The global HVAC controls market, which includes critical components like drain pan float switches, is experiencing steady growth driven by rising demand for energy efficiency, smart building systems, and preventive maintenance solutions. According to Grand View Research, the global HVAC market size was valued at USD 158.5 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 7.1% from 2024 to 2030. Drain pan float switches—essential safety devices that prevent water damage from HVAC system condensate overflow—are becoming increasingly integral as building operators prioritize equipment protection and operational reliability. With industrial and commercial construction on the rise, especially in Asia-Pacific and North America, demand for reliable, UL-certified float switch manufacturers is growing in parallel. This increasing need has elevated the importance of selecting high-quality, durable, and code-compliant drain pan float switches—making the top manufacturers in this niche segment critical partners for OEMs, HVAC contractors, and facility managers alike.

Top 8 Drain Pan Float Switch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Secondary Drain Pan Switches

Domain Est. 1996

Website: diversitech.com

Key Highlights: Asurity Drain Pan Clip Float Switch, Bulk 50/CA. Item #:CS-3-BULK50. Asurity Drain Pan Clip Float Switch. Item #:CS-3. Asurity AC Shutoff Float Switch….

#2 Custom Float Switches For HVAC Units

Domain Est. 1996

Website: smdsensors.com

Key Highlights: Liquid float switches used in condensate traps and condensate overflow pans in A/C HVAC units help with removing excessive moisture….

#3 Safe

Domain Est. 1997

Website: rectorseal.com

Key Highlights: With innovative features and top-quality construction, our switches ensure reliable detection of clogged A/C condensate drains, preventing costly damage and ……

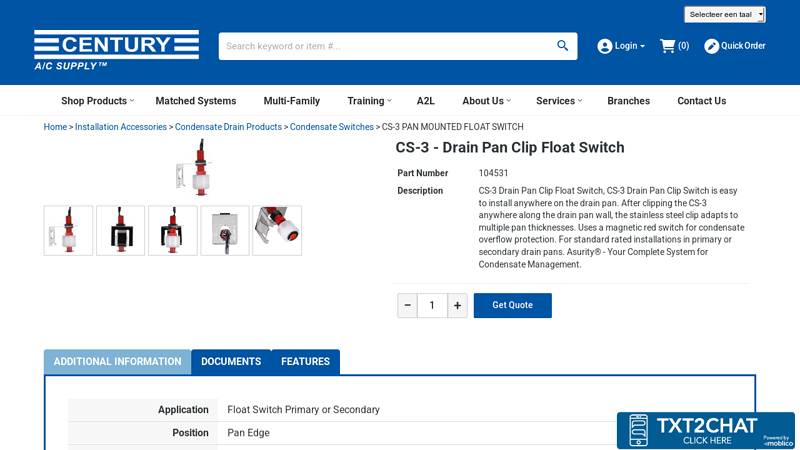

#4 CS

Domain Est. 1998

Website: centuryac.com

Key Highlights: Uses a magnetic red switch for condensate overflow protection. For standard rated installations in primary or secondary drain pans. Asurity® – Your Complete ……

#5 Condensate Switches

Domain Est. 2015

Website: lennoxpros.com

Key Highlights: Rectorseal 83413, All Access AA3 Drain Pan Float Switch. Cat #: 18P86. Model/Part #: 83413. Sign in for pricing and availability….

#6 SS2 L

Domain Est. 2016

Website: petroniatis.com

Key Highlights: The SS2 L-shape float switch is your first line of defense against clogged AC drains and overflowing drain pans. Here’s how it works: normally, the float sits ……

#7 Condensate Float Switch

Domain Est. 2020

Website: quickturn.rochestersensors.com

Key Highlights: A condensate float switch is used to detect if the drain pan if overfilling. The condensate float switch is typically wired into the HVAC or refrigeration ……

#8 Safety Overflow Pan Switch

Domain Est. 2020

Website: asurityhvacr.com

Key Highlights: The Asurity® CC-1 Safety Overflow Pan Switch is a unique clamp-on float switch intended for HVAC drain pan installation (both plastic and metal pans)….

Expert Sourcing Insights for Drain Pan Float Switch

H2: 2026 Market Trends for Drain Pan Float Switch

The global market for drain pan float switches is poised for steady growth through 2026, driven by increasing emphasis on building automation, water damage prevention, and energy efficiency in HVAC systems. These safety devices, which detect water accumulation in condensate drain pans and shut down HVAC equipment to prevent overflow, are becoming essential components in both residential and commercial infrastructure.

One key trend shaping the 2026 landscape is the integration of smart technology. Manufacturers are increasingly embedding IoT (Internet of Things) capabilities into float switches, enabling remote monitoring and real-time alerts via smartphones or building management systems (BMS). This shift toward smart HVAC solutions supports predictive maintenance and reduces service costs, making intelligent drain pan float switches particularly attractive to facility managers and smart home developers.

Another significant factor is the tightening of building codes and insurance requirements, especially in flood-prone and humid regions. Regulatory bodies and insurers are mandating the use of float switches as part of HVAC installations to mitigate water damage risks. This regulatory push is accelerating adoption across North America and parts of Europe, where liability concerns and rising insurance premiums are influencing construction standards.

Additionally, the expansion of green building certifications—such as LEED and BREEAM—is indirectly boosting demand. These standards promote efficient and sustainable HVAC operations, and float switches contribute by preventing system failures that lead to energy waste and water damage. As sustainability becomes a priority in urban development, demand for reliable auxiliary components like float switches is expected to rise.

Lastly, market consolidation and innovation are evident among key players, who are focusing on durable materials (e.g., corrosion-resistant plastics and stainless steel) and improved reliability to meet diverse environmental conditions. With HVAC systems growing more complex and climate change increasing the frequency of extreme weather events, the drain pan float switch is transitioning from a simple safety component to a critical part of resilient building infrastructure by 2026.

Common Pitfalls When Sourcing a Drain Pan Float Switch (Quality and IP Rating)

When selecting a drain pan float switch for HVAC systems, overlooking key quality and Ingress Protection (IP) factors can lead to premature failure, system damage, or safety hazards. Here are critical pitfalls to avoid:

1. Ignoring IP Rating Suitability for Environment

One of the most frequent mistakes is choosing a float switch with an inadequate IP rating for the installation environment. Using a switch with too low an IP rating in damp, humid, or washdown areas can result in internal corrosion, electrical shorts, or failure to activate. For example, an IP65-rated switch is essential in condensate pans exposed to splashing water or high humidity, while a basic IP44 model may suffice in drier indoor locations. Always match the IP rating to the environmental conditions.

2. Compromising on Build Material Quality

Low-cost float switches often use inferior plastics or metals that degrade quickly when exposed to condensate, UV light, or cleaning chemicals. This can lead to brittle housings, sticky floats, or corroded contacts. Opt for models constructed with robust, chemically resistant materials like ABS plastic, polycarbonate, or stainless steel components to ensure long-term reliability and prevent false alarms or failures.

3. Overlooking Float Mechanism Design and Reliability

Not all float mechanisms are equal. Poorly designed floats may stick, bind, or fail to move freely due to debris or mineral buildup in the pan. This can prevent the switch from triggering during an overflow. Choose switches with smooth, guided float movement and designs that minimize the risk of jamming—such as vertical float rods or ball-and-arm mechanisms with wide tolerances.

4. Assuming All Switches Are Suitable for HVAC Applications

Some generic float switches are not rated for the specific electrical loads or duty cycles of HVAC systems. Using an underspecified switch can cause contact welding, arcing, or failure to interrupt the control circuit. Ensure the switch is explicitly rated for HVAC use, with appropriate voltage/current ratings (e.g., 24VAC, 0.5A) and certified for safety standards like UL or CSA.

5. Neglecting Third-Party Certifications

Skipping verification of independent certifications can lead to sourcing substandard components. Reputable float switches should carry certifications such as UL 508 or CSA 22.2, confirming their safety and performance under real-world conditions. Lack of certification increases the risk of non-compliance and potential liability in case of system failure.

6. Failing to Consider Installation and Maintenance Access

Even a high-quality switch can underperform if it’s difficult to install or service. Avoid models that require complex mounting, lack clear wiring terminals, or are hard to inspect. Choose switches with user-friendly designs, accessible test buttons, and compatibility with standard drain pan configurations to simplify maintenance and troubleshooting.

By addressing these common pitfalls—particularly around material quality and appropriate IP protection—you can ensure reliable leak detection and protect HVAC equipment from water damage.

Logistics & Compliance Guide for Drain Pan Float Switch

This guide outlines the essential logistics and compliance considerations for the handling, distribution, installation, and regulatory adherence of drain pan float switches, commonly used in HVAC systems to prevent water damage from condensate overflow.

Product Description and Function

A drain pan float switch is a safety device installed in the condensate drain pan of air conditioning or heating units. It detects rising water levels caused by clogged drain lines or pump failure. When the water reaches a preset level, the float rises and triggers a switch that shuts down the HVAC system, preventing overflow and potential water damage.

Regulatory Compliance

Drain pan float switches must meet various safety and performance standards depending on the region and application.

North America (USA & Canada)

- UL 207: Standard for Electric Motors and Generators – Applies to components within HVAC systems.

- UL 508: Standard for Industrial Control Equipment – Covers the switch mechanism if used in control circuits.

- CSA C22.2 No. 14: Control Devices (Canada) – Equivalent to UL 508 for Canadian markets.

- NEC (National Electrical Code) Compliance: Installation must follow Article 240 and Article 440 for proper circuit protection and HVAC-specific requirements.

- Energy Policy Act (EPCA): While not directly regulating switches, compliance may be indirectly required when integrated into energy-efficient HVAC systems.

European Union

- CE Marking: Required for sale within the EU.

- Low Voltage Directive (LVD) 2014/35/EU: Ensures electrical safety.

- EMC Directive 2014/30/EU: Addresses electromagnetic compatibility.

- RoHS Compliance (2011/65/EU): Restricts hazardous substances such as lead, mercury, and cadmium.

- REACH (EC 1907/2006): Requires disclosure of Substances of Very High Concern (SVHC).

International Standards

- IEC 60947-5-1: Low-voltage switchgear and controlgear – Part 5-1: Control circuit devices and switching elements – Applies to switch functionality and reliability.

- IEC 60529 (IP Code): Defines ingress protection ratings. Most float switches should meet at least IP65 for dust and water resistance.

Packaging and Labeling Requirements

Proper packaging and labeling ensure product integrity and regulatory compliance during shipping and handling.

- Primary Packaging: Individual units should be sealed in anti-static or moisture-resistant bags to protect electrical contacts.

- Labeling:

- Product name and model number

- Manufacturer or distributor name and address

- Voltage and current ratings (e.g., 120V AC, 0.5A)

- Certifications (e.g., UL Listed, CE Mark)

- RoHS and REACH compliance symbols (if applicable)

- Installation warnings and handling instructions

- Multilingual Labels: Required for international distribution (e.g., English, French, German, Spanish).

Shipping and Distribution

Domestic Shipping (USA/Canada)

- Use standard parcel or freight services depending on volume.

- Follow carrier guidelines (e.g., UPS, FedEx, LTL carriers) for package dimensions and weight.

- Include a packing slip and commercial invoice (for B2B shipments).

International Shipping

- Commercial Invoice: Must include HS Code (e.g., 8536.50 for electrical switches), country of origin, and declared value.

- Export Documentation: Required for customs clearance (e.g., Certificate of Origin, Shipper’s Letter of Instruction).

- HS Code Guidance: Typically 8536.50.90 (other switches) or 8415.90 (HVAC parts) depending on classification.

- Import Restrictions: Verify destination country regulations (e.g., India’s BIS, Australia’s RCM mark).

Storage Conditions

- Store in a dry, temperature-controlled environment (5°C to 35°C recommended).

- Avoid exposure to direct sunlight, corrosive chemicals, or high humidity.

- Shelf life: Typically 2–3 years when stored properly.

Installation and Safety Compliance

Proper installation ensures compliance with building and safety codes.

- Qualified Personnel: Must be installed by licensed HVAC technicians.

- NEC 2023 (U.S.): Section 440.61 requires safety controls for condensate removal.

- International Mechanical Code (IMC): Section 307.2 mandates secondary drain overflow protection.

- Manufacturer Instructions: Always follow installation manual to maintain warranty and compliance.

Environmental and Disposal Compliance

- WEEE Directive (EU): Waste Electrical and Electronic Equipment – Producers must facilitate recycling.

- EPA Guidelines (USA): While not classified as hazardous waste, switches containing minimal lead or plastics should be disposed of via electronic waste programs.

- Recycling: Encourage end-users to recycle through certified e-waste handlers.

Warranty and Support

- Standard warranty: 1–2 years, subject to registration and proper installation.

- Technical support: Provide access to installation guides, FAQs, and direct support channels.

- Compliance with Magnuson-Moss Warranty Act (USA): Warranties must be clearly disclosed.

Summary

Adherence to logistics and compliance standards ensures that drain pan float switches are safely delivered, legally sold, and correctly installed. Distributors and installers must verify certifications, follow packaging and shipping protocols, and maintain documentation to meet regional and international requirements.

Conclusion:

After evaluating various sourcing options for a drain pan float switch, it is clear that selecting the right supplier involves balancing factors such as product quality, reliability, cost, and availability. Original Equipment Manufacturer (OEM) parts offer guaranteed compatibility and performance but may come at a higher price point. Aftermarket alternatives can provide cost savings and faster delivery, but require careful vetting to ensure they meet safety and operational standards.

Key considerations include the specific application requirements (e.g., HVAC systems, condensate management), necessary certifications (such as UL or CSA), and compatibility with existing systems. Additionally, establishing relationships with reputable suppliers—whether distributors, online industrial platforms, or local vendors—can ensure long-term reliability and support.

In conclusion, the optimal sourcing strategy involves selecting a high-quality, code-compliant float switch from a trusted supplier that meets technical specifications while offering value and dependable service. Regular maintenance and proper installation are equally important to maximize the effectiveness and lifespan of the drain pan float switch in preventing water damage and system failures.