The global constant velocity (CV) joint market is experiencing robust growth, driven by increasing vehicle production and rising demand for reliable drivetrain components. According to Mordor Intelligence, the CV Joint Market was valued at USD 7.8 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This expansion is fueled by the rising prevalence of front-wheel-drive vehicles—like the Toyota Camry—where CV joints are critical for smooth power transmission and handling. As Camry remains one of the best-selling midsize sedans worldwide, the demand for high-quality, durable CV joints has intensified, prompting both OEMs and aftermarket manufacturers to innovate and scale production. In this competitive landscape, a select group of manufacturers has emerged as leaders in producing CV joints tailored specifically for the Toyota Camry, combining precision engineering with cost-efficiency to meet global quality standards.

Top 9 Cv Joint For Toyota Camry Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Top CV Joint Manufacturers in China

Domain Est. 1997

Website: accio.com

Key Highlights: King Steel Japan Auto Parts CV Joint Tripod Bearing Tripod CV Joint for TOYOTA Camry Hyundai Related product$2-3.20 … CV Joint Manufacturer C.v. ……

#2 CV Axle Brand Recommendations

Domain Est. 2001

Website: toyotanation.com

Key Highlights: Left front CV axle is bad after 205K. Any recommendations on brand? OEM looks to be about 320 plus shipping from eb parts….

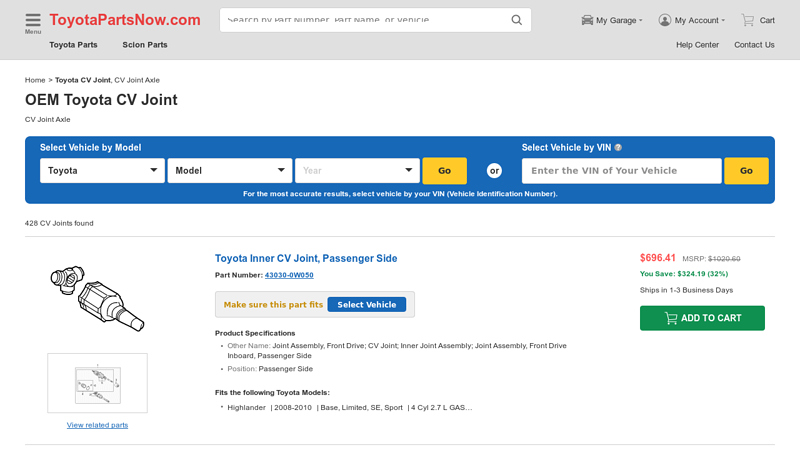

#3 Guaranteed OEM Toyota CV Joint

Domain Est. 2022

Website: toyotapartsnow.com

Key Highlights: 1–4 day deliveryToyota Inner CV Joint, Passenger Side Fits the following Toyota Models: Camry | 2018-2019 | L, LE, SE, XLE, XSE | 4 Cyl 2.5 L GAS….

#4 Right Front CV Axle Shaft For Toyota Camry, Solara, Highlander …

Domain Est. 2022

Website: cloe-boulangerie.com

Key Highlights: It’s brand new, comes with a monster 10-year warranty, and replaces a ton of OEM part numbers (like 4341006221, 4341006231, etc.). The axle is the shaft that ……

#5 What warranty coverage do I have on my Toyota vehicle?

Domain Est. 1994

Website: support.toyota.com

Key Highlights: This warranty covers repairs and adjustments needed to correct defects in materials or workmanship or any part supplied by Toyota, subject to exceptions….

#6 Products

Domain Est. 1996

Website: bilstein.com

Key Highlights: With BILSTEIN B1, we offer a broad range of accessories, which are perfectly adapted to our shock absorbers, for virtually any vehicle model in uncompromising ……

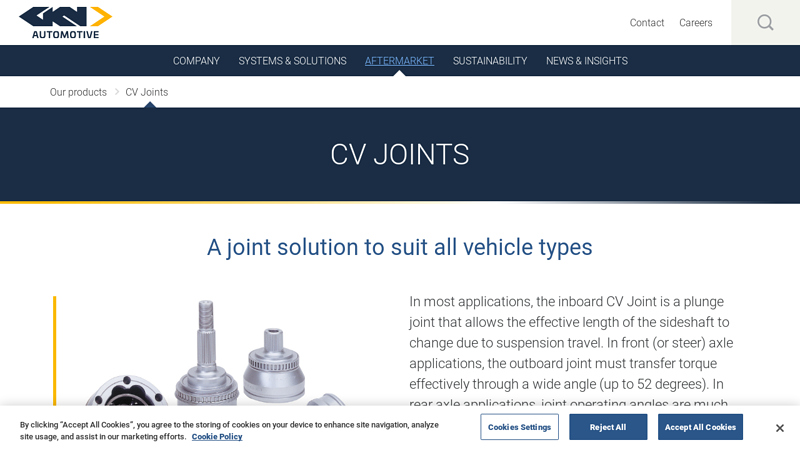

#7 CV Joints

Domain Est. 2001

Website: gknautomotive.com

Key Highlights: In most applications, the inboard CV Joint is a plunge joint that allows the effective length of the sideshaft to change due to suspension travel….

#8 RCV Performance

Domain Est. 2003

Website: rcvperformance.com

Key Highlights: Free delivery over $150RCV Performance Products specializes in industry leading quality parts for countless motorsports applications from Ultra4 race cars, desert cars, Pro4 trucks…

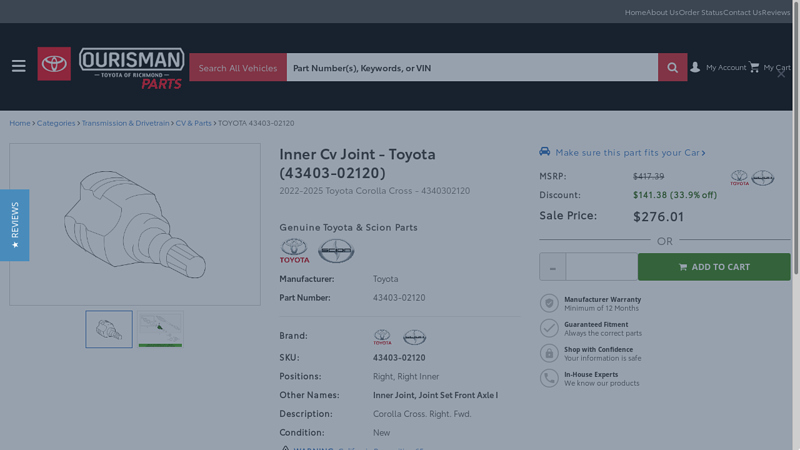

#9 Inner Cv Joint

Domain Est. 2023

Website: toyotaparts.ourismantoyotaofrichmond.com

Key Highlights: In stock $26.55 deliveryGenuine Official Toyota Inner Cv Joint part# 43403-02120 for 2022-2025 Toyota Corolla Cross | Ourisman Toyota Parts | Official Toyota Online Parts Store….

Expert Sourcing Insights for Cv Joint For Toyota Camry

H2: 2026 Market Trends for CV Joints for Toyota Camry

As the global automotive aftermarket evolves, the demand for replacement components such as Constant Velocity (CV) joints for popular models like the Toyota Camry is expected to follow distinct patterns in 2026. The CV joint market, particularly for the Toyota Camry, will be influenced by technological advancements, vehicle longevity, supply chain dynamics, and regional demand variations.

-

Growing Aftermarket Demand Due to Vehicle Longevity

Toyota Camrys are renowned for their reliability and extended service life, with many vehicles surpassing 150,000 miles. As the fleet of older Camrys ages, the need for CV joint replacements will increase. In 2026, a significant portion of Camrys on the road will be between 8 and 15 years old—prime years for drivetrain component wear. This trend will drive steady demand in the independent aftermarket (IAM), especially in regions with high Camry ownership such as North America, the Middle East, and parts of Asia. -

Shift Toward High-Performance and OEM-Equivalent Aftermarket Parts

Consumers are increasingly opting for high-quality aftermarket CV joints that match or exceed OEM specifications. In 2026, brands offering enhanced durability, better grease formulations, and reinforced boot materials will gain market share. Expect growth in remanufactured and premium aftermarket CV axle assemblies, particularly those backed by extended warranties and easy installation features. -

Impact of Electric Vehicle (EV) Transition on CV Joint Demand

While Toyota is expanding its hybrid and electric vehicle lineup, the Camry will likely remain available in combustion-engine and hybrid variants through 2026. However, the gradual shift toward electrification may slightly dampen long-term growth in CV joint demand, as EVs often use different drivetrain architectures. Still, the large existing base of internal combustion engine (ICE) and hybrid Camrys ensures continued relevance for CV joints in the short to medium term. -

Supply Chain and Manufacturing Trends

By 2026, manufacturers in Asia—particularly China, India, and Thailand—will remain dominant in CV joint production due to cost efficiency and strong automotive parts ecosystems. However, nearshoring and supply chain resilience will become more critical. North American and European distributors may increasingly partner with regional suppliers or adopt just-in-time inventory models to mitigate logistics risks, especially for fast-moving SKUs like Camry CV joints. -

E-Commerce and Digital Distribution Growth

Online platforms and digital marketplaces will play a larger role in distributing CV joints. In 2026, B2B and B2C e-commerce channels are expected to account for over 40% of aftermarket auto parts sales in developed markets. Enhanced product data, fitment tools, and customer reviews will drive consumer confidence in purchasing CV joints online, benefiting brands with strong digital presence and accurate catalog integration. -

Regional Market Variations

- North America: Remains the largest market due to high Camry sales volume and consumer preference for DIY repairs.

- Middle East and Africa: Hot climates and rough road conditions accelerate CV joint wear, sustaining demand.

- Asia-Pacific: Rising vehicle ownership in countries like Indonesia and the Philippines supports growth, though price sensitivity favors mid-tier brands.

In conclusion, the 2026 market for CV joints for the Toyota Camry will be characterized by sustained demand driven by vehicle longevity, increasing quality expectations, and digital sales expansion. While long-term electrification presents a challenge, the Camry’s enduring popularity ensures that CV joints will remain a vital segment of the automotive aftermarket.

Common Pitfalls When Sourcing CV Joints for Toyota Camry: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for CV Joint for Toyota Camry

Product Overview

The CV (Constant Velocity) joint is a critical component in the front-wheel drive system of a Toyota Camry, responsible for transmitting power from the transmission to the wheels while allowing for variable angles due to suspension movement and steering. Replacing or shipping CV joints requires adherence to strict logistics and compliance standards to ensure safety, quality, and regulatory conformity.

HS Code Classification

For international shipping and customs clearance, proper Harmonized System (HS) Code classification is essential. The CV joint for the Toyota Camry typically falls under:

– HS Code: 8708.80.00 – Parts and accessories of the transmission for motor vehicles (specifically for CV joints and axle assemblies).

– Note: Always verify the exact HS code with local customs authorities, as classifications may vary slightly by country and product specification (e.g., new vs. remanufactured).

Packaging & Labeling Requirements

Proper packaging ensures product integrity during transit and compliance with shipping regulations.

– Packaging:

– Use sturdy, corrugated cardboard boxes with internal foam or molded inserts to prevent movement.

– Seal all boxes with tamper-evident tape.

– Include desiccant packs if shipping to humid climates to prevent corrosion.

– Labeling:

– Clearly display:

– Product name: “CV Joint – Toyota Camry (Specify Model Year & Engine if Applicable)”

– OEM/Replacement Part Number

– Manufacturer or Supplier Name and Address

– Weight, Dimensions, and Handling Symbols (e.g., “Fragile,” “This Side Up”)

– Country of Origin (e.g., “Made in Japan” or “Manufactured in Thailand”)

– Include barcode or QR code for traceability if part of a larger inventory system.

Shipping & Transportation

- Mode of Transport:

- Air freight: Suitable for urgent deliveries; subject to IATA regulations.

- Ocean freight: Cost-effective for bulk shipments; requires proper containerization and moisture protection.

- Ground transport: Ideal for domestic or regional distribution.

- Temperature & Environmental Conditions:

- Avoid exposure to extreme temperatures and high humidity.

- Store and transport in dry, climate-controlled environments when possible.

- Insurance:

- Always insure shipments against loss, damage, or delay, especially for high-value components.

Regulatory & Safety Compliance

- DOT & FMVSS (U.S.):

- While CV joints are not directly regulated under Federal Motor Vehicle Safety Standards (FMVSS), suppliers must ensure parts meet OEM specifications and do not compromise vehicle safety.

- REACH & RoHS (EU):

- Ensure materials used (e.g., grease, rubber boots) comply with EU regulations on restricted substances (e.g., phthalates, heavy metals).

- Country-Specific Certifications:

- Some markets may require certification marks (e.g., E-Mark for Europe, GCC for Gulf countries). Confirm requirements based on destination.

- Aftermarket Parts Regulations:

- In regions like California (U.S.), aftermarket parts may need to comply with CARB (California Air Resources Board) if affecting emissions—though CV joints typically do not, proper documentation is advised.

Import/Export Documentation

Ensure the following documents accompany each shipment:

– Commercial Invoice (with detailed product description, value, and HS code)

– Packing List

– Bill of Lading (BOL) or Air Waybill (AWB)

– Certificate of Origin (especially for preferential tariffs under trade agreements like USMCA or CPTPP)

– Import License (if required by destination country)

– Product Conformity Certificate (when applicable)

Quality Assurance & Traceability

- ISO Standards:

- Suppliers should comply with ISO 9001 (Quality Management) and IATF 16949 (Automotive QMS) for consistent quality.

- Batch Tracking:

- Implement lot numbering and serialization for traceability in case of recalls or warranty claims.

- Warranty & Returns:

- Clearly state warranty terms (e.g., 12-month or 12,000-mile limited warranty).

- Define return logistics process, including inspection requirements and packaging standards for returned goods.

Environmental & Sustainability Considerations

- Waste Oil & Grease:

- Used CV joints may contain lubricants—classify as hazardous waste if contaminated.

- Follow local regulations for disposal or recycling.

- Packaging Materials:

- Use recyclable or biodegradable packaging materials where possible to reduce environmental impact.

Final Recommendations

- Partner with certified freight forwarders experienced in automotive parts logistics.

- Regularly audit suppliers and logistics providers for compliance.

- Stay updated on trade regulations and tariff changes affecting automotive components.

- Maintain clear communication with customers regarding lead times, compliance status, and documentation.

By following this guide, businesses can ensure efficient, compliant, and reliable logistics for CV joints used in Toyota Camry models across global markets.

In conclusion, sourcing a CV joint for a Toyota Camry requires careful consideration of compatibility, quality, and cost. It is essential to verify the correct part number based on the vehicle’s model year, engine type, and drivetrain configuration to ensure a proper fit. Opting for OEM (original equipment manufacturer) parts guarantees reliability and longevity, while reputable aftermarket brands can offer a more budget-friendly alternative without significantly compromising performance. Purchasing from trusted suppliers—whether online retailers, local auto parts stores, or certified dealerships—helps avoid counterfeit or substandard components. Additionally, reviewing customer feedback and warranty options can further guide the decision-making process. Ultimately, investing time in thorough research will ensure the acquisition of a high-quality CV joint that enhances vehicle safety, smooth operation, and long-term durability.