The global smart lock market, a key segment within the broader door hardware industry, is projected to grow at a CAGR of 13.2% from 2023 to 2030, according to Grand View Research. This surge is driven by rising demand for enhanced home security, increased adoption of smart home technologies, and growing urbanization. As wooden doors remain a preferred choice in residential and commercial architecture—especially in premium and traditional builds—the demand for high-quality, reliable, and technologically advanced door locks tailored for wooden applications has intensified. With the global door hardware market valued at over USD 35 billion in 2022 (Mordor Intelligence), and steady growth expected through the decade, manufacturers specializing in door locks for wooden doors are innovating rapidly to meet evolving consumer expectations for security, aesthetics, and seamless integration. In this competitive landscape, nine manufacturers have emerged as leaders, combining craftsmanship, durability, and smart functionality to dominate the segment.

Top 9 Door Locks For Wooden Doors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Endura Door Components

Domain Est. 1998

Website: enduraproducts.com

Key Highlights: We make endura door components that work better, install faster and last longer to deliver truly maintenance-free performance….

#2 Doors and door hardware

Domain Est. 1996

Website: assaabloy.com

Key Highlights: Our doors and door hardware deliver reliable security and performance. With a variety of solutions designed for enhanced access and durability….

#3 Adams Rite

Domain Est. 1996

Website: adamsrite.com

Key Highlights: Our door hardware solutions and accessories provide reliable solutions for narrow stile aluminum, hollow metal and wood door applications. View Products….

#4 Rockwood

Domain Est. 1997

Website: rockwoodmfg.com

Key Highlights: Rockwood Door Pull Mounting … Our mounting systems firmly attach the pull to the door and are guaranteed for the life of the door. Choose from thrubolt, back-to ……

#5 Baldwin Hardware

Domain Est. 1998

Website: baldwinhardware.com

Key Highlights: Baldwin Hardware is a leading provider of high-quality, stylish and durable door and cabinet hardware for both residential and commercial applications….

#6

Domain Est. 1998

Website: sargentlock.com

Key Highlights: Commercial Locks and Architectural Door Hardware. SARGENT Manufacturing delivers trusted, high-performance door hardware built for today’s commercial and ……

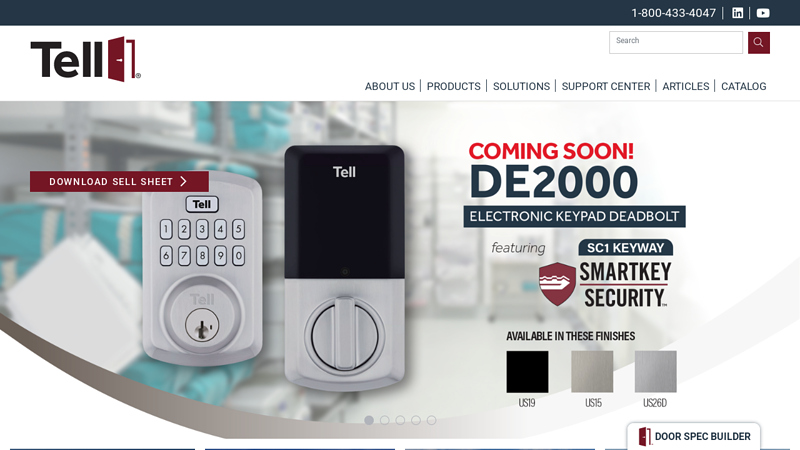

#7 Tell Manufacturing

Domain Est. 1998

Website: tellmfg.com

Key Highlights: We produce high-quality, competitively priced commercial locksets, door closers, exit devices, hinges, trim hardware and commercial hollow metal doors….

#8 Exterior Door Hardware & Interior Door Hardware

Domain Est. 2015

Website: dormakaba.com

Key Highlights: A wide list of closers, operators, locks, exit devices, and electronic access control components, are offered to fit any size or style door. Select a door ……

#9 TESA ASSA ABLOY Product

Website: tesa.es

Key Highlights: TESA security locks provide unparalleled security levels in the market, as well as a new design of the patented anticard latch, independent locking points, ……

Expert Sourcing Insights for Door Locks For Wooden Doors

2026 Market Trends for Door Locks for Wooden Doors

The global market for door locks for wooden doors is poised for significant transformation by 2026, driven by advancements in smart technology, shifting consumer preferences, and increasing concerns about home security. This analysis explores key trends expected to shape the industry in the coming years.

Rising Adoption of Smart Locks

One of the most prominent trends in 2026 will be the accelerated adoption of smart door locks for wooden doors. Consumers are increasingly favoring keyless entry systems that offer remote access, smartphone integration, and biometric authentication (such as fingerprint and facial recognition). These smart locks are not only convenient but also provide enhanced security features, including real-time alerts, activity logs, and integration with home automation systems like Google Home, Amazon Alexa, and Apple HomeKit.

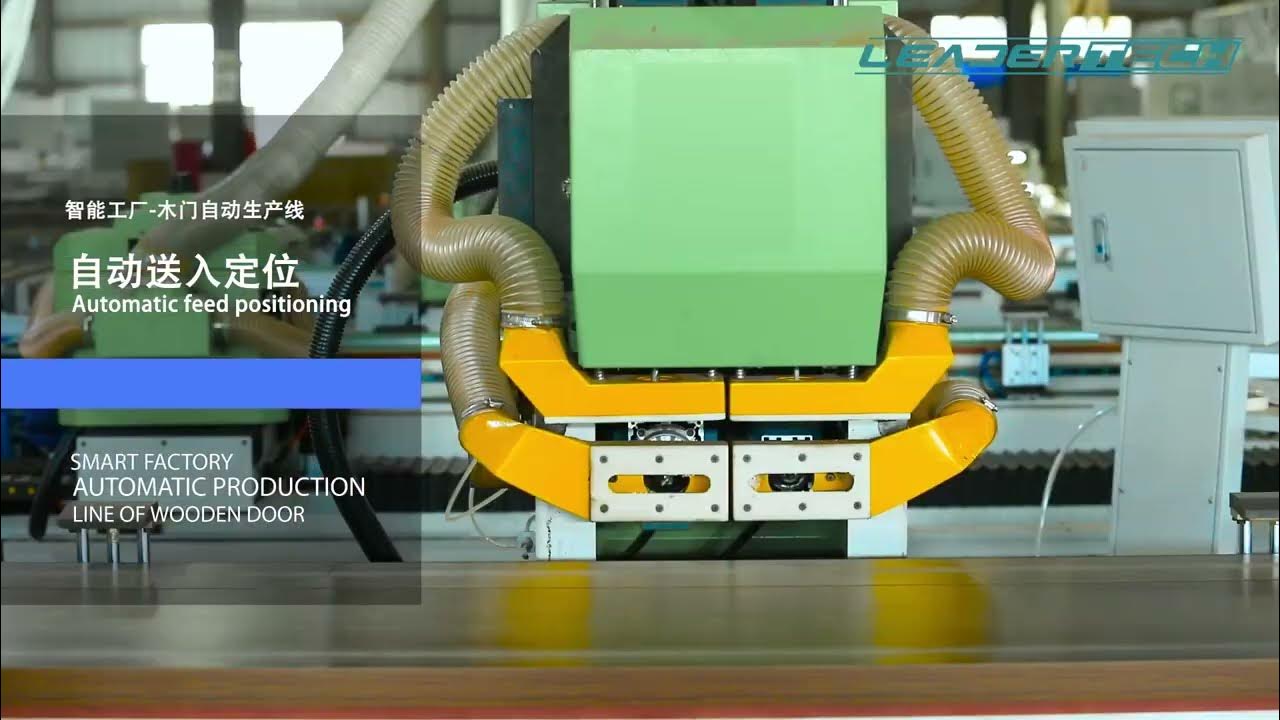

Manufacturers are focusing on designing smart locks that maintain aesthetic compatibility with traditional wooden doors, preserving the visual appeal while offering modern functionality. As IoT (Internet of Things) infrastructure becomes more robust and affordable, smart lock penetration is expected to grow significantly, particularly in urban and newly constructed residential properties.

Emphasis on Design and Aesthetics

In 2026, design will play a critical role in consumer decision-making. Homeowners and interior designers are seeking door locks that complement the architectural style and finish of wooden doors. Premium finishes such as brushed nickel, matte black, antique brass, and oil-rubbed bronze will remain popular. Customizable options, including personalized engraving and modular designs, will cater to the growing demand for bespoke home solutions.

Manufacturers are collaborating with architects and interior designers to create locks that blend seamlessly with high-end wooden doors used in luxury homes and boutique developments. This trend reflects a broader movement toward holistic home design, where even functional hardware contributes to overall aesthetic harmony.

Increased Focus on Security and Anti-Snap Technology

With rising burglary rates in some regions and increased awareness of lock vulnerabilities, security will remain a top priority. In 2026, anti-snap, anti-pick, and anti-bump technologies will be standard features in mid-to-high-end door locks for wooden doors. European cylinder locks with high-security ratings (e.g., TS007 3-star) will gain wider acceptance, especially in markets like the UK and Western Europe.

Additionally, manufacturers will invest in tamper-proof designs and reinforced strike plates to prevent forced entry. The integration of AI-powered anomaly detection in smart locks—such as detecting unusual access attempts—will further bolster perceived and actual security.

Sustainability and Eco-Friendly Materials

Sustainability is becoming a decisive factor in consumer purchasing behavior. By 2026, there will be a growing preference for door locks made from recyclable metals and produced through energy-efficient manufacturing processes. Brands that emphasize low environmental impact, ethical sourcing, and long product lifecycles will gain a competitive edge.

Moreover, as wooden doors themselves are often marketed as eco-friendly, consumers will expect their hardware to align with green values. This includes packaging reductions, modular repairability (to extend product life), and certifications such as Cradle to Cradle or Energy Star compliance where applicable.

Growth in E-Commerce and Direct-to-Consumer Sales

The distribution landscape for door locks will continue to evolve, with e-commerce platforms playing a dominant role by 2026. Online retailers and brand-owned websites will offer detailed product comparisons, 3D visualization tools, and virtual installation guides, enabling informed purchasing decisions.

Direct-to-consumer (DTC) models will allow manufacturers to collect user data, improve customer experience, and offer personalized support. Subscription-based services for lock maintenance, firmware updates, and security monitoring may also emerge as value-added offerings.

Regional Market Dynamics

Growth will vary by region. North America and Western Europe will lead in smart lock adoption due to high disposable incomes and tech-savvy populations. Meanwhile, emerging markets in Asia-Pacific—particularly India, China, and Southeast Asia—will experience rapid growth in both traditional and smart lock segments, driven by urbanization and expanding middle-class housing.

In these regions, hybrid models that combine smart features with traditional key backup will be preferred due to concerns about power outages and digital literacy.

Conclusion

By 2026, the market for door locks for wooden doors will be characterized by technological innovation, aesthetic refinement, and heightened security standards. The convergence of smart functionality with timeless design will redefine consumer expectations. Companies that invest in R&D, prioritize user experience, and align with sustainability goals will be best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing Door Locks for Wooden Doors (Quality and IP Considerations)

Sourcing door locks for wooden doors requires careful attention to both quality and Ingress Protection (IP) ratings, especially when the doors are exposed to harsh environments. Overlooking key factors can lead to premature failure, security vulnerabilities, and increased maintenance costs. Below are the most common pitfalls to avoid.

1. Ignoring Build Quality and Material Standards

One of the biggest mistakes is selecting locks based solely on appearance or price without evaluating the materials used. Low-quality zinc alloys or thin stainless steel can wear quickly, leading to latch failure or difficulty in operation. Always verify that the lock is constructed from durable materials such as solid brass, 304/316 stainless steel, or reinforced zinc alloys designed for long-term use.

2. Overlooking Ingress Protection (IP) Ratings

Many wooden doors, especially exterior ones, are exposed to moisture, dust, and temperature fluctuations. Failing to consider IP ratings can result in internal corrosion or mechanical failure. For outdoor or high-moisture environments, choose locks with an appropriate IP rating—typically IP55 or higher—to ensure protection against water and dust ingress.

3. Assuming All Locks Are Suitable for Wood

Not all door locks are designed for wooden door applications. Using a lock meant for metal or composite doors may lead to improper installation, reduced holding strength, or damage to the wood over time. Ensure the lock set is specifically rated for wooden doors and includes appropriate mounting hardware (e.g., wood screws, back plates).

4. Neglecting Lock Cylinder Quality

The lock cylinder is a critical component for security. Low-quality or non-certified cylinders (e.g., those without Sold Secure or TS007 accreditation) are vulnerable to picking, bumping, or snapping. Invest in high-security cylinders with anti-snap and anti-pick features, especially for external wooden doors.

5. Poor Fit and Dimensional Incompatibility

Wooden doors vary in thickness and stile width. Using a standard lock on a non-standard door can result in misalignment, weak latch engagement, or an inability to install the lock properly. Always confirm door dimensions and ensure the lock is compatible with the door’s thickness and backset measurements.

6. Skipping Environmental and Climate Considerations

Even indoor wooden doors in humid areas (e.g., bathrooms, coastal regions) can suffer from condensation. Locks that aren’t corrosion-resistant may degrade quickly. Choose finishes like brushed nickel, powder-coated, or marine-grade stainless steel for improved durability in challenging climates.

7. Failing to Verify Certification and Compliance

Reputable locks should meet industry standards such as ANSI/BHMA, CE, or EN 12209 for performance and durability. Sourcing uncertified products increases the risk of poor function and non-compliance with building codes or insurance requirements.

8. Underestimating Installation Complexity

Some high-security or smart locks require professional installation. Attempting a DIY fit without proper tools or expertise can damage the wooden door or compromise the lock’s effectiveness. Always assess installation requirements and seek professional help when needed.

9. Prioritizing Aesthetics Over Functionality

While design is important, choosing a lock purely for its look can compromise security and longevity. Ensure that aesthetic choices don’t come at the expense of structural integrity, weather resistance, or ease of operation.

10. Not Planning for Long-Term Maintenance

Even high-quality locks require periodic maintenance, especially on wooden doors that may swell or shrink with humidity. Failing to account for lubrication, alignment checks, or seasonal adjustments can shorten the lock’s lifespan.

By avoiding these common pitfalls, you can ensure the door locks you source for wooden doors deliver reliable performance, long-term durability, and robust security.

Logistics & Compliance Guide for Door Locks for Wooden Doors

Product Classification and HS Code

Door locks for wooden doors are typically classified under Harmonized System (HS) codes related to hardware and building fittings. The most common HS code is 8301.40, which covers “Locks, padlocks, and lock parts, of base metal.” However, classifications may vary by country. For example:

– United States: 8301.40.0000

– European Union: 8301 40 00

– Canada: 8301.40.00

Accurate classification is essential for customs clearance and determining import duties and taxes.

Import and Export Regulations

Compliance with import and export regulations is vital for international trade. Key considerations include:

– Licensing Requirements: Most countries do not require special licenses for door locks, but exporters must verify regional restrictions.

– End-Use Documentation: Some countries may require proof that products are for civilian use only.

– Export Controls: Ensure the product does not contain restricted materials or dual-use technologies that could trigger export control regulations (e.g., ITAR or EAR in the U.S.).

Safety and Performance Standards

Door locks must meet safety and performance standards in the destination market:

– United States: ANSI/BHMA A156.2 – Covers cylindrical locksets and ensures durability, security, and cycle testing.

– European Union: EN 12209 or EN 1303 – Specifies mechanical and security requirements for locks; CE marking is mandatory.

– United Kingdom: BS EN 12209 (post-Brexit, UKCA marking may be required).

– Australia and New Zealand: AS 4145.2 – Covers performance and testing of door locks.

Manufacturers must provide test reports or certificates from accredited laboratories to prove compliance.

Packaging and Labeling Requirements

Proper packaging and labeling ensure product integrity and regulatory compliance:

– Packaging: Use sturdy, anti-corrosive materials to prevent damage during transit. Individual units should be wrapped or boxed to avoid scratches.

– Labeling: Packaging must include:

– Product name and model number

– Material composition (e.g., zinc alloy, brass)

– Country of origin

– Compliance marks (e.g., CE, ANSI, UKCA)

– Manufacturer/importer contact information

– Language: Labels must be in the official language(s) of the destination country.

Transportation and Freight Considerations

Door locks are generally non-hazardous, but logistics must account for:

– Weight and Volume: Locks are typically shipped in bulk; optimize palletization to reduce freight costs.

– Mode of Transport: Suitable for air, sea, or ground freight depending on urgency and volume.

– Incoterms: Clearly define responsibilities using standard terms (e.g., FOB, CIF, DDP) to avoid disputes.

– Insurance: Recommend cargo insurance to cover loss or damage during transit.

Customs Clearance Documentation

Ensure all required documents are prepared accurately:

– Commercial Invoice (with detailed product description, value, and HS code)

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (may be required for preferential tariffs)

– Test Reports or Certificates of Conformity

– Import Declaration (completed by importer or agent)

Environmental and Chemical Compliance

Check for restrictions on substances used in lock manufacturing:

– REACH (EU): Regulates chemicals like lead, nickel, and certain phthalates in metal components.

– RoHS (EU): Applies if locks include electronic components (e.g., smart locks), restricting hazardous substances.

– Proposition 65 (California): Requires warning labels if products contain listed chemicals such as lead.

After-Sales and Warranty Compliance

- Provide multilingual installation instructions and warranty information.

- Comply with consumer protection laws in the destination country, including return policies and warranty duration (e.g., 1–5 years depending on market).

- Establish a local service or distributor network for warranty claims.

Summary

Successfully shipping and selling door locks for wooden doors internationally requires attention to classification, regulatory standards, packaging, and documentation. Proactive compliance reduces delays, avoids penalties, and builds trust with customers and authorities. Always consult local regulatory bodies or a customs broker for market-specific requirements.

In conclusion, sourcing door locks for wooden doors requires careful consideration of several key factors including security level, door thickness, compatibility with wooden door construction, ease of installation, and aesthetic appeal. It is essential to select high-quality locks—such as deadbolts, mortise locks, or cylindrical locksets—made from durable materials like brass or stainless steel to ensure longevity and resistance to tampering. Working with reputable suppliers or manufacturers that provide certifications, warranties, and technical support can further ensure product reliability. Additionally, adhering to local building codes and security standards will help in making compliant and safe choices. By balancing security needs with functionality and design, one can effectively source door locks that enhance both the safety and appearance of wooden doors.