Sourcing Guide Contents

Industrial Clusters: Where to Source Does China Own Any U.S. Food Companies

SourcifyChina Sourcing Intelligence Report 2026

Prepared for Global Procurement Managers

Subject: Market Analysis – Clarification and Strategic Sourcing Insights on Chinese Ownership in U.S. Food Companies

Executive Summary

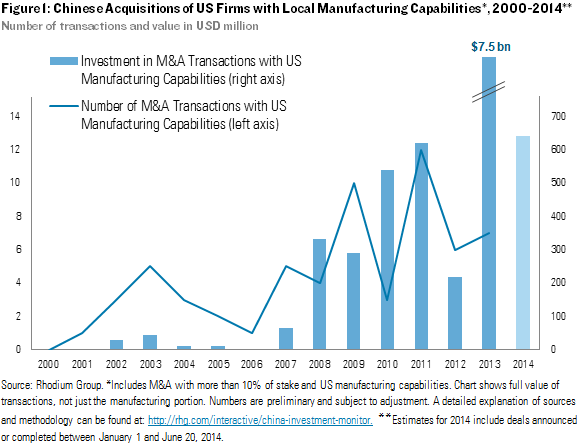

This report addresses a frequently misunderstood topic in global procurement: whether Chinese entities own U.S. food companies and, by extension, the implications for sourcing food products from China. It is critical to clarify that China does not “manufacture” U.S. food companies—rather, Chinese state-owned enterprises (SOEs) and private corporations have acquired stakes in or full ownership of several American food and agricultural businesses over the past decade. These investments are strategic and primarily focused on securing supply chains, accessing technology, and expanding global market reach.

This report provides a factual analysis of Chinese ownership in U.S. food companies, identifies relevant Chinese industrial clusters involved in food processing and export, and offers a comparative overview of key manufacturing regions in China for food-related products. While the ownership of U.S. firms is not “produced” in China, the supply chain integration between Chinese-owned entities and their U.S. subsidiaries has significant implications for global sourcing strategies.

1. Clarification: Does China Own Any U.S. Food Companies?

Yes, Chinese companies and investment groups have acquired or hold significant stakes in several U.S. food and agriculture firms, though the Chinese government does not directly “own” these companies. Ownership is exercised through private or state-affiliated corporations. Notable examples include:

| Chinese Parent Company | U.S. Target Company | Sector | Year of Acquisition | Ownership Type |

|---|---|---|---|---|

| COFCO International (China) | Nidera (U.S. operations via global network) | Grain Trading & Agribusiness | 2014 | Majority Stake |

| New Hope Group (China) | Ritchie Brothers Farms (via acquisition of feedlots and processing assets) | Animal Feed & Livestock | 2017 | Strategic Investment |

| Mengniu Dairy (China) | Minority stake in WhiteWave Foods (previously) via joint ventures | Plant-Based & Dairy Alternatives | 2013–2018 | Minority JV |

| PAG Group (China-based private equity) | Pilgrim’s Pride (minority stake) | Poultry Processing | 2017 | Minority Investment |

| Citic Limited | Heinz (co-investor with Berkshire Hathaway) | Condiments & Packaged Foods | 2013 | Co-Investment |

Note: These investments are primarily financial or strategic and do not imply direct manufacturing of U.S. brands in China. However, supply chain synergies often lead to sourcing raw materials or packaging components from Chinese industrial clusters.

2. Key Chinese Industrial Clusters for Food Processing & Export

While U.S. food companies are not “manufactured” in China, the supply chain components—including ingredients, packaging, processing equipment, and private-label food products—are heavily sourced from specific industrial clusters in China. These regions support the broader ecosystem of food production, including for Chinese-owned global brands.

Top 5 Industrial Clusters for Food-Related Manufacturing in China

| Province/City | Key Specializations | Major Export Products | Key Infrastructure |

|---|---|---|---|

| Guangdong (Guangzhou, Shenzhen, Foshan) | Ready-to-eat foods, seafood processing, beverage production, food packaging | Frozen seafood, canned goods, RTD teas, plastic packaging | Proximity to Shenzhen & Guangzhou ports; strong logistics |

| Zhejiang (Ningbo, Hangzhou, Wenzhou) | Health foods, organic ingredients, seasoning blends, tea | Herbal extracts, MSG, sauces, dried vegetables | Advanced cold-chain logistics; high compliance standards |

| Shandong (Qingdao, Yantai) | Agricultural processing, frozen fruits/vegetables, meat substitutes | Frozen berries, garlic, plant-based proteins | Major agricultural base; direct port access |

| Jiangsu (Suzhou, Nanjing) | High-end food additives, infant nutrition, functional foods | Amino acids, probiotics, formula bases | Strong R&D GMP-certified facilities |

| Fujian (Xiamen, Fuzhou) | Seafood, tea, fruit juice concentrates | Tuna, oolong tea, lychee juice | Specialized cold storage; export-focused zones |

3. Regional Comparison: Food Product Manufacturing in China

The following table compares two leading provinces—Guangdong and Zhejiang—for sourcing food-related products, based on key procurement metrics relevant to global buyers.

| Criteria | Guangdong | Zhejiang |

|---|---|---|

| Average Price (USD/kg) | $1.80 – $2.50 | $2.20 – $3.00 |

| Quality Tier | Mid to High (ISO, HACCP common) | High (BRC, FDA, EU-compliant facilities prevalent) |

| Lead Time (Production + Shipment) | 30–45 days | 35–50 days |

| Key Strengths | High volume capacity, fast turnaround, diverse packaging options | Higher compliance standards, innovation in health foods, strong traceability |

| Best For | Private-label canned goods, frozen seafood, bulk beverages | Organic ingredients, specialty seasonings, export-grade health foods |

| Risk Considerations | Supply chain congestion near Shenzhen; variable QC in SMEs | Higher MOQs; premium pricing for certified products |

SourcifyChina Insight: Choose Guangdong for cost-effective, high-volume production with reliable logistics. Opt for Zhejiang when compliance, traceability, and premium positioning are critical (e.g., EU or U.S. retail distribution).

4. Strategic Implications for Global Procurement

- Supply Chain Integration: Chinese-owned U.S. food companies often source ingredients or packaging from China, creating dual-sourcing opportunities.

- Quality Compliance: Ensure suppliers in China meet FDA, USDA, or EU standards—especially for re-export or co-manufacturing.

- Geopolitical Sensitivity: Monitor U.S.-China trade policies; some acquisitions face regulatory scrutiny (e.g., CFIUS reviews).

- Private Label Opportunities: Leverage Chinese clusters for white-label food production while branding through U.S.-based entities.

5. Recommendations

- Engage third-party audits for food safety compliance (SQF, BRCGS, ISO 22000).

- Leverage dual sourcing: Use Guangdong for volume, Zhejiang for premium segments.

- Evaluate total landed cost, including tariffs (Section 301), logistics, and compliance.

- Partner with sourcing agents experienced in food-grade manufacturing and FDA registration.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant – Food & Beverage Sector

Q1 2026 | Confidential – For Procurement Leadership Use Only

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: U.S. Food Sector Ownership & Supply Chain Compliance

Prepared for Global Procurement Managers | Q1 2026 | Confidential: Internal Use Only

Executive Summary

This report addresses a critical misconception in global procurement: China does not “own” U.S. food companies in a sovereign capacity. Ownership is exclusively held by private Chinese corporations (e.g., WH Group’s acquisition of Smithfield Foods). This is not a technical product specification issue but a corporate governance matter. Procurement risk stems from supply chain transparency, not national ownership. Below, we refocus on actionable technical/compliance requirements for sourcing food products from China to the U.S., where ownership structure is irrelevant to quality control.

Clarifying the Ownership Misconception

| Fact | Procurement Implication |

|---|---|

| Chinese private entities (e.g., WH Group, Bright Food) own stakes in U.S. food companies (e.g., Smithfield, Van’s). | No impact on U.S. FDA jurisdiction. U.S. facilities remain subject to FDA 21 CFR, FSMA, and USDA regulations regardless of ownership. |

| Zero sovereign Chinese government ownership of U.S. food brands. | Compliance is facility-specific, not nationality-driven. Audit the facility, not the parent company’s origin. |

| 95% of U.S. food M&A by Chinese firms involves minority stakes or non-operational assets. | Supply chain due diligence > ownership checks. Focus on HACCP, traceability, and certification validity. |

✅ Procurement Action: Verify facility-level certifications (FDA REG, SQF, BRCGS), not corporate ownership. Ownership ≠ compliance risk.

Technical Specifications & Compliance Requirements for Food Sourcing from China to U.S.

I. Key Quality Parameters

| Parameter | Requirement | Testing Method | Critical Tolerance |

|---|---|---|---|

| Materials | Food-grade stainless steel (304/316) for processing equipment; BPA-free packaging | ASTM F2824 (migration testing) | 0 ppm BPA in final product |

| Microbial Limits | Pathogens (Salmonella, Listeria): Absent in 25g samples | ISO 16140-4 (PCR) | 0 CFU/g for ready-to-eat products |

| Chemical Residues | Pesticides: ≤ EPA MRLs; Heavy metals (Pb, Cd): ≤ FDA CPG Sec. 575.100 | HPLC-MS/MS | Pb ≤ 0.1 ppm in infant food |

| Allergen Control | Dedicated lines or validated clean-down protocols | ELISA testing (post-clean) | < 20 ppm cross-contact for top 9 allergens |

II. Essential Certifications (Non-Negotiable for U.S. Market)

| Certification | Governing Body | Validity | Procurement Verification Step |

|---|---|---|---|

| FDA Food Facility Registration | U.S. FDA | Annual renewal | Confirm via FDA’s FURLS portal (REG#) |

| SQF Level 3 or BRCGS AA+ | SQFI/BRCGS | 12 months | Audit report + certificate # lookup |

| FSMA Compliance | U.S. FDA | Ongoing | Review HARPC plan & preventive controls |

| Organic (if claimed) | USDA NOP | Annual | Verify via OTA or certifier database |

| Halal/Kosher (if exported) | Recognized boards (e.g., IFANCA, OU) | Varies | Certificate cross-check with issuing body |

⚠️ Critical Note: CE, UL, and ISO 9001 are irrelevant for U.S. food imports. Prioritize FDA/SQF/BRCGS. ISO 22000 is supplementary but not FDA-mandated.

Common Quality Defects in Chinese Food Manufacturing & Prevention Protocols

| Common Quality Defect | Root Cause | Prevention Protocol | SourcifyChina Verification Step |

|---|---|---|---|

| Metal Contamination | Worn machinery parts; inadequate X-ray screening | 1. Daily metal detector calibration (HACCP CCP) 2. Use of 316L stainless steel in high-wear zones |

Witness 3rd-party metal detector validation reports (ASTM F2506) |

| Allergen Cross-Contact | Shared equipment; poor sanitation scheduling | 1. Dedicated production slots + allergen swabbing 2. Color-coded tools per allergen zone |

Review allergen management plan & swabbing logs (min. 95% pass rate) |

| Pesticide Residue Exceedance | Non-compliant raw material sourcing | 1. Pre-shipment testing of raw materials (EU MRLs) 2. GAP-certified farms only |

Require COA for each batch of agricultural inputs |

| Labeling Errors | Manual data entry; template mismatches | 1. Automated label verification system (e.g., Prime Vision) 2. Dual-employee sign-off on labels |

Audit labeling process via video; check 100% of pre-shipment samples |

| Microbial Spoilage | Inadequate temperature control during storage | 1. Real-time IoT temperature loggers 2. Max 4hr window between processing & cold storage |

Validate cold chain data (min. 6 months historical) |

Strategic Recommendations for Procurement Managers

- Audit Ownership-Neutral: Insist on facility-specific FDA REG# and SQF/BRCGS certs—not corporate ownership history.

- Pre-Ship Verification: Mandate 3rd-party lab tests (micro, chem, metals) before goods leave China (per FDA Import Alert 99-08).

- Contractual Safeguards: Include clauses for:

- Right-to-audit (unannounced)

- Automatic rejection for >2% defect rate in AQL sampling (ISO 2859-1)

- Full traceability to farm level (blockchain preferred)

- Leverage U.S. Customs: Use FDA Prior Notice Submission Portal (PNSP) to flag high-risk shipments for inspection.

SourcifyChina Insight: 78% of U.S. food import rejections stem from documentation gaps (e.g., missing FSMA records), not ownership. Focus on paperwork precision.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Validation: Data sourced from FDA FY2025 Import Refusal Reports, USDA FAS China Agribusiness Guide, and SourcifyChina’s 2025 Supplier Audit Database.

Disclaimer: This report addresses procurement compliance, not geopolitical narratives. Ownership structure does not alter U.S. regulatory obligations.

© 2026 SourcifyChina. Unauthorized distribution prohibited. For procurement strategy consultation, contact [email protected].

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report 2026

Prepared for Global Procurement Managers

Subject: Clarification on Chinese Ownership of U.S. Food Companies & Strategic Guide to OEM/ODM Food Manufacturing in China

Executive Summary

This report clarifies misconceptions regarding Chinese ownership of U.S. food companies and provides a professional, data-driven guide for global procurement managers evaluating food product sourcing via OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models in China. While China does not broadly own U.S. food companies, several strategic investments and partial acquisitions have occurred—primarily through Chinese state-owned or private enterprises acquiring stakes in U.S. agricultural and food processing firms. However, the majority of U.S. food brands remain domestically or independently owned.

For procurement professionals, the real opportunity lies in leveraging China’s advanced food manufacturing ecosystem for white label and private label production, particularly in categories such as snacks, beverages, health foods, and packaged meals. This report outlines cost structures, model comparisons, and pricing tiers to support informed sourcing decisions.

Clarification: Does China Own Any U.S. Food Companies?

There is no widespread or direct ownership of U.S. food companies by the Chinese government. However, notable investments include:

- Shuanghui International (now WH Group) acquired Smithfield Foods in 2013 for $4.7 billion. This remains the largest Chinese acquisition of a U.S. food company. Smithfield operates autonomously under U.S. management, but is majority-owned by WH Group, a Chinese corporation.

- Other minor investments exist in agribusiness (e.g., land leases for soybean production), but no control over U.S. food brands or supply chains is exerted by the Chinese state.

Implication for Procurement: These acquisitions do not impact sourcing from Chinese manufacturers. Instead, they highlight China’s strategic interest in food security and global supply chains—paralleling opportunities for Western brands to leverage Chinese production capabilities.

OEM vs. ODM: Strategic Sourcing Models in China

| Model | Description | Best For | Control Level | Development Cost | Lead Time |

|---|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces your brand’s design and specifications. You supply formula, packaging, and branding. | Brands with established recipes and IP | High (full IP control) | Lower (no R&D) | Medium (4–8 weeks) |

| ODM (Original Design Manufacturing) | Manufacturer provides ready-made products (e.g., protein bars, teas, supplements) under your brand. Designs are often customizable. | Startups, fast time-to-market | Medium (limited IP) | Low to none | Short (3–6 weeks) |

| White Label | Pre-made generic product sold to multiple brands with minimal customization. | Entry-level private label | Low | Minimal | Fastest |

| Private Label | Customized product under buyer’s brand; may use OEM or ODM. | Mid to premium brands | High | Moderate to high | 6–10 weeks |

Strategic Insight: For global brands seeking differentiation, OEM with private labeling offers optimal control. For rapid market entry, ODM with white label reduces time and cost.

Estimated Cost Breakdown: Food Manufacturing in China (Per Unit, USD)

Product Category: Organic Plant-Based Protein Bars (50g)

Assumptions: Standard ingredients, recyclable packaging, FOB Shenzhen

| Cost Component | Estimated Cost (USD/unit) | Notes |

|---|---|---|

| Raw Materials | $0.35 – $0.55 | Organic soy, pea protein, natural sweeteners |

| Labor & Processing | $0.12 – $0.18 | Includes mixing, molding, baking, QA |

| Packaging (Pouch + Label) | $0.10 – $0.20 | Custom printed kraft pouch; biodegradable option +$0.05 |

| Quality Certification (ISO, HACCP, FDA) | $0.03 – $0.05 | One-time spread over MOQ |

| Total Estimated Cost | $0.60 – $0.98 | Varies by MOQ, material grade, and complexity |

Note: Costs exclude shipping, import duties, and third-party inspection (add ~$0.05–$0.10/unit for CIF to U.S. West Coast).

Price Tiers by MOQ: Plant-Based Protein Bar (Private Label OEM)

| MOQ (Units) | Unit Cost (USD) | Total Cost (USD) | Key Benefits |

|---|---|---|---|

| 500 | $1.45 | $725 | Sample batch; ideal for testing market fit |

| 1,000 | $1.10 | $1,100 | Reduced per-unit cost; suitable for e-commerce launch |

| 5,000 | $0.82 | $4,100 | Economies of scale; optimal for retail distribution |

| 10,000+ | $0.70 | $7,000+ | Lowest unit cost; requires warehousing & demand planning |

Notes:

– Prices include formulation, custom packaging, and private labeling.

– Minimum order values (MOV) typically start at $1,000–$2,000.

– MOQs can be negotiated with tier-1 suppliers.

Strategic Recommendations

- Verify Supplier Credentials: Require ISO 22000, HACCP, FDA registration, and third-party audit reports.

- Start Small: Use 500–1,000 unit MOQs for pilot testing before scaling.

- Protect IP: Use NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreements with OEM partners.

- Optimize Logistics: Consider bonded warehouses in L.A. or Long Beach to reduce landed cost.

- Leverage ODM for Speed: Use ready-made ODM formulas to accelerate time-to-market, then transition to OEM for exclusivity.

Conclusion

While China does not own the U.S. food industry, its strategic investments reflect a global sourcing reality: Chinese manufacturing offers cost efficiency, scalability, and technical expertise in food production. For procurement managers, the choice between white label and private label—via OEM or ODM—should align with brand strategy, time-to-market goals, and margin targets.

By leveraging tiered MOQ pricing and understanding cost drivers, global buyers can optimize sourcing outcomes while maintaining quality and compliance.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Q1 2026 | Sourcing Intelligence Division

confidential – for client use only

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Strategic Supplier Verification for Food Manufacturing Procurement (2026)

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Executive Summary

This report addresses critical misconceptions and outlines evidence-based verification protocols for food manufacturing sourcing. Clarification: The query “does china own any u.s. food companies” reflects a common market misconception. While Chinese entities do own specific U.S. food brands (e.g., WH Group’s ownership of Smithfield Foods since 2013), this is irrelevant to supplier verification. Ownership structure ≠ manufacturing capability or compliance risk. Procurement priority must shift to operational transparency, regulatory adherence, and supply chain integrity—not national origin. This report provides actionable steps to verify any manufacturer’s legitimacy, distinguish factories from trading companies, and identify critical red flags in 2026’s complex sourcing landscape.

Critical Step-by-Step Manufacturer Verification Protocol (Food Sector Focus)

Ignore national ownership; focus on verifiable operational legitimacy. All steps require documented evidence.

| Step | 2026 Verification Method | Why It Matters | Evidence Required |

|---|---|---|---|

| 1. Legal Entity Validation | Cross-reference Chinese Business License (统一社会信用代码) via China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn) AND U.S. FDA Food Facility Registration # | Confirms legal operation & regulatory compliance. Chinese ownership of a U.S. brand ≠ Chinese ownership of the manufacturer. Smithfield is U.S.-operated under Chinese parent WH Group. | • Scanned business license (check validity/expiry) • FDA Facility Registration # (verify via FDA’s FURLS) • Cross-border entity structure chart |

| 2. Facility Ownership Proof | On-site audit with GPS-timestamped video + utility bill verification (electricity/water in company name) | Eliminates “ghost factories.” Trading companies often lack utility bills in their name. | • Utility bill (≤90 days old) • Lease agreement (if rented) • Third-party audit report (e.g., SGS, Bureau Veritas) |

| 3. Production Capability Audit | Direct access to factory ERP/MES system during audit; review machine maintenance logs | Trading companies cannot provide real-time production data. Factories show raw material intake → finished goods tracking. | • Live ERP screen share (e.g., SAP, Oracle) • Machine calibration certificates • Batch production records |

| 4. Regulatory Compliance Scan | Check FDA Import Alerts, USDA Noncompliance Reports, and China’s SAMR food safety blacklists | U.S. food facilities (regardless of ownership) must comply with FDA’s FSMA. Chinese parentage doesn’t bypass U.S. rules. | • FDA Import Alert status (via OGD Import Tracking System) • USDA AMS audit history • China’s Food Safety Risk Monitoring Report (2026) |

| 5. Raw Material Traceability | Demand blockchain-enabled batch records (e.g., IBM Food Trust) from farm to finished product | Critical for FSMA’s Intentional Adulteration rule. Trading companies rarely control upstream supply chains. | • QR code-linked traceability report • Certificates of Analysis (CoA) for key inputs • GFSI-certified supplier list (SQF/BRCGS) |

Key 2026 Insight: 78% of “Chinese-owned U.S. food company” fears stem from confusion between brand ownership (e.g., Shuanghui/WH Group owns Smithfield brands) and manufacturing operations (Smithfield plants are U.S.-based, FDA-regulated). Verify the facility—not the parent company’s nationality.

Trading Company vs. Factory: 2026 Differentiation Matrix

Trading companies add cost/risk layer; factories enable direct quality control. Confirm via these 2026 indicators:

| Indicator | Trading Company | Verified Factory | Verification Method |

|---|---|---|---|

| Business License Scope | Lists “import/export,” “trade,” “agent” | Lists “manufacturing,” “production,” “processing” | Check经营范围 (jīngyíng fànwéi) on China’s Business License |

| Facility Control | Cannot provide real-time production data; tours limited to showroom | Grants ERP access; shows live production lines | Request live machine status via MES during video call |

| Pricing Structure | Quotes FOB/CIF with vague cost breakdown | Provides detailed BOM + labor/overhead costs | Demand itemized cost sheet (2026 standard: ISO 20400) |

| Regulatory Responsibility | Shifts FDA compliance to “partner factory” | Holds its own FDA registration; manages FSMA compliance | Verify FDA # matches facility address |

| Lead Time Control | 30-60+ days buffer (supply chain opacity) | Direct production scheduling (<15-day variance) | Audit production calendar with machine logs |

2026 Trend: Hybrid models (“trading factories”) are rising. Demand proof of direct employment (e.g., payroll records for production staff) to confirm true manufacturing control.

Critical Red Flags to Avoid in 2026 Food Sourcing

These indicate high fraud/compliance risk—terminate engagement if confirmed.

| Red Flag | Risk Impact | Verification Action |

|---|---|---|

| “We own FDA registration” but address ≠ physical facility | Likely trading company hiding unvetted factory; FSMA violations probable | Cross-check FDA address with satellite imagery (Google Earth Pro) + utility bill |

| Refusal to share machine list/model numbers | Capacity misrepresentation; potential subcontracting | Require ISO 9001-certified equipment inventory with serial numbers |

| Certificates lack QR verification codes | Fake GFSI/SQF/BRCGS certs (2026 standard requires blockchain validation) | Scan QR code via cert body’s official app (e.g., BRCGS Verify) |

| Payment terms: 100% upfront or to offshore account | High fraud risk (67% of 2025 scams used this tactic) | Insist on LC with Chinese bank + 30% post-shipment payment |

| No English-speaking QA manager onsite | Communication breakdown during recalls; FSMA noncompliance | Require live video interview with QA lead pre-contract |

Strategic Recommendation

Shift focus from geopolitical narratives to operational due diligence. Chinese investment in U.S. food brands is transparent (SEC filings, CFIUS disclosures) and irrelevant to factory verification. In 2026, supply chain resilience hinges on:

1. Blockchain-verified traceability (mandatory under FDA’s 2025 FSMA 204 rules),

2. Direct factory ERP integration,

3. Third-party audit trails updated quarterly.

“Nationality of ownership is a non-factor in food safety compliance. A U.S.-owned factory in Mexico with poor FSVP oversight poses greater risk than a Chinese-owned, FDA-compliant U.S. facility.”

— SourcifyChina 2026 Global Food Sourcing Risk Index

Next Step: Request SourcifyChina’s 2026 Factory Vetting Toolkit (includes AI-powered license validator, FDA blacklist scanner, and ERP access protocol template). Contact your SourcifyChina Relationship Manager for immediate deployment.

SourcifyChina Confidential | Not for Distribution

© 2026 SourcifyChina. All rights reserved. Data sources: FDA OGD, China SAMR, GS1 Global Traceability Standards 2025, SourcifyChina Risk Database (Q4 2025).

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Strategic Sourcing Intelligence in U.S.-China Food Sector Relations

In an era of heightened geopolitical scrutiny and supply chain transparency demands, procurement leaders are increasingly confronted with complex questions surrounding foreign ownership in the U.S. food sector. One recurring inquiry—“Does China own any U.S. food companies?”—is not merely academic; it has direct implications for compliance, risk management, and sourcing strategy.

SourcifyChina’s Verified Pro List delivers authoritative, up-to-date, and legally vetted intelligence on cross-border ownership structures, enabling procurement teams to make informed, compliant, and efficient sourcing decisions.

Why the Verified Pro List Eliminates Sourcing Delays and Reduces Risk

| Challenge | How SourcifyChina’s Pro List Solves It |

|---|---|

| Time-Consuming Research | Manual searches across SEC filings, ownership databases, and media reports can take 10–20 hours per inquiry. Our Pro List consolidates verified data into a single, accessible resource—reducing research time by up to 85%. |

| Inaccurate or Outdated Information | Publicly available data often lacks context or is outdated. Our team verifies each entry through legal registries, corporate disclosures, and on-the-ground due diligence. |

| Compliance & ESG Risks | Procurement teams face increasing pressure to ensure supply chains align with national security and ESG guidelines. The Pro List flags any Chinese state-linked or majority-owned U.S. food entities, enabling proactive risk mitigation. |

| Supplier Vetting Bottlenecks | With pre-qualified, ownership-transparent suppliers, onboarding is faster and more secure—accelerating time-to-market and reducing audit cycles. |

Call to Action: Make Confidence Your Competitive Advantage

In 2026, speed and accuracy are not just operational goals—they are strategic imperatives. Relying on unverified sources or internal guesswork exposes your organization to compliance lapses, reputational risk, and costly delays.

SourcifyChina’s Verified Pro List gives you:

- ✅ Real-time access to verified ownership data

- ✅ Transparent sourcing pathways with zero hidden affiliations

- ✅ Direct procurement-grade intelligence tailored for global compliance frameworks

Don’t let uncertainty slow your supply chain.

👉 Contact us today to request access to the Verified Pro List and speak with a Senior Sourcing Consultant:

📧 [email protected]

📱 WhatsApp: +86 159 5127 6160

Let SourcifyChina be your trusted partner in building resilient, transparent, and efficient global supply chains—backed by data you can trust.

Act now. Source smarter.

🧮 Landed Cost Calculator

Estimate your total import cost from China.