The global agricultural machinery market, valued at USD 178.7 billion in 2023, is projected to grow at a CAGR of 5.8% through 2030, driven by rising demand for efficient soil preparation tools and precision farming technologies (Grand View Research, 2024). Within this landscape, drag chain harrows—essential for field leveling, residue management, and seedbed preparation—have seen renewed interest due to their durability and low maintenance. Increasing mechanization in emerging markets, coupled with a shift toward sustainable tillage practices, has fueled demand for high-performance harrowing equipment. As farmers seek solutions that enhance soil health and operational efficiency, manufacturers are innovating with heavier-duty chains, modular designs, and compatibility across tractor sizes. Based on market traction, product range, and technological advancements, we’ve identified the top 9 drag chain harrow manufacturers leading this segment’s growth.

Top 9 Drag Chain Harrow Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 to METALX

Domain Est. 2009

Website: chainharrows.com

Key Highlights: We are the manufacturer of world’s best Chain Link Drag Harrows and specialize in wire rod fabrications. Click on the picture for more information….

#2 Chain Harrows

Domain Est. 1996

Website: priefert.com

Key Highlights: Priefert’s pull-style chain harrows are a versatile tool that can be easily attached to a small tractor, riding mower, or ATV for a multitude of uses….

#3 Harrows

Domain Est. 1998

Website: williamhackett.co.uk

Key Highlights: We’ve been making chain harrows from our inception in 1892. Using our Robomac automated bending machines, each harrow is consistently built with quality and ……

#4 Drag Harrows

Domain Est. 1999

Website: taylorpittsburgh.com

Key Highlights: Taylor Pittsburgh’s Drag Harrows are the ideal tool for pasture renovation and maintenance. The Drag Harrows spread and incorporate manure, thatch dead growth….

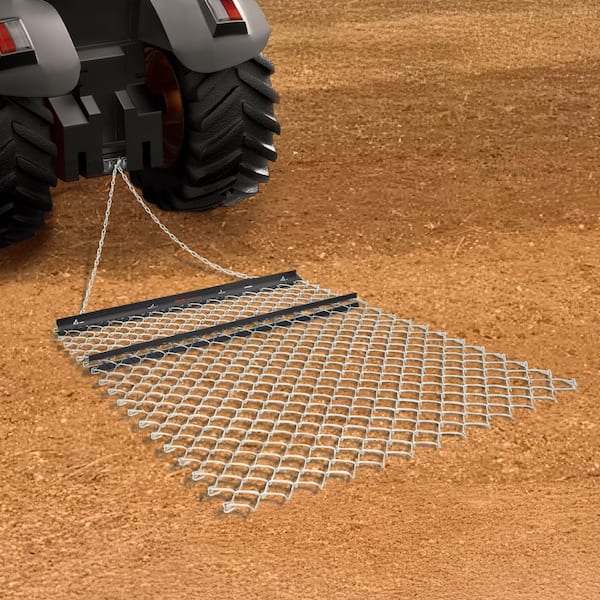

#5 Drag Harrow

Domain Est. 2000

Website: behlencountry.com

Key Highlights: Smooth gravel driveways, level riding arenas, clean up pastures, and tackle countless tasks around your land with Drag Harrows from Behlen Country….

#6 May

Domain Est. 2006

Website: maybridgeharrows.com

Key Highlights: May-Bridge Harrows manufactures high-quality chain harrows for a variety of agricultural sectors. © 2021 May-Bridge Harrows. Contact Us….

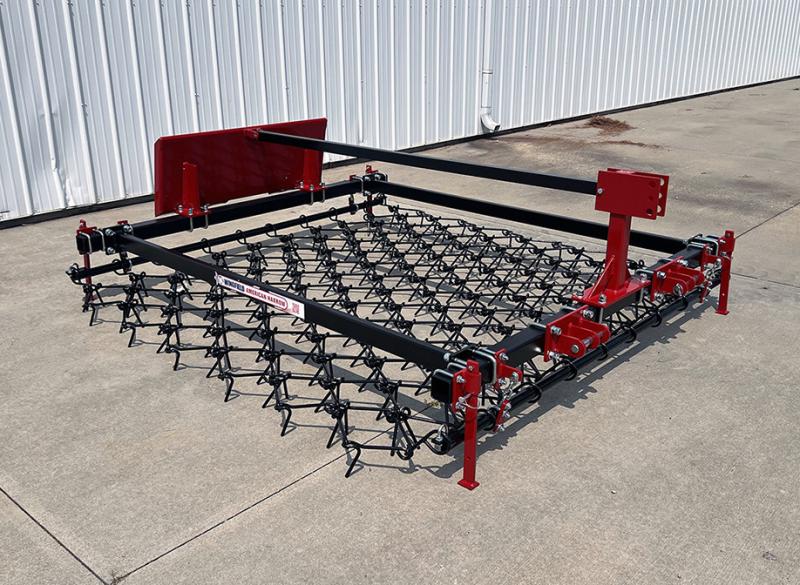

#7 Wingfield American Harrow

Domain Est. 2012

Website: americanharrow.com

Key Highlights: In order to create the strongest chain drag harrow for sale on the market today, we use a high-quality, DRAWN, spring-steel harrow tine. We designed our harrows ……

#8 Harrows

Domain Est. 2018

Website: mcfarlaneag.com

Key Highlights: McFarlane harrows provide superior performance for field finishing, field preparation, and chemical incorporation….

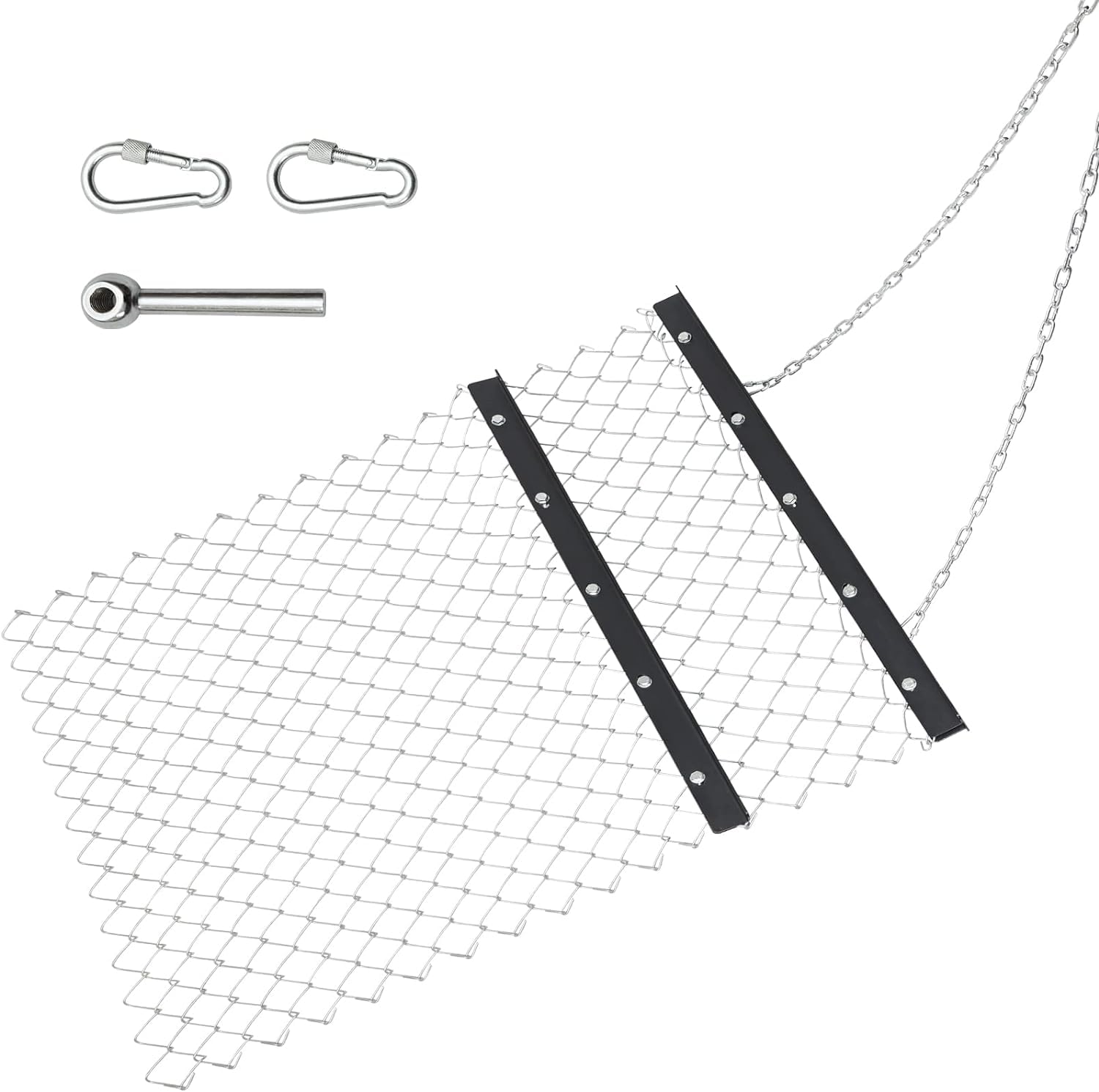

#9 GARVEE 4x3ft ATV Chain Drag Harrow

Domain Est. 2022

Expert Sourcing Insights for Drag Chain Harrow

H2: 2026 Market Trends for Drag Chain Harrow

The global market for drag chain harrows is projected to experience steady growth by 2026, driven by advancements in agricultural mechanization, increasing demand for soil preparation efficiency, and a rising focus on sustainable land management practices. Below is a detailed analysis of the key market trends expected to shape the drag chain harrow industry in 2026:

-

Increased Adoption in Sustainable Agriculture

As sustainable farming practices gain momentum worldwide, farmers are turning to low-impact tillage methods. Drag chain harrows, known for their minimal soil disturbance and effective residue management, are becoming a preferred choice for conservation tillage. This trend is particularly strong in North America and Europe, where regulatory support for eco-friendly farming is robust. -

Growth in Small- to Mid-Scale Farming

The global rise in smallholder and family-run farms—especially in regions like Southeast Asia, Sub-Saharan Africa, and Latin America—is boosting demand for affordable, versatile tillage equipment. Drag chain harrows, with their relatively low cost and ease of use, are well-suited for these operations, contributing to market expansion. -

Technological Integration and Design Innovation

By 2026, manufacturers are expected to introduce smart enhancements such as adjustable chain configurations, modular designs, and compatibility with GPS-guided tractors. These innovations will improve precision, reduce labor costs, and increase operational efficiency, making drag chain harrows more appealing to tech-savvy farmers. -

Expansion in Emerging Markets

Countries in Africa, India, and parts of South America are investing heavily in agricultural infrastructure. As access to mechanized equipment improves, demand for cost-effective tools like drag chain harrows is set to rise. Government subsidies and agricultural development programs will further accelerate adoption. -

Shift Toward Multi-Purpose Equipment

Farmers are increasingly seeking machinery that performs multiple functions. Modern drag chain harrows are being designed to integrate with seeders, rollers, and cultivators, allowing for combined operations such as harrowing and seeding in a single pass. This versatility is expected to drive product demand. -

Environmental and Regulatory Support

With growing awareness of soil health and erosion control, regulatory bodies are promoting reduced-tillage practices. Drag chain harrows align well with these goals by leveling soil, breaking up clods, and managing crop residue without deep inversion. Supportive policies are likely to bolster market growth through incentives and education. -

Competitive Landscape and Market Consolidation

The drag chain harrow market is seeing increased competition among regional and global manufacturers. Companies are focusing on product differentiation, distribution networks, and after-sales service to gain market share. Strategic partnerships and mergers are anticipated, particularly as larger agricultural equipment firms expand their tillage portfolios.

In summary, the 2026 drag chain harrow market will be shaped by sustainability trends, technological improvements, and rising demand in developing regions. As agriculture continues to evolve toward efficiency and environmental stewardship, drag chain harrows are poised to play an essential role in modern soil preparation systems.

Common Pitfalls When Sourcing Drag Chain Harrows (Quality and Intellectual Property)

Poor Material Quality and Construction

One of the most frequent issues when sourcing drag chain harrows—especially from low-cost manufacturers—is substandard material quality. Inferior steel or inadequate heat treatment can lead to rapid wear, chain breakage, and structural failure under field conditions. Buyers may receive harrows with inconsistent link dimensions, weak welds, or rust-prone components, significantly reducing equipment lifespan and reliability.

Inadequate Chain and Link Durability

Low-quality chains often use incorrect pitch, poor-grade alloys, or imprecise manufacturing tolerances. This results in uneven wear, increased maintenance, and potential disengagement during operation. Chains that are not properly hardened or galvanized will degrade faster when exposed to soil abrasion and moisture, leading to costly replacements and downtime.

Lack of Design Standardization and Compatibility

Many sourced drag chain harrows fail to adhere to industry-standard dimensions or hitch configurations. This lack of compatibility can prevent integration with existing tractors or implements, requiring costly modifications. Non-standard designs may also compromise effective soil penetration and residue management, reducing overall field performance.

Absence of Intellectual Property (IP) Due Diligence

Sourcing from manufacturers that copy patented harrow designs—such as specific chain arrangements, frame geometry, or tensioning systems—can expose buyers to IP infringement risks. Using or importing such equipment may lead to legal action, shipment seizures, or reputational damage, particularly in regulated markets like the EU or North America.

Misrepresentation of Origin and Branding

Some suppliers falsely claim association with reputable agricultural brands or list incorrect country of origin to appear more credible. This misrepresentation not only undermines trust but may also bypass import regulations or certifications required for agricultural machinery, leading to compliance issues.

Insufficient Testing and Certification

Drag chain harrows sourced without proper performance validation or third-party testing may not meet safety or durability standards. Lack of certifications (e.g., CE, ISO) can indicate corners cut in design and manufacturing, increasing the risk of field failures and operator hazards.

Inadequate After-Sales Support and Spare Parts Availability

Purchasing from suppliers without reliable customer support or spare parts networks can result in extended downtime when components fail. Many low-cost harrows use proprietary or non-interchangeable parts, making repairs difficult and costly, especially in remote farming regions.

Overlooking Regional Soil and Climate Requirements

Generic designs may not be suited to specific soil types or climatic conditions. For example, a harrow optimized for sandy loam may perform poorly in heavy clay or high-residue environments. Failure to account for regional needs leads to inefficient operation and accelerated wear.

Logistics & Compliance Guide for Drag Chain Harrow

Product Overview

A Drag Chain Harrow is an agricultural implement used for soil preparation, residue management, and seedbed leveling. It typically consists of a series of interconnected chains or tines mounted on a frame, dragged behind a tractor. Proper logistics planning and regulatory compliance are essential for safe and legal transport and use.

Transportation & Handling

- Weight & Dimensions: Confirm the harrow’s total weight, width, and length before transport. Oversized units may require special permits.

- Load Securing: Use rated chains, straps, or binders to secure the harrow to trailers or flatbeds. Ensure even weight distribution to prevent shifting.

- Trailer Requirements: Use a heavy-duty trailer with adequate tongue weight capacity and functioning safety chains, lights, and brakes.

- Transport Speed: Observe speed limits for towed equipment—typically not exceeding 25–35 mph on highways, depending on local regulations.

- Route Planning: Avoid low bridges, narrow roads, and weight-restricted zones. Plan routes suitable for wide or heavy agricultural implements.

Regulatory Compliance

- DOT Regulations (U.S.): Comply with Department of Transportation rules for agricultural equipment transport, including lighting, reflectors, and signage (e.g., slow-moving vehicle emblem if traveling under 25 mph).

- State & Local Permits: Oversized or overweight harrows may require transit permits. Check with state transportation departments for specific requirements.

- Cross-Border Shipments: For international transport, ensure compliance with customs documentation, import tariffs, and regional standards (e.g., CE marking in the EU).

- Safety Standards: Verify that the harrow meets applicable safety standards such as ASABE (American Society of Agricultural and Biological Engineers) or ISO norms.

Import/Export Documentation

- Commercial Invoice: Include product description, value, weight, and country of origin.

- Packing List: Detail components, packaging type, and shipment dimensions.

- Certificate of Origin: Required for tariff assessment and trade agreements.

- Bill of Lading/Air Waybill: Essential for freight tracking and ownership transfer.

- Import Licenses: Check destination country requirements for agricultural machinery imports.

Environmental & Operational Compliance

- Soil Conservation: Use the drag chain harrow in accordance with local soil conservation guidelines to prevent erosion.

- Noise & Emissions: Ensure the towing tractor complies with emissions standards (e.g., EPA Tier 4, EU Stage V).

- Field Use Regulations: Follow local agricultural regulations regarding timing and methods of tillage, especially in protected or environmentally sensitive zones.

Maintenance & Safety Compliance

- Operator Training: Ensure operators are trained in safe hitching, operation, and uncoupling procedures.

- Regular Inspections: Check chains, frame integrity, and hitch points before each use to comply with OSHA and manufacturer safety standards.

- Safety Decals & Manuals: Maintain legible safety warnings and keep operator manuals accessible to meet compliance and warranty requirements.

Storage & Inventory Management

- Indoor Storage: Store in a dry, covered area to prevent rust and degradation of metal components.

- Inventory Tracking: Use barcodes or RFID tags for enterprise-level logistics tracking.

- Rotation & Usage Logs: Maintain logs for compliance with equipment maintenance schedules and warranty conditions.

Emergency & Incident Reporting

- Accident Protocols: Establish procedures for reporting transport accidents involving the harrow, including DOT or local authority notifications if required.

- Spill or Damage Response: Though not hazardous, damaged components (e.g., broken chains) should be safely removed and disposed of according to local waste regulations.

Adhering to this logistics and compliance guide ensures safe, legal, and efficient handling of Drag Chain Harrows throughout their lifecycle—from transport and import to field operation and maintenance.

Conclusion on Sourcing a Drag Chain Harrow

Sourcing a drag chain harrow involves careful consideration of various factors including intended use, soil conditions, equipment compatibility, and budget. After evaluating available options, it is evident that chain harrows are effective tools for land maintenance, seedbed preparation, pasture renovation, and manure spreading, offering benefits such as improved soil aeration, leveling, and surface debris management.

When sourcing, prioritize quality construction and durable materials—such as galvanized chains and sturdy frames—to ensure longevity and resistance to wear. Sourcing from reputable manufacturers or suppliers ensures reliability, proper support, and access to warranties or replacement parts. Additionally, verifying compatibility with existing tractors or towing equipment (PTO requirements, hitch type, weight, and width) is essential for seamless integration into operations.

Whether purchasing new or sourcing used equipment, conducting thorough research, reading customer reviews, and comparing prices across suppliers can lead to a cost-effective and efficient solution. In conclusion, a well-sourced drag chain harrow enhances land management productivity and supports sustainable farming or landscaping practices, making it a valuable investment when selected with care and purpose.