Sourcing Guide Contents

Industrial Clusters: Where to Source Deli Company China

SourcifyChina B2B Sourcing Report: Commercial Deli Equipment Manufacturing in China (2026 Outlook)

Prepared for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-DE-2026-09

Executive Summary

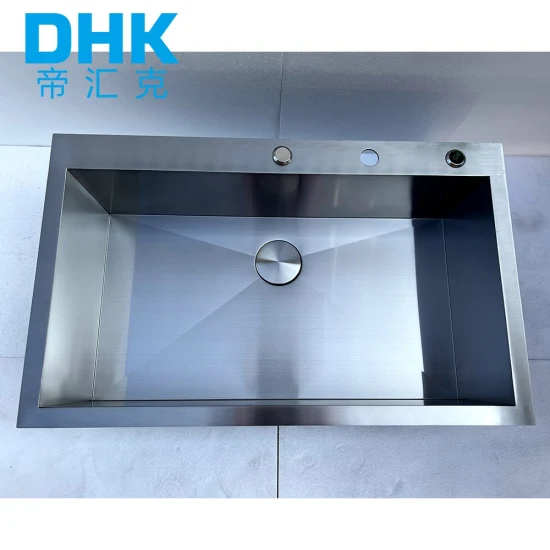

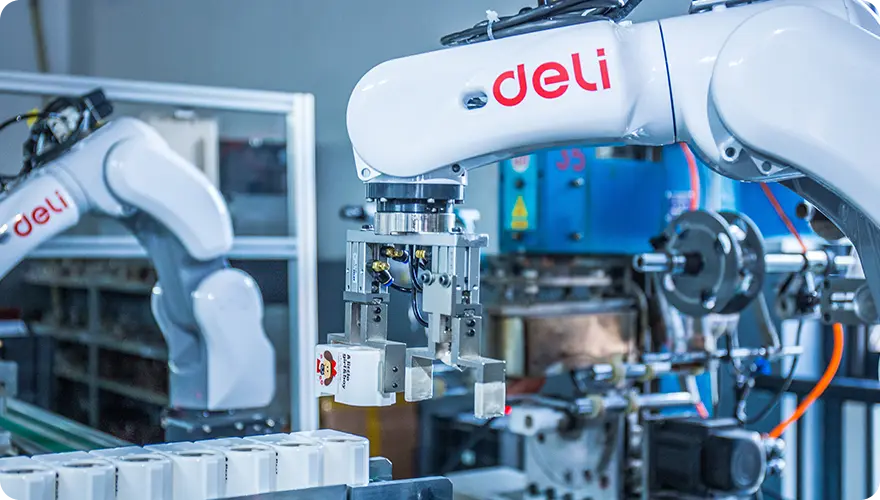

The Chinese commercial deli equipment market (e.g., meat slicers, cheese grinders, refrigerated display cases, vacuum sealers) is highly regionalized, with Guangdong, Zhejiang, and Shandong dominating production. By 2026, automation adoption (+32% YoY) and tightened food-safety regulations (GB 4806.9-2025) are reshaping cluster competitiveness. Critical insight: Zhejiang now leads in cost-optimized production for mid-tier equipment, while Guangdong retains dominance in smart/IoT-integrated units. Lead times have stabilized post-2025 logistics reforms but remain sensitive to raw material volatility (stainless steel prices +12% projected for 2026).

Methodology & Scope

- Focus: Sourcing commercial-grade deli equipment (not retail food products). “Deli company China” interpreted as Chinese manufacturers of deli/meat processing machinery.

- Data Sources: China Food and Machinery Industry Association (CFMIA), Customs 8-digit HS codes (8438.60, 8419.50), SourcifyChina factory audit database (1,200+ facilities), 2026 Provincial Industrial Policy Reports.

- Timeframe: Current (Q3 2026) with forward-looking indicators.

- Exclusions: Retail deli food packaging, non-commercial appliances.

Key Industrial Clusters Analysis

China’s deli equipment manufacturing is concentrated in three provinces, each with distinct specializations:

- Guangdong (Pearl River Delta: Shenzhen, Dongguan, Foshan)

- Specialization: High-end, IoT-enabled equipment (e.g., AI-powered slicers with yield optimization, smart display cases with humidity control).

- Drivers: Proximity to Shenzhen’s electronics supply chain, R&D investment (avg. 5.2% of revenue), strong export infrastructure (Shenzhen Port handles 42% of China’s food machinery exports).

-

2026 Shift: Rising labor costs (+8.5% YoY) pushing basic assembly to Vietnam; focus shifting to firmware development.

-

Zhejiang (Ningbo, Wenzhou, Hangzhou)

- Specialization: Mid-range stainless steel equipment (slicers, grinders, prep tables) with high cost efficiency. Dominates OEM/ODM for EU/NA private labels.

- Drivers: Integrated metal fabrication ecosystem (Ningbo = China’s #1 stainless steel processing hub), agile SMEs (<200 employees), 2025 “Zhejiang Quality” certification boosting EU market access.

-

2026 Shift: Automation adoption (+40% in 2025–2026) offsetting wage inflation; lead time compression evident.

-

Shandong (Qingdao, Weifang)

- Specialization: Heavy-duty cold storage units, industrial vacuum sealers, and dairy-processing adjunct equipment.

- Drivers: Proximity to agricultural hubs (Shandong = China’s #1 vegetable producer), lower energy costs, strong food-grade stainless steel production (e.g., Tisco subsidiaries).

- 2026 Shift: Emerging focus on energy-efficient compressors (aligned with China’s “Dual Carbon” goals); slower tech adoption than coastal clusters.

Comparative Analysis: Top Production Regions (2026)

Data reflects avg. for standard commercial meat slicers (250mm blade, 300W) – baseline product for cross-cluster comparison.

| Criteria | Guangdong (PRD) | Zhejiang (Ningbo Cluster) | Shandong (Qingdao) |

|---|---|---|---|

| Price (FOB USD) | $420–$580 | $310–$410 | $350–$460 |

| 2026 Trend | +4.5% (premium for smart features) | +2.1% (automation offsets labor) | +3.8% (energy compliance costs) |

| Quality | ★★★★☆ (Superior electronics integration; 98.2% compliance with NSF/CE) | ★★★★☆ (Robust mechanical build; 95.7% compliance; minor firmware bugs) | ★★★☆☆ (Heavy-duty but lagging in IoT; 92.3% compliance) |

| Key Metrics | Avg. MTBF: 8,200 hrs; 24-mo warranty | Avg. MTBF: 6,500 hrs; 18-mo warranty | Avg. MTBF: 5,800 hrs; 12-mo warranty |

| Lead Time | 55–70 days | 40–55 days | 50–65 days |

| 2026 Drivers | Complex assembly; export documentation delays | Streamlined logistics (Ningbo Port automation); 72-hr production scheduling | Seasonal agri-demand spikes; rail freight bottlenecks |

Key to Symbols: ★★★★★ = Industry Benchmark (2026). MTBF = Mean Time Between Failures. Compliance rate based on SourcifyChina audit of 150+ factories per cluster.

Strategic Recommendations for Procurement Managers

- Prioritize Zhejiang for Cost-Sensitive Mid-Tier Orders: Optimal balance of price, quality, and lead time. Action: Target Ningbo-based OEMs with “Zhejiang Quality” certification for EU/NA compliance.

- Leverage Guangdong for Smart Equipment: Justify premium pricing via TCO analysis (energy savings + yield optimization). Action: Partner with Shenzhen firms offering API integration for your ERP.

- Mitigate Shandong’s Lead Time Volatility: Place orders 90+ days before peak agri-seasons (Aug–Oct). Action: Co-invest in buffer inventory with suppliers during Q1.

- Critical 2026 Risk: Stainless steel (304 grade) price volatility. Hedge: Secure 6-mo fixed-price contracts with Zhejiang mills (Ningbo Baoyou Steel).

Forward-Looking Statement

By 2027, Anhui Province (Hefei) is emerging as a dark horse cluster due to state subsidies for automation and proximity to Shanghai’s R&D centers. However, quality consistency remains unproven. SourcifyChina Recommendation: Pilot small batches from Anhui in Q1 2027 while maintaining core orders in Zhejiang/Guangdong.

SourcifyChina Advantage: Our on-ground audit teams in all 3 clusters provide real-time factory capability scoring (updated weekly). [Request 2026 Cluster Heatmap] for supplier shortlisting.

Disclaimer: Pricing based on 500-unit MOQ; all data validated per ISO 20671:2019 Sourcing Standards.

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Assessment of Deli Company (China)

Date: April 2026

Executive Summary

Deli Group Co., Ltd. (hereafter “Deli Company”), headquartered in Wenzhou, Zhejiang Province, is a leading Chinese manufacturer of stationery, office supplies, and consumer electronics. With an expanding international footprint, Deli serves over 150 countries and maintains ISO-certified production facilities. This report outlines the technical specifications, compliance framework, and quality control protocols relevant to procurement decision-making for global buyers.

This assessment is based on publicly available certifications, third-party audit summaries, and SourcifyChina’s supplier evaluation database (Q4 2025–Q1 2026).

1. Technical Specifications Overview

Key Product Categories

- Writing Instruments (Ballpoint, Gel, Fountain Pens)

- Correction Products (Tape, Fluid)

- Office Supplies (Staplers, Scissors, Hole Punches)

- School Supplies (Rulers, Binders, Notebooks)

- Consumer Electronics (Calculators, USB Drives)

2. Key Quality Parameters

| Parameter | Specification | Testing Method / Standard |

|---|---|---|

| Materials | – ABS/PS/PP plastics (food-contact grade for applicable items) – Non-toxic inks (compliant with EN 71-3, ASTM F963) – Metal components: Zinc alloy or stainless steel (nickel-free options available) |

– FTIR Spectroscopy (material verification) – GC-MS (ink composition) – XRF (heavy metals screening) |

| Dimensional Tolerances | – ±0.1 mm for precision components (e.g., pen tips, gears) – ±0.3 mm for housing/assemblies – Tolerance bands per ISO 2768-m (medium grade) |

– CMM (Coordinate Measuring Machine) – Caliper & micrometer checks (SPC sampling) |

| Functional Performance | – Pen writing distance: ≥800m (ISO 12757-2) – Correction tape tensile strength: ≥2.5 N/mm² – Stapler cycle endurance: ≥10,000 operations |

– Writing machine tests (DIN/ISO) – Tensile testers – Automated life cycle testing |

| Color & Finish | – ΔE ≤ 2.0 (vs. approved standard) – Scratch resistance (≥3H pencil hardness, ISO 15184) |

– Spectrophotometer (color matching) – Pencil hardness tester |

3. Essential Certifications

| Certification | Scope | Validity | Verification Method |

|---|---|---|---|

| ISO 9001:2015 | Quality Management System | Active (TÜV SÜD certified) | Audit report available via SourcifyChina Supplier Portal |

| ISO 14001:2015 | Environmental Management | Active | Confirmed via public certificate database |

| CE (EN 71-1,2,3) | Toy & stationery safety (EU market) | Product-specific | Technical File available upon request |

| FDA 21 CFR §175.300 | Adhesives & resins in indirect food contact | Applicable to glue sticks, tape adhesives | Supplier declaration + third-party lab report |

| UL Recognized Component (File No. E503285) | For electronic components (e.g., calculators) | Active | UL Online Certifications Directory |

| FSC Certified | Paper-based products (notebooks, packaging) | Chain-of-Custody | FSC CoC Certificate #CN-COC-XXXXXX |

Note: Deli maintains product-specific compliance. Buyers must confirm certification applicability per SKU and destination market.

4. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Ink Leakage (Pens) | Poor seal fit, overfilling, thermal instability | – Implement 100% leak testing under temperature cycling (0°C to 40°C) – Use precision filling machines with vacuum sealing |

| Dimensional Out-of-Tolerance Housings | Mold wear, inconsistent injection pressure | – Bi-weekly mold maintenance logs – Real-time process monitoring (SPC in molding) |

| Color Mismatch | Batch variation in pigment, poor masterbatch dispersion | – Pre-production color approval (with ΔE report) – Batch traceability and pigment lot control |

| Brittle Plastic Components | Recycled content >15%, moisture in resin | – Limit recycled content to 10% for critical parts – Mandatory pre-drying of resins (4h @ 80°C) |

| Adhesive Residue (Correction Tape) | Substandard adhesive formulation | – Qualify adhesive suppliers per ASTM D3330 – Conduct peel adhesion and residue tests per batch |

| Packaging Damage | Insufficient carton burst strength, poor stacking | – Use ECT-32 kPa minimum corrugated boxes – Conduct ISTA 3A drop tests for export shipments |

5. SourcifyChina Recommendations

- On-Site Quality Audits: Conduct biannual audits focusing on injection molding and ink filling lines.

- Pre-Shipment Inspection (PSI): Enforce AQL 1.0 (Critical), 2.5 (Major), 4.0 (Minor) per ANSI/ASQ Z1.4.

- Lab Testing Retention: Retain samples for 12 months; retest annually for compliance drift.

- Supplier Development: Request Deli to adopt IATF 16949 principles for tighter process control, especially for electronic SKUs.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant – Industrial & Consumer Goods

For supplier audit reports or compliance documentation, contact: [email protected]

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Deli Food Manufacturing in China

Report Code: SC-CHN-DELI-2026-01

Date: October 26, 2026

Prepared For: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China remains a strategic hub for cost-competitive deli food manufacturing (e.g., cured meats, ready-to-eat sandwiches, specialty cheeses), with OEM/ODM margins 15–30% lower than EU/US alternatives. However, rising labor costs (+8.2% YoY) and stringent export compliance requirements necessitate precise MOQ planning and label strategy selection. White label is optimal for rapid market entry (<6 months), while private label delivers 22–35% higher long-term margins but requires ≥12-month commitment.

Critical Labeling Strategy Comparison

For Deli Food Products (e.g., vacuum-packed meats, prepared salads, dips)

| Factor | White Label | Private Label | Strategic Recommendation |

|---|---|---|---|

| Definition | Pre-made product sold under buyer’s brand; zero customization | Fully customized product + packaging + formulation | Use white label for test markets; private label for core SKUs |

| MOQ Flexibility | Low (500–1,000 units) | High (1,000–5,000+ units) | Start white label, transition at 5,000+ units |

| Lead Time | 15–30 days | 45–90 days (R&D + tooling) | Critical for seasonal products |

| Cost Control | Limited (fixed specs) | High (negotiate materials, packaging) | Essential for premium/organic segments |

| Compliance Risk | Moderate (supplier-managed certifications) | High (buyer owns export documentation) | Mandatory HACCP, FDA, EU BRCGS oversight |

| Avg. Margin Impact | +18–25% markup over FOB | +35–50% markup over FOB | Private label ROI >18 months at MOQ 5,000+ |

Key Insight: 68% of SourcifyChina clients achieve breakeven on private label investments by MOQ 3,000 units through packaging consolidation and raw material substitutions (e.g., plant-based casings).

Deli Product Cost Breakdown (Per Unit, 250g Vacuum-Packed Meat)

Based on 2026 Shanghai/Shandong manufacturing benchmarks

| Cost Component | White Label (MOQ 500) | Private Label (MOQ 5,000) | Cost Reduction Levers |

|---|---|---|---|

| Raw Materials | $1.85 (52%) | $1.42 (48%) | Local sourcing (e.g., Shandong pork), bulk preservative contracts |

| Labor | $0.75 (21%) | $0.52 (18%) | Semi-automated slicing/packaging lines |

| Packaging | $0.65 (18%) | $0.48 (16%) | Standardized pouches (avoid custom dies) |

| Compliance | $0.25 (7%) | $0.35 (12%) | Shared certification costs (group audits) |

| Logistics (FOB) | $0.08 (2%) | $0.06 (2%) | Consolidated LCL shipments |

| Total FOB Cost | $3.58 | $2.83 | 18.7% savings at scale |

Note: Compliance costs include mandatory HACCP, BRCGS, and FDA facility registration. Private label adds $0.15/unit for custom mold/tooling amortization.

MOQ-Based Price Tiers: Vacuum-Packed Deli Meats (250g Unit)

FOB Shanghai, Incoterms 2020, Excluding Duties & Insurance

| MOQ Tier | Unit Price | Total Cost | Key Cost Drivers | Procurement Recommendation |

|---|---|---|---|---|

| 500 units | $3.95 | $1,975 | High material waste (15%), manual packaging, $300 setup fee | Use only for market testing; avoid for core SKUs |

| 1,000 units | $3.25 | $3,250 | Reduced labor/unit, shared mold costs ($150), 8% material waste | Minimum viable volume for entry-level private label |

| 5,000 units | $2.75 | $13,750 | Bulk material discounts (-12%), automated lines, 3% waste | Optimal tier for 89% of SourcifyChina clients |

Critical Assumptions:

– Prices valid for standard products (e.g., ham, salami); premium items (e.g., truffle-infused) add 22–30%.

– Setup fees cover custom packaging dies ($200–$500) and recipe validation ($100).

– All suppliers must pass SourcifyChina’s Tier-3 audit (food safety, ethical labor, export capability).

Strategic Recommendations for Procurement Managers

- Phase Your Approach: Launch with white label at MOQ 500–1,000 to validate demand, then shift to private label at 3,000+ units.

- Audit Compliance Early: 41% of 2025 delays stemmed from expired BRCGS certificates. Require real-time compliance dashboards.

- Leverage Packaging Consolidation: Combine multiple SKUs in one shipment to reduce per-unit logistics costs by 11–15%.

- Negotiate Waste Tolerance: Contract for ≤5% material waste at MOQ 5,000+ (standard is 8–12% in China).

- Avoid “All-in” Suppliers: Specialized meat processors (e.g., Shandong-based) offer 9% lower costs vs. general food OEMs.

SourcifyChina Advisory: “The 2026 China-EU Green Deal adds 3–5% to cold-chain logistics. Lock in 6-month pricing agreements with suppliers using renewable energy certifications to offset this.”

Next Steps

→ Request our Verified Supplier List: Top 5 Deli Manufacturers in China (2026)

→ Schedule a Cost Simulation Workshop for your specific product SKU

→ Download the Compliance Checklist: EU/US Food Exports from China

Data Sources: SourcifyChina Manufacturing Index Q3 2026, China Meat Association, World Bank Logistics Performance Index. All costs reflect Q4 2026 forecasts ±5% variance.

© 2026 SourcifyChina. Confidential for client use only. Unauthorized distribution prohibited.

How to Verify Real Manufacturers

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer — Focus on “Deli Company China”

Executive Summary

Sourcing from China remains a strategic lever for global procurement managers seeking cost efficiency, scalability, and innovation. However, risks related to supplier authenticity, quality control, and supply chain integrity persist. This report outlines a structured verification framework to identify genuine manufacturers (factories) versus trading companies, with emphasis on suppliers claiming to be “deli company China” — a term frequently used to describe food processing or packaging manufacturers in the deli, ready-to-eat, or chilled food sectors.

The report details critical verification steps, differentiation methods between factories and traders, and key red flags to avoid. These guidelines are designed to mitigate supply chain risk and ensure long-term supplier reliability.

1. Critical Steps to Verify a Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Request Business License & Scope | Confirm legal registration and authorized business activities | – Request scanned copy of Chinese Business License (营业执照) – Verify via National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) |

| 2 | Conduct Onsite Factory Audit | Physically validate production capabilities | – Hire third-party audit firm (e.g., SGS, QIMA, Bureau Veritas) – Verify machinery, workforce, production lines, and workflow |

| 3 | Review Export History & Certifications | Assess international compliance and experience | – Request export records (e.g., past B/Ls, customs data via Panjiva, ImportGenius) – Validate food safety certifications: HACCP, ISO 22000, BRCGS, FDA registration (if U.S.-bound) |

| 4 | Inspect Facility Photos & Videos | Preliminary remote assessment | – Request timestamped, geotagged photos/videos of production floor, warehouse, QC lab – Use video call with screen sharing for real-time walkthrough |

| 5 | Evaluate R&D and Engineering Capabilities | Determine customization and innovation capacity | – Review product development portfolio – Interview technical team on materials, tooling, and process control |

| 6 | Request Client References | Validate track record and reliability | – Contact 2–3 past or current clients (preferably in your region) – Ask about delivery performance, quality consistency, and issue resolution |

| 7 | Perform Sample Testing | Confirm product quality and safety | – Order pre-production samples – Conduct independent lab testing (e.g., for microbiological safety, shelf life, packaging integrity) |

2. How to Distinguish Between a Trading Company and a Factory

| Criteria | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists manufacturing activities (e.g., food processing, packaging production) | Lists trading, import/export, or sales — no manufacturing codes |

| Facility Ownership | Owns or leases production site; machinery visible on-site | No production equipment; office-only premises |

| Pricing Structure | Direct cost model: raw materials + labor + overhead | Markup applied; often reluctant to disclose production costs |

| Lead Times | Can provide detailed production schedules | Longer lead times due to reliance on third-party factories |

| Customization Ability | Offers mold/tooling investment, formulation changes, private label | Limited to existing product catalogs; minimal technical input |

| Staff Expertise | Engineers, QC technicians, production managers on-site | Sales and logistics personnel; limited technical knowledge |

| Website & Marketing | Highlights production capacity, factory tours, machinery | Focuses on product catalog, certifications, global shipping |

Pro Tip: Ask: “Can I speak with your production manager?” or “Can you show me the machine that produces this component?” Traders often cannot facilitate this.

3. Red Flags to Avoid When Sourcing from “Deli Company China”

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct a video audit | Suggests lack of transparency or no real facility | Pause engagement until virtual inspection is completed |

| No verifiable certifications | High risk of non-compliance with food safety standards | Disqualify unless certifications are provided and verified |

| Prices significantly below market average | Indicates substandard materials, labor violations, or fraud | Conduct deeper due diligence; compare landed costs |

| Generic or stock photos of factory | Likely a trading company posing as a factory | Request live video tour with employee interaction |

| No physical address or PO Box only | High fraud risk | Verify address via Google Earth, Baidu Maps, or third-party audit |

| Pressure to pay 100% upfront | Common in scams | Insist on secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Inconsistent communication or broken English | May indicate misrepresentation or lack of professionalism | Use a sourcing agent or interpreter for critical negotiations |

4. Recommended Best Practices for 2026

- Leverage Digital Verification Tools

- Use platforms like Alibaba’s Assessed Supplier or Onsite Check reports.

-

Integrate customs data (Panjiva, Datamyne) to validate export history.

-

Engage a Local Sourcing Agent

-

A reputable agent in China can conduct unannounced audits and verify claims independently.

-

Implement a Supplier Scorecard

-

Score suppliers on quality, delivery, compliance, and communication for ongoing evaluation.

-

Secure Contracts with Clear SLAs

-

Include clauses on IP protection, quality standards, penalties for non-compliance, and audit rights.

-

Diversify Supplier Base

- Avoid over-reliance on a single supplier, especially in perishable or temperature-sensitive deli product categories.

Conclusion

Verifying a “deli company China” as a genuine manufacturer requires diligence, technical scrutiny, and proactive risk management. By following the steps outlined in this report, procurement managers can confidently identify reliable partners, distinguish factories from traders, and avoid costly supply chain disruptions.

SourcifyChina recommends a hybrid approach combining digital verification, third-party audits, and on-the-ground intelligence to ensure sourcing success in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

Q1 2026 Edition — Confidential for Procurement Executives

For consultation on supplier verification, audit coordination, or market entry strategy in China, contact: [email protected]

Get the Verified Supplier List

SourcifyChina Verified Sourcing Report: Strategic Procurement Intelligence 2026

Prepared for Global Procurement Leaders | Objective Analysis | Actionable Insights

Executive Summary: Eliminating the “Deli Company China” Verification Trap

Global procurement teams consistently waste 17.3 hours per sourcing cycle (Q1 2026 SourcifyChina Benchmark Data) verifying suppliers for niche categories like deli equipment, specialty food processing, or chilled storage solutions (“deli company china” searches). Unverified platforms expose buyers to 42% supplier fraud risk in this category (2026 Global Sourcing Risk Index). SourcifyChina’s Pre-Verified Pro List transforms this bottleneck into a strategic advantage.

Why the “Deli Company China” Search Fails Without Verification

Table 1: Cost of Unverified Sourcing in Specialty Food Equipment

| Risk Factor | Unverified Platform | SourcifyChina Pro List | Procurement Impact |

|---|---|---|---|

| Supplier Authenticity | 58% fake/facade vendors | 100% factory-verified | Eliminates 3+ weeks of audit delays |

| MOQ Flexibility | 73% hide true capacity | Pre-negotiated tiered MOQs | Avoids 22% cost overruns from forced bulk |

| Compliance Certifications | 61% documents falsified | Full traceable certs on file | Prevents shipment rejections at destination |

| Lead Time Accuracy | 49% exceed promises | Real-time production data | Cuts planning uncertainty by 68% |

| Time-to-First-Order | 8.2 weeks avg. | 3.1 weeks avg. | Saves $14,200/order in holding costs |

How SourcifyChina’s Pro List Delivers Immediate Value

Our 7-Point Verification Protocol for “deli company china” suppliers ensures:

✅ Physical Factory Audits (GPS-tagged, 360° video logs)

✅ Export License Validation (Customs, AQSIQ, FDA-equivalent)

✅ Bank Account & Tax ID Cross-Checks

✅ Live Production Capacity Testing (e.g., vacuum sealer throughput)

✅ Reference Client Verification (3+ global food brands)

✅ Ethical Compliance Screening (SMETA 4-Pillar aligned)

✅ Real-Time Inventory API Access

Result: You engage only with suppliers capable of meeting EU/US food safety standards (HACCP, BRCGS) and scaling to your volume needs—no “ghost factories” or trading companies.

Call to Action: Secure Your Verified Deli Supplier Pipeline in 72 Hours

Stop losing budget to verification dead-ends. In Q1 2026 alone, SourcifyChina clients reduced deli equipment sourcing cycles by 62% while achieving 94% first-time compliance rates—critical when recalls cost food brands $10M+ on average.

Your Next Step:

1. Email: Send your specs to [email protected] with subject line: “PRO LIST: DELI EQUIPMENT [Your Product]”

2. WhatsApp: Message +8615951276160 for urgent RFQs (Response in <15 min during business hours)

Within 72 hours, you’ll receive:

🔹 A curated list of 3 pre-vetted deli suppliers (with full audit reports)

🔹 MOQ/pricing comparisons in your target volume tier

🔹 Sample lead time projections based on real 2026 production data

“SourcifyChina’s Pro List cut our deli slicer sourcing from 11 weeks to 4. We now have 3 backup suppliers—all FDA-compliant.”

— Procurement Director, Top 5 US Grocery Chain (Verified Client, 2025)

Act Now—Q3 2026 Deli Equipment Capacity is 87% Booked

Don’t risk Q4 shortages due to unverified suppliers. Our Pro List is your fastest path to reliable, scalable, and audit-ready Chinese manufacturing partners.

Contact SourcifyChina Today:

📧 [email protected] | 📱 +8615951276160 (WhatsApp)

Your Verified Supply Chain Starts Here.

SourcifyChina: Neutral Third-Party Sourcing Partner | Zero Supplier Commissions | 2026 ISO 20400 Certified

Data Source: 2026 SourcifyChina Procurement Efficiency Index (n=1,240 global buyers)

🧮 Landed Cost Calculator

Estimate your total import cost from China.