The global paper products market continues to expand, driven by rising demand for specialty packaging, personalized printing, and creative office solutions. According to Grand View Research, the global paper packaging market was valued at USD 422.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030—reflecting broader trends in customization and value-added paper processing. As demand for precision in document finishing and decorative paper crafting increases, custom paper punch manufacturers are playing a pivotal role in meeting diverse industrial, commercial, and artisan needs. These specialized manufacturers deliver everything from intricate die-cut patterns to high-volume hole-punching systems, supporting sectors ranging from publishing and education to luxury retail and event design. In this evolving landscape, innovation, material versatility, and engineering precision define the top performers. Based on market presence, product range, technological capabilities, and global reach, here are the top 8 custom paper punch manufacturers shaping the industry today.

Top 8 Custom Paper Punch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Top Automatic Hole Punches Manufacturer

Domain Est. 2010

Website: eagle-stationery.com

Key Highlights: As a trusted automatic hole punches manufacturer, we offer high-quality, durable punching machines designed for precision and efficiency….

#2 Custom Hole Punching

Domain Est. 1997

Website: unipunch.com

Key Highlights: Make custom holes with UniPunch tooling. Hole shapes are made to your specifications. Punch parts fast! Inquire at 1-(877)-832-9947!…

#3 OXCO Nonwoven Solutions

Domain Est. 1998

Website: oxco.com

Key Highlights: We offer innovative non-woven solutions to meet every need. For over 30 years, OXCO has built a reputation for delivering high-quality materials and ……

#4 Custom Punches

Domain Est. 1999

Website: holepunch.com

Key Highlights: CUSTOM PUNCHES. We have tooling for over 1,700 different punch designs. If you do not find what you are looking for in our design list, ……

#5 Punch Bunch

Domain Est. 2000

Website: thepunchbunch.com

Key Highlights: One punch is all you need to create tags of any size and proportion, to match all your projects. Ideal for gifts, labels, banners and more….

#6 Paper Punches from EK Tools and We R Makers

Domain Est. 2000

Website: americancrafts.com

Key Highlights: Free delivery over $75 Free 30-day returns…

#7 Custom Hole Punch

Domain Est. 2000

Website: ldproducts.com

Key Highlights: 40-sheet three-hole/two-hole punch provides power handle leverage that lets you easily punch through up to 40 sheets of 20 lb. paper….

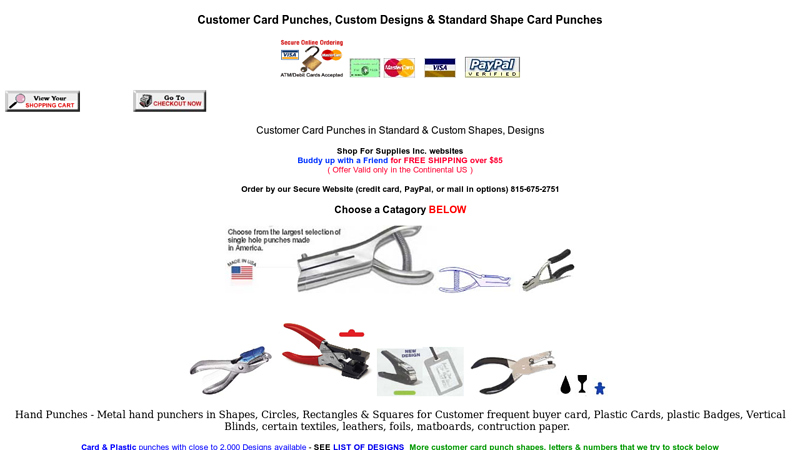

#8 Customer Card Punches, Custom Designs and Standard Shape …

Domain Est. 2011

Website: customercardpunch.com

Key Highlights: CustomerCardPunch is the one source for all your customized punching needs and personalized event and identification punches. Hole Punch Tools made to your ……

Expert Sourcing Insights for Custom Paper Punch

2026 Market Trends for Custom Paper Punch

Rising Demand for Personalization and Branding

By 2026, the custom paper punch market is expected to experience strong growth driven by the increasing demand for personalized stationery, promotional materials, and branded packaging. Businesses and consumers alike are prioritizing unique, tactile experiences in an increasingly digital world. Custom paper punches allow companies to create distinctive logos, shapes, and patterns on invitations, business cards, labels, and retail packaging—enhancing brand recognition and customer engagement. This trend is amplified by the popularity of DIY crafts, event planning, and small-batch product launches, all of which benefit from custom die-cut elements.

Expansion in E-Commerce and On-Demand Manufacturing

The proliferation of online marketplaces and print-on-demand platforms is enabling faster, more accessible production of custom paper punches. By 2026, advancements in digital die-cutting technology and automation will allow smaller businesses and independent creators to order custom punches affordably and with shorter lead times. This shift supports micro-manufacturing and sustainable practices by reducing waste and overproduction. Integration with design software and cloud-based ordering systems will further streamline the customization process, expanding the customer base beyond traditional printing services to include artists, educators, and entrepreneurs.

Sustainability and Eco-Friendly Materials

Environmental consciousness will play a pivotal role in shaping the custom paper punch sector. Consumers and businesses are increasingly favoring sustainable materials such as recycled paper, biodegradable substrates, and non-toxic inks. By 2026, manufacturers of custom punches will need to align with eco-certifications and offer green alternatives to remain competitive. Additionally, durable, reusable metal punches that minimize plastic components will gain market traction, appealing to environmentally responsible buyers seeking long-term solutions.

Technological Integration and Smart Tools

The integration of smart technology into paper punching tools is expected to emerge as a niche but growing trend. By 2026, we may see the adoption of programmable electronic punches with Bluetooth connectivity, allowing users to download and execute custom designs via mobile apps. These innovations will cater to professional designers and high-volume users who require precision, repeatability, and digital design compatibility. While manual punches will remain popular for craft and small-scale use, digital enhancements will open new applications in packaging prototyping and marketing production.

Growth in Niche and Regional Markets

Beyond mainstream commercial applications, specialized sectors such as luxury packaging, wedding stationery, and educational materials will drive demand for intricate and artistic paper punches. In emerging markets, particularly in Asia-Pacific and Latin America, rising disposable incomes and expanding small business ecosystems will fuel interest in affordable custom branding tools. Localized design preferences and cultural motifs will encourage regional customization, prompting manufacturers to offer diverse shape libraries and localized support services by 2026.

In summary, the custom paper punch market in 2026 will be shaped by personalization, digital accessibility, sustainability, technological innovation, and regional diversification—positioning it as a dynamic segment within the broader graphic arts and packaging industries.

Common Pitfalls When Sourcing Custom Paper Punches (Quality and Intellectual Property)

Sourcing custom paper punches—whether for die-cutting, embossing, or specialty shaping—can streamline production and enhance product appeal. However, overlooking critical quality and intellectual property (IP) considerations can lead to costly delays, legal disputes, or subpar results. Below are common pitfalls to avoid during the sourcing process.

Overlooking Tooling Quality and Material Specifications

One of the most frequent mistakes is failing to verify the quality standards of the punch tooling. Low-grade steel or imprecise manufacturing can result in inconsistent cuts, premature wear, and frequent replacements. Always confirm the material type (e.g., tool steel grade), heat treatment, and precision tolerances. Request sample punches or test cuts before large-scale production to ensure durability and accuracy.

Inadequate Communication of Design Requirements

Ambiguity in design specifications can lead to deviations from the intended shape, size, or functionality. Ensure technical drawings include exact dimensions, tolerances, bevel angles, and alignment features. Misunderstandings at this stage may result in non-conforming tools that require rework or replacement—increasing costs and lead times.

Choosing Suppliers Without IP Protection Agreements

When designing a custom paper punch, the design itself may represent proprietary innovation. Failing to establish clear intellectual property (IP) agreements with the supplier risks unauthorized replication or resale of the tooling to competitors. Always use a non-disclosure agreement (NDA) and include clauses in the contract that assign IP ownership to your company, especially for custom tooling developed to your specifications.

Assuming Ownership of Tooling by Default

Many buyers assume that paying for a custom punch automatically grants them full ownership. However, some suppliers retain rights to the tooling or its design, especially if they contributed to engineering improvements. Clarify ownership terms upfront to avoid disputes and ensure you can reproduce or modify the tool in the future without dependency on the original vendor.

Neglecting Long-Term Maintenance and Support

Custom punches require maintenance to remain effective over time. Sourcing from a supplier without a clear support plan—such as sharpening services, spare parts, or technical guidance—can disrupt operations when wear occurs. Evaluate the supplier’s ability to provide ongoing service before finalizing the order.

Ignoring International Sourcing Risks

Sourcing punches from overseas manufacturers may offer cost savings but introduces risks related to quality control, shipping delays, and IP enforcement. Jurisdictional differences can make it difficult to pursue legal action if designs are copied. Conduct thorough due diligence, consider third-party inspections, and work with trusted intermediaries when sourcing internationally.

Failing to Verify Compliance with Industry Standards

Depending on the application—especially in packaging for food, pharmaceuticals, or children’s products—custom punches may need to meet regulatory standards (e.g., FDA compliance for food-safe materials). Overlooking these requirements can result in rejected products or compliance violations down the line.

By proactively addressing these pitfalls, businesses can ensure they receive high-quality, legally protected custom paper punches that meet both functional and strategic objectives.

Logistics & Compliance Guide for Custom Paper Punch

This guide outlines the essential logistics and compliance considerations for manufacturing, shipping, and selling Custom Paper Punch products. Adhering to these guidelines ensures smooth operations, regulatory compliance, and customer satisfaction.

Product Specifications and Documentation

Clearly define and document all product specifications, including dimensions, materials (e.g., steel type, plastic components), weight, and intended use. Maintain accurate technical drawings, product manuals, and safety warnings. Proper documentation supports compliance with labeling requirements and facilitates customs clearance.

Material Sourcing and Supply Chain Compliance

Ensure all raw materials, particularly metals and plastics, are sourced from suppliers who comply with environmental and ethical standards (e.g., REACH, RoHS). Verify that materials are free from restricted substances. Maintain a transparent supply chain with documented due diligence to meet import/export regulations and sustainability expectations.

Manufacturing and Quality Control

Implement strict quality control processes during production to ensure consistency and safety. Conduct regular inspections for sharpness, durability, and structural integrity. Align manufacturing practices with ISO 9001 or other applicable quality standards. Retain batch records for traceability in case of recalls or audits.

Packaging and Labeling Requirements

Package Custom Paper Punch units to prevent damage during transit. Use eco-friendly packaging where possible. Labels must include product name, model number, manufacturer information, country of origin, safety warnings (e.g., “Caution: Sharp Edges”), and compliance marks (e.g., CE, UKCA if applicable). Bilingual labeling may be required for certain markets.

International Shipping and Customs Clearance

Prepare accurate commercial invoices, packing lists, and certificates of origin for international shipments. Classify the product under the correct HS code (e.g., 8205.59 for hand tools). Be aware of import duties, taxes, and import restrictions in destination countries. Partner with reliable freight forwarders experienced in handling industrial tools.

Regulatory Compliance by Region

Ensure compliance with regional regulations:

– EU: CE marking per Machinery Directive or General Product Safety Directive; adherence to REACH and RoHS.

– USA: Compliance with CPSIA for safety; FTC labeling rules; OSHA guidelines if used in industrial settings.

– UK: UKCA marking; UK REACH regulations post-Brexit.

– Canada: Compliance with CCC and Health Canada requirements if applicable.

Product Safety and Risk Management

Conduct risk assessments to identify potential hazards (e.g., pinching, cutting). Include safety instructions in user manuals and on packaging. Consider product liability insurance and have a product recall plan in place. Monitor customer feedback and incident reports proactively.

Environmental and Sustainability Considerations

Adopt environmentally responsible practices in production and disposal. Offer take-back programs or recycling guidance for worn-out units. Comply with WEEE directives if electronic components are included. Communicate sustainability efforts to enhance brand reputation.

Recordkeeping and Audits

Maintain comprehensive records of compliance certifications, test reports, supplier audits, and shipping documentation. Conduct internal audits annually to ensure ongoing adherence to logistics and compliance standards. Be prepared for third-party inspections or regulatory audits.

Conclusion

Effective logistics and compliance management for Custom Paper Punch products minimizes risks, ensures legal conformity, and supports global market access. Regularly review and update procedures to reflect changing regulations and industry best practices.

In conclusion, sourcing a custom paper punch requires careful consideration of various factors including design specifications, material quality, production capabilities, cost-efficiency, and supplier reliability. By clearly defining your requirements—such as punch shape, size, durability, and volume—businesses can identify manufacturers or suppliers that align with their needs. Engaging with experienced suppliers, requesting samples, and evaluating lead times and minimum order quantities are essential steps to ensure a successful partnership. Ultimately, investing time in thorough research and due diligence will lead to a high-quality, customized paper punch that enhances productivity, supports branding efforts, and meets the functional demands of your specific application.