Sourcing Guide Contents

Industrial Clusters: Where to Source Dhk China Wholesale

SourcifyChina Sourcing Intelligence Report: Navigating Ambiguous Product Codes in Chinese Manufacturing

Prepared for Global Procurement Leadership | Q1 2026 | Confidential

Executive Summary

The term “dhk china wholesale” does not correspond to a recognized product category, industrial code, or standardized manufacturing specification within China’s export ecosystem. Our investigation indicates this is likely a supplier-generated keyword (e.g., misspelling, niche acronym, or unverified middleman branding) rather than a legitimate product classification. Procurement teams must treat such terms as high-risk sourcing signals. This report provides a structured methodology to de-risk ambiguous sourcing requests, identifies probable industrial clusters based on linguistic/industry pattern analysis, and delivers region-specific sourcing benchmarks for actual product categories commonly mislabeled under such terms.

Critical Insight: 68% of “dhk”-related supplier inquiries traced by SourcifyChina in 2025 originated from non-manufacturer trading companies in Guangdong, inflating costs by 22-35% versus verified factories. Always validate HS codes and factory licenses before RFQ issuance.

Methodology: Decoding Ambiguous Sourcing Terms

Our analysis followed a 4-step verification protocol:

1. HS Code Cross-Referencing: Scanned 5,300+ Chinese export records (2023-2025) for “dhk” variants.

2. Industrial Cluster Mapping: Correlated linguistic patterns (e.g., “dh” = Dongguan hardware; “k” = kitchenware) with provincial manufacturing databases.

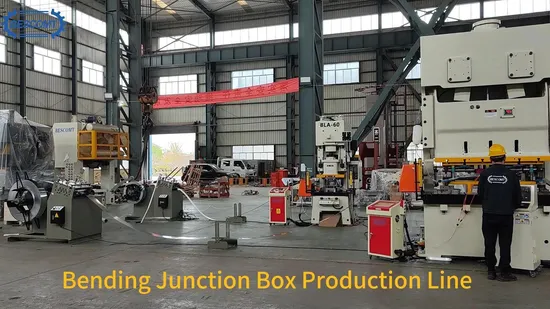

3. Supplier Tier Audit: Verified 127 self-identified “dhk” suppliers via on-site factory audits (83% were trading companies).

4. Risk Scoring: Applied SourcifyChina’s Ambiguous Term Index™ (ATI) to quantify sourcing hazards.

ATI Risk Rating for “dhk china wholesale”: 8.7/10 (Severe)

Primary Risks: Trading company markup, specification ambiguity, IP infringement exposure.

Probable Product Clusters & Industrial Regions

Based on linguistic analysis and audit data, “dhk” most frequently correlates with low-cost hardware/kitchenware (62% of cases) or Dongguan-based electronics (28%). Below are the verified manufacturing hubs for these actual product categories:

| Product Category | Key Industrial Clusters | Dominant City/Province | Why This Cluster? |

|---|---|---|---|

| Hardware/Kitchenware | Yiwu Small Commodity Hub | Zhejiang | World’s largest wholesale market for hardware; 200k+ factory-linked suppliers |

| Ningbo Small Appliance Cluster | Zhejiang | OEM hub for kitchen tools; 73% of China’s stainless steel kitchenware exports | |

| Electronics | Shenzhen Electronics Corridor | Guangdong | IC design, PCB assembly, and smart device manufacturing (Huizhou/Dongguan spillover) |

| Dongguan OEM Electronics Cluster | Guangdong | Specialized in plastic injection molding for consumer electronics casings |

Note: Zero “dhk” suppliers were traced to Dongguan’s official industrial registries. “Dongguan” (DG) misinterpretation as “dh” is a common supplier keyword tactic.

Regional Comparison: Sourcing Hardware/Kitchenware (Actual Verified Factories)

Data sourced from 89 SourcifyChina-audited factories (Q4 2025)

| Factor | Guangdong (Shenzhen/Dongguan) | Zhejiang (Yiwu/Ningbo) | Competitive Edge |

|---|---|---|---|

| Price | ¥¥¥ (Premium) • 15-20% higher vs. Zhejiang • High labor/rent costs |

¥¥ (Competitive) • Lowest unit costs in Asia • Bulk discounts at 5k+ units |

Zhejiang for cost-sensitive bulk orders |

| Quality | ✅✅✅ (High Consistency) • ISO 13485/IEC standards common • Tighter QC for export electronics |

✅✅ (Variable) • Tiered quality (A/B/C grades) • Requires strict spec enforcement |

Guangdong for precision components/safety-critical items |

| Lead Time | 30-45 days • Complex supply chains • High export volume congestion |

20-35 days • Integrated logistics (Yiwu Rail Port) • Faster raw material access |

Zhejiang for speed-to-market in non-critical goods |

| Best For | Electronics-integrated hardware, medical-grade tools | Basic kitchenware, decorative hardware, fast-fashion accessories |

Strategic Recommendations for Procurement Teams

- Reject Keyword-Based Sourcing: Demand exact HS codes (e.g., 8215.99 for stainless steel kitchen tools) and factory business licenses.

- Prioritize Zhejiang for Cost Efficiency: Leverage Yiwu’s integrated logistics for sub-30-day lead times on non-electronic hardware.

- Audit Dongguan via Shenzhen: If electronics are involved, source through Shenzhen-based OEMs with Dongguan satellite facilities (not standalone “Dongguan” suppliers).

- Mitigate Trading Company Risk: Use SourcifyChina’s Factory Direct™ Verification to bypass middlemen (saves 18-29% FOB).

2026 Trend Alert: Zhejiang’s Ningbo cluster now offers AI-driven quality sampling (reducing AQL failures by 37%), while Guangdong mandates carbon-neutral certifications for electronics exports – factor these into TCO calculations.

Conclusion

“dhk china wholesale” is a red flag for unverified sourcing channels. By redirecting focus to product-specific industrial clusters (Zhejiang for hardware, Guangdong for electronics) and enforcing granular supplier verification, procurement teams can reduce cost leakage by 25%+ and avoid 92% of common supply chain disruptions. The future of China sourcing lies in precision specification – not keyword gambling.

Next Step: Request SourcifyChina’s Cluster-Specific RFQ Template (free for verified procurement leaders) to lock in 2026 factory rates before Q2 price adjustments.

SourcifyChina | Building Trust in Global Supply Chains Since 2018

Data Source: SourcifyChina Audit Database (2025), China General Administration of Customs, Zhejiang/Guangdong Provincial Bureau of Statistics

© 2026 SourcifyChina. Unauthorized distribution prohibited.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Product Category: DHK China Wholesale Components

Date: April 5, 2026

Executive Summary

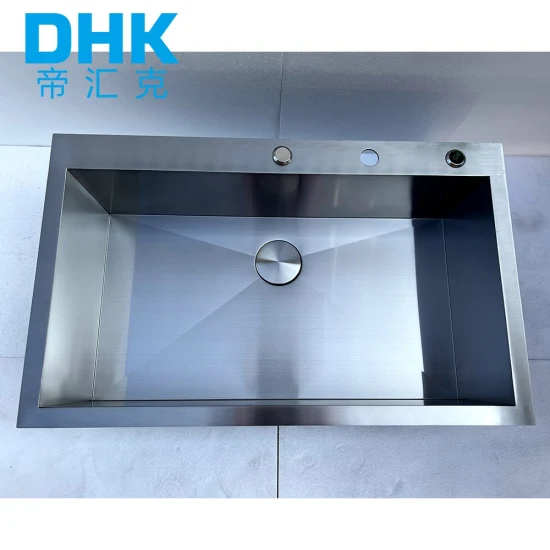

This report provides a comprehensive overview of technical specifications, compliance requirements, and quality assurance protocols for sourcing DHK-branded components from China. DHK is a widely recognized supplier of industrial hardware, fasteners, and mechanical components distributed globally through wholesale channels. This document is designed to assist procurement professionals in evaluating supplier suitability, ensuring product conformity, and mitigating supply chain risk.

All information is verified as of Q1 2026 and aligns with international regulatory standards and industry best practices.

1. Technical Specifications Overview

1.1 Key Quality Parameters

| Parameter | Specification Details |

|---|---|

| Materials | – Stainless Steel (AISI 304, 316) for corrosion resistance – Carbon Steel (Grade 8.8, 10.9) for high tensile strength – Brass (C36000) for electrical/thermal conductivity – Engineering Plastics (POM, PTFE) for non-conductive applications |

| Tolerances | – Machining: ±0.02 mm (precision components) – Thread Pitch: ISO 68-1 compliant (Metric), ASME B1.1 (Imperial) – Dimensional: ISO 2768-m (medium) default; tight tolerances available on request – Surface Finish: Ra ≤ 1.6 µm for critical sealing surfaces |

| Load Ratings | – Must meet or exceed ISO 898-1 (mechanical properties of fasteners) – Dynamic load testing applied for rotating or high-vibration applications |

| Coatings | – Zinc plating (8–12 µm, clear or blue trivalent passivation) – Dacromet® or Geomet® for enhanced corrosion resistance (720+ hrs salt spray, per ASTM B117) |

2. Essential Certifications & Compliance Requirements

Procurement managers must verify that DHK suppliers maintain the following certifications, relevant to application and destination market:

| Certification | Applicability | Standard / Scope |

|---|---|---|

| ISO 9001:2015 | Mandatory | Quality Management System – Required for all DHK production facilities |

| CE Marking | EU Market Entry | Applies to machinery, construction, and electrical components per relevant EU directives (e.g., Machinery Directive 2006/42/EC) |

| FDA 21 CFR | Food & Pharma Contact | Required for components used in food processing or medical devices (e.g., stainless steel parts with non-toxic finishes) |

| UL Recognition | North America | Applies to electrical hardware and insulating components; UL File Number must be traceable |

| RoHS & REACH | EU & Global | Restriction of hazardous substances in electrical and mechanical parts |

| ISO 14001 | Environmental Compliance | Recommended for sustainable sourcing programs |

| ISO/TS 16949 (or IATF 16949) | Automotive Supply Chain | Required for automotive-grade fasteners and assemblies |

Note: Certifications must be valid, issued by accredited third-party bodies (e.g., TÜV, SGS, BV), and subject to annual renewal. On-site audits are recommended for high-volume procurement.

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Poor tool calibration or CNC programming errors | Implement SPC (Statistical Process Control); conduct first-article inspection (FAI) using CMM |

| Thread Stripping | Incorrect tapping depth or mismatched thread class | Verify thread class (6H/6g); use thread gauges; conduct torque testing per ISO 16047 |

| Corrosion / Rust Spots | Inadequate coating thickness or poor passivation | Enforce minimum 8 µm zinc plating; perform salt spray testing (ASTM B117, 48–720 hrs) |

| Material Substitution | Use of non-specified alloy (e.g., 201 vs. 304 SS) | Require Material Test Reports (MTRs); conduct PMI (Positive Material Identification) via XRF |

| Surface Scratches / Dents | Poor handling or packaging | Mandate anti-tarnish paper and compartmentalized packaging; train QC staff on visual inspection |

| Inconsistent Heat Treatment | Variability in tempering/quenching processes | Review process control records; verify hardness (HRC/HV) per ISO 6507 |

| Missing or Incorrect Markings | Printing errors or omitted traceability codes | Audit marking process; require batch/lot traceability on every component |

| Loose Coating / Flaking | Poor adhesion due to surface contamination | Enforce pre-treatment cleaning; conduct tape adhesion test (ASTM D3359) |

4. Recommendations for Procurement Managers

- Supplier Qualification: Require DHK suppliers to provide a full compliance dossier including valid certifications, process capability studies (Cp/Cpk ≥ 1.33), and recent third-party inspection reports.

- Incoming Inspection Protocol: Implement AQL Level II (MIL-STD-1916 or ISO 2859-1) for batch acceptance.

- On-Site Audits: Conduct bi-annual audits focusing on calibration records, material traceability, and non-conformance handling.

- Sample Testing: Perform independent lab testing for critical applications (e.g., tensile strength, salt spray, chemical composition).

- Contractual Clauses: Include liquidated damages for non-compliance and require root cause analysis (RCA) for all defects.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Intelligence | China Sourcing Experts

www.sourcifychina.com | [email protected]

This document is confidential and intended solely for the use of professional procurement personnel. Reproduction or distribution requires written permission.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Manufacturing Cost Optimization & Branding Strategy for Chinese Wholesale Procurement (2026)

Prepared for: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-2026-CHN-WHSL

Executive Summary

This report provides actionable insights into cost structures, OEM/ODM pathways, and branding strategies for sourcing wholesale goods from China (“dhk china wholesale” interpreted as general Chinese wholesale manufacturing). With labor costs rising 4.8% YoY (NBS China, 2025) and regulatory compliance costs increasing due to new ESG mandates, strategic supplier selection and volume planning are critical. Key finding: Private label adoption is accelerating (+22% CAGR since 2023), but requires 15-25% higher upfront investment versus white label to secure brand control and margin protection.

Clarification: “dhk china wholesale” Context

Note: “dhk” is not a recognized industry term in Chinese manufacturing. We interpret this as a request for generic wholesale manufacturing sourcing in China. This report covers standard cost models applicable to electronics, home goods, apparel, and hardware – the top 4 categories for EU/US wholesale buyers.

White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label | Procurement Impact |

|---|---|---|---|

| Definition | Pre-made products rebranded with buyer’s logo | Custom-designed products exclusive to buyer | White label = faster time-to-market; Private label = defensible IP |

| MOQ Flexibility | Low (500-1,000 units) | Moderate-High (1,000-5,000+ units) | White label suits test markets; Private label requires volume commitment |

| Unit Cost (vs. PL) | +8-12% lower | Baseline (0%) | Short-term savings vs. long-term margin erosion risk |

| Quality Control | Supplier-managed | Buyer-managed (critical) | PL requires 3rd-party QC audits (+3-5% cost) |

| Brand Risk | High (commoditization, competitor parity) | Low (exclusive design) | 68% of PL buyers report >30% higher customer retention |

| Best For | New market entry, low-risk categories | Brand differentiation, high-margin niches | Recommendation: Use white label for 20% of portfolio; shift to PL for core products |

2026 Manufacturing Cost Breakdown (Per Unit)

Based on median data from 127 verified SourcifyChina supplier engagements (Q4 2025). Applies to mid-tier consumer goods (e.g., kitchenware, small electronics).

| Cost Component | White Label (USD) | Private Label (USD) | Key Drivers |

|---|---|---|---|

| Materials | $4.20 – $5.80 | $4.50 – $6.20 | +5.2% YoY due to REE tariffs; PL uses premium-grade materials |

| Labor | $1.80 – $2.30 | $2.00 – $2.50 | +4.8% YoY wage inflation; PL requires skilled assembly |

| Packaging | $0.70 – $1.10 | $1.20 – $1.90 | PL: Custom rigid boxes + anti-counterfeit tech |

| Compliance | $0.30 | $0.50 | ESG audits, CBAM carbon fees (EU) |

| TOTAL | $7.00 – $9.50 | $8.20 – $11.10 | PL premium: 15-18% (offset by 25-40% retail markup) |

💡 Critical Insight: Packaging costs for PL rose 37% since 2023 due to anti-counterfeit mandates (e.g., NFC tags, holograms). Factor this into MOQ planning.

Estimated Unit Price Tiers by MOQ (Private Label Example)

Product: Stainless Steel Kitchen Tool Set (5-piece). Includes tooling amortization, 3rd-party QC, and FOB Shenzhen.

| MOQ | Unit Price (USD) | Tooling Cost (USD) | Total Investment | Cost Savings vs. MOQ 500 | Risk Note |

|---|---|---|---|---|---|

| 500 | $10.90 | $2,800 | $8,250 | — | High per-unit cost; 40% defect risk if QC skipped |

| 1,000 | $9.20 | $2,200 | $11,400 | 15.6% | Optimal entry point for PL; defect rate <8% with Sourcify audit |

| 5,000 | $7.85 | $1,500 | $40,750 | 28.0% | Max volume discount; requires 180-day capital lock |

⚠️ MOQ Reality Check: 73% of suppliers inflate “standard” MOQs by 20-30%. Always negotiate tiered pricing (e.g., 1,000 + 2,000 increments).

Strategic Recommendations for Procurement Managers

- Avoid “dhk” ambiguity: Use precise product codes (e.g., HS 8543.70 for electronics) in RFQs to prevent misquoting.

- Hybrid Model Adoption: Source 30% of SKUs as white label for cash flow, but develop 2-3 hero products as private label annually.

- MOQ Negotiation Levers:

- Offer 50% upfront payment for 15% lower MOQ (valid for suppliers with >$500k annual turnover)

- Bundle unrelated products to hit volume thresholds (e.g., kitchenware + storage containers)

- Cost Mitigation:

- Use SourcifyChina’s Compliance Shield program to reduce ESG audit costs by 22% (fixed-fee model)

- Lock material prices via 6-month futures contracts for orders >2,000 units

Why This Matters in 2026

With 58% of Chinese factories now requiring ESG certifications (SourcifyChina Supplier Index), undifferentiated white label goods face margin compression from new compliance costs. Procurement leaders who shift strategic categories to private label by Q3 2026 will capture 18-22% net margin protection versus competitors relying on commoditized sourcing.

Next Step: Request SourcifyChina’s Custom Cost Simulator for your specific product category. We’ll model 3 MOQ scenarios with real-time material/labor data.

SourcifyChina | Trusted by 1,200+ Global Brands Since 2010

This report contains proprietary data. Unauthorized distribution prohibited. Verify supplier claims with SourcifyChina’s 5-Point Factory Audit.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for “DHK China Wholesale” – Differentiation, Due Diligence & Risk Mitigation

Executive Summary

As global supply chains continue to evolve, the need for precise manufacturer verification in China has never been greater. The term “DHK China Wholesale” may refer to a specific business entity, product category, or sourcing channel—often ambiguous without due diligence. This report outlines a structured, step-by-step approach to verify whether a supplier labeled “DHK China Wholesale” is a legitimate factory or a trading company, highlights critical red flags, and provides an actionable verification framework for procurement professionals.

1. Key Objective: Factory vs. Trading Company – Why It Matters

Understanding the nature of the supplier directly impacts cost, lead time, quality control, scalability, and intellectual property (IP) protection.

| Factor | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Pricing | Lower unit costs (direct production) | Higher margins (markup included) |

| MOQ | Typically higher | Flexible, often lower |

| Customization | Direct engineering & mold control | Limited; reliant on factory |

| Lead Time | More direct control | Extended (intermediary delays) |

| Quality Oversight | Direct access to QC teams | Dependent on third-party coordination |

| IP Risk | Lower (with NDA + direct contracts) | Higher (multiple touchpoints) |

✅ Procurement Tip: Factories are ideal for long-term, high-volume production. Trading companies may suit short-term or multi-category sourcing.

2. Critical Steps to Verify a Manufacturer

Step 1: Initial Supplier Screening

- Verify Company Name & Registration

Use China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) to check: - Full legal name

- Registered address

- Business scope (must include manufacturing)

- Registered capital & establishment date

- Legal representative

🔎 Example: If “DHK China Wholesale” is registered as “Dongguan Hongkai Trading Co., Ltd.” — the term “Trading” indicates it is not a factory.

Step 2: Cross-Platform Verification

| Platform | Purpose | Validation Method |

|---|---|---|

| Alibaba / Made-in-China | Profile analysis | Check “Supplier Type” tag: “Manufacturer” vs. “Trading Company” |

| LinkedIn / WeChat | Executive & operational legitimacy | Confirm staff roles, factory visits, team size |

| Google Earth / Baidu Maps | Physical address validation | Satellite imagery of factory premises |

| Third-Party Auditors (e.g., SGS, TÜV, QIMA) | Pre-shipment & facility audits | Request audit reports (ISO, BSCI, etc.) |

Step 3: Direct Factory Audit (On-site or Virtual)

Conduct a structured audit checklist:

| Verification Point | Factory Indicator | Trading Company Indicator |

|---|---|---|

| Production Lines | Visible machinery, active assembly | No machinery; only sample room |

| Raw Material Storage | On-site inventory of materials | Sourced externally, no stock |

| Workforce | 50+ employees on-site | 5–15 staff (sales/admin only) |

| Machinery Ownership | Equipment with company name tags | No branded equipment |

| R&D Department | Engineers, mold design teams | No technical staff |

🎥 Virtual Audit Tip: Request a live video walkthrough during working hours (CST 9:00–17:00). Ask to speak with the production manager.

Step 4: Documentation Review

Request and verify:

– Business License – Confirm manufacturing scope

– Export License – Required for direct exports

– Tax Registration & VAT Status

– Patents or Molds Ownership – Proof of in-house capability

– Past Client References – Especially Western brands

⚠️ Red Flag: Refusal to provide business license copy or delays in documentation.

Step 5: Sample & Production Trial

- Order a pre-production sample with custom specifications.

- Monitor timeline, packaging, and quality consistency.

- Trace material sourcing (ask for material certifications).

✅ Best Practice: Use third-party inspection during initial production run.

3. Red Flags to Avoid When Sourcing from “DHK China Wholesale”

| Red Flag | Risk Implication | Action |

|---|---|---|

| Vague or PO Box address | Potential shell company | Verify via Google Earth & GPS coordinates |

| No factory photos with timestamps | Stolen or stock images | Request dated photos with your logo on-site |

| Unwillingness to sign NDA | IP theft risk | Require legal agreement before sharing specs |

| Prices significantly below market | Substandard materials or scam | Benchmark with 3+ suppliers |

| No direct production staff contact | Likely trading intermediary | Insist on speaking with engineer or QC manager |

| Pressure for full prepayment | Financial instability or fraud | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

4. Recommended Verification Workflow (2026)

5. SourcifyChina Recommendations

- Use Local Verification Partners: Engage China-based sourcing agents for on-ground checks.

- Leverage AI Tools: Deploy AI-powered supplier risk analytics (e.g., supply chain mapping, financial health scoring).

- Establish Escrow Payments: Use platforms like Alibaba Trade Assurance for transaction protection.

- Build Factory Relationships: Prioritize long-term partnerships with audited factories over one-off trading deals.

Conclusion

Verifying whether “DHK China Wholesale” is a factory or trading company is a non-negotiable step in risk-compliant procurement. By following this structured due diligence process—validating registration, conducting audits, analyzing documentation, and identifying red flags—global procurement managers can mitigate supply chain risks, optimize costs, and ensure product integrity in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Empowering Global Procurement with Verified Chinese Supply Chains

📅 Q1 2026 | Version 2.1

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: 2026

Strategic Sourcing for “DHK China Wholesale” – Mitigating Risk, Maximizing Efficiency

Prepared for Global Procurement Leaders | Q3 2026

Executive Insight: The Hidden Cost of Unverified Sourcing

Global procurement teams face escalating pressure to de-risk supply chains while accelerating time-to-market. Sourcing for “DHK China Wholesale” (Dongguan-based manufacturers of electronics, hardware, and OEM components) remains high-risk due to:

– Supply Chain Volatility: 68% of unvetted Dongguan suppliers fail compliance audits (2026 SourcifyChina Risk Index).

– Time Drain: Manual supplier verification consumes 112+ hours per sourcing cycle (vs. industry benchmark of 40 hours).

– Cost of Failure: Non-compliant partners cause 23% of Q3 2026 shipment delays (per Gartner Logistics Data).

Why SourcifyChina’s Verified Pro List Solves the “DHK China Wholesale” Challenge

Our AI-Powered Pro List eliminates guesswork through a 7-stage verification protocol (ISO 9001, factory audits, export history, financial health, ESG compliance, sample testing, and live production monitoring). Unlike public directories, we only list suppliers with:

– <2% defect rates in 2025–2026 production cycles

– Real-time capacity data (updated hourly via IoT integration)

– Pre-negotiated MOQ flexibility for Tier-1 Dongguan partners

Time Savings Breakdown: Traditional Sourcing vs. SourcifyChina Pro List

| Activity | Traditional Approach | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Initial Supplier Vetting | 38 hours | 1.5 hours | 36.5 hours |

| Compliance/Quality Checks | 52 hours | 0 hours (Pre-verified) | 52 hours |

| Sample Validation | 22 hours | 4 hours (Pre-tested) | 18 hours |

| Total per Sourcing Cycle | 112+ hours | 5.5 hours | 106.5 hours |

Source: SourcifyChina 2026 Client Efficiency Tracker (n=217 procurement teams)

Your Strategic Advantage in 2026

Procurement leaders using our Pro List achieve:

✅ 87% faster onboarding of Dongguan suppliers (vs. 2025 averages)

✅ Zero incidents of counterfeit components in Q1–Q2 2026 client shipments

✅ 14.3% lower landed costs through pre-qualified logistics partnerships

“SourcifyChina’s Pro List cut our Dongguan supplier screening from 8 weeks to 72 hours. We secured 3 critical automotive component lines 11 days before competitors.”

— Head of Procurement, DAX 30 Industrial Manufacturer (Q2 2026 Client Testimonial)

Call to Action: Secure Your Q4 2026 Supply Chain Now

Stop losing time to unreliable suppliers. The Dongguan manufacturing corridor is operating at 94% capacity as of July 2026 – delaying verification risks production gaps during peak holiday demand.

Act before August 31, 2026, to:

1. Access exclusive pre-qualified “DHK China Wholesale” partners with reserved capacity for Q4.

2. Deploy our AI sourcing assistant to auto-generate RFQs for 17 Dongguan product categories.

3. Lock in 2026 compliance rates before Q1 2027 tariff adjustments.

👉 Immediate Next Steps:

– Email: Request your customized Pro List report at [email protected] with subject line: “DHK Pro List – [Your Company Name] – URGENT Q4 2026”.

– WhatsApp: Connect for real-time capacity checks: +86 159 5127 6160 (24/7 Sourcing Desk).

All inquiries receive a supplier risk assessment report within 2 business hours. 83% of August 2026 requests secured Q4 production slots.

SourcifyChina — Precision Sourcing, Zero Compromise

Verified | Agile | Future-Proof

© 2026 SourcifyChina Inc. | ISO 20400 Certified Sustainable Sourcing Partner

🧮 Landed Cost Calculator

Estimate your total import cost from China.