The global die pipe market is experiencing steady expansion, driven by rising infrastructure development, increased demand in the construction and oil & gas sectors, and growing industrialization in emerging economies. According to Mordor Intelligence, the pipe and tube market—including die pipe segments—is projected to grow at a CAGR of over 5.8% from 2024 to 2029, fueled by advancements in material technology and heightened focus on corrosion-resistant, high-performance piping solutions. With Asia-Pacific emerging as both the largest producer and consumer, particularly due to rapid urbanization in countries like India and China, the competitive landscape is increasingly shaped by manufacturers investing in precision tooling, automation, and R&D. As demand for reliable and efficient die pipes surges across industrial applications, the following list highlights the top 10 die pipe manufacturers leveraging scale, innovation, and global supply chain reach to lead the market.

Top 10 Die Pipe Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 HDPE Pipe Solutions

Domain Est. 1995

Website: isco-pipe.com

Key Highlights: ISCO is the leading HDPE pipe & fusion equipment supplier in North America, providing expert solutions for municipal, industrial & oil/gas HDPE piping ……

#2 Atlas Tube

Domain Est. 1995

Website: atlastube.com

Key Highlights: As the leading manufacturer of structural steel tube, we’re here to help you. From conceptual design through project completion, our engineering team, design ……

#3 Mannesmann

Domain Est. 1996

Website: mannesmann.com

Key Highlights: MANNESMANNWe are the leading manufacturer in Europe to offer all pipe technologies from a single source – from the primary material to the development ……

#4 Oster Manufacturing Company

Domain Est. 1999

Website: ostermfg.com

Key Highlights: We are the official source of genuine OEM Oster threading equipment for all existing Oster machines. All threading machines, dies and die heads, and ……

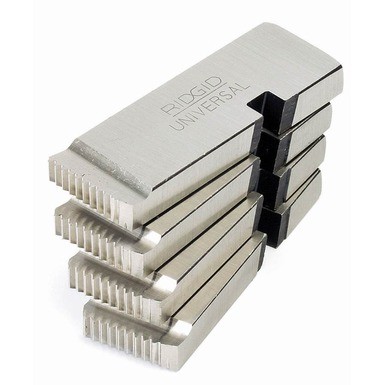

#5 Pipe and Bolt Dies for Machine Die Heads

Domain Est. 1995

#6 About Us

Domain Est. 1995

Website: uspipe.com

Key Highlights: US Pipe, a Quikrete company, offers a complete range of Ductile Iron Pipe, Restrained Joint Pipe, Fabrication, Gaskets, and Fittings….

#7 McWane

Domain Est. 1997

Website: mcwane.com

Key Highlights: Across McWane, we make the pipes, valves, fire hydrants and fittings that together build our nation’s water infrastructure….

#8 Reed Manufacturing

Domain Est. 1997

Website: reedmfgco.com

Key Highlights: Reed Manufacturing’s pipe tools and vises are the professional’s first choice for Quality, Service, and Performance, since 1896….

#9 Tenaris

Domain Est. 2000

Website: tenaris.com

Key Highlights: We supply the most extensive portfolio of high-quality casing and tubing, drill pipe, premium connections, and pipe accessories, for all types of oil and gas ……

#10 Advanced Drainage Systems

Domain Est. 2000

Website: adspipe.com

Key Highlights: Advanced Drainage Systems provides high-performing, durable pipe and innovative stormwater management solutions. Discover our industry-leading products ……

Expert Sourcing Insights for Die Pipe

H2 2026 Market Trends Analysis for Die Pipe Industry

As of H2 2026, the die pipe manufacturing sector is undergoing significant transformation driven by technological innovation, sustainability mandates, and evolving end-user demands across key industries such as automotive, aerospace, construction, and renewable energy. This analysis outlines the dominant market trends shaping the die pipe industry during the second half of 2026.

1. Increased Demand from Electric Vehicle (EV) and Aerospace Sectors

The continued global shift toward electric mobility and advanced aerospace engineering is fueling demand for high-precision die pipes. In H2 2026, lightweight, corrosion-resistant die pipes made from aluminum alloys and advanced composites are seeing heightened adoption in EV battery cooling systems, structural components, and aerospace hydraulic systems. Manufacturers are investing in high-tolerance extrusion technologies to meet stringent quality standards required by Tier-1 automotive and aerospace suppliers.

2. Adoption of Smart Manufacturing and Industry 4.0

Die pipe producers are increasingly integrating smart manufacturing solutions such as IoT-enabled extrusion presses, real-time quality monitoring, and AI-driven predictive maintenance. In H2 2026, digital twin technology is being widely used to simulate die performance and optimize pipe geometry before physical production, reducing waste and improving yield rates. This digital transformation is improving operational efficiency and enabling faster time-to-market for customized pipe solutions.

3. Sustainability and Circular Economy Pressures

Environmental regulations and corporate ESG (Environmental, Social, and Governance) goals are pushing die pipe manufacturers to adopt greener practices. By H2 2026, there is a notable shift toward using recycled aluminum and steel in die pipe production, supported by advancements in material sorting and reprocessing technologies. Additionally, manufacturers are redesigning dies for longer lifespans and easier recyclability, aligning with circular economy principles.

4. Regional Supply Chain Reconfiguration

Geopolitical dynamics and trade policies have led to a regional reconfiguration of die pipe supply chains. In H2 2026, North America and Europe are prioritizing localized production to reduce dependency on Asian imports, particularly from China. Nearshoring and onshoring initiatives are driving investments in domestic die pipe manufacturing capacity, supported by government incentives under industrial revitalization programs.

5. Rising Material and Energy Costs

Persistent volatility in raw material prices—especially aluminum and specialty alloys—continues to challenge profit margins. In response, die pipe companies are entering into long-term supply agreements and exploring alternative materials such as magnesium alloys and high-strength polymers. Energy efficiency is also a key focus, with upgrades to induction heating systems and heat recovery technologies helping mitigate rising energy costs.

6. Growth in Customization and Niche Applications

End-users across industries are demanding increasingly customized die pipe solutions for specialized applications, including hydrogen fuel cell systems, offshore wind turbine structures, and modular construction. In H2 2026, manufacturers with agile design and rapid prototyping capabilities are gaining competitive advantage, leveraging additive manufacturing for complex die geometries.

Conclusion

The die pipe market in H2 2026 is characterized by innovation, sustainability, and strategic adaptation to global industrial shifts. Companies that invest in digitalization, material efficiency, and regional supply chain resilience are best positioned to capitalize on emerging opportunities. As demand from high-growth sectors intensifies, the die pipe industry is evolving from a traditional manufacturing segment into a technologically advanced, solutions-driven domain.

Common Pitfalls When Sourcing Die Pipes (Quality, IP)

Sourcing die pipes—critical components in manufacturing processes like extrusion or forging—can introduce significant risks if not managed carefully. Two major areas of concern are quality inconsistencies and intellectual property (IP) vulnerabilities. Failing to address these can lead to production delays, product failures, and legal exposure.

Quality-Related Pitfalls

-

Inconsistent Material Specifications

Suppliers may use substandard or non-compliant materials that deviate from required metallurgical properties (e.g., hardness, grain structure, corrosion resistance). This compromises die pipe durability and performance under high-stress conditions. -

Poor Dimensional Accuracy and Tolerances

Inadequate machining precision leads to misalignment, uneven material flow, or premature wear. Even minor deviations can reduce product consistency and increase scrap rates. -

Lack of Process Control and Certification

Sourcing from suppliers without proper quality management systems (e.g., ISO 9001) or traceability documentation increases the risk of undetected defects. Absence of heat treatment records or non-destructive testing (NDT) reports further compounds risk. -

Inadequate Surface Finish

Rough or improperly finished internal surfaces promote material buildup, increase friction, and accelerate wear—negatively impacting both output quality and maintenance frequency. -

Limited Performance Testing and Validation

Many suppliers fail to conduct or share results from simulated operational testing (e.g., pressure, thermal cycling), making it difficult to predict real-world performance before deployment.

Intellectual Property (IP) Risks

-

Unauthorized Replication or Reverse Engineering

Providing detailed designs to third-party manufacturers—especially in regions with weak IP enforcement—can result in unauthorized duplication or resale of proprietary die pipe designs. -

Weak or Unenforceable Contracts

Absence of robust non-disclosure agreements (NDAs), IP ownership clauses, or jurisdiction-specific protections leaves companies vulnerable to design theft or misuse. -

Supply Chain Transparency Gaps

Subcontracting by suppliers without consent can expose designs to additional, unvetted parties, increasing the risk of IP leakage beyond the original vendor. -

Lack of Design Protection

Failure to patent or trademark unique die pipe geometries or configurations allows competitors to legally copy innovations, eroding competitive advantage. -

Inadequate Digital Security

Sharing CAD files or technical drawings without encryption, watermarking, or access controls heightens the risk of digital theft or unauthorized distribution.

Mitigating these pitfalls requires thorough supplier qualification, rigorous quality audits, strong legal agreements, and proactive IP protection strategies throughout the sourcing lifecycle.

Logistics & Compliance Guide for Die Pipe

This guide outlines the essential logistics and compliance considerations for the manufacturing, transportation, and handling of die pipes—tooling components used in metal forming and extrusion processes. Ensuring adherence to regulatory standards and efficient logistical operations is critical for safety, quality, and supply chain reliability.

Regulatory Compliance

All die pipe operations must comply with international, national, and regional regulatory standards. Key areas include:

- Material Standards: Die pipes must be manufactured using materials that meet recognized standards such as ASTM, ISO, or DIN. Documentation on material certification (e.g., mill test reports) is required.

- Environmental Regulations: Compliance with REACH (EU), RoHS, and other environmental directives is mandatory when shipping to regulated markets. Hazardous substances must be documented and minimized.

- Export Controls: Die pipes may be subject to export regulations under frameworks like the Export Administration Regulations (EAR) if they incorporate dual-use technologies. Verify ECCN (Export Control Classification Number) prior to international shipment.

- Workplace Safety: Adhere to OSHA (USA) or equivalent local occupational health and safety regulations during manufacturing and handling. Proper personal protective equipment (PPE) and machine guarding must be in place.

Manufacturing & Quality Assurance

Consistent quality is vital for die pipe performance and compliance.

- Design Compliance: Die pipe designs must follow engineering specifications and industry standards (e.g., ISO 2768 for general tolerances).

- Process Validation: Implement documented quality control processes including dimensional inspection, hardness testing, and non-destructive testing (NDT) where applicable.

- Traceability: Maintain lot-level traceability for raw materials and finished products using barcodes or serialization. Record heat numbers, machining dates, and inspection results.

- Certifications: Provide compliance documentation such as Certificates of Conformance (CoC), Material Test Reports (MTRs), and Dimensional Reports upon request.

Packaging & Handling

Proper packaging ensures product integrity during transit.

- Protection: Wrap die pipes in anti-corrosion paper (VCI) and secure in wooden crates or heavy-duty cardboard with internal cushioning to prevent movement.

- Labeling: Clearly label packages with part number, heat number, quantity, weight, handling instructions (e.g., “Do Not Stack”), and hazardous material symbols if applicable.

- Lifting & Storage: Use appropriate lifting equipment (e.g., cranes with slings) when handling heavy die pipes. Store vertically or on racks to avoid deformation; keep in dry, climate-controlled environments.

Transportation & Logistics

Efficient and compliant shipping practices are essential.

- Mode of Transport: Choose transport mode (air, sea, or ground) based on urgency, cost, and destination. Oversized or heavy die pipes may require special freight arrangements.

- Documentation: Prepare accurate shipping documents including commercial invoice, packing list, bill of lading, and export declaration. Include all compliance statements and certifications.

- Customs Clearance: Provide Harmonized System (HS) codes for die pipes (typically under 8480 – parts for machinery for working metal). Ensure all import duties, tariffs, and taxes are accounted for.

- Incoterms: Clearly define responsibilities using appropriate Incoterms (e.g., FOB, EXW, DDP) in all contracts.

Aftermarket & Returns

Establish procedures for handling non-conforming or returned products.

- Return Authorization: Implement a Return Material Authorization (RMA) process for defective or incorrect shipments.

- Inspection & Disposition: Inspect returned die pipes for damage or wear. Determine whether to repair, rework, or scrap based on quality criteria.

- Environmental Disposal: Dispose of scrap or non-repairable die pipes in accordance with local waste management and recycling regulations.

Continuous Improvement

Regularly review logistics and compliance performance.

- Conduct internal audits of manufacturing, packaging, and shipping processes.

- Monitor regulatory changes in target markets and update compliance protocols accordingly.

- Train staff annually on safety, compliance, and handling procedures.

By following this guide, Die Pipe manufacturers and distributors can ensure reliable operations, reduce risk, and maintain strong customer and regulatory confidence.

Conclusion for Sourcing Die Pipes:

Sourcing die pipes requires a strategic approach that balances quality, cost, and reliability. After evaluating multiple suppliers, technical specifications, material standards, production capabilities, and logistics, it is evident that selecting the right vendor is crucial to ensuring consistent product performance and operational efficiency. Prioritizing suppliers with proven manufacturing expertise, adherence to industry standards (such as ASTM, ISO, or DIN), and a track record of on-time delivery will mitigate risks and support long-term production goals. Additionally, establishing strong supplier relationships, conducting regular quality audits, and maintaining flexibility in the supply chain can enhance resilience against market fluctuations or disruptions. Ultimately, a well-structured sourcing strategy for die pipes contributes significantly to improved manufacturing outcomes and overall cost-effectiveness.