The global market for commercial vehicle suspension components, including delivery truck shocks, is experiencing steady growth driven by rising e-commerce demand, expanding last-mile logistics networks, and increasing fleet modernization initiatives. According to a report by Mordor Intelligence, the global commercial vehicle suspension market was valued at USD 13.4 billion in 2023 and is projected to grow at a CAGR of 5.8% from 2024 to 2029. This growth is further fueled by the surge in parcel deliveries and the need for enhanced ride stability, durability, and safety in urban delivery vehicles. As fleet operators prioritize vehicle uptime and driver comfort, the demand for high-performance shock absorbers has intensified. In this competitive landscape, several manufacturers have emerged as leaders, combining advanced engineering, rigorous testing, and global supply capabilities to meet the evolving needs of delivery truck OEMs and aftermarket customers alike. The following list highlights the top 10 delivery truck shock absorber manufacturers shaping the industry.

Top 10 Delivery Truck Shocks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Shop Truck Shocks

Domain Est. 1998

Website: bds-suspension.com

Key Highlights: Free delivery over $750Upgrade your lifted truck with FOX & BDS performance shocks. Perfect for lifted trucks and off-road rigs, offering unmatched durability and a smooth ride.Mis…

#2 Truck Shocks & Strut Assemblies

Domain Est. 1995

Website: monroe.com

Key Highlights: Trucks and SUVs need shocks and struts that can handle the load. Count on Monroe for shocks, struts and strut assemblies that are up to the job….

#3 Belltech

Domain Est. 1995

Website: belltech.com

Key Highlights: Choose Your Style. Belltech delivers premium suspension solutions that transform your truck or SUV with a lower stance, smoother ride, and enhanced performance….

#4 Gabriel shocks

Domain Est. 1996

Website: gabriel.com

Key Highlights: Gabriel shock absorbers are available online or in a store near you! Visit our easy-to-use dealer locator to find a Gabriel dealer today!…

#5 Products

Domain Est. 1996

Website: offroad.bilstein.com

Key Highlights: BILSTEIN B8 5100 (Ride Height Adjustable) Leveling shocks for OE coilover applications….

#6 Shock Absorbers, Dampers & Suspension

Domain Est. 1996

Website: aftermarket.zf.com

Key Highlights: ZF Aftermarket supplies a full range of parts for a vibration-free drive, including dampers, suspension struts and suspension-strut inserts for virtually ……

#7 Timbren

Domain Est. 1999

Website: timbren.com

Key Highlights: Timbren manufactures industry-leading truck suspension and trailer suspension upgrade kits. For Timbren SES, Off-Road Bumpstops, Axle-less Trailer ……

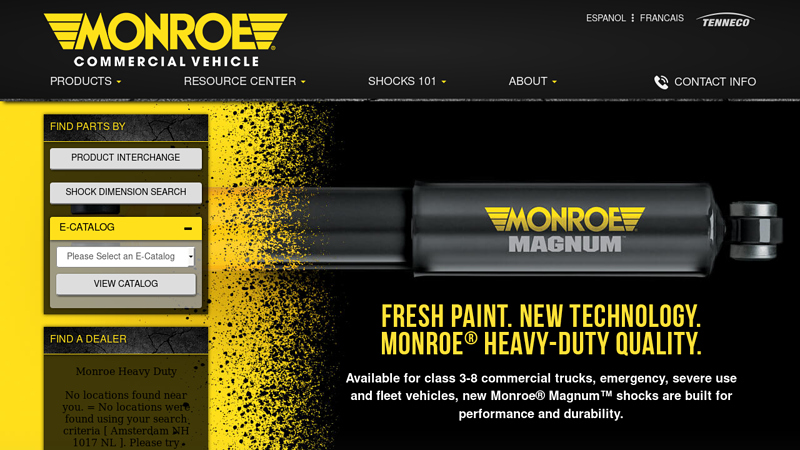

#8 MONROE® COMMERCIAL VEHICLE

Domain Est. 2002

Website: monroeheavyduty.com

Key Highlights: Shock Construction. Monroe® Magnum™ shock absorbers are designed to handle the demands of high mileage and severe use, delivering reduced cost-per-mile….

#9 Truck Shocks

Domain Est. 2009

Website: ridefox.com

Key Highlights: 2.5 PERFORMANCE SERIES SHOCKS No reservoirs. No compression adjusters. Just bolt on for exceptional performance, at exceptional value….

#10 Shock Absorbers for Trucks & Cars

Domain Est. 2014

Website: aldanamerican.com

Key Highlights: Find the best shock absorbers for custom builds and performance upgrades. Our universal vehicle shocks improve ride quality, handling, and overall control….

Expert Sourcing Insights for Delivery Truck Shocks

H2: 2026 Market Trends for Delivery Truck Shocks

The delivery truck shock absorber market in 2026 is poised for significant transformation, driven by evolving logistics demands, technological advancements, and sustainability imperatives. Key trends shaping the sector include:

1. Surge in E-Commerce and Last-Mile Delivery Fleets

The continued expansion of e-commerce will sustain high demand for delivery trucks, particularly light- and medium-duty models used in last-mile logistics. This directly increases the need for durable, high-performance shocks capable of handling frequent stops, urban terrain, and variable payloads. Fleets prioritizing vehicle uptime and driver comfort will drive demand for premium shock systems.

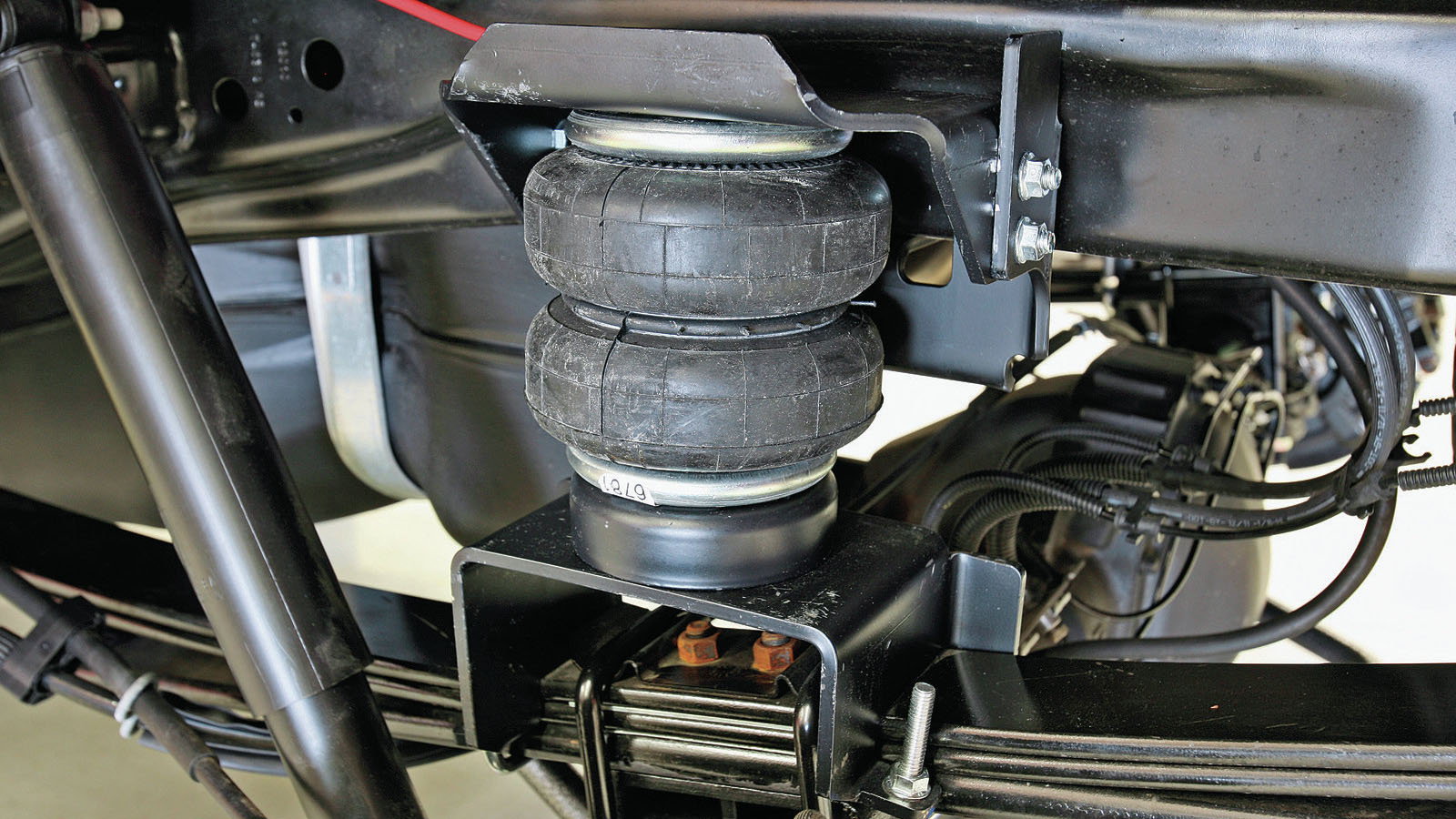

2. Electrification of Delivery Vehicles

As electric delivery vans and trucks become more prevalent by 2026, shock absorber design must adapt to unique EV characteristics. Heavier battery packs increase vehicle weight, requiring shocks with enhanced load capacity and damping performance. Additionally, manufacturers are developing shocks optimized for regenerative braking dynamics and smoother ride quality to complement the quiet operation of electric powertrains.

3. Advancement of Smart and Adaptive Suspension Systems

Intelligent shock technologies, including semi-active and adaptive dampers, will gain traction in premium delivery fleets. These systems use sensors and real-time data to adjust damping force based on road conditions and load, improving ride stability, cargo protection, and driver comfort. Integration with telematics enables predictive maintenance, reducing downtime and total cost of ownership.

4. Emphasis on Durability and Total Cost of Ownership (TCO)

With delivery trucks operating intensively in stop-and-go environments, fleet operators will prioritize shocks with extended service life and reduced maintenance needs. Manufacturers are responding with corrosion-resistant materials, advanced seal technologies, and modular designs for easier servicing—factors critical to minimizing TCO.

5. Sustainability and Circular Economy Initiatives

Environmental regulations and corporate sustainability goals will drive demand for eco-friendly manufacturing processes and recyclable materials in shock production. Remanufactured and reconditioned shocks are expected to gain market share, offering cost-effective and sustainable alternatives without compromising performance.

6. Regional Market Divergence

North America and Europe will lead in adopting advanced suspension technologies due to mature logistics infrastructure and stringent emissions standards. Meanwhile, Asia-Pacific—especially China and India—will see robust volume growth driven by booming e-commerce and expanding urban delivery networks, favoring cost-effective yet reliable shock solutions.

In summary, the 2026 delivery truck shock market will be defined by innovation in response to electrification, smart technology integration, and the relentless pace of urban logistics—positioning advanced, durable, and intelligent suspension systems as critical components of modern delivery fleets.

Common Pitfalls When Sourcing Delivery Truck Shocks: Quality and Intellectual Property Risks

Sourcing delivery truck shocks—especially from overseas suppliers—exposes fleets and distributors to significant quality and intellectual property (IP) risks. Overlooking these pitfalls can lead to costly downtime, safety issues, warranty claims, and legal complications. Below are key challenges to watch for:

Poor Shock Absorber Quality and Material Substitution

Many low-cost suppliers cut corners by using inferior materials such as low-grade steel, substandard hydraulic fluid, or inadequate seals. These compromises reduce shock absorber lifespan, leading to premature failure, uneven tire wear, and compromised vehicle handling. Without rigorous third-party testing or material certifications, buyers may receive products that fail to meet OEM performance standards.

Inconsistent Manufacturing and Lack of Quality Control

Sourcing from manufacturers without ISO or IATF 16949 certification increases the risk of inconsistent production. Without documented quality management systems, batch-to-batch variations can occur, resulting in unreliable performance. Buyers often discover defects only after installation, leading to recalls or fleet-wide replacements.

Misrepresentation of OEM Compatibility and Specifications

Some suppliers falsely claim that their shocks are “OEM equivalent” or “direct fit” without proper engineering validation. These claims may be based on superficial measurements rather than dynamic performance testing. Using incompatible shocks can void vehicle warranties and lead to suspension damage or safety hazards.

Intellectual Property Infringement and Counterfeit Products

A major risk is inadvertently sourcing shocks that infringe on patented designs or trademarks of established brands (e.g., Monroe, Bilstein, KYB). Some suppliers produce look-alike products with logos or packaging that mimic well-known brands, exposing buyers to legal liability for trademark infringement or customs seizures. Even if not counterfeit, some designs may violate utility or design patents.

Lack of Traceability and Documentation

Reputable shock absorber manufacturing requires full traceability—batch numbers, material certifications, and test reports. Many low-cost suppliers fail to provide this documentation, making it difficult to investigate failures or support warranty claims. Without traceability, establishing product liability becomes nearly impossible.

Inadequate Testing and Certification

Many sourced shocks lack proof of compliance with industry standards such as SAE J145 or ISO 13326. Suppliers may claim “high performance” without providing shock dynamometer test results or durability cycle data. Without verified testing, buyers cannot confirm real-world performance under heavy delivery fleet conditions.

Hidden Costs from Warranty and Field Failures

Although initial pricing may appear attractive, poor-quality shocks often result in higher total cost of ownership. Frequent replacements, increased maintenance labor, and unplanned vehicle downtime erode savings. Additionally, warranty support from unreliable suppliers is often slow or nonexistent.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence:

– Audit suppliers in person or via third parties

– Require material certifications and test reports

– Verify IP compliance and request design freedom-to-operate opinions

– Start with small trial orders before scaling

– Use contracts with clear quality clauses and IP indemnification

By addressing these quality and IP risks proactively, organizations can ensure reliable performance, legal compliance, and long-term cost efficiency in their delivery truck operations.

Logistics & Compliance Guide for Delivery Truck Shocks

Product Classification and Description

Delivery truck shocks are critical components of a vehicle’s suspension system, designed to absorb road impacts and ensure stable handling. These parts fall under automotive replacement parts (HS Code 8708.80 – shock absorbers and parts thereof). Proper classification is essential for accurate customs declaration and tariff application.

Transportation and Handling Requirements

- Packaging: Shocks must be securely packaged in durable, moisture-resistant materials to prevent corrosion and physical damage during transit. Individual units should be sealed and labeled with part numbers and manufacturer details.

- Loading: Stack packages evenly on pallets; avoid overloading. Use straps or shrink wrap to stabilize loads.

- Environmental Conditions: Store and transport in dry, temperature-controlled environments to prevent degradation of rubber seals and metal components.

Domestic and International Shipping Regulations

- Domestic (U.S.): Comply with Department of Transportation (DOT) regulations for commercial vehicle parts. No special permits required for non-hazardous automotive components.

- International: Adhere to destination country import regulations. Ensure compliance with local vehicle safety and emissions standards (e.g., EU ECE R90 for shock absorbers).

- Customs Documentation: Provide commercial invoices, packing lists, and a bill of lading/air waybill. Include accurate HS codes and country of origin.

Import/Export Compliance

- Export Controls: Delivery truck shocks are generally not subject to ITAR or EAR restrictions, but verify with the manufacturer for any military or dual-use variants.

- Import Duties and Taxes: Duty rates vary by country. In the U.S., shocks typically enter at a rate of 2.5% under HTSUS 8708.80. Use a valid Certificate of Origin to claim preferential rates under trade agreements (e.g., USMCA).

- Labeling Requirements: Products must display the country of manufacture, part number, and safety compliance marks (e.g., DOT, E-mark for Europe).

Quality and Safety Standards

- Certifications: Ensure shocks meet recognized standards such as ISO 9022 (durability testing) and SAE J1483 (performance).

- Compliance Testing: Manufacturers should provide proof of testing for fatigue, corrosion resistance, and performance consistency.

- Recall Preparedness: Maintain traceability via lot numbers and retain production records. Follow NHTSA guidelines if part is subject to motor vehicle safety standards.

Reverse Logistics and Returns Management

- Defective Returns: Establish a return material authorization (RMA) process. Inspect returned units for damage or misuse.

- Waste Disposal: Used shocks are typically non-hazardous waste but may contain residual hydraulic fluid. Dispose of in accordance with local environmental regulations.

- Refurbishment: If applicable, follow EPA and OSHA guidelines for cleaning and reconditioning processes.

Recordkeeping and Audit Readiness

Maintain records of all shipments, compliance certifications, test reports, and customs filings for a minimum of five years. Conduct annual audits to ensure adherence to logistics and compliance protocols.

Conclusion for Sourcing Delivery Truck Shocks

In sourcing delivery truck shocks, it is essential to balance performance, durability, cost, and supplier reliability to ensure optimal vehicle safety and operational efficiency. After evaluating various suppliers, product specifications, and total cost of ownership, it is clear that investing in high-quality, application-specific shocks leads to reduced maintenance downtime, improved ride stability, and increased driver satisfaction—key factors in maintaining a reliable delivery fleet. Partnerships with reputable manufacturers offering strong warranties and technical support further enhance long-term value. By prioritizing quality components and strategic supplier relationships, fleet operators can achieve improved vehicle performance, lower lifecycle costs, and enhanced service reliability. Therefore, the recommended approach is to select shocks from trusted suppliers with proven performance in urban and regional delivery conditions, ensuring sustained fleet productivity and safety.