The global drain floor strainer market is experiencing steady growth, driven by increasing infrastructure development, stringent building regulations, and rising demand for efficient wastewater management systems. According to a report by Mordor Intelligence, the global floor drain market was valued at USD 5.8 billion in 2023 and is projected to grow at a CAGR of 5.2% over the forecast period (2024–2029). This expansion is fueled by urbanization, commercial construction, and industrial facility upgrades, particularly across North America, Europe, and the Asia Pacific regions. As demand for durable and code-compliant drainage solutions rises, manufacturers are focusing on innovative materials such as stainless steel, cast iron, and corrosion-resistant polymers to meet diverse application needs. In this evolving landscape, selecting the right drain floor strainer manufacturer is critical for ensuring long-term performance and compliance with industry standards. Below is a data-driven look at the top nine manufacturers leading the market through innovation, quality, and global reach.

Top 9 Drain Floor Strainer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Floor Drains

Domain Est. 1995

Website: zurn.com

Key Highlights: Commercial floor drains from Zurn provides a complete plumbing fixtures of line floor drains that are durable and easy to install….

#2 Floor & Area Drains

Domain Est. 1995

Website: watts.com

Key Highlights: There’s no corner cutting with Watts specification grade floor and area drains. Epoxy coating, ductile iron grating, and solid nickel bronze top assemblies….

#3 Commercial Drain Strainers

Domain Est. 1996

Website: oatey.com

Key Highlights: Oatey® Commercial Drain Strainers are an essential component for commercial drainage systems, effectively preventing smaller debris and unwanted objects ……

#4 BLÜCHER

Domain Est. 1996

Website: blucher.com

Key Highlights: Our product range comprises more than 2,500 products, including standard and customized floor drains & channels, pipes & fittings, marine drains & penetrations, ……

#5 Floor Drains with Adjustable Strainer Heads

Domain Est. 1996

Website: jrsmith.com

Key Highlights: A versatile drain for finished floors · Constructed of cast iron with a corrosion resistant coating · Highly customizable through optional add-ons · Reversible ……

#6 On-Grade Floor Drains

Domain Est. 1997

Website: siouxchief.com

Key Highlights: On-Grade Floor Drains · Available with nickel bronze, stainless steel or ABS strainer for use in pedestrian areas · Prop 65 WARNING….

#7 Wade Drainage

Domain Est. 1998

#8 Drains and strainers for restaurants and commercial kitchens

Domain Est. 2013

Website: drain-tech.com

Key Highlights: Free delivery 30-day returnsA Drain-Net™ brand drain strainer captures all the food scraps, solids, and trash that would otherwise clog your floor drains….

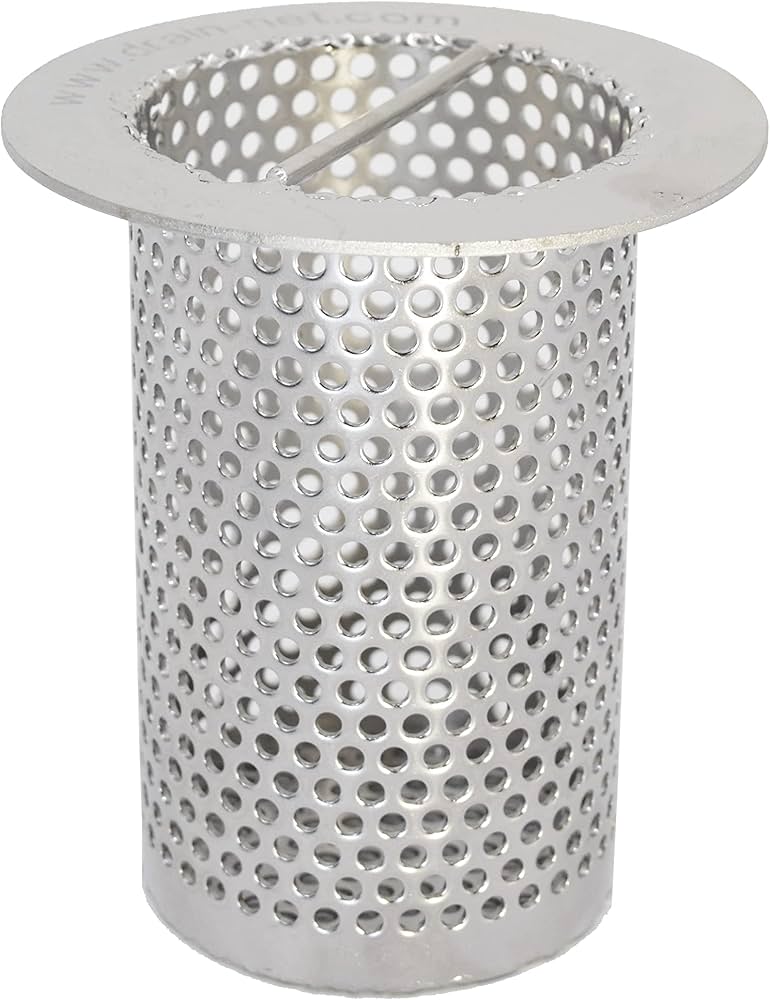

#9 Floor Drain Baskets

Domain Est. 2020

Website: tundrafmp.com

Key Highlights: 10-day deliveryGet floor drain baskets for your commercial business, & find many more drains at TundraFMP Restaurant Supply….

Expert Sourcing Insights for Drain Floor Strainer

H2: 2026 Market Trends for Drain Floor Strainers

The global drain floor strainer market is poised for steady growth by 2026, driven by increasing urbanization, stricter building regulations, and rising demand for efficient drainage solutions across residential, commercial, and industrial sectors. Key trends shaping the market include:

-

Growing Infrastructure Development

Rapid urbanization, especially in emerging economies across Asia-Pacific, Latin America, and Africa, is fueling construction activities. New residential complexes, shopping malls, and industrial facilities require robust drainage systems, boosting demand for high-performance floor strainers. -

Emphasis on Hygiene and Sanitation

Post-pandemic, there is heightened awareness of sanitation in public and commercial spaces such as hospitals, food processing plants, and airports. This has led to increased adoption of stainless steel and antimicrobial-coated drain strainers that prevent clogging and bacterial growth. -

Sustainability and Eco-Friendly Materials

Manufacturers are shifting toward recyclable and corrosion-resistant materials like recycled stainless steel and composite polymers. Green building certifications (e.g., LEED, BREEAM) are encouraging the use of sustainable drainage components, including eco-conscious floor strainers. -

Smart Drainage Integration

By 2026, smart building technologies are expected to incorporate IoT-enabled drainage monitoring systems. Some advanced floor strainers may include sensors to detect blockages, water levels, or maintenance needs, improving efficiency in large facilities. -

Regulatory Compliance and Safety Standards

Stricter plumbing codes and safety regulations in North America and Europe are mandating the use of load-rated, slip-resistant, and vandal-proof strainers in public installations. These requirements are driving innovation in design and material engineering. -

Rise in Industrial and Commercial Renovations

The retrofitting of older buildings to meet modern drainage standards is creating replacement demand. Commercial kitchens, breweries, and manufacturing plants are upgrading to heavy-duty strainers capable of handling grease, debris, and high flow volumes. -

Regional Market Dynamics

While North America and Europe remain mature markets with steady demand, the Asia-Pacific region is expected to witness the highest growth due to expanding construction and industrial activities in countries like China, India, and Vietnam.

In conclusion, the drain floor strainer market in 2026 will be shaped by technological innovation, regulatory demands, and sustainability trends. Manufacturers who focus on durability, design efficiency, and smart integration will gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Drain Floor Strainers (Quality and IP Rating)

Sourcing drain floor strainers requires careful attention to both material quality and Ingress Protection (IP) ratings to ensure durability, safety, and performance. Overlooking key aspects can lead to premature failure, safety hazards, or non-compliance. Below are common pitfalls to avoid:

1. Ignoring Material Quality and Corrosion Resistance

One of the most frequent mistakes is selecting strainers made from substandard materials. Low-grade stainless steel (e.g., non-304 or 316 grades), thin-gauge metals, or inferior castings can corrode quickly—especially in wet, chemical-rich, or outdoor environments. This leads to structural weakness, unsightly rust, and potential safety risks.

Avoid by: Specifying high-quality materials like 304 or 316 stainless steel, galvanized steel with proper coating, or heavy-duty polypropylene for corrosive environments. Request material certifications and conduct spot checks on deliveries.

2. Overlooking IP Rating Requirements

The IP (Ingress Protection) rating indicates the level of protection against solid objects and liquids. Many buyers assume all drain strainers are inherently waterproof, but without the correct IP rating (e.g., IP68 for full submersion), water or debris may enter surrounding systems, especially in washdown or outdoor areas.

Avoid by: Clearly defining the environmental conditions (e.g., high-pressure cleaning, standing water, dust exposure) and selecting strainers with appropriate IP ratings. Confirm IP certification through third-party testing documentation.

3. Assuming All Strainers Are Load-Rated for Their Application

Floor strainers in industrial, commercial, or vehicular areas must support specific load weights. Using a lightweight strainer in a forklift traffic zone can result in cracking, collapse, or injury.

Avoid by: Matching the strainer’s load class (e.g., EN 1433 standards: A15, B125, C250, D400) to the intended location. Verify load ratings with the supplier and ensure compliance with local building codes.

4. Neglecting Drainage Efficiency and Clog Resistance

Poorly designed strainers with inadequate aperture size or layout can lead to slow drainage and frequent clogging—especially in kitchens, workshops, or car washes. Some budget models have small openings or suboptimal flow patterns.

Avoid by: Evaluating hydraulic performance and debris-handling capacity. Choose designs with wide slots or perforations suited to the expected debris type (e.g., hair, leaves, grease).

5. Failing to Verify Compliance and Certifications

In regulated environments (e.g., food processing, healthcare), strainers may need to meet hygiene standards (e.g., NSF, EHEDG) or fire safety codes. Sourcing non-compliant products can lead to failed inspections or liability issues.

Avoid by: Requesting relevant certifications and ensuring the product meets industry-specific requirements. Confirm traceability and compliance documentation.

6. Choosing Based on Price Alone

Opting for the cheapest available option often results in poor durability, frequent replacements, and higher lifecycle costs. Low-cost strainers may lack proper finishing, welding integrity, or design precision.

Avoid by: Conducting a total cost of ownership analysis. Invest in higher-quality strainers that reduce maintenance, downtime, and replacement frequency.

By addressing these common pitfalls—particularly around material integrity and correct IP ratings—buyers can ensure reliable, safe, and long-lasting drainage solutions.

Logistics & Compliance Guide for Drain Floor Strainer

Product Classification and Documentation

Ensure accurate product classification using the Harmonized System (HS) code, typically 7325.10 or 7326.90, depending on material and design. Maintain up-to-date commercial invoices, packing lists, and certificates of origin to support customs clearance. Confirm product specifications, including material composition (e.g., stainless steel, brass), dimensions, and load rating, are clearly documented for compliance with international trade standards.

Packaging and Labeling Requirements

Package drain floor strainers securely to prevent damage during transit, using moisture-resistant and crush-proof materials. Clearly label each package with product type, quantity, HS code, country of origin, and handling instructions (e.g., “Fragile,” “This Side Up”). Ensure labeling complies with destination country regulations, including language requirements and safety markings where applicable.

Import/Export Regulations

Verify compliance with import regulations in the destination country, including sanitary, environmental, and construction standards (e.g., ASTM, EN, or ISO standards). Some markets may require product certification or third-party testing for plumbing components. Monitor export control lists to confirm the product is not subject to restrictions, especially when shipping to sanctioned regions.

Transportation and Freight Considerations

Choose appropriate freight mode (air, sea, or land) based on shipment size, urgency, and cost. For sea freight, ensure proper container loading and use of desiccants to prevent corrosion. Declare accurate weight and dimensions for freight classification. Utilize Incoterms (e.g., FOB, CIF) clearly in contracts to define responsibilities for shipping, insurance, and risk transfer.

Customs Clearance and Duties

Prepare all required customs documentation in advance, including import licenses if necessary. Be aware of applicable tariffs, VAT, or anti-dumping duties on metal fixtures in the destination market. Engage a licensed customs broker in the importing country to facilitate smooth clearance and resolve any inspection requests promptly.

Environmental and Safety Compliance

Confirm that materials used in the drain floor strainer comply with environmental regulations such as REACH (EU) or TSCA (USA), particularly regarding restricted substances like lead content. If applicable, provide Environmental Product Declarations (EPD) or Material Safety Data Sheets (MSDS). Ensure manufacturing processes adhere to local environmental standards to avoid compliance issues during audits.

Recordkeeping and Audit Preparedness

Maintain comprehensive records of all shipments, compliance certifications, test reports, and correspondence with regulatory authorities for a minimum of five years. Implement a traceability system to track batch numbers and production dates. Regularly review logistics and compliance procedures to align with evolving international trade laws and standards.

Conclusion for Sourcing Drain Floor Strainer:

In conclusion, sourcing a suitable drain floor strainer requires a balanced assessment of material quality, durability, compliance with industry standards, and cost-effectiveness. The selection should align with the specific application environment—whether residential, commercial, or industrial—taking into account factors such as load capacity, corrosion resistance, and ease of maintenance. Engaging reliable suppliers with proven track records, competitive pricing, and timely delivery is essential to ensure consistent product quality and project efficiency. By conducting thorough market research, evaluating technical specifications, and considering long-term performance, organizations can make informed procurement decisions that enhance functionality, safety, and sustainability in drainage systems.