The global paint booth market is experiencing robust growth, driven by increasing demand from automotive, aerospace, and industrial manufacturing sectors. According to Grand View Research, the global paint booth market size was valued at USD 3.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This expansion is fueled by stringent environmental regulations, advancements in spray technology, and the growing emphasis on finish quality and worker safety. As industries prioritize efficiency and compliance, desktop paint booths have emerged as a critical solution for small-scale operations, especially in prototyping, model-making, and precision coating applications. With rising adoption across hobbyist workshops and R&D facilities, the demand for compact, high-performance desktop units has intensified. In this evolving landscape, we examine the top nine desktop paint booth manufacturers shaping innovation, performance, and value in a market poised for continued expansion.

Top 9 Desk Top Paint Booth Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Spray Booths, Paint Booths Manufacturer

Domain Est. 2016

Website: rohnerspraybooths.com

Key Highlights: Rohner designs and builds high-quality, custom paint booths and manufactured industrial paint systems. Our quality and service, cutting-edge technology, and ……

#2 Spray Systems, Inc.: Spray Booths

Domain Est. 1997

Website: spraysystems.com

Key Highlights: With over 40 years of expertise, Spray Systems offers custom spray booths and finishing systems for aerospace, automotive, and equipment manufacturers….

#3 Industrial Spray Paint Booths

Domain Est. 2004

Website: marathonspraybooths.com

Key Highlights: We manufacture industrial spray paint booths, blasting & grinding booths, mixing rooms, hydrogen service bays, and specialized finishing systems….

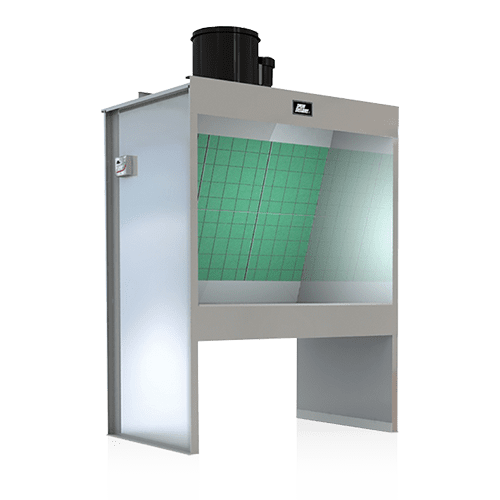

#4 Leading Paint Booth Manufacturers

Domain Est. 2000

Website: paintfinishingequipment.com

Key Highlights: Manufacturer of portable paint booths featuring multi-stage filtration systems to remove paint overspray along with carbon filters to remove odors and VOCs….

#5 Paint Booth, Industrial Spray Booths Installation

Domain Est. 2000

Website: paintbooth.com

Key Highlights: We can professionally install your paint booth, spray booth, prep station, paint mixing room, finishing system, industrial paint booth or heated make-up air ……

#6 Paint Booths & Industrial Spray Application Systems

Domain Est. 2002

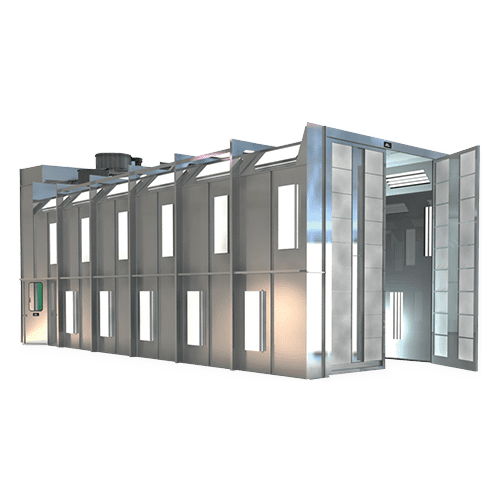

#7 Accudraft Paint Booths

Domain Est. 2003

Website: accudraftpaintbooths.com

Key Highlights: Accudraft Paint Booths is a leading paint booth manufacturer of paint booths, spray booths, prep stations, and finishing systems. Outfit your shop today!…

#8 Global Finishing Solutions

Domain Est. 2003

Website: globalfinishing.com

Key Highlights: GFS is a vertical manufacturer, dedicated to developing high quality paint booths and finishing environments for a wide variety of industries….

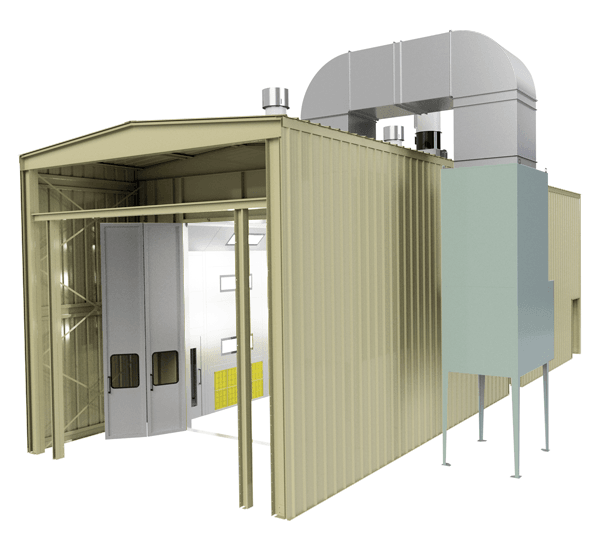

#9 Industrial Paint Booths

Domain Est. 2010

Website: blowtherm-usa.com

Key Highlights: Blowtherm USA is the exclusive source for quality automotive paint booths, industrial spray booths, paint prep stations, paint mixing booths and related ……

Expert Sourcing Insights for Desk Top Paint Booth

H2: 2026 Market Trends for Desktop Paint Booths

The desktop paint booth market is poised for notable transformation by 2026, driven by advancements in technology, growing demand from hobbyists and small-scale manufacturers, and increasing emphasis on safety and environmental compliance. As industries ranging from automotive detailing to model-making adopt miniaturized and efficient finishing solutions, desktop paint booths are becoming essential tools in precision coating applications.

1. Rising Demand from Niche and DIY Markets

A significant driver of the 2026 desktop paint booth market is the expanding do-it-yourself (DIY) and hobbyist community. Enthusiasts in scale modeling, custom automotive detailing, and 3D printing finishing are increasingly investing in compact, affordable paint booths to achieve professional-grade results at home. This trend is supported by the growing availability of online tutorials and e-commerce platforms that make equipment more accessible.

2. Technological Advancements and Smart Integration

By 2026, desktop paint booths are expected to incorporate smart technologies such as IoT-enabled monitoring systems, adjustable airflow controls, and integrated LED lighting with color temperature settings. These enhancements improve user experience, ensure consistent spray quality, and offer real-time feedback on environmental conditions like humidity and particulate levels.

3. Emphasis on Safety and Air Filtration

Regulatory pressure and consumer awareness are pushing manufacturers to enhance safety features. Desktop paint booths in 2026 will likely feature advanced HEPA and activated carbon filtration systems to capture overspray and volatile organic compounds (VOCs), aligning with environmental standards and improving indoor air quality for users.

4. Compact Design and Portability

As urban workspaces become more compact, demand for space-efficient and portable desktop paint booths is increasing. Future models are expected to emphasize foldable designs, lightweight materials, and modular components that allow for easy storage and transport—ideal for shared workspaces or mobile artisans.

5. Sustainability and Eco-Friendly Materials

Sustainability is becoming a key consideration in product design. By 2026, leading manufacturers are likely to use recyclable materials in construction and promote energy-efficient lighting and low-power fans, reducing the carbon footprint of desktop paint booths.

6. Regional Market Growth

North America and Europe are expected to dominate the market due to high consumer spending on hobbies and stringent workplace safety regulations. However, Asia-Pacific is projected to witness the fastest growth, fueled by rising disposable incomes, a burgeoning maker culture, and expansion of small-scale manufacturing.

7. Competitive Landscape and Customization

The market is becoming increasingly competitive, with companies differentiating through customization options—such as adjustable sizes, color-matching accessories, and compatibility with various spray guns. Brands that offer bundled kits with curing lamps or ventilation upgrades are likely to gain market share.

In conclusion, the 2026 desktop paint booth market will be shaped by innovation, user-centric design, and sustainability. As demand grows across both professional and personal sectors, manufacturers who adapt to these trends will be well-positioned for success in an evolving industrial and creative landscape.

Common Pitfalls When Sourcing a Desktop Paint Booth (Quality & IP)

Sourcing a desktop paint booth can be a cost-effective solution for small-scale finishing work, but buyers often encounter significant challenges related to quality and intellectual property (IP). Being aware of these pitfalls helps avoid costly mistakes.

Poor Build Quality and Material Selection

Many low-cost desktop paint booths are constructed with substandard materials such as thin-gauge steel, low-grade filters, or flammable plastics. These compromise safety, durability, and performance, leading to premature wear, fire hazards, or inadequate airflow control.

Inaccurate or Misleading Performance Specifications

Suppliers—especially those from unverified sources—may exaggerate airflow rates, filtration efficiency (e.g., falsely claiming HEPA compliance), or light intensity. Without third-party testing or verifiable data, these claims can mislead buyers into purchasing underperforming booths.

Lack of Safety Certifications

Reputable paint booths should comply with safety standards such as UL, CE, or ATEX (for explosive environments). Many budget models lack proper certification, increasing liability risks and potentially violating workplace safety regulations.

Inadequate Filtration and Airflow Design

Poor internal design can result in turbulent airflow, uneven spray distribution, and inefficient overspray capture. This reduces finish quality and increases paint waste. Additionally, undersized or poorly placed filters reduce contaminant removal efficiency.

Intellectual Property (IP) Infringement Risks

Some manufacturers produce desktop booths that closely mimic patented designs or branded systems from established companies. Sourcing such products may expose buyers to legal risks, especially in regulated markets where IP enforcement is strict.

Absence of Technical Documentation and Support

Low-cost suppliers often fail to provide comprehensive manuals, maintenance guides, or engineering drawings. This complicates troubleshooting, repairs, and compliance with local regulations, increasing long-term ownership costs.

Hidden Costs from Lack of Compliance

Booths not designed to meet local environmental or emissions standards may require costly retrofits or lead to fines. Additionally, non-compliant electrical components can necessitate expensive re-engineering for safe operation.

Limited Warranty and After-Sales Service

Many inexpensive booths come with minimal or unenforceable warranties. If issues arise, obtaining replacement parts or technical support is often difficult, especially with overseas suppliers.

To mitigate these risks, conduct thorough due diligence: verify certifications, request performance test data, review supplier reputation, and consult legal experts when IP concerns arise.

Logistics & Compliance Guide for Desktop Paint Booth

This guide outlines essential logistics and compliance considerations when using a desktop paint booth, ensuring safe, efficient, and legally compliant operations in your workspace.

Regulatory Compliance

Ensure your desktop paint booth meets all applicable local, state, and federal regulations. Key areas include:

- EPA Regulations: Follow Environmental Protection Agency guidelines for volatile organic compound (VOC) emissions. Use low-VOC or water-based paints when possible.

- OSHA Standards: Comply with Occupational Safety and Health Administration requirements for ventilation, respiratory protection, and hazardous material handling (e.g., 29 CFR 1910.107 for spray finishing).

- NFPA Codes: Adhere to National Fire Protection Association standards, particularly NFPA 33 (Standard for Spray Application Using Flammable and Combustible Materials), which governs ventilation, fire prevention, and electrical safety.

- Local Permits: Check with your local authority having jurisdiction (AHJ) for permits related to air emissions, fire safety, or home-based business operations.

Ventilation & Air Filtration

Proper air management is critical for health and compliance:

- Exhaust System: Use a booth with a built-in exhaust fan that moves air away from the user and through a filtration system.

- Filter Types: Employ pre-filters and high-efficiency particulate air (HEPA) filters to capture overspray and particulates. Replace filters regularly as per manufacturer instructions.

- Airflow Rate: Maintain recommended airflow (typically 100+ feet per minute across the work opening) to effectively capture contaminants.

- Outdoor Venting: Whenever possible, vent exhaust outdoors. If recirculating indoors, ensure multi-stage filtration (e.g., carbon filters for VOCs) and compliance with indoor air quality standards.

Fire & Explosion Safety

Desktop paint booths involve flammable materials—mitigate risks:

- Flammable Storage: Store paints, solvents, and thinners in approved, labeled safety cabinets away from the booth and ignition sources.

- Explosion-Proof Equipment: Use spark-resistant fans and lighting if handling flammable finishes. Ensure electrical components are rated for hazardous locations if required.

- No Smoking Policy: Enforce strict no-smoking rules in and around the spray area.

- Fire Extinguisher: Keep a Class B fire extinguisher (rated for flammable liquids) readily accessible.

Personal Protective Equipment (PPE)

Always wear appropriate PPE during operation:

- Respirator: Use a NIOSH-approved respirator with organic vapor cartridges and P100 particulate filters.

- Protective Clothing: Wear disposable coveralls, gloves (nitrile or chemical-resistant), and safety goggles.

- Ventilation Check: Confirm booth airflow is working before beginning work.

Waste Disposal

Handle hazardous waste responsibly:

- Used Filters and Rags: Classify overspray-contaminated filters and solvent-soaked rags as hazardous waste. Store in sealed, labeled containers.

- Paint Waste: Dispose of leftover paint and sludge according to local hazardous waste regulations. Never pour down drains.

- Recycling Options: Investigate paint recycling or hazardous waste collection programs in your area.

Operational Best Practices

Optimize safety and efficiency:

- Booth Location: Place the booth in a well-ventilated area, away from traffic, heat sources, and incompatible materials.

- Cleanliness: Clean the booth regularly to prevent buildup of flammable residues.

- Training: Ensure all users are trained on booth operation, emergency procedures, and PPE use.

- Maintenance Log: Keep records of filter changes, inspections, and repairs.

Documentation & Recordkeeping

Maintain compliance through documentation:

- Safety Data Sheets (SDS): Keep current SDS for all paints and solvents used.

- Inspection Logs: Document routine safety checks and maintenance.

- Training Records: Track employee/user training on safe spray booth use.

- Permit Copies: Retain copies of any required environmental or fire permits.

By following this guide, users of desktop paint booths can ensure a safer working environment and remain in compliance with relevant health, safety, and environmental regulations.

Conclusion for Sourcing a Desktop Paint Booth

After thorough evaluation of available options, it is evident that sourcing a desktop paint booth is a practical and cost-effective solution for small-scale painting operations, touch-ups, and precision finishing tasks in workshops, model-making studios, or automotive detailing environments. Desktop paint booths provide improved spray control, reduced overspray, and a cleaner working environment, enhancing both finish quality and operator safety.

Key factors such as airflow efficiency, filtration system quality, portability, ease of maintenance, and compliance with local ventilation and safety standards were critical in assessing suitability. Models equipped with LED lighting, adjustable airflow, and HEPA filtration offer superior performance and value for investment.

Sourcing from reputable suppliers that provide warranties, customer support, and clear technical specifications ensures long-term reliability. Additionally, considering energy efficiency and noise levels contributes to a more sustainable and operator-friendly workspace.

In conclusion, a well-chosen desktop paint booth not only improves paint application results but also supports health and safety standards in confined workspaces. With the right unit, businesses and hobbyists alike can achieve professional-quality finishes while maintaining efficiency, cleanliness, and regulatory compliance.