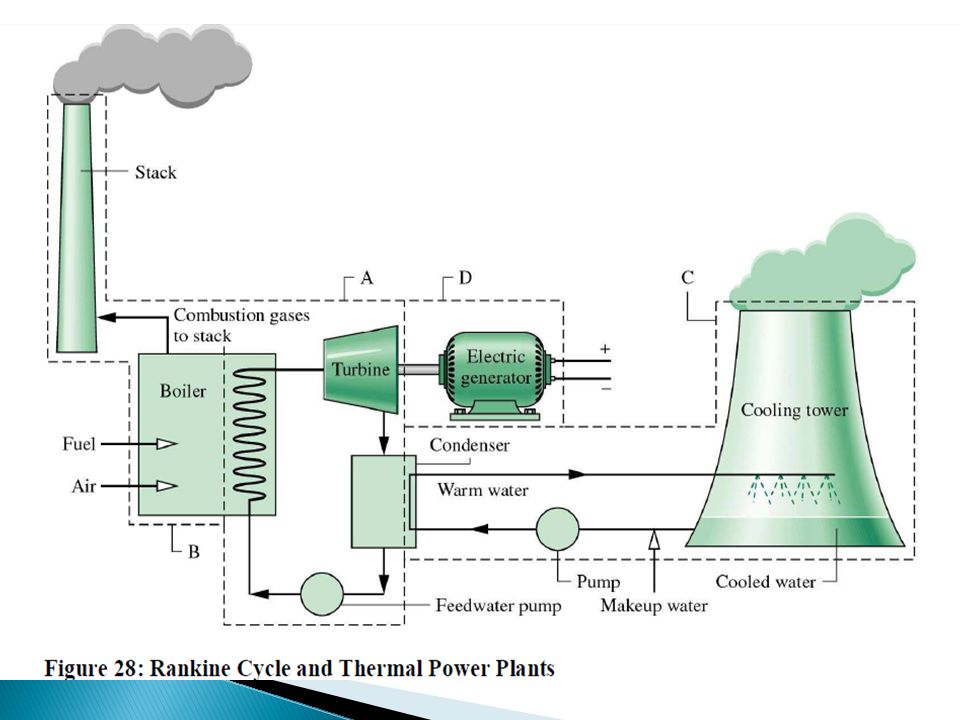

The global cooling tower market is experiencing steady expansion, driven by rising industrialization, increased demand for efficient thermal management systems, and growing infrastructure in power generation, HVAC, and manufacturing sectors. According to Mordor Intelligence, the cooling tower market was valued at USD 2.7 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2029. Cooling towers play a critical role in maintaining operational efficiency by dissipating excess heat, particularly in water-intensive industries. With sustainability and energy efficiency becoming key priorities, companies are increasingly investing in advanced, high-performance cooling solutions. As demand rises, several manufacturers have emerged as industry leaders, distinguished by innovation, reliability, and global footprint. Below, we highlight the top four diagram cooling tower manufacturers shaping the future of thermal management solutions.

Top 4 Diagram Cooling Tower Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

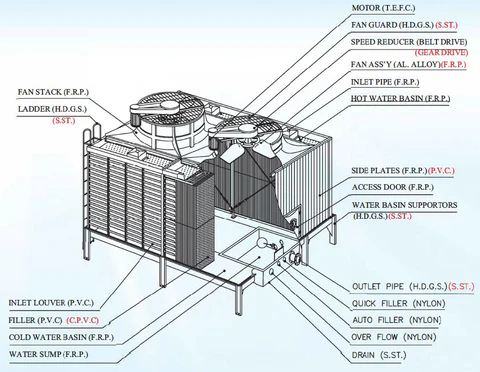

#1 Assembly Drawings for Models T

Domain Est. 1999

Website: coolingtowersystems.com

Key Highlights: Tower Specifications & Drawings. Contact Us. Cooling Tower Systems, Inc. 196 Lower Cherry Street Macon, GA 31201. Manufacturing Warehouse. 196 Lower Cherry ……

#2 Advantage Engineering

Domain Est. 2003

Website: cooling-towers.net

Key Highlights: Open loop cooling tower makes use of direct contact with the air in order to cool down the water. It is essentially a heat exchanger….

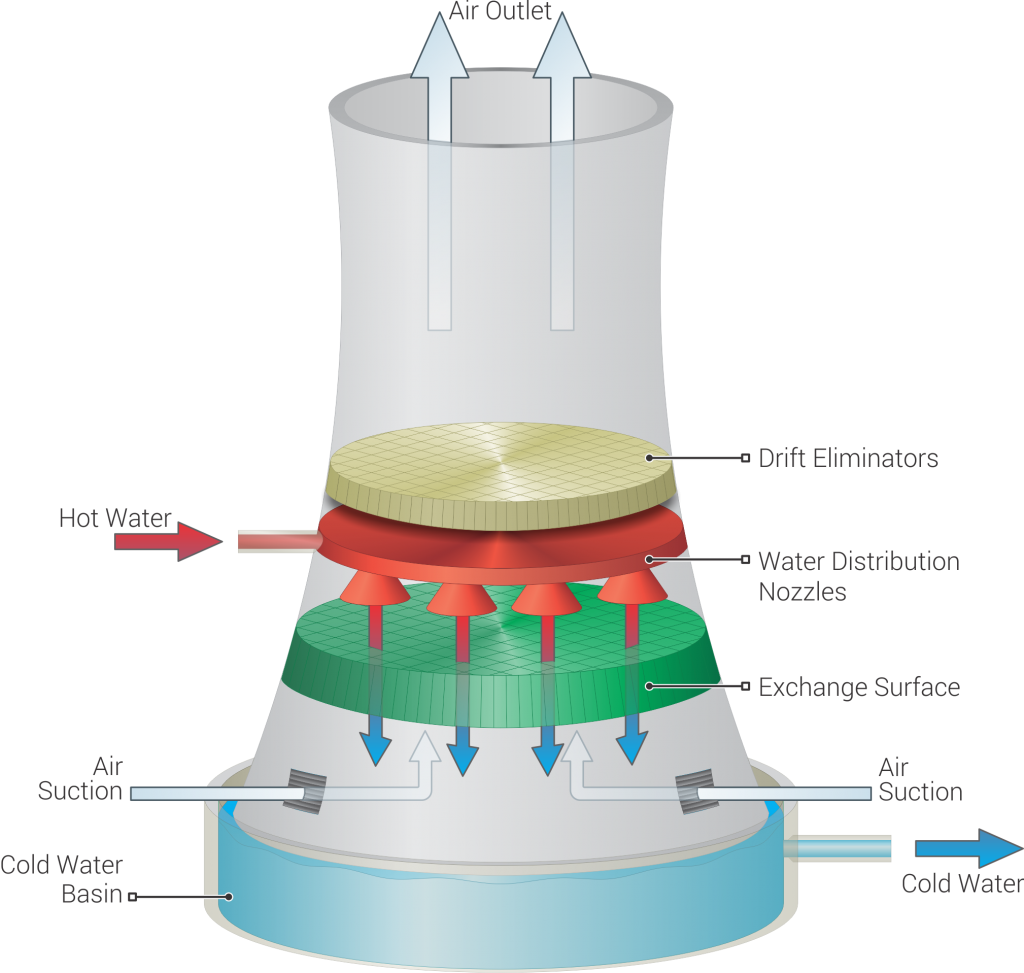

#3 How Cooling Towers Work (W/ Diagram, Pictures & Principles)

Domain Est. 2009

Website: perfectcoolingtowers.com

Key Highlights: Rating 5.0 · Review by 9786Ever wondered how do cooling towers work? Here we explain in full detail how does a cooling tower work, cooling tower working principles with exampl…

#4 COOLING TOWER

Domain Est. 2020

Website: constructandcommission.com

Key Highlights: Below we will provide a high-level overview of the cooling tower piping design covering each of the pipework connections above, including some diagrams….

Expert Sourcing Insights for Diagram Cooling Tower

H2: 2026 Market Trends for Diagram Cooling Towers

The global cooling tower market, including Diagram Cooling Tower, is anticipated to undergo significant transformation by 2026, driven by technological advancements, increasing demand for energy efficiency, and growing industrialization. As a notable player in the sector, Diagram Cooling Tower is expected to align with several key market trends that will shape its strategic positioning, product development, and regional expansion.

-

Growth in Industrial and HVAC Applications

By 2026, the demand for cooling towers is projected to rise across industries such as power generation, chemical processing, oil & gas, and data centers. Diagram Cooling Tower is likely to benefit from increased investments in HVAC systems for commercial buildings and industrial facilities, particularly in emerging economies. Urbanization and infrastructure development in Asia-Pacific and the Middle East will further drive market growth. -

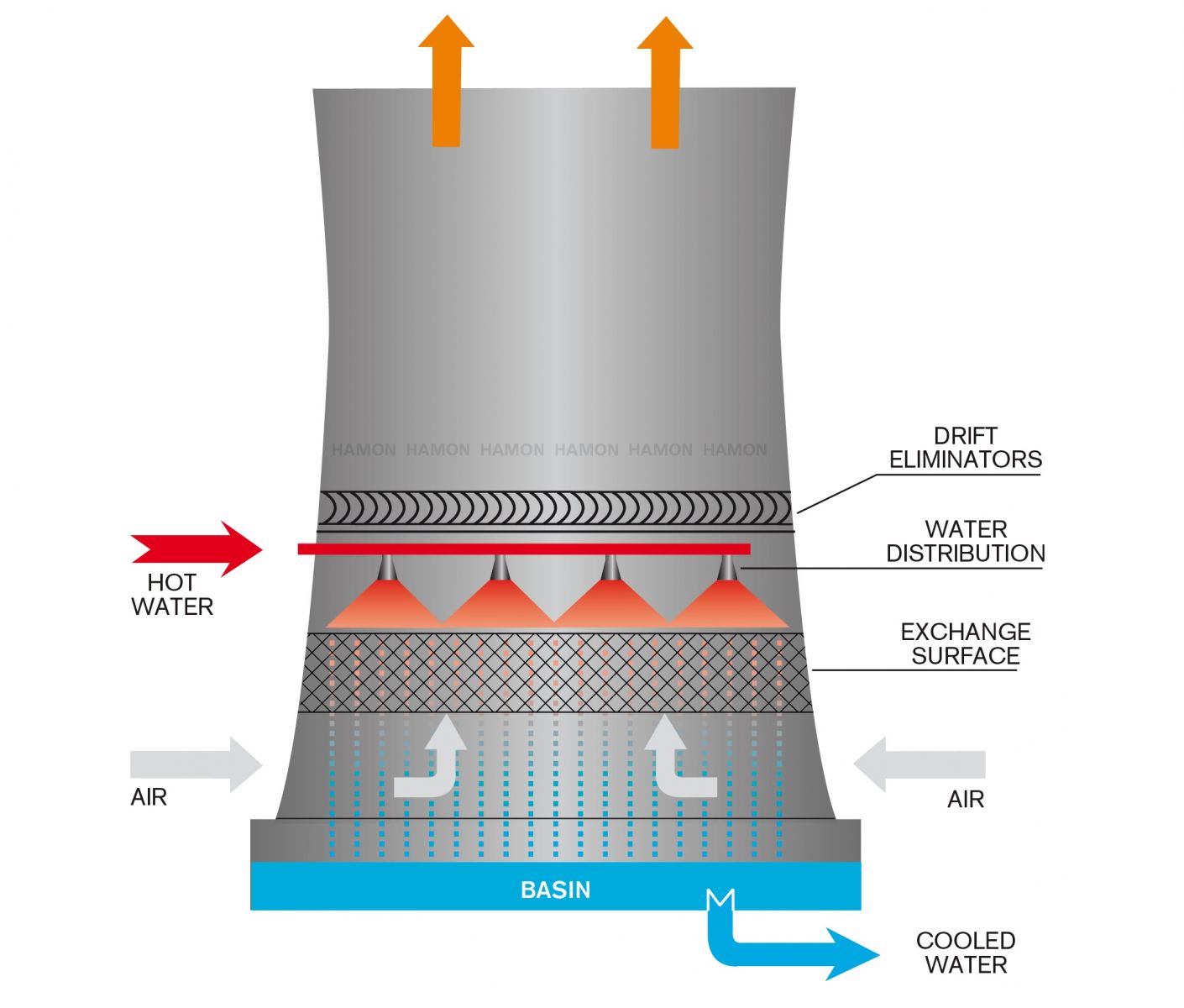

Shift Toward Energy-Efficient and Sustainable Solutions

Environmental regulations and corporate sustainability goals are pushing industries to adopt energy-efficient cooling technologies. Diagram Cooling Tower is expected to enhance its product line with features such as variable speed drives, advanced fill materials, and low-drift eliminators to reduce water and energy consumption. Compliance with standards like ISO 50001 and LEED certification will become increasingly important. -

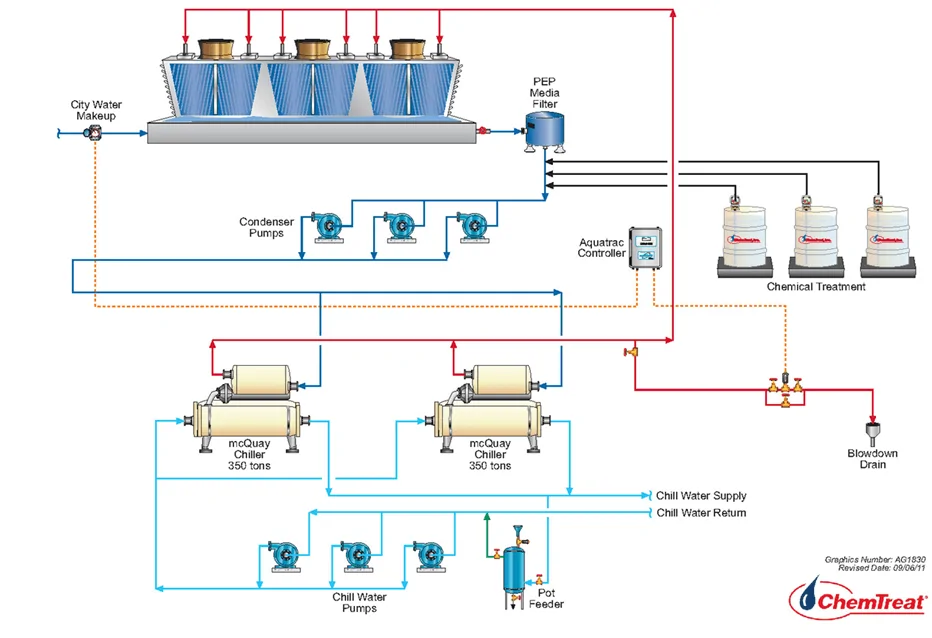

Adoption of Smart and IoT-Enabled Cooling Systems

The integration of IoT (Internet of Things) and predictive maintenance technologies in cooling towers is a growing trend. By 2026, Diagram Cooling Tower may expand its offerings to include smart monitoring systems that enable real-time performance tracking, remote diagnostics, and automated control—improving operational efficiency and reducing downtime. -

Increased Focus on Water Conservation

With water scarcity becoming a critical global issue, closed-loop and hybrid cooling towers—which minimize water loss—are gaining traction. Diagram Cooling Tower may emphasize its hybrid and dry cooling solutions to meet demand from water-sensitive regions and industries under strict regulatory scrutiny. -

Regional Market Expansion and Competitive Dynamics

The Asia-Pacific region is expected to dominate the cooling tower market by 2026 due to rapid industrial growth in countries like India, China, and Southeast Asian nations. Diagram Cooling Tower may strengthen its distribution networks and form strategic partnerships or joint ventures to capture market share. At the same time, competition from local manufacturers offering lower-cost alternatives will require continuous innovation and value-added services. -

Impact of Regulatory Policies and Green Building Initiatives

Governments worldwide are implementing stricter environmental regulations on emissions, water usage, and energy efficiency. In response, Diagram Cooling Tower may align with global green building initiatives and invest in R&D to develop eco-friendly materials and corrosion-resistant coatings that extend equipment life and reduce environmental impact.

In conclusion, by 2026, Diagram Cooling Tower is poised to navigate a dynamic market landscape shaped by sustainability, digitalization, and regional growth opportunities. Success will depend on the company’s ability to innovate, adapt to regulatory changes, and meet the evolving needs of industrial and commercial clients worldwide.

Common Pitfalls in Sourcing a Diagram Cooling Tower (Quality and IP)

When sourcing technical diagrams for cooling towers, organizations often encounter critical challenges related to quality and intellectual property (IP). Failing to address these issues can lead to design inaccuracies, legal exposure, and project delays. Below are the most common pitfalls:

Poor Diagram Quality and Accuracy

Low-quality or inaccurate diagrams can severely impact engineering integrity and system performance. Key issues include:

-

Outdated or Generic Representations: Many free or low-cost sources provide generic cooling tower diagrams not tailored to specific models or configurations, leading to misalignment with actual equipment dimensions, connections, or performance parameters.

-

Incorrect Scaling or Missing Dimensions: Sourced diagrams may lack critical measurements or contain scaling errors, resulting in installation conflicts, clearance issues, or incorrect piping layouts.

-

Incomplete Technical Details: Absence of essential information—such as material specifications, flow rates, inlet/outlet locations, or control system interfaces—compromises the diagram’s usefulness in design and integration phases.

-

Low-Resolution or Non-Editable Formats: Diagrams provided as low-resolution images (e.g., JPEG) or non-editable PDFs hinder modification and integration into engineering software (e.g., AutoCAD, Revit), reducing their practical value.

Intellectual Property (IP) Risks

Improper sourcing of diagrams can result in serious IP violations, exposing organizations to legal and financial consequences:

-

Unauthorized Use of Manufacturer Drawings: Downloading and using detailed cooling tower diagrams from manufacturer websites or third-party repositories without proper licensing infringes on copyright and design patents.

-

Lack of Licensing Clarity: Many online sources do not clearly state usage rights. Assuming a diagram is “public domain” or “for educational use” does not always permit commercial or engineering applications.

-

Derivative Work Infringement: Modifying a sourced diagram—even slightly—without permission may still violate the original creator’s IP rights, especially if the core design elements remain intact.

-

Use of Proprietary Information in Tenders or Submissions: Including unlicensed diagrams in project proposals or bids can trigger legal disputes, especially if the diagram contains confidential or patented design features.

Mitigation Strategies

To avoid these pitfalls:

- Source Directly from OEMs: Obtain diagrams through official channels with proper licensing agreements.

- Verify Usage Rights: Ensure documentation includes commercial use permissions and redistribution rights where needed.

- Request Native CAD Files: Whenever possible, acquire editable, dimensionally accurate files (e.g., DWG, STEP) directly from the manufacturer.

- Conduct IP Due Diligence: Perform legal checks when using third-party or open-source diagrams, especially in commercial projects.

Neglecting quality and IP considerations when sourcing cooling tower diagrams can lead to costly rework, compliance issues, and reputational damage. Prioritizing authorized, high-fidelity documentation is essential for successful project execution.

Logistics & Compliance Guide for Diagram Cooling Tower

This guide outlines the essential logistics and compliance considerations for the transportation, installation, operation, and maintenance of Diagram Cooling Tower units. Adherence to these guidelines ensures safety, regulatory compliance, and optimal performance.

Transportation and Delivery

Ensure all Diagram Cooling Tower units are securely packaged and appropriately labeled for shipment. Use certified freight carriers experienced in handling heavy industrial equipment. Confirm delivery site accessibility—verify road weight limits, overhead clearance, and ground load capacity. Coordinate delivery schedules with on-site personnel to avoid delays. Upon arrival, inspect units immediately for shipping damage and document any discrepancies with photographs and delivery reports.

Import/Export Regulations

Comply with international trade laws when shipping Diagram Cooling Towers across borders. Secure necessary export licenses and adhere to destination country import requirements, including product certification, customs declarations, and tariff classifications. Maintain accurate records of Harmonized System (HS) codes, commercial invoices, and bills of lading. For units containing refrigerants or electrical components, verify compliance with regional regulations such as REACH (EU), TSCA (USA), or RoHS.

Installation Requirements

Installation must comply with local building, electrical, and mechanical codes. Only qualified technicians should perform setup, following Diagram-provided installation manuals. Ensure structural support can bear the operational weight, including water load. Properly ground all electrical components and connect to a dedicated circuit as specified. Confirm adequate ventilation and clearance around the unit for airflow and maintenance access. Submit final installation reports to local authorities where required.

Environmental Compliance

Diagram Cooling Towers must operate in accordance with environmental protection standards. Implement water treatment programs to control microbial growth (e.g., Legionella) and minimize chemical discharge. Comply with local regulations on blowdown water disposal, especially in areas governed by the Clean Water Act (USA) or Water Framework Directive (EU). Monitor and report emissions if applicable. Use only environmentally approved biocides and corrosion inhibitors.

Operational Safety and Standards

All units must adhere to recognized safety standards such as ASHRAE Guideline 12, OSHA regulations (29 CFR 1910), and local occupational health codes. Equip cooling towers with safety features including emergency shutoffs, leak detection, and防滑 surfaces. Provide personnel with appropriate PPE when performing inspections or maintenance. Conduct regular training on safe operation and emergency response procedures.

Maintenance and Documentation

Establish a preventive maintenance schedule in line with Diagram’s recommendations. Keep detailed records of inspections, water quality tests, repairs, and part replacements. Retain documentation for audit purposes and to support warranty claims. Calibrate sensors and controls annually. Submit compliance reports to regulatory agencies as required, particularly for facilities subject to environmental or industrial safety audits.

Certification and Labeling

Ensure each Diagram Cooling Tower bears necessary certifications such as CE, UL, or CSA, depending on the market. Do not operate uncertified units. Verify nameplate data accuracy, including model number, serial number, electrical specifications, and flow rates. Affix warning labels in local languages where applicable, especially for high voltage, hot surfaces, or moving parts.

By following this guide, operators and logistics teams can ensure the safe, legal, and efficient deployment of Diagram Cooling Tower systems across global installations.

Conclusion for Sourcing Diagram of a Cooling Tower:

The sourcing diagram for a cooling tower provides a comprehensive overview of the procurement, supply chain, and integration of critical components necessary for the efficient and reliable operation of the system. By identifying key suppliers, material specifications, quality assurance protocols, and logistical considerations, the sourcing diagram ensures transparency, traceability, and consistency across all stages of acquisition and installation. It supports strategic decision-making by highlighting potential risks such as supply delays, component incompatibility, or quality variances, enabling proactive mitigation measures. Furthermore, aligning the sourcing strategy with project requirements—such as sustainability goals, performance standards, and cost-efficiency—enhances overall system durability and operational effectiveness. In conclusion, a well-structured sourcing diagram is essential for the successful implementation and long-term performance of a cooling tower within industrial or commercial facilities.