The direct-to-garment (DTG) printing market has experienced robust growth, driven by rising demand for customized apparel, advancements in inkjet technology, and the expansion of e-commerce platforms. According to Grand View Research, the global textile printing market was valued at USD 9.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030, with DTG technology capturing an increasing share due to its efficiency in short-run and on-demand production. This surge in demand has fueled competition and innovation among equipment manufacturers, positioning DTG printers as essential tools for print shops, brands, and entrepreneurs. As the industry evolves, identifying the leading DTG shirt printer manufacturers—those combining technological excellence, reliability, and scalability—becomes critical for businesses aiming to capitalize on the customization trend. The following list highlights the top 10 manufacturers shaping the future of garment printing, based on market presence, technological innovation, customer reviews, and performance data.

Top 10 Direct To Garment Shirt Printer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 M&R Printing Equipment Inc. :: DTF

Domain Est. 1996

Website: mrprint.com

Key Highlights: M&R makes a wide range of textile printing equipment, including Direct to Film (DTF), Direct to Garment, (DTG), Hybrid Digital Printing, manual & automatic ……

#2 Hybrid DTG/DTFilm Printers

Domain Est. 1991

Website: epson.com

Key Highlights: Epson’s powerhouse hybrid DTG/DTFilm printers: engineered for high quality, hybrid print capabilities, and on-demand printing….

#3 DTG G4 Printer: Benefits for Your Business

Domain Est. 2010

Website: coldesi.com

Key Highlights: DTG Printers are Inkjet printers that squirt the ink directly onto the t-shirt. But not all of that ink ends up in the garment. Some is sprayed into the air ……

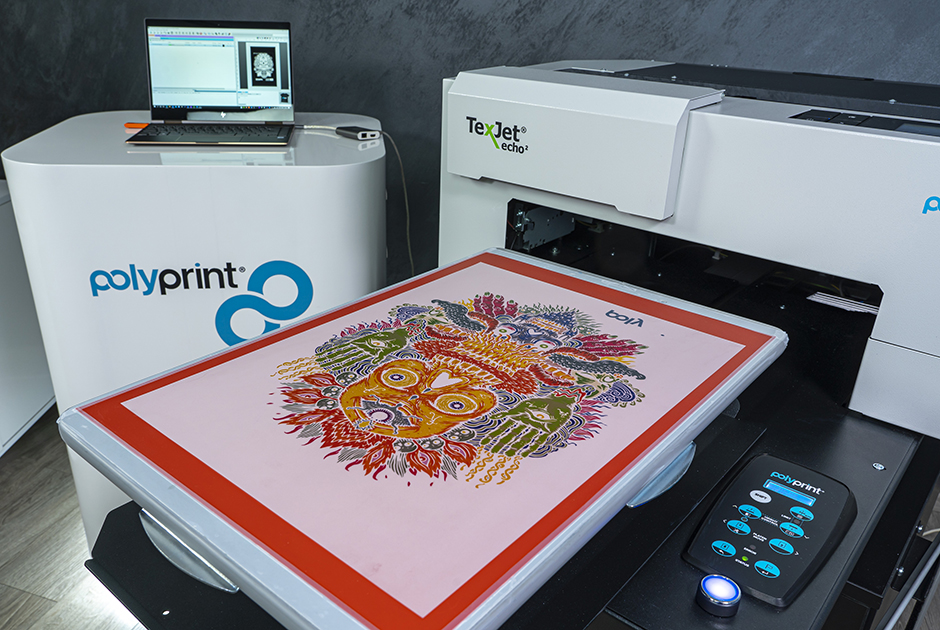

#4 POLYPRINT

Domain Est. 2014

Website: polyprintdtg.com

Key Highlights: We design, develop, and manufacture DTG & DTF printers and pretreatment machines, providing everything you need to create a successful garment printing ……

#5 T-Shirt Printing & Fulfillment

Domain Est. 2014

Website: scalablepress.com

Key Highlights: PRINT-ON-DEMAND FULFILLMENT. Scalable Press lets you order 1000s of print-on-demand products from different suppliers through a single-invoice ordering platform….

#6 GTXpro Direct to Garment Printer Specifications

Domain Est. 2015

Website: brotherdtg.com

Key Highlights: Built from the ground up with the best software & print heads, the GTXpro direct to garment printer is a powerful tool for your business….

#7 DTG Printers

Domain Est. 2017

Website: dtgpro.com

Key Highlights: 4-day delivery · 30-day returnsDTG Printers are Direct to Garment Printers. Innovative and cutting edge textile printing solutions are now within reach! PRINT ON DEMAND. 100% CUST…

#8 Direct to Garment (DTG) Printing

Domain Est. 1997

Website: directcolorsystems.com

Key Highlights: Our DTG printer uses the best digital printing methods to produce high-quality garment designs with strength and durability….

#9 DTG Printer Best Direct to Garment Printing Machines for T

Domain Est. 2019

#10 Best DTG Printer For Sale DTG Printing Machine For Small Business

Domain Est. 2023

Website: antprintmall.com

Key Highlights: Free deliveryA3 Direct To Garment Printer. A3 size dtg printer with max printing size 33*50cm format, it can print 1 pcs A3 size adult tshirt, or 2 pcs small A4 ……

Expert Sourcing Insights for Direct To Garment Shirt Printer

H2: 2026 Market Trends for Direct-to-Garment (DTG) Shirt Printers

The Direct-to-Garment (DTG) shirt printing market is poised for significant transformation by 2026, driven by technological advancements, shifting consumer preferences, and the expansion of on-demand and sustainable fashion. As businesses increasingly embrace customization and rapid production, DTG printers are emerging as a core component of modern apparel manufacturing. Here are the key trends shaping the DTG printer market in 2026:

1. Technological Innovations Enhancing Speed and Quality

By 2026, DTG printers are expected to feature faster print speeds, improved ink formulations, and higher resolution capabilities. Manufacturers are investing in advanced printhead technology and automated pre-treatment systems to reduce labor costs and increase throughput. Integration with IoT and AI is enabling predictive maintenance and real-time performance monitoring, boosting operational efficiency for both small businesses and large-scale operations.

2. Growing Demand for Customization and Personalization

Consumers continue to favor personalized apparel, especially in e-commerce and niche markets. DTG technology excels in short-run, on-demand printing, aligning perfectly with this trend. Platforms integrating user-friendly design tools with direct DTG fulfillment are gaining popularity, enabling individuals and brands to launch custom merchandise with minimal inventory risk. This trend is particularly strong in regions with high e-commerce penetration, such as North America and Western Europe.

3. Expansion of Sustainable and Eco-Friendly Practices

Sustainability is a major driver in the DTG market. By 2026, water-based, low-VOC inks and energy-efficient printers are becoming standard. Consumers and brands alike are prioritizing environmentally responsible production, and DTG offers advantages over traditional screen printing by minimizing water waste and chemical use. Print-on-demand models further reduce overproduction and textile waste, supporting circular fashion initiatives.

4. Integration with E-Commerce and Print-on-Demand Platforms

DTG printers are increasingly integrated with major e-commerce platforms like Shopify, Etsy, and Amazon. Automated workflows allow seamless order processing from design upload to shipping, enabling entrepreneurs to run profitable print-on-demand businesses with minimal upfront investment. This integration is lowering entry barriers and fueling market growth, especially among micro-entrepreneurs and creative freelancers.

5. Geographic Market Expansion

While North America and Europe remain dominant, emerging markets in Asia-Pacific, Latin America, and the Middle East are witnessing rapid adoption of DTG technology. Rising disposable incomes, urbanization, and a growing middle class are increasing demand for customized apparel. Localized production hubs using DTG printers are reducing shipping times and import costs, further accelerating regional growth.

6. Competitive Pricing and Market Consolidation

Increased competition among DTG printer manufacturers—such as Epson, Brother, and Kornit—is driving down equipment costs and improving accessibility. At the same time, larger players are acquiring niche brands to expand their portfolios, leading to market consolidation. This dynamic is expected to enhance innovation while offering users more comprehensive end-to-end solutions.

7. Focus on Workflow Automation and Software Integration

By 2026, DTG systems are not just hardware but integrated ecosystems. Advanced RIP (Raster Image Processing) software, cloud-based design management, and ERP integrations are streamlining operations. Automation in pre-treatment, drying, and finishing processes is reducing turnaround times and labor dependency, making DTG viable for higher-volume production.

In conclusion, the 2026 DTG shirt printer market is characterized by faster, smarter, and more sustainable printing solutions. As customization, sustainability, and digital integration become central to the apparel industry, DTG technology is well-positioned to lead the next wave of innovation in garment printing.

Common Pitfalls When Sourcing a Direct-to-Garment (DTG) Shirt Printer: Quality and Intellectual Property Risks

When sourcing a Direct-to-Garment (DTG) printer—whether for in-house production or outsourcing to a third-party provider—businesses often encounter critical challenges related to print quality consistency and intellectual property (IP) protection. Overlooking these pitfalls can result in customer dissatisfaction, brand damage, legal issues, and financial losses.

Inconsistent Print Quality and Durability

One of the most frequent issues when sourcing DTG printing services or equipment is inconsistent output quality. Poor color accuracy, faded prints after washing, cracking, or misalignment can severely impact customer satisfaction.

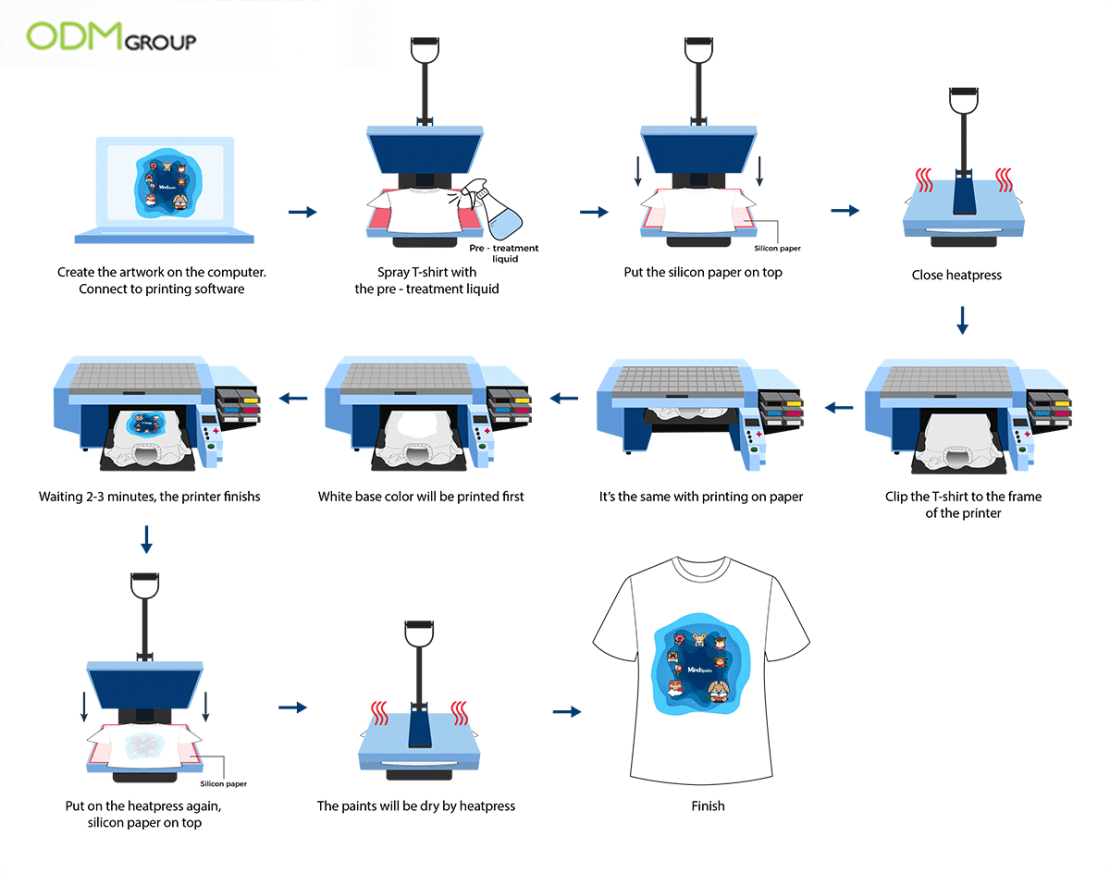

- Inadequate Pre-Treatment Application: DTG printing on dark garments requires a pre-treatment solution to help ink adhere. Inconsistent application leads to uneven prints or ink washout.

- Substandard Ink and Maintenance Practices: Low-quality or incompatible inks degrade faster and may not meet safety or environmental standards. Poor printer maintenance results in clogged printheads and banding.

- Lack of Calibration and Color Management: Without proper color profiling and regular calibration, prints may vary significantly between batches, harming brand consistency.

- Improper Curing Techniques: Prints must be heat-cured correctly to become durable. Under-curing causes fading; over-curing may damage fabric or inks.

Tip: Always request physical print samples, test wash durability, and verify the printer’s maintenance and quality control protocols before committing.

Intellectual Property (IP) Infringement and Data Security Risks

Sourcing DTG printing externally introduces significant IP vulnerabilities, especially when handling custom designs, logos, or licensed artwork.

- Unauthorized Use or Reproduction of Designs: Unethical suppliers may copy or resell your designs without permission, especially in regions with weak IP enforcement.

- Lack of Confidentiality Agreements: Many third-party printers do not proactively offer NDAs or contracts that protect your artwork, leaving your IP exposed.

- Data Storage and Access Risks: Digital design files stored on a vendor’s system could be accessed, leaked, or used for unauthorized production runs.

- Use of Copyrighted or Trademarked Elements: If your designs include third-party IP (e.g., sports logos, characters), the printer may unknowingly—or knowingly—produce infringing goods, implicating your business legally.

Tip: Require signed IP agreements, limit file access, use watermarked proofs, and audit your vendor’s security practices. Ensure they understand and respect copyright laws.

By proactively addressing these quality and IP-related pitfalls, businesses can safeguard their brand reputation, ensure customer satisfaction, and avoid costly legal or operational setbacks when sourcing DTG printing solutions.

Logistics & Compliance Guide for Direct-to-Garment (DTG) Shirt Printing

Order Management & Fulfillment Workflow

Establish a streamlined order processing system using e-commerce platforms (e.g., Shopify, WooCommerce) integrated with print management software. Automate order confirmations, payment verification, and file checks for design resolution and format compliance. Implement quality control checkpoints before, during, and after printing to ensure consistency and customer satisfaction.

Inventory Management for Blanks & Supplies

Maintain accurate inventory of blank garments, inks, pre-treatment solutions, and packaging materials. Use inventory tracking tools to monitor stock levels, prevent overstocking, and reduce waste. Store blank garments in a clean, dry environment to prevent contamination. Rotate stock using the FIFO (First In, First Out) method to ensure older blanks are used first.

Production Workflow & Equipment Maintenance

Schedule DTG printing in batches to optimize machine efficiency and reduce downtime. Perform daily nozzle checks, weekly deep cleans, and monthly maintenance on printers per manufacturer guidelines. Calibrate printers regularly for color accuracy and registration. Keep a maintenance log to track service history and anticipate part replacements.

Shipping & Packaging Standards

Use eco-friendly, branded packaging that protects garments during transit. Fold and insert shirts in poly bags or tissue paper to prevent ink transfer. Choose appropriate box or mailer sizes to minimize shipping costs and environmental impact. Partner with reliable carriers (e.g., USPS, UPS, FedEx) and offer multiple shipping options. Automate label generation and tracking number updates to customers.

Domestic & International Compliance

Adhere to FTC Care Labeling Rule by attaching permanent fabric content and washing instructions to each garment. Ensure all products comply with CPSIA (Consumer Product Safety Improvement Act) standards, especially for children’s apparel. For international shipments, provide accurate HS codes, commercial invoices, and comply with destination country regulations (e.g., EU REACH, UKCA marking).

Environmental & Safety Regulations

Store inks and pre-treatment chemicals according to SDS (Safety Data Sheet) guidelines. Use spill containment trays and proper ventilation in the printing area. Recycle ink cartridges and dispose of waste materials in accordance with local environmental regulations. Comply with OSHA standards for workplace safety, including PPE (gloves, masks) and equipment guarding.

Intellectual Property & Design Compliance

Verify you have proper licensing or written permission before printing trademarked logos, characters, or copyrighted artwork. Implement a design review process to avoid infringement. Use original designs or royalty-free assets from trusted sources. Include disclaimers where applicable and maintain records of permissions.

Tax & Financial Compliance

Collect and remit sales tax based on nexus rules in applicable states (use automated tax calculation tools like Avalara or TaxJar). Maintain accurate financial records for income, expenses, and inventory. Obtain an EIN and applicable local business licenses. If selling internationally, understand VAT/GST requirements and consider IOSS registration for EU imports under €150.

Returns, Refunds & Customer Policies

Establish a clear return and exchange policy compliant with FTC Mail Order Rule. Process returns promptly and inspect items for eligibility. Communicate policy details on your website and in order confirmations. Document disputes and resolutions to improve quality and service.

In conclusion, sourcing a Direct to Garment (DTG) shirt printer is a strategic investment for businesses aiming to offer high-quality, custom apparel with fast turnaround times and greater design flexibility. DTG printing excels in producing detailed, full-color graphics on various fabric types, making it ideal for on-demand printing, small batch orders, and personalized merchandise. When sourcing a DTG printer, it is essential to consider factors such as print quality, production speed, ink efficiency, machine durability, ease of maintenance, and long-term cost of ownership. Additionally, evaluating technical support, warranty, and compatibility with different garment types will ensure seamless integration into your operation. By selecting the right DTG printer and partnering with reliable suppliers, businesses can enhance their customization capabilities, reduce inventory waste, and remain competitive in the growing custom apparel market.