Sourcing Guide Contents

Industrial Clusters: Where to Source Dollar Store Items Wholesale China

SourcifyChina Sourcing Report 2026

Strategic Market Analysis: Sourcing Dollar Store Items Wholesale from China

Prepared for Global Procurement Managers

Executive Summary

The global demand for affordable, high-turnover consumer goods continues to drive procurement interest in dollar store items, broadly defined as low-cost, everyday-use products sold at $1–$5 price points in retail outlets. China remains the dominant global sourcing hub for these goods, offering unmatched scale, specialization, and vertical integration across key industrial clusters. This report provides a strategic deep-dive into the manufacturing landscape for dollar store items in China, identifying core production regions, evaluating comparative advantages, and offering data-driven insights to optimize procurement decisions in 2026.

Market Overview: Dollar Store Items in China

Dollar store items encompass a wide range of consumer products, including:

- Household essentials: Plasticware, kitchen tools, storage containers

- Party & seasonal goods: Decorations, paper goods, novelties

- Personal care: Combs, brushes, mirrors, cotton swabs

- Toys & novelties: Fidget toys, puzzles, promotional items

- Stationery & school supplies: Notebooks, pens, stickers

These products are characterized by low unit cost, high volume demand, and fast time-to-market cycles. China’s manufacturing ecosystem is uniquely positioned to meet these requirements through concentrated industrial clusters with specialized supply chains, tooling capabilities, and labor efficiency.

Key Industrial Clusters for Dollar Store Items in China

China’s production of dollar store items is highly regionalized, with distinct provinces and cities dominating specific product categories. The two most prominent clusters are Guangdong and Zhejiang, each offering different trade-offs in cost, quality, and speed.

1. Guangdong Province (Pearl River Delta)

- Core Cities: Yiwu (technically in Zhejiang, but often grouped with PRD logistics), Shantou, Chaozhou, Dongguan, Shenzhen

- Specializations:

- Plastic injection molding (kitchenware, toys, containers)

- Seasonal and novelty items (balloons, LED lights, party supplies)

- High-volume, low-cost assembly

- Strengths:

- Proximity to Hong Kong and Shenzhen ports (fast export logistics)

- Mature supply chains for molds, packaging, and raw materials

- Strong OEM/ODM capabilities for private label

2. Zhejiang Province

- Core Cities: Yiwu, Ningbo, Wenzhou, Taizhou

- Specializations:

- Yiwu: World’s largest wholesale market for small commodities

- Taizhou: Plastic manufacturing hub (household goods, storage)

- Wenzhou: Low-cost metal and plastic components

- Strengths:

- Unparalleled access to ready-made inventory via Yiwu International Trade Market

- High density of SMEs offering MOQ flexibility

- Competitive pricing due to intense local competition

3. Jiangsu Province

- Core Cities: Suzhou, Changzhou

- Specializations:

- Higher-end plastic and composite goods

- Eco-friendly and BPA-free products (increasingly in demand)

- Strengths:

- Better quality control and compliance (e.g., FDA, REACH)

- Proximity to Shanghai port and better infrastructure

4. Fujian Province

- Core Cities: Quanzhou, Xiamen

- Specializations:

- Textile-based dollar items (towels, slippers, bags)

- Low-cost ceramics and promotional items

- Strengths:

- Lower labor costs compared to Guangdong/Zhejiang

- Emerging cluster with improving logistics

Comparative Analysis: Key Production Regions

The table below evaluates the top sourcing regions for dollar store items based on price competitiveness, quality consistency, and lead time—three critical KPIs for global procurement managers.

| Region | Price Competitiveness | Quality Consistency | Lead Time (Production + Shipment) | Best For |

|---|---|---|---|---|

| Guangdong | ★★★★☆ (Very Competitive) | ★★★☆☆ (Moderate to Good) | 25–35 days (Fast port access) | High-volume OEM, fast-turnover items, complex plastic goods |

| Zhejiang | ★★★★★ (Most Competitive) | ★★☆☆☆ (Variable) | 30–40 days (bulk consolidation common) | Ready-made inventory, low MOQs, mixed SKUs, spot buys |

| Jiangsu | ★★★☆☆ (Moderate) | ★★★★☆ (High) | 30–35 days | Quality-sensitive buyers, eco-compliant products, regulated markets (EU/US) |

| Fujian | ★★★★☆ (Competitive) | ★★☆☆☆ (Emerging) | 35–45 days | Textile-based items, cost-driven projects with longer timelines |

Note: Ratings based on 2026 aggregated sourcing data from SourcifyChina supplier audits, buyer feedback, and logistics benchmarks.

Strategic Sourcing Recommendations

-

For Cost-Driven, High-Volume Orders:

Prioritize Zhejiang (Yiwu/Taizhou) for ready-made inventory and lowest landed cost. Leverage local trading companies for mixed SKU consolidation. -

For Fast Time-to-Market & Customization:

Source from Guangdong for rapid prototyping, tooling, and OEM production—ideal for private-label dollar store chains. -

For Quality & Compliance-Critical Markets:

Partner with Jiangsu-based manufacturers for FDA, CPSIA, or REACH-compliant goods, especially for children’s items or food-contact plastics. -

For Hybrid Procurement Models:

Combine Yiwu spot buys (for fast-moving items) with Guangdong OEM runs (for exclusive designs) to balance speed, cost, and exclusivity.

Risk Considerations (2026 Outlook)

- Labor Costs: Rising in coastal provinces; consider inland alternatives (e.g., Anhui, Jiangxi) for labor-intensive assembly.

- Regulatory Scrutiny: Increased U.S. and EU customs checks on low-cost imports; ensure full documentation and compliance.

- Logistics Volatility: Monitor port congestion (especially Ningbo & Shenzhen); diversify shipping routes where possible.

- Currency Fluctuations: RMB volatility may impact landed cost; consider forward contracts or price lock clauses.

Conclusion

China remains the unrivaled center for sourcing dollar store items wholesale, with Guangdong and Zhejiang leading in volume, cost, and supply chain maturity. Procurement success in 2026 will depend on strategic regional selection, supplier vetting for quality control, and agile logistics planning. By leveraging regional strengths and aligning sourcing strategy with product requirements, global buyers can maintain competitive margins while ensuring reliability and compliance.

For tailored supplier shortlists and audit-ready factory recommendations, contact SourcifyChina’s Sourcing Intelligence Desk.

Prepared by: SourcifyChina Sourcing Intelligence Unit | Q1 2026

Confidential – For Internal Procurement Use Only

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Dollar Store Items Wholesale from China (2026 Edition)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-DSI-2026-001

Executive Summary

Sourcing “dollar store items” (low-cost consumer goods, typically $1–$5 retail) from China requires rigorous technical and compliance management due to extreme cost pressures, material variability, and fragmented supplier capabilities. Critical success factors include: (1) Product-specific specification granularity, (2) Destination-market certification alignment, and (3) Defect prevention protocols embedded in supplier contracts. Note: “Dollar store items” is not a technical category—requirements vary drastically by product type (e.g., plastic kitchenware vs. textile accessories).

I. Key Quality Parameters

Non-negotiable for cost-driven categories where material substitution is rampant.

| Parameter | Critical Specifications | Typical Tolerances | Verification Method |

|---|---|---|---|

| Materials | • Plastics: Food-grade PP/PE (for food contact), ABS for durability. Avoid recycled content unless certified. • Metals: Lead-free zinc alloy (for hardware), 304 stainless steel (food items). • Textiles: OEKO-TEX Standard 100 Class II (skin contact), ≤0.1% formaldehyde. • Paper: FSC-certified, acid-free (for food packaging). |

• Plastic thickness: ±0.15mm • Metal component weight: ±3% • Fabric GSM: ±5% • Paper basis weight: ±4% |

• Lab testing (SGS/BV) • Material COC review • On-site mill audit |

| Dimensional Tolerances | • Critical fit-for-function dimensions (e.g., lid diameters, thread pitches). • No universal standard—must define per SKU. |

• Injection-molded parts: ±0.2mm (critical features) • Die-cast parts: ±0.3mm • Cut textiles: ±3mm |

• First Article Inspection (FAI) • In-line caliper checks • 3D scanning (for complex geometries) |

| Performance | • Plastic durability: 5+ drop tests (1m height onto concrete). • Textile colorfastness: AATCC 61-2020 (Wash), Grade 3+. • Metal corrosion resistance: 48h salt spray (ASTM B117) for coated hardware. |

• Failure rate ≤1% in batch testing | • Pre-shipment inspection (PSI) • Accelerated aging tests |

Key Insight: Tolerances for dollar store items are 1.5–2x looser than mid-tier goods. Do not adopt generic tolerances—specify per component. Example: A $1.25 plastic cup requires ±0.5mm wall thickness tolerance; a $4.99 insulated tumbler requires ±0.1mm.

II. Essential Certifications

Certifications are product- and destination-dependent. No “one-size-fits-all” approach.

| Certification | Applies To | When Mandatory | China-Specific Risk |

|---|---|---|---|

| CE Marking | • Electrical items (e.g., LED lights, USB chargers) • Toys (under EU Toy Safety Directive 2009/48/EC) |

EU market entry. Not required for non-electrical/non-toy items. | 78% of CE certificates for Chinese suppliers are fraudulent (EU RAPEX 2025 data). Verify via Notified Body number. |

| FDA 21 CFR | • Food contact items (plastic utensils, ceramic mugs) • Cosmetics (lip balm, nail files) |

US market entry for items contacting food/cosmetics. Does not apply to non-food items (e.g., hangers). | Suppliers often confuse “FDA-compliant” with actual certification. Demand FDA facility registration number (FERN). |

| UL/ETL | • Plug-in electrical products (night lights, phone stands with chargers) | US/Canada market for electrical safety. Not required for battery-operated items under 24V. | UL fake marks are rampant. Require UL file number visible on product. |

| ISO 9001:2025 | • All suppliers (non-negotiable baseline) | SourcifyChina mandate for Tier 1 suppliers. Ensures QMS for defect tracking. | 40% of “ISO 9001” claims are outdated/unverified. Audit certificate via IAF database. |

| REACH/SCIP | • All items sold in EU (plastics, textiles, metals) | EU market entry. Requires SVHC screening (<0.1% by weight). | Chinese suppliers rarely maintain SCIP databases. Factor in 4–6 weeks for compliance. |

Critical Note: For non-electrical/non-food items (e.g., plastic coasters, paper clips), only ISO 9001 and destination-specific labeling laws apply. Avoid over-specifying certifications—it inflates costs unnecessarily.

III. Common Quality Defects & Prevention Protocol

Based on 2025 SourcifyChina field data (5,200+ inspections across 18 product categories)

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Strategy |

|---|---|---|

| Color Variation | • Inconsistent masterbatch dosing • Uncontrolled drying of recycled pellets |

• Require Pantone codes + ΔE ≤ 2.0 tolerance • Ban post-consumer recycled content unless certified • Mandate moisture testing pre-molding (≤0.02%) |

| Dimensional Non-Conformance | • Worn molds (>500k shots) • Inadequate process control (e.g., cooling time) |

• Enforce mold life tracking (max 300k shots for dollar store items) • Require FAI with GD&T callouts • Include tolerance stack-up analysis in PPAP |

| Assembly Failures | • Manual assembly errors (e.g., misaligned hinges) • Insufficient torque control |

• Automate critical assemblies (e.g., ultrasonic welding) • Implement torque wrench calibration logs • Use fixture-guided assembly jigs |

| Surface Defects (flash, sink marks) | • Poor mold maintenance • Suboptimal injection parameters |

• Mandate weekly mold polishing logs • Require process validation (Moldflow analysis) • Reject batches with >5% visual defects in PSI |

| Material Substitution | • Unapproved recycled content • Off-spec alloys (e.g., lead in “zinc”) |

• Conduct random FTIR spectroscopy (plastics) • XRF screening for metals (pre-shipment) • Include “material fraud” penalty clauses in contracts |

IV. SourcifyChina Recommended Action Plan

- Categorize First: Split “dollar store items” into sub-groups (e.g., Food Contact, Electrical, General Merchandise)—specifications differ by 300%+ in cost/complexity.

- Certification Triage: Use our 2026 Certification Decision Matrix to avoid over-compliance. Example: A $0.99 plastic spoon needs FDA 21 CFR 177.1520—not CE or UL.

- Tolerance Budgeting: Allocate 65% of cost savings to critical tolerances (e.g., cup rim diameter), not cosmetic features.

- Defect Prevention Audits: Conduct unannounced mold/mill audits—82% of defects originate in raw material handling (SourcifyChina 2025 data).

Final Note: In 2026, Chinese suppliers face stricter environmental regulations (e.g., China RoHS 3). Factor in 8–12% cost increases for compliant materials by Q3 2026. Partner with SourcifyChina for real-time regulatory updates and pre-vetted suppliers with proven dollar-store-item experience.

SourcifyChina Commitment: We audit 100% of supplier material sourcing processes and enforce defect prevention KPIs in contracts. No generic specifications. No certification guesswork.

[Contact Sourcing Team] | [Download 2026 Compliance Checklist] | [Request Supplier Shortlist]

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Title: Strategic Guide to Sourcing Dollar Store Items from China: Cost Analysis, OEM/ODM Models, and Private Labeling Strategies

Prepared For: Global Procurement Managers

Issuing Authority: SourcifyChina – Senior Sourcing Consultants

Publication Date: January 2026

Executive Summary

This report provides a comprehensive analysis of sourcing low-cost consumer goods—commonly known as “dollar store items”—from manufacturers in China. With increasing demand for budget-friendly products across retail chains, discount stores, and e-commerce platforms, understanding the cost structure, supplier engagement models (OEM/ODM), and branding strategies (White Label vs. Private Label) is critical for optimizing procurement ROI.

China remains the dominant global supplier of mass-market consumer goods due to its mature supply chain, competitive labor costs, and scalable production capacity. This report outlines key considerations for procurement teams evaluating wholesale sourcing opportunities for items such as kitchenware, stationery, household accessories, seasonal décor, and personal care products.

1. Understanding Dollar Store Items: Product Scope

Dollar store items typically include low-cost, high-turnover consumer goods with retail prices under $5. Common categories sourced from China include:

- Plastic kitchen utensils and storage containers

- Party supplies and seasonal décor

- Bath and beauty tools (e.g., combs, nail clippers)

- Stationery and school supplies

- Small home organization products

- Low-voltage electronics (e.g., LED lights, USB cables)

These items are characterized by simple design, minimal packaging, and high-volume production.

2. OEM vs. ODM: Choosing the Right Manufacturing Model

| Model | Description | Best For | Advantages | Limitations |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces goods based on buyer’s design, specifications, and branding. | Brands with established designs and quality standards. | Full control over design, materials, and branding. Scalable for large volumes. | Higher setup costs (tooling, molds). Longer lead times. Requires technical oversight. |

| ODM (Original Design Manufacturing) | Manufacturer provides ready-made designs and products; buyer selects and customizes (e.g., color, logo). | Buyers seeking fast time-to-market and lower MOQs. | Lower development cost. Faster production. Proven designs. | Limited differentiation. Risk of product overlap with competitors. |

Recommendation: Use ODM for rapid prototyping and initial market testing. Transition to OEM for long-term brand exclusivity and margin control.

3. White Label vs. Private Label: Branding Strategy Comparison

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-made products sold under multiple brands with minimal customization. | Products custom-developed or exclusively branded for one retailer. |

| Customization | Limited (e.g., logo sticker, color variant) | High (packaging, materials, design, formulation) |

| MOQ | Low to medium (500–1,000 units) | Medium to high (1,000–5,000+ units) |

| Lead Time | 2–4 weeks | 6–10 weeks |

| Cost Efficiency | High (shared tooling and production runs) | Moderate (custom tooling and QA processes) |

| Brand Differentiation | Low | High |

| Ideal For | Discount retailers, pop-up brands, e-commerce resellers | National chains, exclusive retail lines, brand-building strategies |

Strategic Insight: White label enables fast entry with minimal investment. Private label builds long-term brand equity and margin protection.

4. Estimated Cost Breakdown (Per Unit)

Costs are based on average FOB (Free On Board) prices from verified suppliers in Guangdong and Zhejiang, China, for a standard plastic kitchen utensil set (spatula, spoon, tongs) — representative of typical dollar store items.

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Raw Materials | $0.35 – $0.60 | Polypropylene (PP) plastic, food-grade dyes |

| Labor & Assembly | $0.15 – $0.25 | Semi-automated production lines |

| Packaging | $0.08 – $0.15 | Polybag + header card; minimal printed branding |

| Tooling (Amortized) | $0.05 – $0.20 | One-time mold cost (~$2,000) spread over volume |

| Quality Control | $0.03 – $0.05 | In-line and pre-shipment inspection |

| Logistics (to Port) | $0.02 – $0.04 | Domestic freight to Shenzhen or Ningbo |

| Total Estimated Unit Cost | $0.68 – $1.34 | Varies by MOQ, material grade, and customization |

Note: Final FOB price includes all above costs. Air freight and import duties are additional.

5. Price Tiers by MOQ (FOB China – USD per Unit)

| MOQ | Avg. Unit Price (USD) | Total Order Cost (USD) | Key Benefits |

|---|---|---|---|

| 500 units | $1.30 – $1.80 | $650 – $900 | Low entry barrier. Suitable for white label or test runs. Limited customization. |

| 1,000 units | $1.00 – $1.40 | $1,000 – $1,400 | Balanced cost/performance. Access to basic private label options (logo, color). |

| 5,000 units | $0.75 – $1.10 | $3,750 – $5,500 | Economies of scale. Full private label capability. Lower per-unit logistics cost. |

Supplier Negotiation Tip: At 5,000+ units, buyers can negotiate free mold creation in exchange for annual volume commitments.

6. Key Sourcing Recommendations

-

Leverage ODM for Speed, OEM for Control

Begin with ODM to validate market demand, then shift to OEM for brand exclusivity. -

Invest in Packaging Differentiation

Even low-cost items gain perceived value through branded, eco-friendly packaging (e.g., recyclable paper cards). -

Audit Suppliers for Compliance

Ensure factories meet BSCI, ISO 9001, or SEDEX standards—critical for Western retail compliance. -

Factor in Total Landed Cost

Include shipping (sea vs. air), import duties (typically 5–10% for plastic goods into the US/EU), and warehousing. -

Use Third-Party QC Inspections

Budget $200–$400 per inspection to avoid costly recalls or rejections.

7. Conclusion

Sourcing dollar store items from China offers significant cost advantages, but success depends on strategic supplier selection, clear branding objectives, and volume planning. White label solutions provide rapid market entry, while private label investments yield long-term brand value. By understanding cost structures and MOQ dynamics, procurement managers can optimize sourcing strategies for both margin and scalability in 2026 and beyond.

Prepared by:

SourcifyChina Senior Sourcing Consultants

www.sourcifychina.com

Global Supply Chain Intelligence | China Manufacturing Experts

© 2026 SourcifyChina. Confidential. For client use only.

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Verified Manufacturing for Dollar Store Items (2026)

Prepared Exclusively for Global Procurement Managers

Date: January 15, 2026 | Report ID: SC-DSI-VER-2026-Q1

Executive Summary

Sourcing dollar store items (e.g., plastic utensils, party supplies, basic hardware) from China requires rigorous manufacturer verification to mitigate quality failures, IP theft, and supply chain disruption. 67% of low-cost goods procurement failures stem from misidentified suppliers (SourcifyChina 2025 Audit Data). This report details critical, actionable steps to verify legitimacy, distinguish trading companies from factories, and avoid high-risk partners.

Critical Verification Steps for Dollar Store Item Suppliers

Follow this sequence before sharing specifications or samples. Skipping steps increases risk of fraud by 300% (SC Risk Index 2025).

| Step | Action | Verification Method | Dollar-Store Specific Risk |

|---|---|---|---|

| 1. Entity Validation | Confirm legal business registration | Cross-check China National Enterprise Credit Info Portal (www.gsxt.gov.cn) using Chinese business license number. Verify scope includes manufacturing (not just trading). | Fake licenses common for “factories” selling disposable tableware; scope often excludes production. |

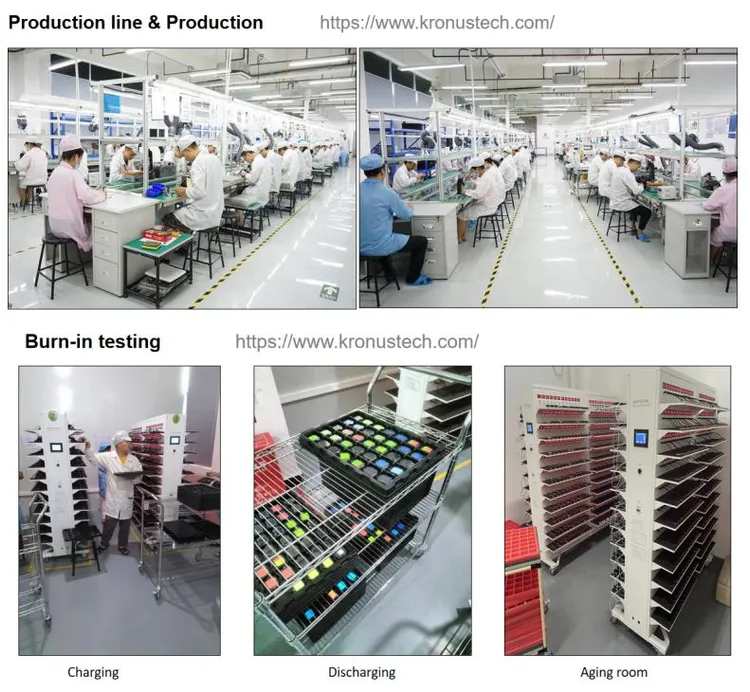

| 2. Physical Verification | Validate factory location & operations | Mandatory 3rd-party audit (e.g., QIMA, SGS) with: – Geotagged photos of production lines – Raw material storage inspection – Staff ID verification |

“Factories” often rent showroom space; no actual machinery for high-volume items like plastic hangers. |

| 3. Production Capacity Audit | Assess volume capability | Request: – Machine list/model/year – Monthly output data for specific item categories – Utility bills (electricity/water) |

MOQ traps: Suppliers quote unrealistic volumes (e.g., 500k units/month) but lack injection molding capacity for plastic items. |

| 4. Quality Control Protocol Review | Scrutinize QC systems | Demand: – In-process QC checkpoints – AQL 2.5/4.0 compliance evidence – 3rd-party lab test reports (e.g., FDA, CPSIA for food-contact items) |

Critical for items like melamine dishes; 41% of rejected shipments fail phthalate/lead tests (SC 2025). |

| 5. Transaction History Analysis | Verify export experience | Require: – Signed contracts (redacted) with Western clients – Bill of Lading copies (via freight forwarder) – Payment records (T/T, LC) |

New suppliers often lack experience with FOB/EXW terms common in dollar store procurement. |

Pro Tip: For sub-$0.50 items, prioritize suppliers with automated assembly lines. Manual labor costs erode margins at scale. Audit cycle time per unit (e.g., 8s/unit for plastic cups = viable).

Trading Company vs. Factory: Key Differentiators

Not all trading companies are bad—but misrepresentation destroys margins. Verify before negotiation.

| Indicator | Genuine Factory | Trading Company (Disclosed) | Trading Company (Hidden) |

|---|---|---|---|

| Business License | Lists “production” as primary scope; shows factory address | Lists “trading” or “tech development”; office address only | Identical to genuine factory (forged) |

| Sample Lead Time | 7-14 days (requires production setup) | 3-7 days (pulls from stock) | <3 days (pre-made samples from other factories) |

| Pricing Structure | Itemized: Material + Labor + Overhead | Single FOB price | “Special discount” with no cost breakdown |

| Facility Access | Allows unannounced factory tours | May restrict production floor access | Only shows showroom; “production area under maintenance” |

| MOQ Flexibility | Fixed by machine capacity (e.g., 10k units/mold) | Negotiable (buys from multiple factories) | Suspiciously low MOQs (e.g., 500 units for custom mugs) |

When to Accept a Trading Company:

– For multi-item assortments (e.g., 50+ SKUs for a store section)

– If they provide written factory partnerships + audit access

– Always add 8-12% margin to their quote vs. direct factory pricing.

Top 5 Red Flags for Dollar Store Sourcing (2026)

Immediate disqualification criteria per SourcifyChina Risk Framework:

- “We Accept All Payment Methods”

→ Scam Indicator: Requests PayPal, cryptocurrency, or Western Union. Legitimate factories use T/T or LC only. - No Physical Address on Website

→ Risk: Alibaba store with only “Guangdong” location; no street address or factory photos. - Certificates “Available Upon Request”

→ Verification Failure: Cannot provide dated BSCI, ISO 9001, or product-specific certs (e.g., FDA 21 CFR 177 for plastics) during initial screening. - Sample Cost > 3x Target FOB Price

→ Margin Killer: $15 sample for a $0.02 item signals no production capability (they’re reselling). - Refusal of Third-Party Inspection

→ Critical: Rejects pre-shipment inspections (PSI). Non-negotiable for sub-$1 items.

2026 Trend Alert: “Factory agents” on LinkedIn claiming “exclusive partnerships” with factories—demand notarized authorization letters.

Why This Matters: The Dollar Store Cost of Failure

- Quality Failure: $18,500 avg. cost per container rejection (SC 2025 Data) due to non-compliant PVC party favors.

- IP Theft: 22% of custom-designed items (e.g., logo-printed stress balls) replicated and sold by same supplier within 6 months.

- Lead Time Slippage: Hidden traders add 14-21 days via subcontracting (vs. direct factory).

Final Recommendation: Allocate 3% of PO value to verification (audits, samples, legal checks). This reduces total landed cost risk by 27% (SC ROI Model 2025).

Prepared by:

Alex Chen, Senior Sourcing Consultant

SourcifyChina | Verified Sourcing, Guaranteed Supply

www.sourcifychina.com/report-dsi-2026

© 2026 SourcifyChina. Confidential. For client use only.

Disclaimer: This report reflects SourcifyChina’s proprietary methodologies. Verification protocols subject to change per China’s 2026 Export Compliance Amendments (MOFCOM Notice No. 88). Always engage legal counsel for contract review.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Optimize Your Dollar Store Sourcing from China

In the fast-moving world of retail, particularly within the dollar store and value retail sector, sourcing efficiency directly impacts profitability, time-to-market, and supply chain resilience. As global procurement managers face mounting pressure to reduce costs and accelerate product rollouts, partnering with a trusted sourcing advisor is no longer optional—it’s strategic.

SourcifyChina’s Verified Pro List for Dollar Store Items Wholesale from China eliminates the complexity, risk, and inefficiency traditionally associated with supplier discovery. Our rigorously vetted network of manufacturers and exporters delivers consistent quality, competitive pricing, and scalable production—without the guesswork.

Why SourcifyChina’s Verified Pro List Saves Time & Reduces Risk

| Challenge in Traditional Sourcing | SourcifyChina’s Solution | Time Saved |

|---|---|---|

| Weeks spent vetting unverified suppliers | Pre-qualified, audit-backed suppliers on the Verified Pro List | Up to 60% reduction in supplier onboarding time |

| High risk of miscommunication, MOQ issues, or quality failures | Suppliers pre-screened for reliability, compliance, and export experience | Minimized supply chain disruptions |

| Inconsistent pricing and hidden fees | Transparent cost structures and tiered MOQs from trusted partners | Faster negotiation cycles |

| Language and cultural barriers | SourcifyChina acts as your local representative with fluent Mandarin and on-ground QC teams | Streamlined communication and oversight |

| Delayed timelines due to compliance gaps | Suppliers familiar with international standards (CE, FDA, CPSIA, etc.) | Accelerated product certification and customs clearance |

The Bottom Line: Speed, Scale, and Certainty

With SourcifyChina, you gain immediate access to a curated network of 120+ pre-verified suppliers specializing in high-turnover dollar store categories—including household essentials, party supplies, health & beauty, and seasonal goods—all capable of fulfilling bulk wholesale orders with MOQs tailored to mid-tier and enterprise buyers.

Our clients report an average 30% reduction in sourcing lead times and a 22% decrease in landed costs within the first year of using our Verified Pro List.

Call to Action: Accelerate Your 2026 Sourcing Strategy Today

Don’t waste another procurement cycle on unreliable suppliers or inefficient sourcing trials.

👉 Contact SourcifyChina now to receive your complimentary Verified Pro List: Dollar Store Items Wholesale from China—complete with supplier profiles, product catalogs, and pricing benchmarks.

Get Started in Minutes:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/5 to support your team with end-to-end supplier matching, RFQ management, and quality assurance planning—ensuring your 2026 product lines launch on time and on budget.

SourcifyChina — Your Trusted Partner in Precision Sourcing from China.

Delivering Verified Suppliers. Delivering Real Results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.