The global die-cutting dies market is experiencing steady growth, driven by rising demand across packaging, printing, and crafting industries. According to Grand View Research, the global die-cutting machines market size was valued at USD 2.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, fueled by advancements in automation and increasing customization in packaging. Parallel growth in the arts and crafts sector, particularly in personalized stationery and DIY products, has amplified demand for precision letter dies. Mordor Intelligence projects consistent expansion in the die-cutting tools market, with increased adoption of laser-cut and digital dies enhancing accuracy and production efficiency. As brands and consumers alike prioritize unique typography and high-quality finishes, manufacturers specializing in letter dies are at the forefront of innovation. Below are the top 7 die-cutting dies letter manufacturers leading this evolving landscape.

Top 7 Die Cutting Dies Letters Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Alphabet & Number Dies

Domain Est. 1995

Website: accucut.com

Key Highlights: Choose from our wide selection of alphabet dies to cut your own letters and numbers out of any material you can cut with scissors. Sizes range from 1″ to 10″!…

#2 Craft Cutting Dies

Domain Est. 1996

#3 Steel Rule Dies for Letterpress

Domain Est. 2005

Website: keydies.com

Key Highlights: Key Dies makes custom type-high steel rule dies used on those old and reliable letterpresses. From platens to windmills, our die makers have the skills to craft ……

#4 Mini Alphabet and Numbers

Domain Est. 2006

Website: karenburniston.com

Key Highlights: Packed with value, these innovative, cutting edge die sets will take your paper crafting to new heights. Check out our videos for inspiration and instructions….

#5 DIE

Domain Est. 2006

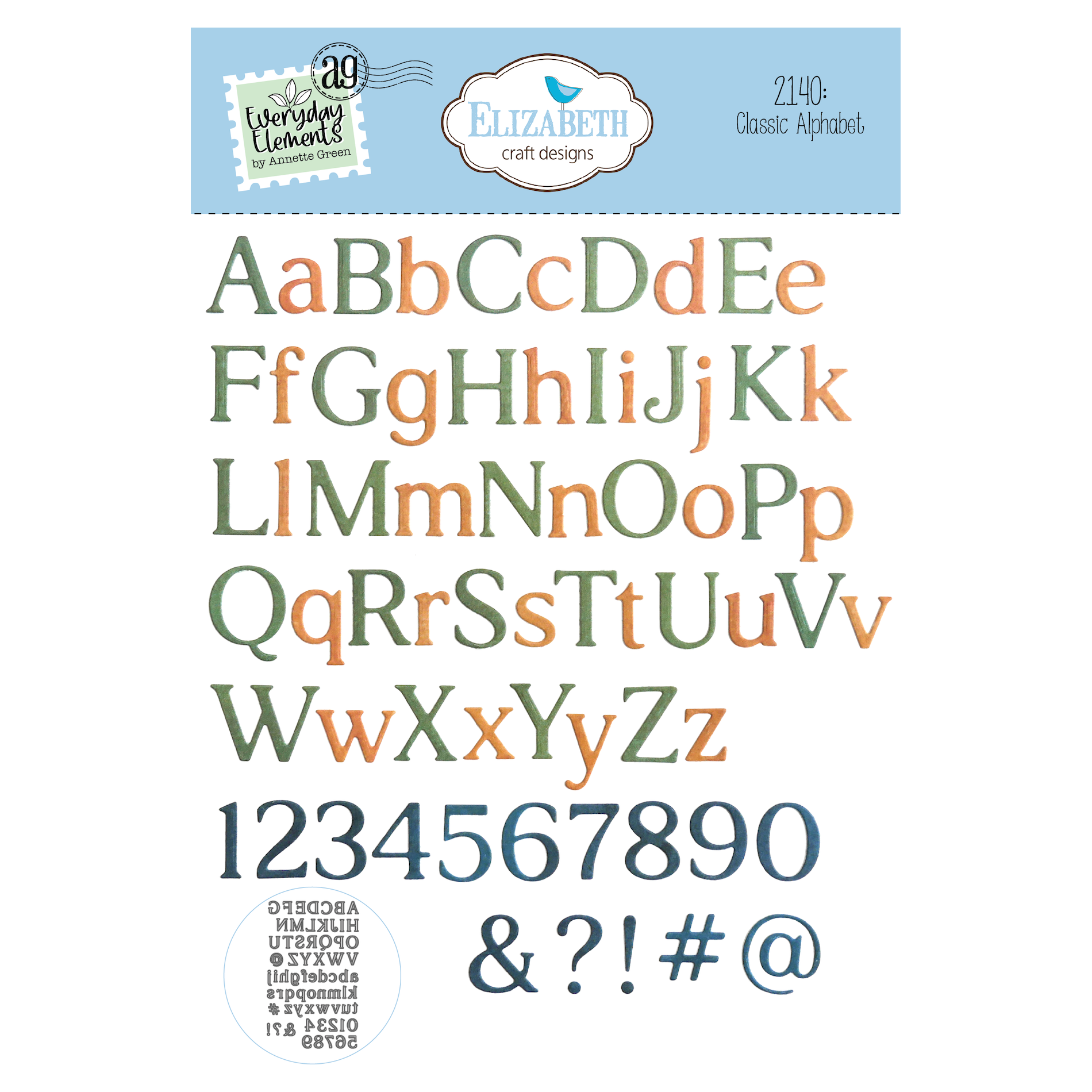

#6 Elizabeth Craft Designs Classic Alphabet Dies 2140

Domain Est. 2008

Website: simonsaysstamp.com

Key Highlights: This comprehensive set comprises 67 wafer-thin dies, with the largest measuring approximately 0.8 x 0.9 inches. It includes the full alphabet in both uppercase ……

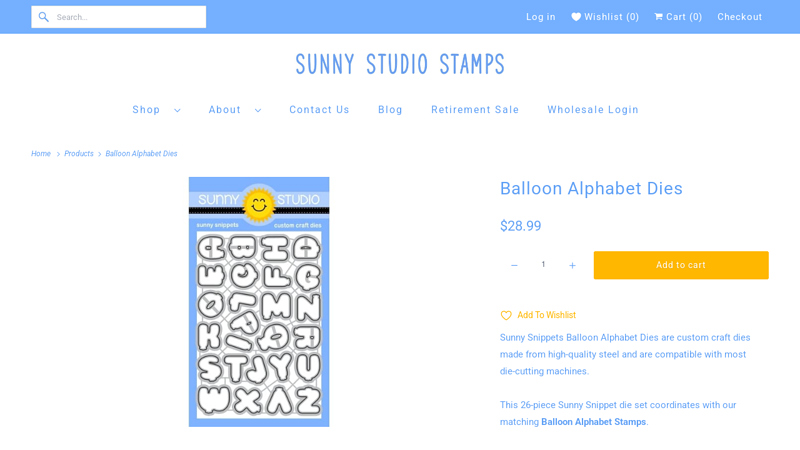

#7 Balloon Alphabet Dies

Domain Est. 2015

Website: sunnystudiostamps.com

Key Highlights: In stock $6 deliverySunny Snippets Balloon Alphabet Dies are custom craft dies made from high-quality steel and are compatible with most die-cutting machines….

Expert Sourcing Insights for Die Cutting Dies Letters

2026 Market Trends for Die Cutting Dies Letters

Rising Demand in Customization and Personalization

The global market for die cutting dies letters is expected to see substantial growth by 2026, primarily driven by increasing consumer demand for personalized and custom-designed products. Consumers across industries such as crafts, packaging, retail, and event planning are seeking unique, tailored items—ranging from custom invitations and greeting cards to branded packaging. This trend fuels the need for versatile and precise letter dies that enable small businesses, hobbyists, and manufacturers to produce professional-quality, customized outputs efficiently.

Expansion of the Craft and DIY Sector

The do-it-yourself (DIY) and crafting communities continue to expand, especially with the support of online platforms like Etsy, Pinterest, and YouTube tutorials. By 2026, die cutting dies letters will remain a staple tool in the crafting toolkit, with manufacturers focusing on user-friendly, durable, and multi-size letter sets. The integration of digital marketplaces and subscription-based craft boxes is expected to further boost accessibility and adoption of letter dies among hobbyists and micro-entrepreneurs.

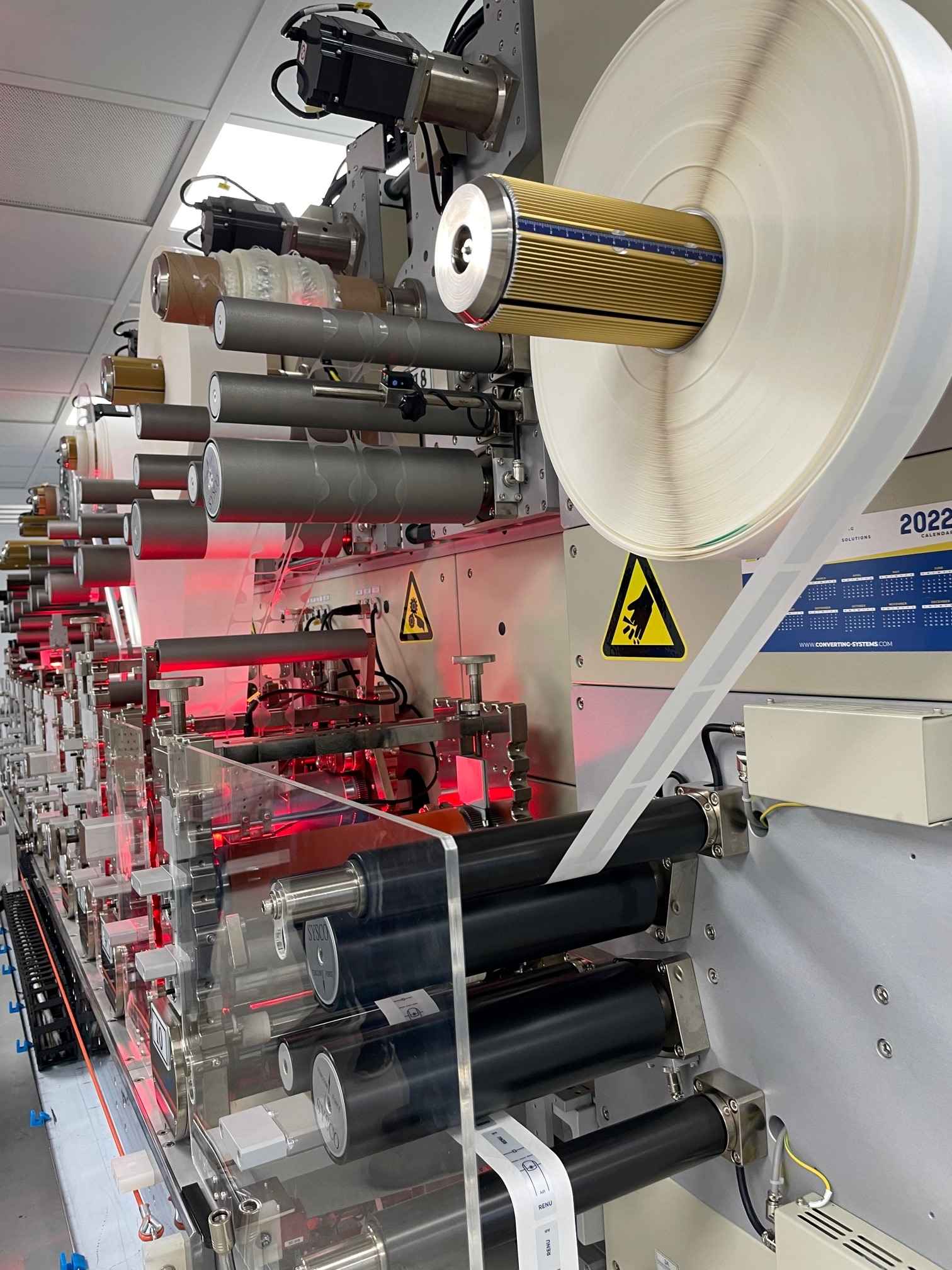

Technological Advancements in Die Cutting Machines

Advancements in digital die cutting machines—such as those by Cricut, Silhouette, and Brother—are shaping the demand for compatible letter dies. While digital cutting reduces reliance on physical dies, hybrid models that support both digital and manual cutting are gaining traction. In response, manufacturers of traditional metal and magnetic letter dies are innovating to ensure compatibility, precision, and longevity. Expect a rise in laser-cut dies with enhanced edge sharpness and durability to meet professional-grade standards.

Sustainability and Eco-Friendly Materials

Sustainability will play a pivotal role in shaping the 2026 market. Consumers and businesses alike are prioritizing eco-conscious manufacturing practices. Die cutting die producers are responding by using recyclable steel, reducing waste in production, and offering long-lasting dies that minimize replacement frequency. Additionally, demand for dies compatible with recycled and biodegradable materials (such as kraft paper, bamboo, or compostable plastics) is growing, especially in eco-friendly packaging applications.

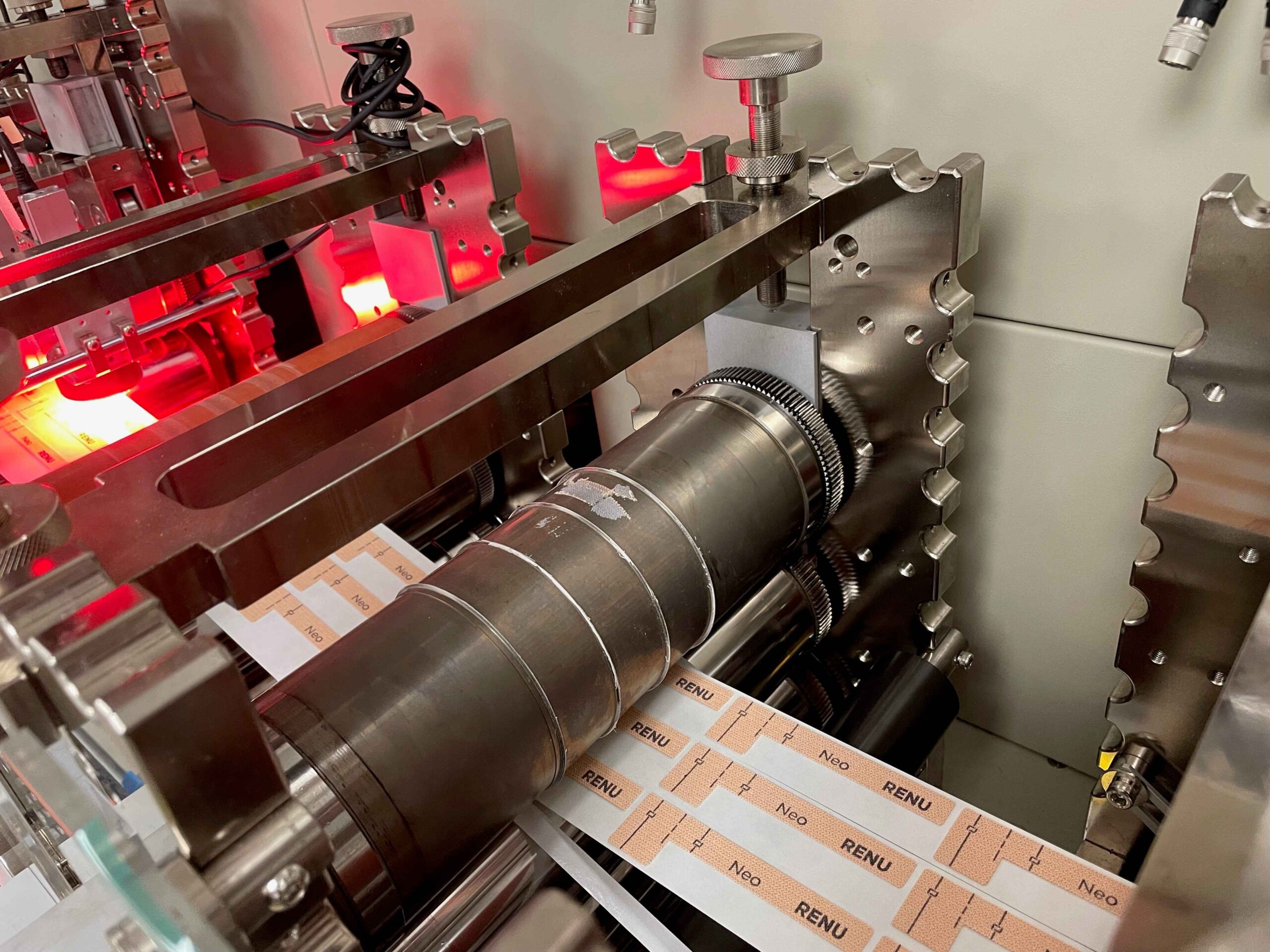

Growth in Packaging and Branding Applications

Brands are increasingly leveraging die-cut lettering for premium packaging, luxury labels, and limited-edition product launches. Custom typography created with letter dies adds a tactile and visually appealing element to unboxing experiences. By 2026, the integration of die-cut letters in sustainable luxury packaging—particularly in cosmetics, food & beverage, and fashion—will be a key growth driver, pushing innovation in precision, scalability, and design flexibility.

Regional Market Expansion

While North America and Europe remain dominant markets due to strong craft cultures and advanced manufacturing, Asia-Pacific is expected to witness the fastest growth by 2026. Rising disposable incomes, expanding e-commerce, and growing small business ecosystems in countries like China, India, and South Korea will increase demand for affordable, high-quality die cutting dies letters. Localization of product offerings—such as dies supporting non-Latin scripts (e.g., Cyrillic, Arabic, or Kanji)—will become more common to cater to global audiences.

Conclusion

The die cutting dies letters market in 2026 will be shaped by personalization, technological integration, sustainability, and global expansion. As industries from crafts to luxury branding adopt more intricate and customized typographic elements, manufacturers must innovate to deliver precision, durability, and eco-friendly solutions. The convergence of traditional craftsmanship with digital readiness will define competitive advantage in the evolving landscape.

Common Pitfalls When Sourcing Die Cutting Dies for Letters

Sourcing custom die cutting dies for letters—whether for packaging, labels, or crafts—can be a cost-effective way to achieve clean, professional results. However, several common pitfalls can compromise quality, increase costs, or lead to legal issues. Awareness of these risks is essential for successful procurement.

Poor Die Quality and Durability

One of the most frequent issues is receiving dies made from substandard materials or with imprecise craftsmanship. Low-quality steel or improper heat treatment can lead to rapid wear, dulling, or warping after minimal use. Dies produced with outdated or inaccurate tooling may not cut cleanly, resulting in ragged edges, incomplete cuts, or inconsistent performance across production runs. Always verify the material specifications (e.g., tool steel grade) and request samples or references before placing bulk orders.

Inaccurate Letter Dimensions and Spacing

Precision is critical when cutting letters, as even minor deviations can affect readability and alignment. Dies sourced from unreliable suppliers may have inconsistent kerning, incorrect letter sizing, or distortion due to poor vector file conversion. This often stems from inadequate file preparation or lack of quality control. Ensure your design files are provided in the correct format (e.g., vector AI or DXF) and confirm dimensional accuracy with the manufacturer before production.

Intellectual Property (IP) Infringement Risks

Using fonts or letter designs protected by copyright or trademark law can lead to serious legal consequences. Many commercially available typefaces are not licensed for physical die cutting, especially in branded or mass-produced goods. Sourcing dies based on copyrighted fonts without proper licensing exposes your business to infringement claims. Always confirm that the font or letter style is either licensed for commercial die use or falls under a permissible open-source or public domain license.

Lack of Customization and Flexibility

Some suppliers offer only standard letter sets or limited customization options, which can restrict creative or branding needs. Off-the-shelf dies may not accommodate unique spacing, stylistic flourishes, or special materials (e.g., thick cardstock or laminates). Confirm with the vendor whether they support fully custom designs and are capable of adjusting die specifications for your specific application.

Hidden Costs and Minimum Order Requirements

Initial quotes may appear competitive but fail to include setup fees, shipping, or costs for custom design work. Some suppliers impose high minimum order quantities (MOQs), making small-batch production impractical. Always request a detailed breakdown of all potential charges and confirm MOQs upfront to avoid budget overruns.

Inadequate Support and Revision Process

If the die doesn’t perform as expected, the ability to make revisions is crucial. Some suppliers offer limited support or charge exorbitant fees for modifications. Establish clear communication channels and understand the revision policy before committing. A responsive manufacturer can save time and reduce waste during the testing phase.

By anticipating these pitfalls—prioritizing quality materials, verifying IP rights, ensuring precision, and clarifying costs—you can source die cutting dies for letters that deliver reliable, legal, and professional results.

Logistics & Compliance Guide for Die Cutting Dies (Letters)

Overview

This guide outlines the essential logistics and compliance considerations when shipping and handling die cutting dies used for letter production. These specialized tools are commonly used in packaging, labeling, and printing industries and require careful management due to their material composition, sharp edges, and international regulatory implications.

Packaging & Handling

Proper packaging ensures the safety of personnel and integrity of the dies during transit.

– Use durable, corrugated cardboard or wooden crates with internal foam or bubble wrap to prevent movement.

– Secure sharp edges with protective corner guards or edge protectors to prevent injuries.

– Clearly label each package: “Fragile,” “Sharp Edges,” and “This Side Up.”

– Include internal padding to prevent metal-on-metal contact, which can cause deformation.

– For custom letter dies, include a layout diagram or template inside the package for easy identification.

Transportation & Shipping

Select appropriate carriers and shipping methods to ensure timely and safe delivery.

– Use freight services for large or heavy dies; small dies may ship via express courier.

– Declare accurate weight and dimensions to avoid carrier surcharges.

– Choose carriers compliant with international freight regulations (e.g., IATA for air, IMDG for sea if applicable).

– For international shipments, provide a commercial invoice detailing product description, value, and HS code (e.g., 8205.59 – “Other handtools”).

– Avoid air freight for dies with ferromagnetic materials if they may interfere with navigation systems (verify with carrier).

Regulatory Compliance

Adhere to national and international regulations governing tools and metal goods.

– Comply with export controls under EAR (Export Administration Regulations) if shipping from the U.S. Dies generally fall under ECCN 2B999 (no license required for most destinations).

– Verify destination country import restrictions—some nations regulate tool imports for security reasons.

– Ensure dies do not incorporate restricted materials (e.g., conflict minerals) if shipping to EU or U.S. markets.

– For EU shipments, confirm compliance with REACH and RoHS directives if dies contain coatings or alloys of concern.

Customs Documentation

Accurate documentation minimizes delays at borders.

– Prepare a detailed commercial invoice including:

– Full product description: “Custom Steel Die for Letter Die-Cutting, Used in Packaging Manufacturing”

– Harmonized System (HS) Code: Typically 8205.59 or 8443.99 depending on use

– Item quantity, unit price, and total value

– Country of origin (e.g., “Made in Germany”)

– Include a packing list matching shipment contents.

– For business-to-business shipments, provide EORI numbers (EU) or IRS number (U.S.).

– Retain records for at least 5 years for audit purposes.

Safety & Workplace Compliance

Ensure safe handling in warehouse and production environments.

– Follow OSHA (U.S.) or equivalent local regulations for handling sharp metal objects.

– Provide employees with cut-resistant gloves and training on die handling procedures.

– Store dies vertically in racks with protective caps to prevent edge damage and injuries.

– Label storage areas with hazard signage where applicable.

Environmental & Disposal Considerations

Dispose of worn or obsolete dies responsibly.

– Recycle steel dies through certified metal recyclers; do not landfill.

– Comply with local environmental regulations (e.g., EPA in U.S., WEEE in EU) for metal waste.

– Maintain records of recycling or disposal for compliance reporting.

Conclusion

Effective logistics and compliance management for letter die cutting dies ensures safety, avoids delays, and supports international trade requirements. By following this guide, businesses can streamline operations, reduce risk, and maintain regulatory adherence across the supply chain.

In conclusion, sourcing die cutting dies for letters requires careful consideration of material quality, precision engineering, supplier reliability, and cost-effectiveness. Whether intended for crafting, packaging, signage, or industrial applications, high-quality letter dies ensure clean, consistent cuts and long-term durability. Evaluating suppliers based on customization options, turnaround time, and customer support can significantly impact project success. By prioritizing reputable manufacturers and clearly defining specifications, businesses and hobbyists alike can achieve professional results and streamline production processes. Ultimately, investing in well-made die cutting dies for letters is a strategic move that enhances both efficiency and output quality.