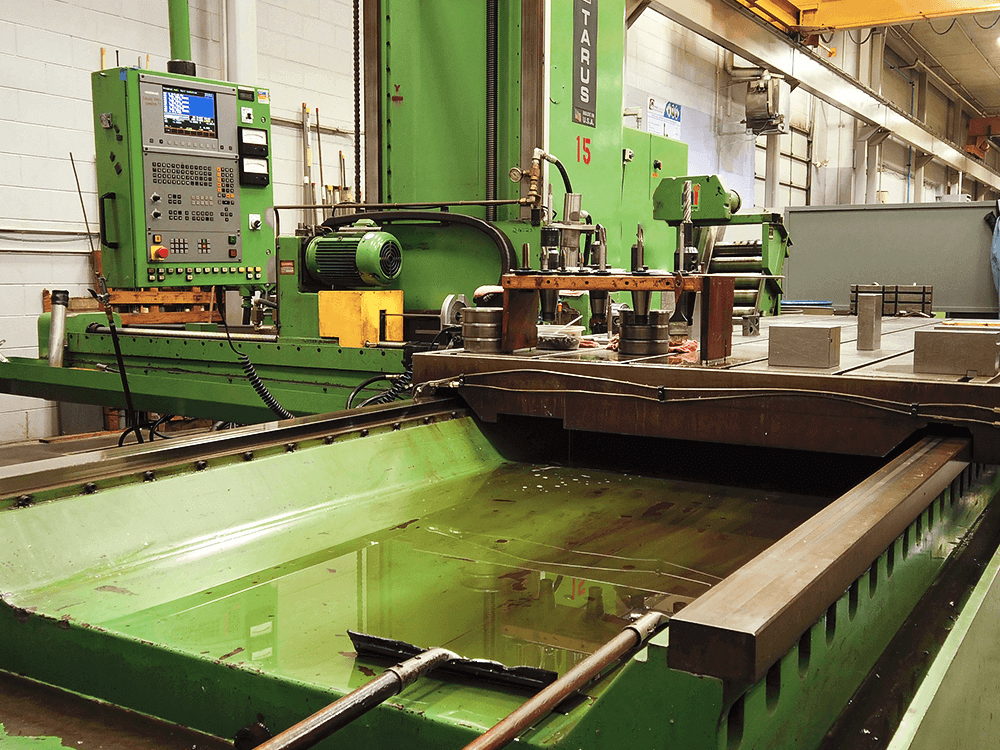

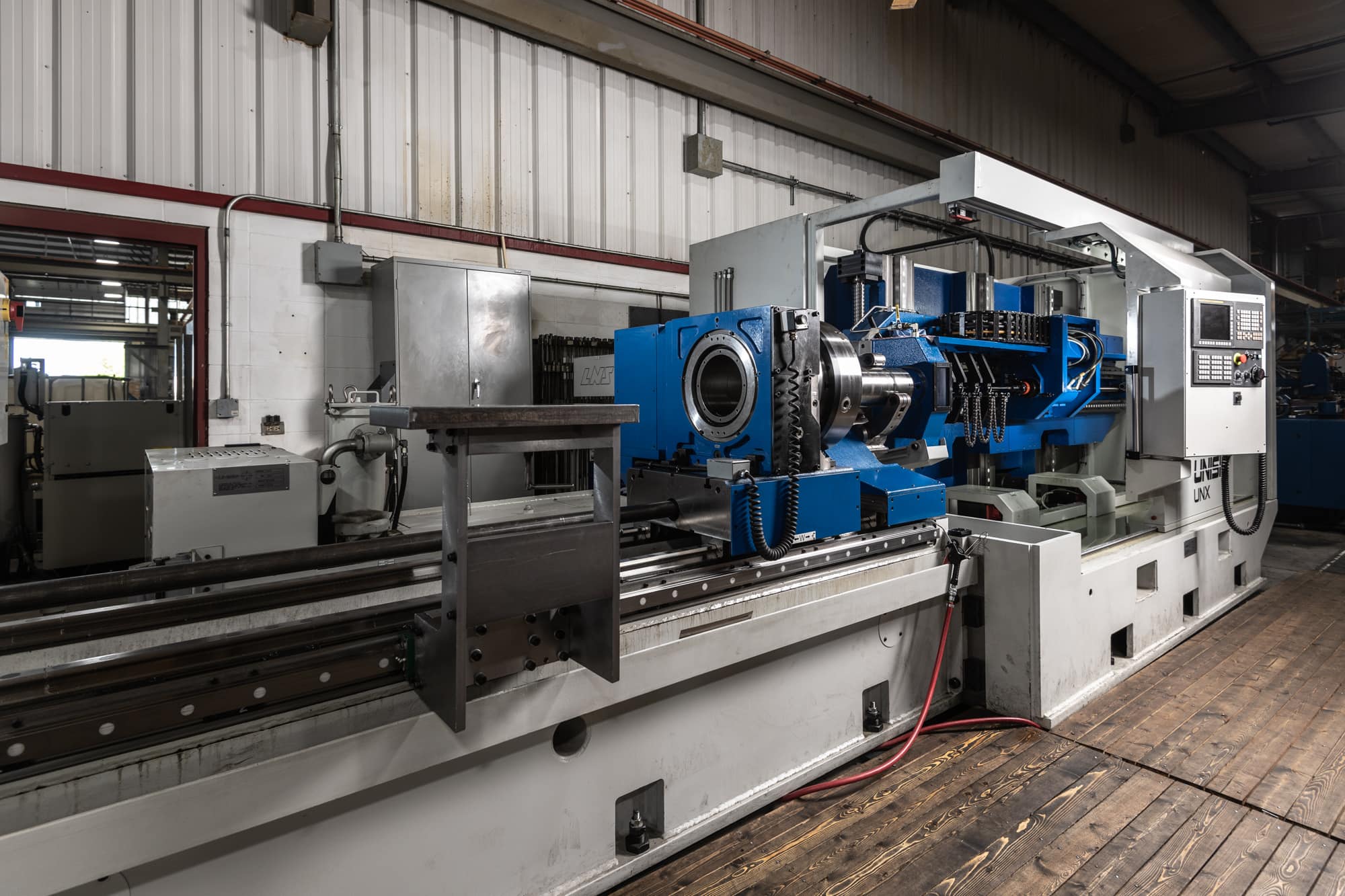

#7 Drilling Tools International

Domain Est. 1998

Website: drillingtools.com

Key Highlights: Drilling Tools International is a leading oilfield services company that manufactures and rents downhole drilling tools used in horizontal and directional ……

#8 Drilling Service Company

Domain Est. 1999

Website: drillingserviceco.com

Key Highlights: Our goal is to provide the underground construction and earth retention services that will safely and cost-effectively address your project’s needs….

#9 Arabian Drilling

Domain Est. 2004

Website: arabdrill.com

Key Highlights: Arabian Drilling is an award winning onshore and offshore gas and oil rig drilling company in Saudi Arabia with an extensive track record of operational ……

#10 Borr Drilling

Domain Est. 2016

Website: borrdrilling.com

Key Highlights: Borr Drilling is a leading international jackup drilling contractor with a strong operational track record, providing quality, safe and efficient services….

Expert Sourcing Insights for Drilling Services

H2 2026 Market Trends Analysis for Drilling Services

The global drilling services market in H2 2026 is expected to navigate a complex landscape shaped by persistent energy demand, evolving energy transition priorities, and technological advancements. While growth remains uneven across regions and segments, several key trends will define the market’s trajectory in the latter half of the year.

1. Sustained, But Selective, Demand Growth Driven by E&P Investment:

* Oil Price Stability as a Catalyst: H2 2026 will likely see oil prices stabilizing within a range ($75-$95/bbl Brent) that supports continued investment in exploration and production (E&P), particularly in key regions. This stability provides operators with the confidence to maintain or incrementally increase drilling budgets.

* Focus on “Core” Assets & Near-Term Production: Operators will prioritize drilling activity in proven, high-margin basins (e.g., Permian Basin in the US, Guyana, Brazil pre-salt, Middle East onshore) and projects with shorter development timelines. This focus favors drilling contractors with fleets suited for efficiency and rapid deployment in these specific geologies.

* Gas-Led Growth in Specific Regions: Natural gas demand, particularly in Asia and for power generation/industrial use, will drive significant drilling activity, especially in LNG export-focused projects (e.g., Mozambique, Qatar North Field Expansion, potential US Gulf Coast expansions). This benefits contractors specializing in deep onshore and offshore gas wells.

2. Offshore Resurgence Gaining Momentum:

* Deepwater & Ultra-Deepwater Revival: After years of underinvestment, H2 2026 will see a tangible acceleration in deepwater and ultra-deepwater drilling activity. Projects in Guyana, Brazil, West Africa, and the US Gulf of Mexico will be major demand drivers for high-specification jack-ups and drillships. Dayrates for modern, efficient rigs are expected to continue their upward trajectory.

* Enhanced Utilization of Modern Fleet: The market will remain tight for modern, efficient, and environmentally compliant rigs (especially 5th/6th gen floaters and high-spec jack-ups). Utilization rates for these assets are forecast to remain high (>80-85%), supporting strong pricing power for contractors.

* Focus on Efficiency & Cost Management: Despite rising dayrates, operators will intensely scrutinize non-productive time (NPT) and overall well delivery costs. Drilling service providers will need to demonstrate superior operational efficiency, reliability, and integrated solutions (e.g., drilling + completions) to win contracts.

3. Intensifying Pressure from the Energy Transition:

* ESG Mandates Driving Technology Adoption: Environmental, Social, and Governance (ESG) criteria are no longer optional. Operators and rig owners face increasing pressure to reduce emissions. This will accelerate the adoption of drilling technologies focused on:

* Emission Reduction: Widespread use of hybrid/electric rigs (especially onshore), shore power for jack-ups, low-emission engines, and methane leak detection/repair (LDAR) integrated into drilling operations.

* Drilling Waste Minimization: Advanced mud systems, closed-loop systems, and improved cuttings handling/reuse technologies will be increasingly demanded.

* “Dual-Purpose” Rigs & Flexibility: Contractors investing in rigs capable of supporting both conventional oil/gas drilling and emerging energy sources (e.g., geothermal drilling, carbon capture & storage – CCS well construction, offshore wind foundation installation) will gain a strategic advantage. Flexibility will be key.

* Regulatory Scrutiny: Stricter emissions regulations (e.g., IMO 2030/2050, regional methane rules) will impact offshore operations, potentially increasing operating costs but also creating demand for compliant solutions.

4. Technological Acceleration and Digitalization:

* AI & Data Analytics for Optimization: Artificial Intelligence and machine learning will move beyond pilots into core operations. Predictive maintenance, real-time drilling optimization (e.g., automated drilling systems), NPT prediction, and reservoir navigation will become more sophisticated, improving efficiency and safety.

* Automation and Remote Operations: Increased automation of drilling processes (e.g., pipe handling, tripping) and expansion of remote operations centers (ROCs) will continue, aiming to reduce personnel on rigs, improve safety, and enable expertise sharing across operations.

* Integrated Drilling Solutions: The market will favor service providers offering bundled, integrated solutions (drilling, logging, measurement-while-drilling, completion tools, engineering) rather than fragmented services, driven by the need for efficiency and accountability.

5. Geopolitical & Supply Chain Dynamics:

* Regional Divergence: Growth will be highly regional. The Americas (especially US shale and Latin America) and the Middle East will likely see robust activity. Asia-Pacific will be mixed (strong gas demand vs. slower oil E&P). Europe (North Sea) will see activity focused on gas and life-of-field extensions, with a strong emphasis on emission reduction.

* Supply Chain Constraints: While easing from 2022-2023 peaks, supply chain challenges (e.g., specialized equipment, skilled labor shortages, port congestion) will persist in H2 2026, potentially impacting project timelines and costs. Local content requirements will remain significant in key markets (e.g., Middle East, Latin America).

Conclusion for H2 2026:

The drilling services market in H2 2026 will operate in a state of “managed growth amidst transformation.” While fundamentals driven by sustained E&P investment, particularly offshore and in core onshore assets, support positive demand, the industry is being fundamentally reshaped. Success will depend on a contractor’s ability to:

1. Leverage Modern Assets: Capitalize on the high dayrate environment for efficient, compliant rigs.

2. Embrace Sustainability: Integrate emission-reducing technologies and transparent ESG reporting.

3. Deliver Efficiency: Utilize digital tools and integrated services to minimize costs and NPT.

4. Adapt to Energy Transition: Position for opportunities beyond traditional oil/gas, like geothermal and CCS.

Contractors failing to adapt to these converging trends risk being left behind as the market increasingly rewards innovation, efficiency, and environmental responsibility alongside operational excellence.

Common Pitfalls in Sourcing Drilling Services: Quality and Intellectual Property Risks

Sourcing drilling services—whether for oil and gas, geothermal, mining, or construction—exposes organizations to significant risks if not managed carefully. Two critical areas where problems frequently arise are quality assurance and intellectual property (IP) protection. Overlooking these aspects can lead to project delays, cost overruns, safety incidents, and loss of proprietary advantage.

Quality-Related Pitfalls

-

Inadequate Vetting of Contractor Capabilities

Selecting drilling contractors based solely on cost or availability without thoroughly assessing their technical expertise, equipment condition, and safety records can compromise operational integrity. Poorly maintained rigs or underqualified personnel increase the risk of non-compliance, downtime, and accidents. -

Lack of Clear Quality Specifications and KPIs

Failing to define measurable quality standards—such as drilling accuracy, rate of penetration, borehole stability, and adherence to environmental protocols—makes it difficult to evaluate performance. Without agreed-upon KPIs and monitoring mechanisms, deviations may go unnoticed until they cause significant issues. -

Insufficient On-Site Oversight and Reporting

Relying solely on contractor self-reporting without independent supervision or real-time monitoring can lead to undetected quality lapses. Inadequate documentation and delayed reporting further hinder timely corrective actions. -

Neglecting Industry Standards and Certifications

Working with contractors who do not comply with recognized standards (e.g., ISO 9001, API Q1/Q2, or IADC guidelines) increases the likelihood of substandard workmanship and inconsistent service delivery.

Intellectual Property-Related Pitfalls

-

Ambiguous Ownership of Drilling Data and Methodologies

Drilling operations generate valuable geotechnical, geological, and operational data. Without clear contractual terms, disputes can arise over who owns this data—the operator or the drilling contractor. Assumptions about IP ownership can lead to unauthorized use or disclosure. -

Failure to Protect Proprietary Drilling Techniques

Companies often develop unique drilling methods, mud formulations, or downhole tools. If NDA (Non-Disclosure Agreement) terms are weak or absent, contractors may use or share such proprietary information with competitors, eroding competitive advantage. -

Unsecured Data Transfer and Storage

Digital drilling data is vulnerable to cyber threats or unauthorized access. Sourcing agreements that don’t specify secure data handling protocols (e.g., encryption, access controls, data residency) expose sensitive information to potential breaches. -

Lack of Post-Contract IP Clauses

Many contracts fail to address IP rights after service completion. This oversight allows contractors to reuse project data or techniques in future bids or operations, potentially violating the client’s exclusive rights.

Mitigation Strategies

To avoid these pitfalls, organizations should:

– Conduct thorough due diligence on potential drilling service providers.

– Define precise quality requirements and audit mechanisms in contracts.

– Establish robust IP clauses specifying data ownership, permitted use, and confidentiality obligations.

– Implement secure data management practices and enforce compliance through contractual penalties.

– Engage legal and technical experts during procurement and contract negotiation.

Proactive management of quality and intellectual property concerns ensures safer, more efficient drilling operations and protects long-term business value.

Logistics & Compliance Guide for Drilling Services

This guide outlines key logistics and compliance considerations essential for the safe, efficient, and legally compliant execution of drilling operations. Adherence to these guidelines ensures operational integrity, environmental protection, and regulatory alignment across all project phases.

Equipment Transportation and Mobilization

Plan and coordinate the timely transport of drilling rigs, support equipment, and materials to and from the site. Ensure all equipment meets road, rail, or maritime transport regulations. Utilize certified carriers with experience in oversized or heavy-load transport. Conduct pre-mobility equipment inspections and verify load security, route permits, and environmental safeguards during transit.

Site Access and Infrastructure Requirements

Verify site accessibility for heavy machinery and establish necessary infrastructure, including access roads, laydown areas, and rig pads. Coordinate with local authorities for right-of-way permissions and environmental clearances. Assess ground conditions to prevent damage and ensure stability during operations. Implement erosion and sediment control measures where required.

Regulatory Permitting and Approvals

Obtain all required permits prior to commencing drilling activities. These may include environmental impact assessments (EIA), drilling permits, water use licenses, air emissions permits, and waste discharge authorizations. Maintain accurate records of all permits and ensure renewal timelines are monitored. Engage with regulatory bodies proactively to address compliance queries.

Environmental Compliance and Management

Adhere to environmental regulations by implementing a site-specific Environmental Management Plan (EMP). Control emissions, manage drilling fluids and cuttings responsibly, and prevent soil and water contamination. Employ closed-loop systems where feasible, and ensure proper handling, storage, and disposal of hazardous materials. Conduct regular environmental monitoring and reporting.

Health, Safety, and Security (HSS) Protocols

Enforce strict HSS standards in accordance with OSHA, ISO 45001, or local equivalents. Conduct comprehensive risk assessments, provide site-specific safety training, and implement emergency response plans. Mandate use of personal protective equipment (PPE), conduct routine safety audits, and maintain safety documentation. Ensure all personnel are trained in well control and spill response procedures.

Waste Management and Disposal

Develop and follow a Waste Management Plan that classifies, segregates, and tracks all waste streams (drill cuttings, spent fluids, contaminated materials). Utilize approved disposal methods such as re-injection, landfill, or recycling in compliance with environmental regulations. Maintain detailed waste manifests and disposal records for audit purposes.

Customs and Cross-Border Compliance

For international operations, ensure all equipment and materials comply with customs regulations. Prepare accurate import/export documentation, including commercial invoices, packing lists, and certificates of origin. Address duties, tariffs, and restricted item classifications. Utilize customs brokers where necessary to expedite clearance and avoid delays.

Documentation and Recordkeeping

Maintain a comprehensive compliance and logistics documentation system. Required records include equipment logs, inspection reports, training certifications, permit copies, waste manifests, and incident reports. Store documents securely and ensure accessibility for audits or regulatory inspections.

Stakeholder and Community Engagement

Engage with local communities, landowners, and indigenous groups as required. Communicate project scope, timelines, and mitigation measures transparently. Address concerns promptly and comply with social license to operate expectations. Document all community interactions and agreements.

Decommissioning and Demobilization

Plan for safe and compliant well abandonment and site restoration. Follow regulatory guidelines for plugging and abandonment (P&A), reclaiming disturbed land, and removing infrastructure. Conduct post-demobilization environmental assessments to verify site rehabilitation. Archive all project records for future reference and regulatory compliance.

Conclusion for Sourcing Drilling Services

In conclusion, sourcing drilling services requires a strategic and well-informed approach to ensure operational efficiency, safety, and cost-effectiveness. By carefully evaluating key factors such as the service provider’s technical expertise, equipment capabilities, safety record, regulatory compliance, and past performance, organizations can select a reliable partner that aligns with their project goals and timelines. Additionally, establishing clear contractual terms, fostering strong communication, and conducting ongoing performance monitoring contribute to the successful execution of drilling operations.

Ultimately, a thorough vetting process and long-term collaboration with a reputable drilling contractor not only mitigate risks but also enhance project outcomes, supporting sustainable development in the energy, mining, or construction sectors. Effective sourcing of drilling services is therefore a critical component of project success, warranting careful planning, due diligence, and continuous improvement.