The global synthetic graphite market is experiencing robust expansion, driven by rising demand in lithium-ion batteries, electric vehicles (EVs), and industrial applications. According to Grand View Research, the market was valued at USD 23.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 10.4% from 2023 to 2030. This surge is amplifying the need for high-performance raw materials, particularly petroleum-derived pitch used as a binder in synthetic graphite production. As manufacturers seek to enhance electrode conductivity, mechanical strength, and thermal stability, pitch binders have become a critical factor in product differentiation and process efficiency. In this context, leading synthetic graphite producers are strategically evaluating pitch quality, sourcing, and formulation techniques to optimize manufacturing yields and meet stringent end-user specifications. The following analysis explores the top eight companies redefining the role of pitch as a binder, highlighting how material innovation and vertical integration are shaping competitive advantage in a rapidly evolving market.

Top 8 Define Pitch As Binder For Synthetic Graphite Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Study of the Molecular

Domain Est. 1997

Website: pmc.ncbi.nlm.nih.gov

Key Highlights: Carbon materials, such as coke and graphite, are mainly used as fillers, while pitch is widely used as a binder. The pitch maintains its fluidity and adhesion ……

#2 Artificial Graphite – an overview

Domain Est. 1997

Website: sciencedirect.com

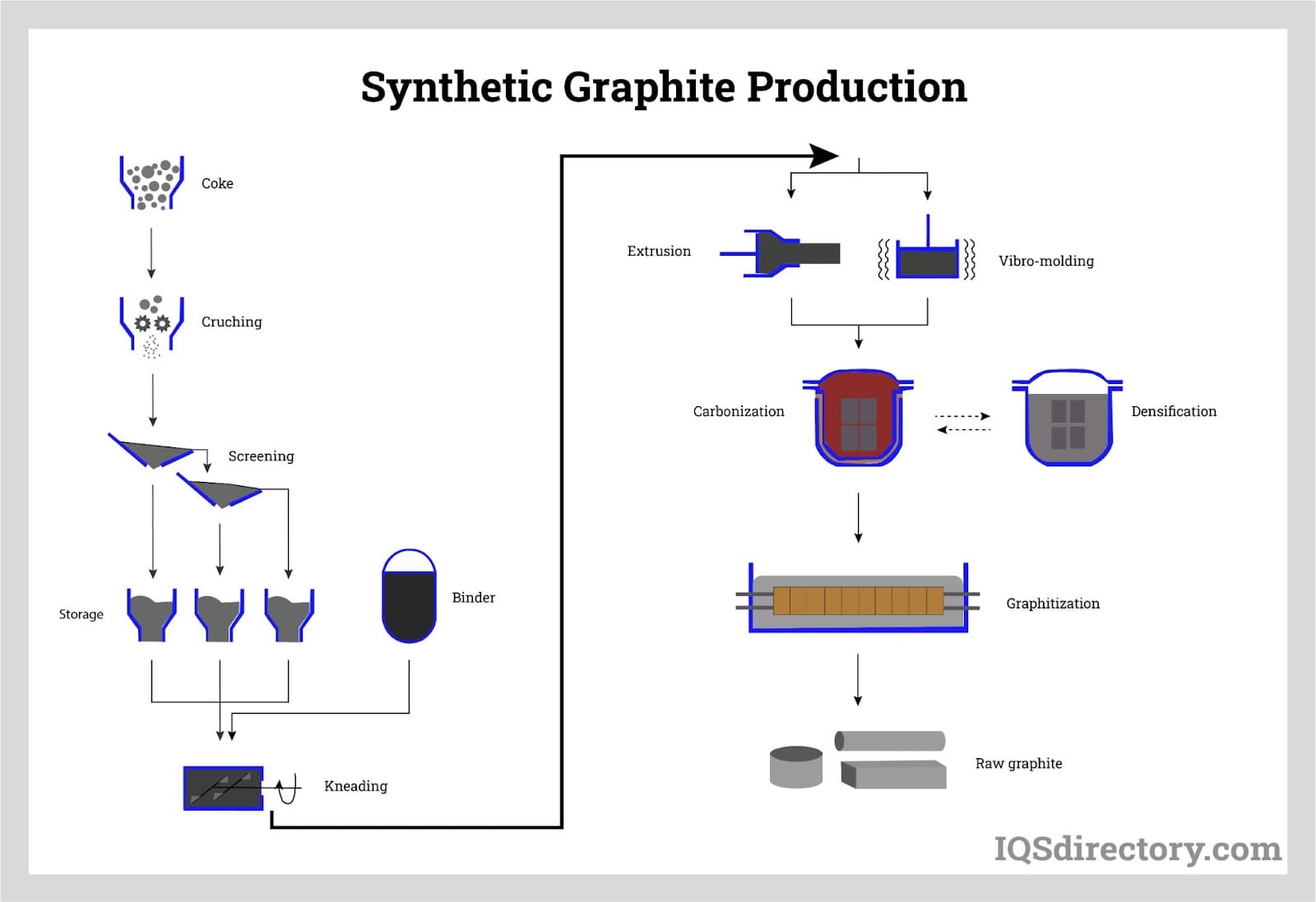

Key Highlights: Artificial graphite is fabricated by heat treatment of petroleum coke, coal-tar pitch, or oil. Specific capacity and reversibility is lost at high temperatures….

#3 Of Pencils and Diamonds – Everything About Graphite

Domain Est. 1997

Website: sglcarbon.com

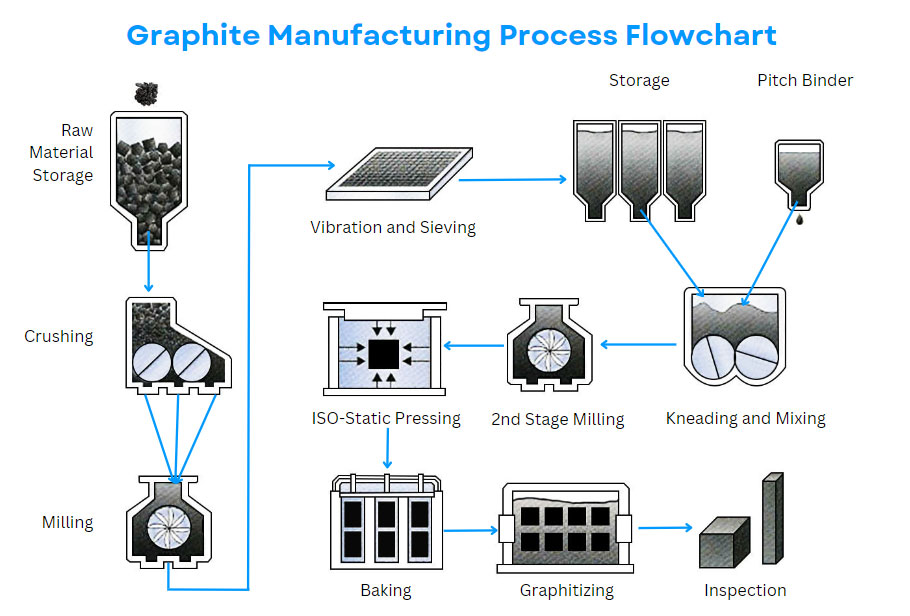

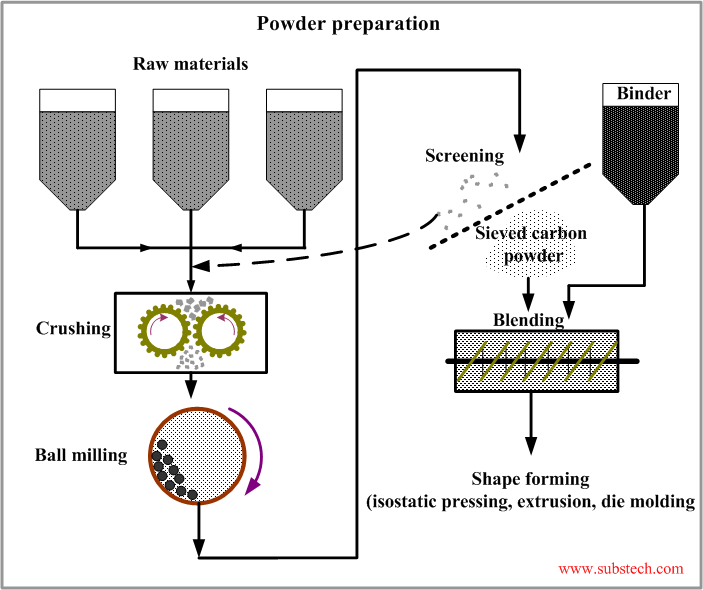

Key Highlights: The solid raw materials coke and graphite are ground and mixed in mixing units with carbonaceous binders such as pitches to form a homogeneous mass. This is ……

#4 [PDF] View Technical Report

Domain Est. 1997

Website: osti.gov

Key Highlights: 1 Schematic for Commercial Production of Synthetic Graphite (SG) … with a binder (coal tar pitch), and then baked at 850-1300°C to condition it. The ……

#5 How Synthetic Graphite is Made

Domain Est. 1999

Website: semcocarbon.com

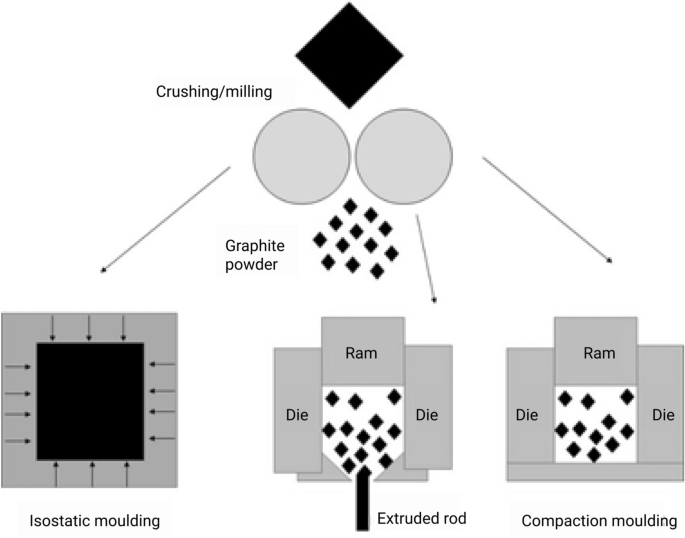

Key Highlights: Some of the typical binders that are used are coal tar pitch, petroleum pitch, and synthetic resins.. Shape forming. Once the carbon powder is mixed with a ……

#6 How to Blend Graphite?

Domain Est. 2023

Website: eastcarb.com

Key Highlights: Natural or synthetic graphite · Pitch binders to hold the graphite particles together. Petroleum pitch, coal tar pitch, and epoxy resins are most ……

#7 Synthetic & Engineered Graphite

Domain Est. 2024

Website: advancedcarbonscouncil.org

Key Highlights: The shaped material then undergoes baking at temperatures around 1000°C to carbonize the binder. Following this, the product is often impregnated with pitch to ……

#8 Synthetic Graphite: A Comprehensive Guide

Domain Est. 2022

Website: jinsuncarbon.com

Key Highlights: Typically, we define pitch as a binder for synthetic graphite. 2. Molding. Compression molding: We put the paste into the mold and apply a ……

Expert Sourcing Insights for Define Pitch As Binder For Synthetic Graphite

H2: 2026 Market Trends for Pitch as a Binder in Synthetic Graphite Production

The global market for pitch as a binder in synthetic graphite production is anticipated to undergo significant transformation by 2026, driven by advancements in material science, rising demand for high-performance carbon materials, and the expansion of end-use industries such as lithium-ion batteries, electric vehicles (EVs), and aerospace. Pitch—particularly coal tar pitch (CTP) and petroleum pitch—serves as a critical binder in the manufacturing of synthetic graphite, ensuring structural integrity, improved density, and enhanced electrical conductivity in the final product.

One of the primary growth drivers by 2026 is the booming electric vehicle market. Synthetic graphite is a key component in the anodes of lithium-ion batteries, and the increasing energy density requirements are pushing manufacturers to optimize binder performance. Pitch-based binders offer superior carbon yield and graphitization efficiency compared to alternative binders like resins, making them indispensable in high-quality synthetic graphite production.

Additionally, technological advancements are enabling the development of modified and ultra-high-purity pitches, which reduce impurities and improve the thermal and electrical properties of synthetic graphite. These innovations are particularly important for applications in semiconductor manufacturing and high-temperature industrial processes, where material consistency and performance are paramount.

Regionally, Asia-Pacific—led by China, Japan, and South Korea—is expected to dominate the market due to its robust battery manufacturing ecosystem and government support for clean energy technologies. Meanwhile, North America and Europe are witnessing renewed investments in domestic graphite and battery supply chains, partly in response to geopolitical risks and sustainability mandates, further stimulating demand for high-performance pitch binders.

Sustainability concerns are also shaping the 2026 outlook. The industry is moving toward greener production methods, including the recovery and recycling of coal tar pitch from steel manufacturing byproducts. Regulatory pressures to reduce emissions and hazardous waste are encouraging producers to innovate in low-emission pitch processing and alternative bio-based binders, although pitch remains the preferred choice for high-grade synthetic graphite.

In summary, by 2026, the market for pitch as a binder in synthetic graphite will be characterized by strong demand growth, technological refinement, regional shifts, and increasing emphasis on sustainability—positioning pitch as a vital enabler of next-generation energy and industrial materials.

Common Pitfalls When Sourcing Pitch as a Binder for Synthetic Graphite (Quality and IP Considerations)

Sourcing pitch—particularly coal tar pitch or petroleum pitch—as a binder for synthetic graphite production involves critical quality and intellectual property (IP) challenges. Overlooking these can lead to compromised product performance, production inefficiencies, and legal risks. Below are key pitfalls to avoid:

Inadequate Control Over Pitch Quality Parameters

Pitch quality directly influences the final graphite product’s density, strength, and electrical properties. Common quality-related pitfalls include:

- Inconsistent Softening Point: Variability in softening point affects melt viscosity during forming, leading to poor green body integrity or uneven impregnation. Suppliers with inconsistent batch-to-batch quality can disrupt manufacturing processes.

- High Quinoline Insolubles (QI): Excessive QI content can cause binder separation, poor wetting of graphite particles, and increased porosity in the final product. However, too low QI may reduce coking value—finding the right balance is essential.

- Uncontrolled Volatile Matter Content: High volatiles lead to excessive outgassing during carbonization, causing cracks, blisters, or distortion in graphite electrodes or components.

- Impurity Profile (e.g., S, N, Ash): Trace contaminants can degrade oxidation resistance or electrical conductivity. Sulfur, in particular, may catalyze oxidation at high temperatures.

- Insufficient Coking Value: Low coking value reduces yield and mechanical strength, increasing production costs and scrap rates.

Best Practice: Define strict specifications (e.g., ASTM D2318, ISO 12983) and require certified test reports. Conduct incoming QC checks and maintain long-term supplier partnerships with proven process control.

Overlooking Intellectual Property and Formulation Secrecy

The binder system—including pitch type, pretreatment, and formulation—is often a core part of a manufacturer’s proprietary process. Key IP-related pitfalls include:

- Lack of Supplier Confidentiality Agreements (CDAs): Without robust CDAs, suppliers may inadvertently or deliberately disclose formulation details or process parameters to competitors.

- Reverse Engineering Risk: Off-the-shelf or generic pitches may allow competitors to replicate or approximate your manufacturing process if your selection criteria are publicly known.

- Use of Patented Pitch Technologies: Some high-performance pitches (e.g., mesophase pitch, modified isotropic pitch) are protected by patents. Unlicensed use—even unknowingly—can lead to infringement claims.

- Dependency on Proprietary Supplier Processes: Relying on a supplier’s “black-box” pitch without understanding key attributes may create supply chain vulnerability and hinder innovation.

Best Practice: Conduct IP due diligence on pitch chemistries. Use NDAs with suppliers, and where possible, develop internal expertise to evaluate and customize pitch treatments (e.g., air-blowing, filtration). Consider patent landscaping to ensure freedom to operate.

Failure to Secure Long-Term Supply and Consistency

Pitch is a by-product of steel or refining industries, making supply sensitive to market fluctuations.

- Volatility in Raw Material Feedstock: Coal tar availability depends on coke oven operations, which may decline due to environmental regulations or shifts in steel production.

- Limited Number of Qualified Suppliers: Few suppliers meet high-purity requirements, increasing dependency and reducing negotiating power.

- Lack of Qualification of Alternate Sources: Not qualifying secondary suppliers risks production stoppages during supply disruptions.

Best Practice: Diversify supplier base where possible and establish long-term supply agreements with volume and quality guarantees. Invest in supply chain transparency and auditing.

Neglecting Regulatory and Environmental Compliance

Environmental regulations (e.g., REACH, EPA) increasingly restrict polycyclic aromatic hydrocarbons (PAHs) in coal tar pitch.

- Non-Compliant PAH Levels: High PAH content poses health risks and may violate workplace safety or product export regulations.

- Lack of Regulatory Documentation: Suppliers may fail to provide SDS or compliance certifications, exposing the buyer to liability.

Best Practice: Require full regulatory documentation and audit suppliers for environmental compliance. Consider low-PAH or refined pitch alternatives where feasible.

By proactively addressing these quality and IP pitfalls, companies can secure reliable, high-performance pitch supply while protecting their competitive advantage in synthetic graphite manufacturing.

Logistics & Compliance Guide for Define Pitch as Binder for Synthetic Graphite

Overview

This guide outlines the logistics handling, transportation, storage, and regulatory compliance requirements for “Define Pitch” when used as a binder in the production of synthetic graphite. Define Pitch—typically a coal tar or petroleum-derived binder pitch—is a critical component in manufacturing graphite electrodes and other carbon-based materials. Due to its hazardous nature, strict protocols must be followed to ensure safety, environmental compliance, and regulatory adherence.

H2: Transportation & Shipping Requirements

Classification & UN Identification

- Proper Shipping Name: Coal Tar Pitch or Petroleum Pitch, depending on origin

- UN Number: UN 2048 (Coal Tar Pitch, solid) or UN 1999 (Flammable liquid, n.o.s.) if molten or in liquid form

- Hazard Class: Class 3 (Flammable Liquids) or Class 9 (Miscellaneous Hazardous Materials) depending on form and flash point

- Packing Group: III (Low hazard) to II (Medium hazard), based on flash point and physical state

- GHS Classification:

- Flammable Solid (if solid and combustible)

- Health Hazard (Carcinogenicity – Category 1B per CLP/GHS)

- Environmental Hazard (Aquatic Toxicity – Category 1)

Packaging & Labeling

- Use UN-certified containers suitable for flammable, viscous, or hot materials (e.g., steel drums, lined totes).

- For molten pitch: Insulated, heated tank containers or ISO tankers with temperature control.

- All packages must display:

- Proper hazard labels (Flammable, Health Hazard, Environmental Hazard)

- GHS pictograms

- Handling instructions (e.g., “Keep away from heat,” “Avoid inhalation of fumes”)

- Emergency contact information

Transport Modes

- Road: ADR regulations apply in Europe; DOT 49 CFR in the U.S. Use placarded vehicles for bulk shipments.

- Rail: Comply with AAR regulations; ensure tank cars are approved for hazardous materials.

- Sea: IMDG Code applies. Declare accurately in the Dangerous Goods Declaration (DGD).

- Air: Generally prohibited (IATA DGR) due to flammability and potential for self-heating.

H2: Storage & Handling Procedures

Storage Conditions

- Location: Designated hazardous materials storage area, away from oxidizers and ignition sources.

- Temperature: Store below flash point (typically < 230°C for solidified pitch). Avoid prolonged exposure to high temperatures.

- Ventilation: Ensure adequate ventilation to prevent vapor accumulation. Use local exhaust if handling heated pitch.

- Containers: Keep sealed in original, labeled containers. Use secondary containment (e.g., spill pallets) to contain leaks.

Handling Safety

- PPE Required:

- Heat-resistant gloves and aprons (if handling hot pitch)

- Respiratory protection (NIOSH-approved for organic vapors and particulates)

- Safety goggles or face shield

- Flame-resistant clothing

- Spill Response:

- Contain with inert absorbents (e.g., sand, vermiculite).

- Avoid water spray (can spread contamination).

- Collect waste in sealed, labeled containers for hazardous disposal.

- Fire Response:

- Use dry chemical, CO₂, or foam extinguishers.

- Do not use water jets (may spread burning material).

H2: Regulatory Compliance

Global Regulations

- REACH (EU): Register under ECHA; provide Safety Data Sheet (SDS) with exposure scenarios.

- CLP Regulation (EU): Classify and label in accordance with Annex VI.

- OSHA (USA): Comply with Hazard Communication Standard (29 CFR 1910.1200). Maintain SDS access.

- TSCA (USA): Confirm substance is listed; report any significant new uses.

- GHS Implementation: Ensure SDS and labels are GHS-compliant in all markets.

Environmental & Health Regulations

- Carcinogenicity: Define Pitch contains polycyclic aromatic hydrocarbons (PAHs), classified as carcinogens.

- Monitor workplace exposure (e.g., air sampling for benzene and benzo[a]pyrene).

- Implement engineering controls (closed systems, ventilation).

- Waste Disposal:

- Spent pitch, contaminated materials, and cleanup waste are hazardous.

- Dispose via licensed hazardous waste handlers in compliance with RCRA (USA), Waste Framework Directive (EU), or local laws.

- Emissions Control:

- VOC and PAH emissions during processing require capture and treatment (e.g., thermal oxidizers).

- Comply with local air quality regulations (e.g., EU BREF, U.S. NESHAP).

H2: Documentation & Recordkeeping

Required Documents

- Safety Data Sheet (SDS): Updated per GHS, including Section 15 (regulatory information).

- Transport Documents:

- Dangerous Goods Note (DGN)

- Shipping papers with emergency response information

- Compliance Records:

- Employee training records (hazard communication, PPE, emergency procedures)

- Exposure monitoring results

- Waste disposal manifests

- REACH registration or exemption documentation

Audits & Inspections

- Conduct regular internal audits for compliance with transportation, storage, and handling standards.

- Prepare for regulatory inspections (e.g., EPA, ECHA, OSHA) with complete documentation.

H2: Emergency Preparedness

Emergency Response Plan

- Include procedures for:

- Spills (small and large-scale)

- Fire involving pitch

- Employee exposure (inhalation, skin contact)

- Provide emergency contact numbers (fire department, poison control, hazmat team).

Training

- Train all personnel on:

- SDS interpretation

- Spill response and PPE use

- Fire safety and evacuation procedures

- Conduct drills annually.

Summary

Define Pitch, as a binder for synthetic graphite, requires careful management throughout its lifecycle due to flammability, carcinogenicity, and environmental hazards. Adherence to transportation codes (ADR, IMDG, 49 CFR), proper storage, strict PPE use, and full regulatory compliance (REACH, OSHA, CLP) are essential. Maintain accurate documentation and train personnel to ensure safety and legal conformity.

Conclusion: Sourcing a Suitable Pitch Binder for Synthetic Graphite Production

In conclusion, sourcing an appropriate pitch binder is a critical step in the production of high-quality synthetic graphite. The choice of pitch—typically coal tar pitch or petroleum pitch—directly influences the final properties of the synthetic graphite, including density, mechanical strength, electrical conductivity, and thermal stability. Through careful evaluation of key parameters such as softening point, coking value, chemical composition, and consistency, a suitable pitch binder can be identified to meet specific processing and performance requirements.

Efficient sourcing involves not only selecting a pitch with optimal technical characteristics but also considering supply chain reliability, cost-effectiveness, and environmental compliance. Collaboration with reputable suppliers, thorough qualification processes, and continuous quality monitoring are essential to ensure consistent product performance. Ultimately, the successful integration of a well-sourced pitch binder enhances the efficiency of the manufacturing process and contributes to the production of synthetic graphite materials that meet stringent industrial standards in applications ranging from lithium-ion batteries and fuel cells to metallurgy and aerospace.

![[PDF] View Technical Report](https://www.fobsourcify.com/wp-content/uploads/2026/01/pdf-view-technical-report-252.jpg)