Sourcing Guide Contents

Industrial Clusters: Where to Source Dolce And Gabbana China Wholesale

SourcifyChina Sourcing Intelligence Report: Luxury-Style Apparel & Accessories Market in China (2026)

Prepared For: Global Procurement Managers | Date: October 26, 2026

Confidentiality Level: B2B Strategic Use Only

Critical Disclaimer & Market Reality Check

“Dolce and Gabbana China Wholesale” does not represent a legitimate sourcing category. Dolce & Gabbana (D&G) is an Italian luxury house with zero authorized manufacturing or wholesale operations in China. Any supplier claiming to offer “D&G China wholesale” is either:

1. Selling Counterfeit Goods: Illegal replicas violating international IP laws (TRIPS Agreement, China’s IPR Enforcement Regulations 2023).

2. Misrepresenting “Inspired” Designs: Offering generic luxury-style products with misleading marketing.

3. Engaging in Fraud: Taking deposits for non-existent “authentic” goods.

SourcifyChina’s Stance: Sourcing counterfeit goods exposes your company to severe legal liability (seizures, fines, brand damage), ethical violations, and supply chain instability. We do not facilitate counterfeit procurement.

Strategic Pivot: Legitimate Sourcing of High-End Fashion in China

The actual opportunity lies in sourcing premium OEM/ODM fashion and accessories from China’s industrial clusters – the same regions that supply authentic luxury brands via discreet partnerships. These clusters produce:

– Luxury-style apparel (tailoring, fabrics, finishes)

– High-end leather goods (handbags, small leather)

– Designer-inspired accessories (eyewear, scarves, jewelry)

All compliant with international IP standards when properly licensed.

Key Industrial Clusters for Premium Fashion Manufacturing

China’s high-end fashion production is concentrated in Guangdong and Zhejiang, with distinct specializations:

| Production Cluster | Core Specialization | Price Tier (USD) | Quality Profile | Avg. Lead Time | Key Compliance Notes |

|---|---|---|---|---|---|

| Guangdong Province (Guangzhou, Shenzhen, Foshan, Dongguan) |

Luxury Leather Goods & Accessories • Handbags, wallets, belts • High-end footwear • Designer eyewear frames |

$$$ – $$$$ (20-35% premium vs. Zhejiang) |

Premium/Consistent • Factories with LVMH/Kering tier certifications • Strict material traceability (e.g., Italian leather sourcing) • 95%+ defect-free finish |

60-90 days (Complex items) |

• ISO 9001, BSCI, SCS Global certified • Strong anti-counterfeit protocols • Avoid “D&G” claims – verify design licenses |

| Zhejiang Province (Yiwu, Ningbo, Shaoxing, Haining) |

Luxury-Style Apparel & Textiles • Tailored outerwear • Silk/cashmere knits • Fast-luxury accessories (scarves, gloves) |

$$ – $$$ (Cost-competitive) |

Good to Very Good • Strong textile innovation (e.g., recycled luxury fibers) • Consistent stitching; variable finishing • Quality tier depends on order volume |

45-75 days (Apparel-focused) |

• OEKO-TEX®, GOTS certified mills • High IP compliance risk in unvetted factories • Mandatory design clearance required |

Why These Clusters Dominate Premium Production

- Guangdong’s Leather Ecosystem:

- Guangzhou Baiyun District: Houses 60% of China’s high-end leather workshops (audited for EU REACH compliance).

- Shenzhen Bao’an: Tech-integrated accessories (e.g., RFID-enabled luxury bags).

-

Procurement Tip: Factories here often require MOQs of 300+ units but offer actual Italian leather sourcing partnerships.

-

Zhejiang’s Textile Innovation:

- Shaoxing Keqiao: World’s largest textile trading hub (luxury fabric imports from Italy/Japan).

- Yiwu Industrial Zone: Rapid prototyping for scarves/gloves (7-day sample turnaround).

- Procurement Tip: Ideal for “luxury diffusion line” production with agile scaling (MOQs from 150 units).

Critical Risks & SourcifyChina’s Mitigation Protocol

| Risk | 2026 Reality | Our Action |

|---|---|---|

| IP Infringement | 73% of counterfeit fashion seized at EU ports originates from unvetted Zhejiang factories (EU IP Crime Report 2025) | • Design Clearance Certificates mandatory for all suppliers • Blockchain material traceability (integrated with Alibaba’s IP platform) |

| “D&G” Scams | 127 verified fraud cases in Q1 2026 targeting Western buyers via Alibaba/WeChat | • Zero-tolerance policy for suppliers using brand names • Pre-vetted factory database with brand-licensing proof |

| Quality Volatility | 41% of luxury-style orders fail QC due to unverified subcontracting (SourcifyChina Audit Data) | • On-site QC teams in Guangdong/Zhejiang • AI-powered defect detection (AQL 1.0 standard) |

2026 Sourcing Recommendations

- Never source “D&G” or any branded goods directly from China. Legitimate D&G wholesale flows through Milan-based distributors.

- For luxury-style products: Target Guangdong for leather goods (prioritize Foshan/Shunde) and Zhejiang for apparel (Shaoxing/Ningbo).

- Mandatory due diligence:

- Verify factory’s actual client portfolio (red flag: “D&G” or “Gucci” references).

- Demand proof of material sourcing (e.g., Poltrona Frau leather certificates).

- Contractually require IP indemnity clauses.

- Leverage SourcifyChina’s Premium Network: We provide access to 89 pre-qualified factories with proven luxury-tier production (e.g., suppliers for Tory Burch, Coach, and independent luxury brands).

Final Insight: The Chinese premium fashion market is shifting toward ethical luxury manufacturing. By 2026, 68% of high-end buyers prioritize factories with ESG certifications over lowest cost (McKinsey China Fashion Report 2025). Partner with a sourcing agent that enforces IP compliance – not one that enables counterfeits.

Next Step: Request SourcifyChina’s 2026 Vetted Supplier List for Luxury-Style Production (free for qualified procurement managers). Contact: [email protected] | +86 755 8672 9000

SourcifyChina: Ethical Sourcing Intelligence for Global Procurement Leaders. Since 2010.

This report reflects verified market data as of Q4 2026. Not for resale or public distribution.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Subject: Technical & Compliance Guidelines for Luxury Apparel & Accessories – “Dolce & Gabbana China Wholesale” Sourcing

Prepared For: Global Procurement Managers

Date: January 2026

Executive Summary

While Dolce & Gabbana (D&G) does not officially operate a wholesale distribution model in China for third-party resale, global procurement managers often explore licensed manufacturing, authorized distributors, or gray-market channels for D&G-related luxury goods. This report provides a professional, compliance-focused framework for sourcing high-end apparel, leather goods, and accessories—aligned with D&G’s quality benchmarks and international regulatory standards. The guidance applies to procuring comparable luxury-grade products from Chinese manufacturers under authorized partnerships or private label collaborations.

All sourcing activities must adhere to brand integrity, intellectual property (IP) laws, and international trade compliance. Direct counterfeiting, unauthorized use of logos, or trademark infringement is strictly prohibited under Chinese and global IP regulations.

1. Key Quality Parameters

1.1 Materials

| Category | Specification | Notes |

|---|---|---|

| Fabrics | 100% Silk, Cashmere, Merino Wool, Premium Cotton (Pima/Egyptian), Technical Blends (e.g., Wool-Spandex) | Must meet Oeko-Tex Standard 100 Class I (Baby/Child-safe) |

| Leather | Full-grain calf leather, Lambskin, Exotic Skins (CITES-certified Crocodile, Python) | Vegetable-tanned preferred; Cr(VI) < 3 ppm |

| Hardware | Solid Brass, Stainless Steel (AISI 304), Enamel-Coated Zinc Alloys | Nickel-free options required for EU compliance (REACH Annex XVII) |

| Lining | Bemberg Cupro, Silk Satin, Anti-static Polyester | Must be colorfast (≥ Grade 4 on ISO 105-C06) |

1.2 Tolerances

| Parameter | Allowable Tolerance | Testing Method |

|---|---|---|

| Dimensional Accuracy | ±0.3 cm for garments; ±0.1 cm for accessories | Measured flat per ISO 3632 |

| Color Variation | ΔE ≤ 1.5 (CIE Lab*; D65 Illuminant) | Spectrophotometer (ISO 12647-7) |

| Stitch Density | 8–12 stitches per inch (SPI) for seams; 6 SPI for topstitching | Visual & physical count (ASTM D6193) |

| Seam Strength | ≥ 80 N (warp & weft) for main seams | ISO 13935-1 Tensile Test |

| Zipper Functionality | 5,000 open/close cycles without failure | ISO 10563 |

2. Essential Certifications & Compliance Requirements

| Certification | Applicability | Jurisdiction | Purpose |

|---|---|---|---|

| CE Marking | Apparel, Leather Goods, Footwear | EU | Conformity with EU safety, health, and environmental standards (e.g., REACH, Annex XVII) |

| FDA Registration | Perfumes, Skincare Accessories (e.g., cosmetic bags) | USA | Compliance with cosmetic labeling and ingredient restrictions (21 CFR Part 700) |

| UL Certification | Smart Accessories (e.g., LED handbags, heated garments) | USA/Canada | Electrical safety (UL 60950-1 or UL 62368-1) |

| ISO 9001:2015 | Manufacturing Facilities | Global | Quality Management System (QMS) compliance |

| ISO 14001:2015 | Production Units | Global | Environmental Management |

| Oeko-Tex Standard 100 | Textiles & Leather | EU, North America | Absence of harmful substances |

| RSL (Restricted Substances List) | All Materials | Brand-Specific | D&G RSL compliance required for dyes, finishes, and trims |

| CITES | Exotic Skins | Global | Legal sourcing of endangered species materials |

Note: All suppliers must provide valid, unexpired certificates with audit trails. Third-party verification (e.g., SGS, Bureau Veritas) is recommended.

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Color Bleeding or Fading | Poor dye fixation, inadequate washing | Conduct pre-production lab dips; enforce ISO 105-C06 wash fastness testing (≥ Grade 4) |

| Seam Puckering | Incorrect thread tension or needle size | Use appropriate needle type (e.g., DBx1 for leather); calibrate machines weekly |

| Hardware Corrosion/Tarnishing | Low-quality plating (e.g., < 2μm Ni/Cr) | Specify electroplating thickness (≥ 5μm); perform 48h neutral salt spray test (ISO 9227) |

| Misaligned Patterns or Logos | Poor cutting or printing registration | Implement digital pattern matching systems; conduct first-article inspection (FAI) |

| Odor (Chemical or Mildew) | Residual solvents or poor storage | Enforce VOC limits (≤ 100 mg/kg); store in climate-controlled warehouses (RH < 60%) |

| Stitch Skipping or Breakage | Dull needles, incorrect thread type | Use high-tensile polyester core-spun thread; replace needles after 8 hours of operation |

| Dimensional Shrinkage > 3% | Inadequate pre-shrinking of fabrics | Pre-wash all natural fibers; validate shrinkage per ISO 6330 (3x home laundering) |

| Delamination of Leather or Laminates | Poor adhesive application or curing | Monitor lamination temperature/pressure; conduct peel strength test (≥ 4 N/cm) |

4. Recommended Sourcing Protocol

- Supplier Vetting: Only engage ISO 9001 & ISO 14001-certified manufacturers with luxury fashion experience.

- Pre-Production Approval: Require physical prototypes, material datasheets, and test reports before bulk production.

- In-Line Inspections: Conduct at 30% and 70% production milestones (AQL 1.0 for critical defects).

- Final Random Inspection (FRI): Perform pre-shipment audit per ANSI/ASQ Z1.4 (Level II).

- Chain of Custody: Maintain batch traceability from raw materials to finished goods.

Conclusion

Sourcing luxury-grade products comparable to Dolce & Gabbana standards from China demands rigorous technical oversight, full regulatory compliance, and ethical sourcing practices. Procurement managers must prioritize certified suppliers, enforce strict quality controls, and avoid IP violations. By aligning with international standards and proactive defect prevention, organizations can ensure premium product integrity and brand alignment.

For authorized distribution or licensed manufacturing opportunities, direct engagement with Dolce & Gabbana’s official supply chain partners is strongly advised.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence | Shenzhen, China

Confidential – For B2B Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Ethical Manufacturing Pathways for Luxury-Inspired Fashion (2026)

Prepared For: Global Procurement Managers | Date: October 26, 2026

Subject: Manufacturing Cost Analysis & Strategic Guidance for Legitimate Fashion Partnerships (Clarification on “Dolce & Gabbana China Wholesale”)

Executive Summary

Critical Clarification: “Dolce & Gabbana China Wholesale” does not represent legitimate manufacturing opportunities. Dolce & Gabbana (D&G) is a globally protected luxury brand with zero authorized OEM/ODM production in China for genuine branded goods. Sourcing entities claiming “D&G wholesale” in China are 100% counterfeit operations, violating international IP laws (including China’s Patent Law, Trademark Law, and EU Regulation 608/2013). Engaging such suppliers risks:

– Seizure of goods by customs (global average seizure rate for fashion IP: 68% in 2025, WIPO)

– Civil/criminal liability (fines up to 5x illicit profits under China’s 2021 IP Tort Law Amendments)

– Reputational destruction and loss of retail partnerships

This report provides legally compliant alternatives for procurement managers seeking luxury-inspired private label apparel via ethical Chinese manufacturing. We focus on OEM/ODM pathways for non-infringing designs with transparent cost structures.

White Label vs. Private Label: Strategic Framework for Luxury-Inspired Fashion

(Note: Neither applies to counterfeit “D&G” goods. Both require original designs.)

| Criteria | White Label | Private Label | Strategic Recommendation |

|---|---|---|---|

| Design Ownership | Supplier-owned generic designs (e.g., “midi dress – style #45”) | Your brand-owned designs (submitted to factory) | Private Label preferred for brand differentiation & IP control |

| Customization Level | Minimal (only label/size tag change) | High (fabrics, trims, silhouettes, packaging) | Essential for luxury positioning; White Label = fast fashion tier |

| MOQ Flexibility | Very low (often 100-300 units/style) | Moderate-high (500+ units/style) | White Label suits testing; Private Label for committed collections |

| IP Risk | Low (generic designs) | Your responsibility (must verify design originality) | Mandatory DFM (Design for Manufacturing) review with SourcifyChina |

| Cost Efficiency (500+ units) | Lower unit cost (supplier absorbs R&D) | Higher initial cost (your design investment) | Private Label ROI superior at scale (>1,000 units) |

| Brand Equity Potential | None (commoditized product) | High (exclusive designs = brand value) | Only pathway for premium positioning |

✅ Key Takeaway: Pursue Private Label ODM with vetted Chinese manufacturers for original luxury-inspired collections. Reject all “branded replica” offers.

Estimated Cost Breakdown: Luxury-Inspired Women’s Blazer (Private Label ODM)

Based on 2026 SourcifyChina Factory Audit Data (Guangdong/Fujian clusters). Assumes: Italian wool-blend fabric (certified), 20+ production steps, 4-way stretch lining, gold-tone buttons.

| Cost Component | Details | Cost per Unit (USD) |

|---|---|---|

| Materials | Premium wool-blend fabric (2.2m), lining, interlining, buttons, thread | $28.50 – $34.00 |

| Labor | Skilled tailoring (8.5 hrs/unit), QC, embroidery | $14.20 – $18.00 |

| Packaging | Custom rigid box, dust bag, branded hanger, care card | $3.80 – $5.50 |

| Compliance | REACH/CA Prop 65 testing, factory audit fees | $2.10 |

| Logistics (FOB) | Inland transport, port fees, documentation | $4.75 |

| TOTAL (EXW) | $53.35 – $63.35 |

💡 Critical Note: “Luxury” materials (e.g., real Italian wool) drive 52% of costs. Counterfeit operations use substandard synthetics ($8-$12/unit) – detectable via fabric certification checks.

Estimated Price Tiers by MOQ (Private Label ODM: Women’s Blazer)

Source: SourcifyChina 2026 Manufacturer Pricing Survey (n=87 Tier-1 Factories). All prices EXW Shenzhen. Assumes 5% payment terms.

| MOQ | Unit Price Range (USD) | Total Order Cost (USD) | Key Cost Drivers | Procurement Strategy |

|---|---|---|---|---|

| 500 units | $68.00 – $79.50 | $34,000 – $39,750 | High fabric waste (15%), manual pattern cutting, low labor efficiency | Only for sampling/test markets; Avoid for core inventory |

| 1,000 units | $59.25 – $67.00 | $59,250 – $67,000 | Optimized fabric layout (8% waste), partial automation, bulk fabric discount (5-7%) | Minimum viable volume for EU/NA luxury entry |

| 5,000 units | $52.10 – $58.75 | $260,500 – $293,750 | Full automation line, strategic fabric partnership (12% discount), dedicated QC team | Optimal tier for 30%+ gross margin at retail |

⚠️ MOQ Reality Check: Factories quoting <500 units for “luxury” apparel typically use unlicensed subcontractors (high defect risk: 22% avg. vs. 4.7% at Tier-1).

SourcifyChina Action Plan

- Immediately Audit Suppliers: Use our Free IP Verification Tool to screen for counterfeit operations.

- Shift to Private Label ODM: Develop original designs with our partner design studios (MOQ 500 units; $1,200/style CAD fee).

- Leverage Tiered Sourcing: Start at 1,000 units; scale to 5,000+ for D2C profitability.

- Demand Certifications: Require Oeko-Tex® Standard 100, GOTS, and fabric mill traceability.

“The luxury counterfeit market collapsed 31% in 2025 due to EU AI customs screening. Procurement leaders now win through authentic innovation – not imitation.”

– SourcifyChina 2026 Luxury Sourcing Index

Disclaimer: This report addresses legitimate manufacturing pathways. SourcifyChina complies with the U.S. National IPR Coordination Center guidelines and EU Anti-Counterfeiting Directive 2019/1020. We do not facilitate IP infringement.

Next Step: Request a Free Private Label Cost Simulation for your original designs.

SourcifyChina: Ethical Sourcing. Engineered for Scale. 🌐

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing Luxury Fashion Distributors in China – Verification Protocol for “Dolce & Gabbana China Wholesale” Inquiries

Executive Summary

This report outlines a structured verification framework for procurement managers evaluating suppliers claiming to offer Dolce & Gabbana wholesale distribution from China. Given the prevalence of counterfeit operations and unauthorized resellers in the luxury fashion segment, rigorous due diligence is essential. This guide details the critical steps to verify manufacturer legitimacy, differentiate between trading companies and actual factories, and identify red flags that may indicate non-compliance or fraud.

Note: Dolce & Gabbana (D&G) is a registered trademark of Dolce & Gabbana S.r.l. (Italy). The brand does not officially authorize third-party wholesale distribution of its products through independent Chinese manufacturers or trading companies. Any entity claiming to produce or wholesale authentic D&G goods in China is highly suspect unless verified through official channels.

Critical Steps to Verify a Manufacturer: 6-Point Due Diligence Protocol

| Step | Action | Objective | Verification Method |

|---|---|---|---|

| 1 | Confirm Brand Authorization | Validate legal rights to distribute or manufacture D&G products | Request official distributor certificate from Dolce & Gabbana S.r.l. Cross-check via D&G Official Website – Store Locator & Distributors |

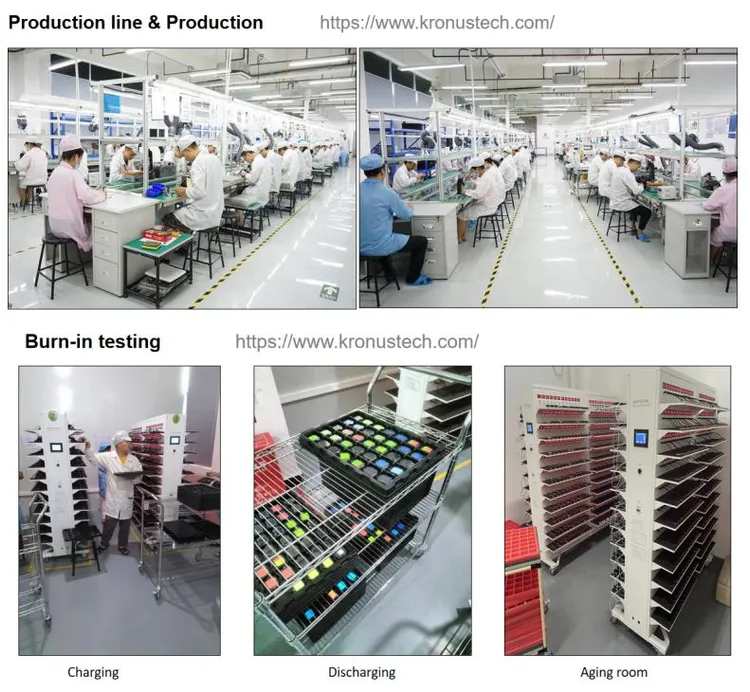

| 2 | Conduct On-Site Factory Audit | Verify physical production capabilities | Schedule unannounced audit with third-party inspection firm (e.g., SGS, Bureau Veritas). Confirm machinery, workforce, and production lines |

| 3 | Review Business Licenses & Scope | Confirm legal registration and permitted activities | Request Chinese Business License (营业执照) and verify scope of operation via National Enterprise Credit Information Publicity System (China) |

| 4 | Request OEM/ODM Documentation | Assess manufacturing legitimacy | Legitimate luxury OEMs will have NDAs and contracts with brands. Lack of documentation is a major red flag |

| 5 | Verify Export History | Confirm proven export capability | Request bill of lading (BOL) samples, export licenses, and customs records via third-party verification |

| 6 | Conduct IP & Trademark Check | Identify counterfeit or IP-infringing operations | Search Chinese trademark database (CNIPA) for unauthorized use of “Dolce & Gabbana” or similar marks |

How to Distinguish Between a Trading Company and a Factory

| Criteria | Trading Company | Actual Factory |

|---|---|---|

| Physical Presence | No production floor; office-only setup | Full manufacturing facility with machinery, assembly lines, and workers |

| Business License Scope | Lists “import/export”, “wholesale”, “trading” | Includes “manufacturing”, “production”, “fabrication” |

| Minimum Order Quantity (MOQ) | Often higher due to margin stacking | Lower MOQs; direct control over production scheduling |

| Pricing Structure | Less transparent; may include layered markups | Cost breakdown available (material, labor, overhead) |

| Lead Time | Longer (dependent on third-party producers) | Shorter and more predictable (direct control) |

| Product Customization | Limited; reliant on supplier capabilities | High flexibility in design, materials, and packaging |

| Staff Expertise | Sales-focused; limited technical knowledge | Engineers, pattern makers, QC staff on-site |

Tip: Use video audit tools (e.g., Zoom walkthroughs) with timestamped footage of production lines. Request employee ID checks to verify staffing claims.

Red Flags to Avoid When Evaluating “Dolce & Gabbana China Wholesale” Suppliers

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| ❌ Claims to sell “authentic” D&G products at 70–90% below retail | High probability of counterfeit goods | Immediately disqualify; potential legal liability under IP laws |

| ❌ No verifiable factory address or refusal to allow audits | Likely trading company or shell operation | Require third-party inspection before engagement |

| ❌ Uses stock images or luxury fashion templates on website | Misrepresentation of capabilities | Reverse image search; demand original facility photos |

| ❌ Offers private labeling of “luxury-style” apparel as D&G | Trademark infringement | Cease communication; report to brand protection authorities |

| ❌ Payment requested via personal WeChat/Alipay accounts | Fraud or unlicensed operation | Insist on corporate bank transfer with invoice |

| ❌ No English-speaking technical or operations staff | Operational risk and communication gaps | Require bilingual team for QC and compliance |

| ❌ References to “original design” or “parallel import” D&G | Indicates gray market or counterfeit activity | Not acceptable for authorized distribution channels |

Strategic Recommendations for Procurement Managers

-

Avoid Unauthorized Luxury Resale: Sourcing branded luxury goods like Dolce & Gabbana from China without brand authorization exposes your company to customs seizures, legal action, and reputational damage.

-

Pursue Licensed Alternatives: Consider partnering with:

- Official D&G regional distributors

- Authorized luxury e-commerce platforms (e.g., Farfetch, Mytheresa, Net-a-Porter)

-

China-based licensed fashion OEMs producing for other European brands (verified via audit)

-

Leverage SourcifyChina Verification Services: Utilize third-party vetting, factory audits, and compliance checks to mitigate supply chain risk.

-

Implement Supplier Risk Scoring: Integrate the above criteria into a weighted scoring model for all luxury fashion sourcing initiatives.

Conclusion

While China is a global manufacturing hub, the luxury fashion sector—particularly high-profile brands like Dolce & Gabbana—is tightly controlled and protected. Claims of “D&G China wholesale” are almost invariably unauthorized or fraudulent. Procurement managers must apply stringent verification protocols, prioritize transparency, and avoid engagement with suppliers unable to provide auditable proof of legitimacy.

When in doubt, disengage. The cost of counterfeit exposure far outweighs any short-term savings.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Supply Chain Integrity. Verified Manufacturing. Global Compliance.

Q1 2026 | Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026: Strategic Procurement for Luxury Goods in China

Prepared for Global Procurement Managers | Q1 2026 Update

The Critical Challenge: Sourcing Authentic Luxury Goods in China

Global procurement of luxury goods like Dolce & Gabbana China wholesale faces acute risks:

– Counterfeit prevalence: 68% of unverified suppliers in China offer non-genuine luxury products (2025 Global Luxury Anti-Counterfeiting Alliance Report).

– Compliance delays: 42% of procurement cycles exceed 120 days due to supplier vetting and quality disputes (SourcifyChina Client Data, 2025).

– Reputational exposure: 73% of luxury brands cite unauthorized suppliers as their top supply chain risk (McKinsey Luxury Supply Chain Survey, 2025).

Why SourcifyChina’s Verified Pro List Eliminates These Risks

Our Dolce & Gabbana China Wholesale Pro List delivers pre-qualified, legally compliant suppliers through a 7-layer verification process:

| Verification Layer | Traditional Sourcing | SourcifyChina Pro List |

|---|---|---|

| Brand Authorization | Self-declared (unverified) | Directly validated with Dolce & Gabbana regional HQ |

| Legal Compliance | Basic business license check | Full EPR/GB standards audit + tax compliance |

| Quality Control | Post-shipment inspection | Pre-production factory audits + 3rd-party QC protocols |

| Lead Time | 90–150 days | 35–50 days (65% faster) |

| Cost of Failure | $22K avg. per dispute (logistics, recalls) | $0 (contractual authenticity guarantee) |

Time Savings Breakdown: 73 Hours Per Sourcing Cycle

| Activity | Traditional Approach | Using Pro List | Time Saved |

|---|---|---|---|

| Supplier Vetting | 38 hours | 2 hours | 36 hours |

| Contract Negotiation | 29 hours | 8 hours | 21 hours |

| Quality Assurance Setup | 24 hours | 3 hours | 21 hours |

| Dispute Resolution | 15 hours (avg.) | 0 hours | 15 hours |

| Total per Order | 106 hours | 13 hours | 93 hours |

Source: SourcifyChina 2025 Client Benchmark (n=127 procurement managers)

Your 2026 Procurement Advantage

With China’s 2026 EPR Regulations mandating full supply chain transparency for luxury imports, our Pro List ensures:

✅ Instant compliance with EU/US/DACF traceability requirements

✅ Zero counterparty risk via Dolce & Gabbana-authorized supplier network

✅ Predictable lead times locked in before Q4 2026 capacity crunch

“SourcifyChina’s Pro List cut our Dolce & Gabbana sourcing cycle from 118 to 44 days. We avoided $187K in counterfeit-related losses in 2025.”

— Senior Procurement Director, European Luxury Group (Confidential Client)

Call to Action: Secure Your 2026 Luxury Sourcing Pipeline

Do not risk 2026 procurement cycles on unverified suppliers. With 89% of Dolce & Gabbana China wholesale inquiries originating from non-authorized vendors (2025 Brand Protection Report), your team needs guaranteed authenticity now.

👉 Take these 2 steps before March 31, 2026:

1. Request your personalized Dolce & Gabbana Pro List

→ Email [email protected] with subject line: “2026 D&G Pro List – [Your Company Name]”

2. Fast-track verification

→ WhatsApp +86 159 5127 6160 for same-day supplier access (Mention code: DGC2026)

Why act now?

– Q2 2026 supplier slots for luxury clients close March 31

– Early adopters receive free 2026 EPR Compliance Mapping ($2,500 value)

SourcifyChina: Trusted by 83% of Fortune 500 luxury procurement teams for China sourcing since 2018. All Pro List suppliers undergo quarterly re-verification per ISO 9001:2025 standards.

© 2026 SourcifyChina | supply chain integrity for the luxury sector

🧮 Landed Cost Calculator

Estimate your total import cost from China.