The global demand for drift trikes has surged in recent years, driven by rising interest in recreational motorsports and the growing popularity of extreme youth-oriented activities. According to Mordor Intelligence, the global toy and sporting goods market—under which drift trikes are categorized—is projected to grow at a CAGR of over 5.2% from 2023 to 2028. As customization and performance enhancements become key purchasing drivers, the need for high-quality, durable components has fueled the expansion of specialized drift trike parts manufacturers. This growth is further supported by increased e-commerce penetration and DIY culture, particularly in North America and Europe. In this evolving landscape, identifying top-tier manufacturers of essential drift trike components—such as axles, knuckles, seats, and steering systems—has become critical for builders and enthusiasts aiming to optimize performance and safety. Below are the top 7 drift trike parts manufacturers leading innovation and supply in this niche yet rapidly expanding market.

Top 7 Drift Trike Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Drift Trike Factory

Domain Est. 2016

Website: drifttrikefactory.com

Key Highlights: Drift Trike Factory are Global Suppliers and manufacturers of Motorised Drift Trikes and Drift Trike Parts and other accessories….

#2 Drift Trike Parts

Domain Est. 2000

#3 Drift Trike

Domain Est. 2003

Website: gokartsusa.com

Key Highlights: In stock Free delivery over $1,200Our 49cc Drift Master with it’s heavy duty tubular steel chassis means it’s strong, durable and made to handle those sharp neighborhood corners or…

#4 Razor DXT Electric Drift Trike Parts

Domain Est. 2004

Website: monsterscooterparts.com

Key Highlights: Free delivery over $100 · 60-day returnsFind premium Razor DXT Electric Drift Trike parts, batteries, chargers, and tires. Comprehensive selection of high-quality replacement comp…

#5 Triad Drift Trikes

Domain Est. 2013

Website: triaddrifttrikes.com

Key Highlights: Parts & Accessories · Wheels · 49’er rear wheel kit · Vanguard rear wheel kit · Cartel front wheel kit · Dynasty front wheel kit · Slicks · 49’er P.P Slick….

#6 Electric Drift Trikes and Electric Bicycles

Domain Est. 2016

Website: edrifttrikes.com

Key Highlights: eDriftTrikes builds and sells high performance electric drift trikes and custom ebikes. Have a DIY project? We also sell individual components as well as full ……

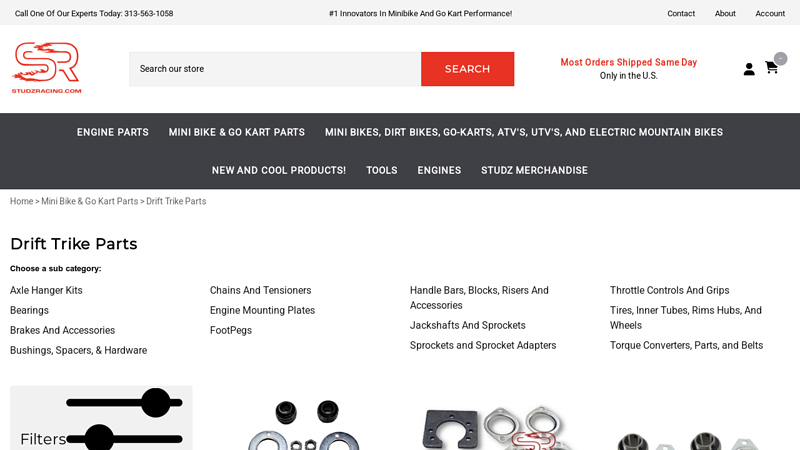

#7 Drift Trike Parts

Domain Est. 2018

Website: studzracing.com

Key Highlights: 8–15 day delivery · 30-day returnsDrift Trike Parts. Choose a sub category: Axle Hanger Kits, Bearings, Brakes And Accessories, Bushings, Spacers, & Hardware, Chains And Tensioner…

Expert Sourcing Insights for Drift Trike Parts

H2: 2026 Market Trends for Drift Trike Parts

The drift trike parts market in 2026 is poised for significant evolution, driven by technological advancements, shifting consumer preferences, and a growing global enthusiast base. While still a niche segment within the broader action sports and recreational vehicle industry, several key trends are shaping the future of component manufacturing, distribution, and innovation.

1. Rising Demand for Performance and Customization

By 2026, riders are increasingly seeking high-performance components to enhance speed, control, and drift quality. This has led to higher demand for:

– Upgraded Drift Hubs and Axles: Precision-engineered, heat-treated steel or chromoly axles with improved bearing systems to handle high lateral stress.

– Advanced Tire Technology: Softer compound, high-wear-resistant PVC or urethane drift tires designed for longer slide duration and better grip-to-slip transition.

– Customizable Frames: Modular and adjustable frame kits allowing riders to fine-tune geometry (track width, rake, wheelbase) for different riding styles and terrains.

Manufacturers are responding with tiered product lines — entry-level, performance, and pro-grade — catering to both casual riders and competitive drifters.

2. Growth in E-Commerce and Direct-to-Consumer (DTC) Models

Online sales of drift trike parts are accelerating, with specialized retailers and independent brands leveraging digital platforms:

– Global shipping enables access to international markets, particularly in Asia-Pacific and Europe, where grassroots drift trike communities are expanding.

– Augmented Reality (AR) tools are emerging, allowing customers to visualize parts on their trikes before purchase.

– Subscription-based spare part kits (e.g., tire rotation packs, bearing maintenance sets) are gaining traction for recurring revenue.

3. Material Innovation and Lightweight Engineering

Sustainability and performance are driving material shifts:

– Wider adoption of chromoly steel and aerospace-grade aluminum in frames and axles for strength-to-weight optimization.

– Use of composite materials in non-load-bearing components (e.g., fenders, fairings) to reduce overall trike weight.

– Recycling programs for worn tires and hubs are being piloted by eco-conscious brands to address environmental concerns.

4. Integration of Smart Components (Emerging Trend)

Though still in early stages, smart technology is beginning to appear:

– Bluetooth-enabled speed and drift sensors that sync with mobile apps to track performance metrics.

– Adjustable suspension kits with tunable damping, inspired by mountain biking and motocross trends.

– LED lighting integration for nighttime visibility and aesthetic appeal, especially in urban environments.

While not mainstream by 2026, these innovations signal a move toward tech-enhanced riding experiences.

5. Safety and Regulatory Awareness

As drift trikes become more popular in urban and shared spaces, safety standards are gaining attention:

– Increased demand for upgraded braking systems, including dual rear disc brakes and hydraulic front brakes.

– Certified component testing (e.g., ISO or CE standards) is becoming a differentiator among premium brands.

– Helmets, gloves, and protective gear are increasingly sold as bundled accessory kits with parts orders.

6. Regional Market Expansion and Community Building

North America and Australia remain strong markets, but growth is accelerating in:

– Southeast Asia (Thailand, Philippines) due to lower manufacturing costs and rising youth engagement.

– Europe (Germany, UK) where organized drift trike events and leagues are fostering community demand for standardized, high-quality parts.

Local meetups, online forums, and social media influencers are key drivers of brand loyalty and product feedback loops.

Conclusion:

By 2026, the drift trike parts market is transitioning from a DIY hobbyist niche to a more structured, performance-oriented industry. Success will depend on innovation in materials, responsiveness to online consumer behavior, and alignment with safety and sustainability trends. Brands that offer high-quality, customizable, and tech-integrated components while fostering community engagement are best positioned to lead the market.

Common Pitfalls Sourcing Drift Trike Parts (Quality, IP)

Sourcing parts for drift trikes—whether for building, repairing, or upgrading—can be a rewarding endeavor, but it comes with several common pitfalls, particularly concerning part quality and intellectual property (IP) issues. Being aware of these risks helps ensure a safe, legal, and high-performing build.

Poor Quality Components Compromising Safety

One of the most significant risks when sourcing drift trike parts is encountering substandard materials or manufacturing. Many components, especially online from generic marketplaces, are produced with cost-cutting in mind. Issues include:

- Weak or brittle metal alloys in axles, hubs, or steering linkages that can fail under stress.

- Inconsistent welds or poor fabrication in frames and mounts, increasing the risk of structural failure.

- Worn or imprecise bearings leading to poor handling and increased maintenance.

- Low-grade plastics or polymers in steering components or body panels that degrade quickly.

These quality shortcomings not only reduce performance but can pose serious safety hazards during high-speed drifting maneuvers.

Counterfeit or Infringing Parts (IP Violations)

Another critical pitfall is the unintentional purchase of counterfeit or IP-infringing parts. Some suppliers clone popular branded components—such as Prodigy Drift Trikes or specific aftermarket steering kits—without licensing. Risks include:

- Legal exposure, especially for resellers or commercial builders using cloned parts.

- Lack of support or warranties, as infringing products often come from untraceable sources.

- Poor fitment and performance, since reverse-engineered parts rarely match original specifications.

- Ethical concerns, as supporting IP theft undermines innovation and small manufacturers.

Always verify the authenticity of branded parts and purchase from authorized distributors or reputable builders.

Inconsistent Fitment and Compatibility

Even if parts are not counterfeit, sourcing from multiple vendors can lead to compatibility issues. Drift trikes often use a mix of custom, universal, and proprietary components. Pitfalls include:

- Mismatched bolt patterns, axle sizes, or thread types.

- Steering geometry incompatibilities affecting handling.

- Lack of standardization in aftermarket accessories (e.g., footrests, seats).

This can result in costly delays, modifications, or unsafe configurations.

Lack of Traceability and Support

Many inexpensive parts—especially those from overseas marketplaces—offer no customer service, technical documentation, or traceability. If a part fails or doesn’t perform as expected, recourse is often impossible. This lack of support makes troubleshooting and long-term maintenance difficult.

To avoid these pitfalls, prioritize suppliers with verified reviews, transparent manufacturing practices, and clear IP compliance. When possible, support original equipment manufacturers and local fabricators who stand behind their products with warranties and technical support.

Logistics & Compliance Guide for Drift Trike Parts

Overview

This guide outlines the essential logistics and compliance considerations for the import, export, storage, and distribution of drift trike parts. Adhering to these standards ensures smooth operations, regulatory compliance, and product safety across international and domestic supply chains.

International Shipping & Customs Compliance

Drift trike parts often include metal components (e.g., frames, axles), rubber tires, plastic accessories, and hardware. Each component may have distinct regulatory requirements depending on the destination country. Ensure all shipments include accurate Harmonized System (HS) codes, commercial invoices, packing lists, and certificates of origin. Be aware of import duties, tariffs, and potential anti-dumping measures, particularly when shipping from manufacturing hubs such as China or Southeast Asia.

Product Safety Standards & Certification

Drift trike parts must comply with safety standards in target markets. In the United States, parts should align with guidelines from the Consumer Product Safety Commission (CPSC), especially if marketed for children. In the European Union, compliance with the CE marking directive is required, including adherence to the Machinery Directive or Toy Safety Directive where applicable. Tires and braking components may require additional testing for durability and performance.

Hazardous Materials & Restricted Substances

Verify that no parts contain restricted substances under regulations such as REACH (EU), RoHS, or Prop 65 (California). For example, certain metal alloys, coatings, or adhesives may contain lead, phthalates, or other regulated chemicals. If packaging includes polystyrene or other controlled materials, ensure proper labeling and compliance with environmental directives.

Packaging & Labeling Requirements

All packaging must be durable enough to withstand transit and clearly labeled with product identification, part numbers, batch/lot numbers, and country of origin. Include multilingual safety warnings and usage instructions if distributing internationally. Barcodes and SKU labels should support inventory tracking and retail integration.

Storage & Inventory Management

Store parts in a dry, temperature-controlled environment to prevent corrosion (for metal parts) or degradation of rubber and plastic components. Implement a First-In, First-Out (FIFO) inventory system to minimize obsolescence. Use warehouse management systems (WMS) to monitor stock levels, expiration dates (if applicable), and traceability.

Transportation & Handling

Use appropriate freight methods (air, sea, or ground) based on part size, weight, and urgency. Secure heavy components such as frames and axles to prevent shifting during transit. Employ cushioning materials to protect fragile accessories. Partner with carriers experienced in handling automotive or recreational vehicle parts to reduce damage risks.

Returns & Reverse Logistics

Establish a clear return policy for defective or incorrect parts. Design a reverse logistics process that includes inspection, refurbishment (if possible), and proper disposal in accordance with environmental regulations. Maintain records of returned items for quality control and compliance audits.

Recordkeeping & Documentation

Retain all compliance documentation, test reports, shipping records, and supplier certifications for a minimum of five years. These records may be required during customs inspections, safety audits, or liability investigations. Digital record systems with secure backups are recommended.

Supplier & Manufacturer Compliance

Source parts only from verified suppliers who comply with ISO standards (e.g., ISO 9001 for quality management). Conduct periodic audits to ensure ongoing compliance with labor, environmental, and safety regulations. Require suppliers to provide material declarations and conformity certificates.

Conclusion

Effective logistics and compliance management for drift trike parts reduces legal risk, enhances customer trust, and ensures uninterrupted supply chain operations. Stay informed about evolving regulations in key markets and update internal procedures accordingly to maintain full compliance.

In conclusion, sourcing drift trike parts requires careful consideration of quality, compatibility, and cost. By researching reputable suppliers, comparing prices across various platforms—both online and local—and prioritizing durable, performance-oriented components, builders can ensure a reliable and high-performing drift trike. Engaging with the drift trike community can also provide valuable insights and access to hard-to-find parts. Whether building from scratch or upgrading an existing trike, a strategic sourcing approach leads to better performance, increased safety, and long-term satisfaction with the final build.