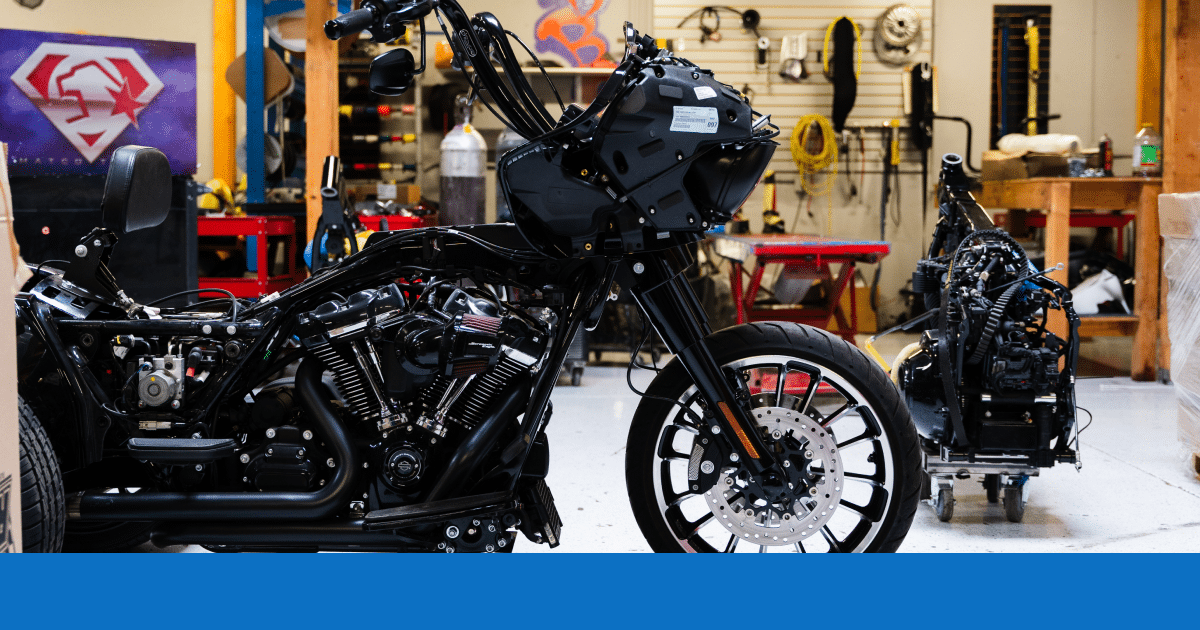

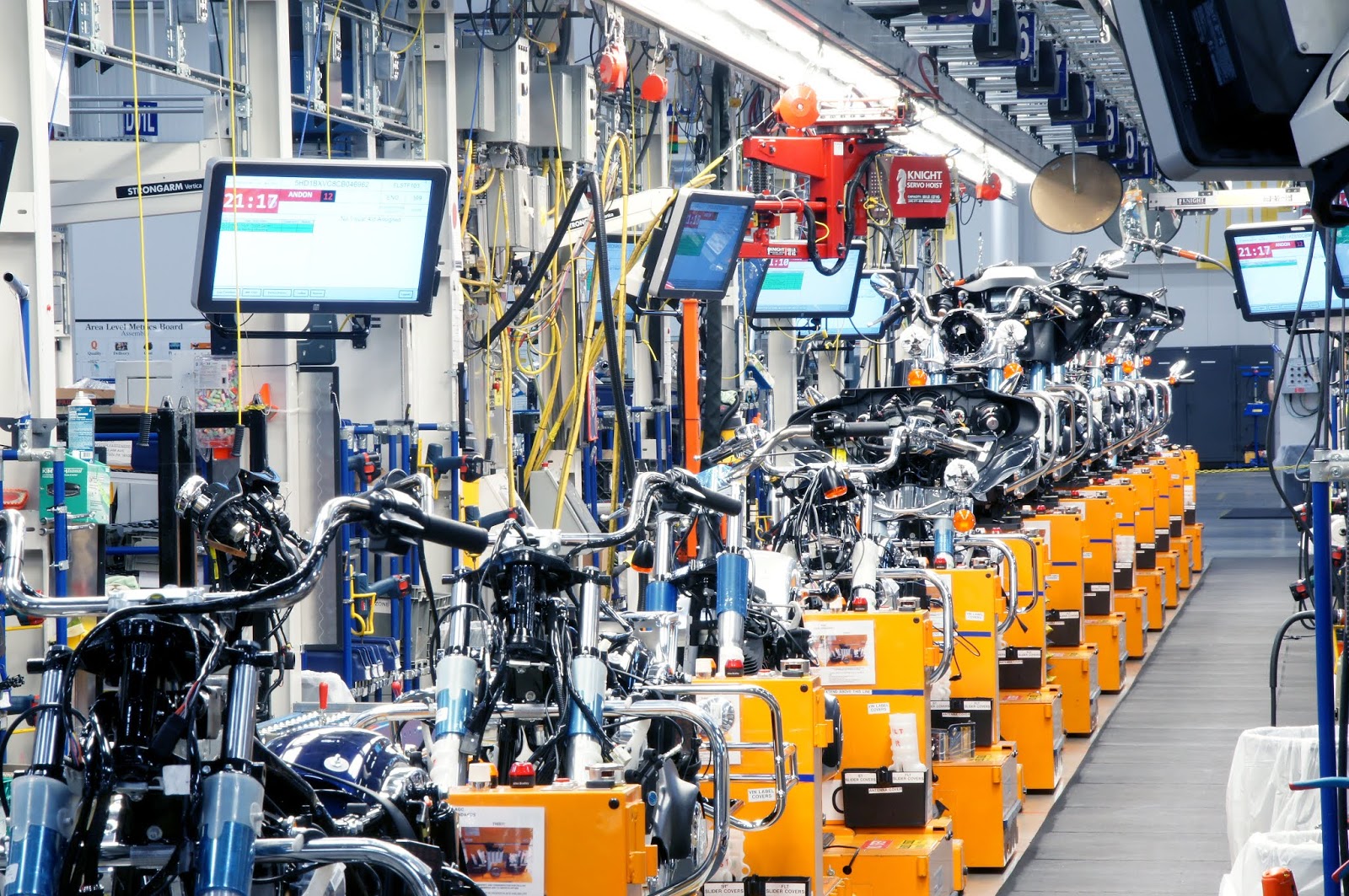

The global motorcycle aftermarket parts industry is experiencing robust growth, driven by rising demand for vehicle customization, especially among premium and cruiser segments like Harley Davidson. According to Grand View Research, the global motorcycle aftermarket size was valued at USD 29.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Enthusiasts’ increasing preference for personalized aesthetics, improved performance, and enhanced riding experiences are fueling demand for high-quality custom components. Within this niche, Harley Davidson riders represent a loyal and active segment, with customized builds playing a central role in the brand’s culture. As the market expands, a select group of manufacturers has emerged as leaders in producing premium, reliable, and innovative custom parts—from exhaust systems and handlebars to engine upgrades and lighting solutions. Based on market presence, product range, customer reviews, and innovation, here are the top 6 custom Harley Davidson parts manufacturers shaping the industry today.

Top 6 Custom Harley Davidson Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ronnie’s Harley

Domain Est. 2009

Website: shopronniesharleydavidson.com

Key Highlights: Home · Parts & Accessory Catalog · 2020 Harley-Davidson® · 2021 Harley-Davidson® · OEM Harley-Davidson® Parts Finder · Company Info….

#2 Arlen Ness Motorcycles

Domain Est. 1996

Website: arlenness.com

Key Highlights: Free delivery 365-day returnsQuality Motorcycle Parts From California Craftsmen 1970. For over 50 years Arlen Ness has designed and manufactured industry leading performance parts …

#3 Drag Specialties®

Domain Est. 1996

Website: dragspecialties.com

Key Highlights: Drag Specialties is the world’s largest distributor of aftermarket accessories in the powersports industry….

#4 Kuryakyn Motorcycle Parts

Domain Est. 1996

Website: kuryakyn.com

Key Highlights: We know you want to customize your bike and kick it up a notch, and with our Kuryakyn motorcycle parts, you can do just that! Explore our collection today….

#5 V

Domain Est. 1998

Website: vtwinmfg.com

Key Highlights: V-Twin Manufacturing – Largest Selection of Aftermarket Parts and Accessories for Harley Davidson Motorcycles. Search over 30000 Parts!…

#6 Dirty Bird Concepts

Domain Est. 2012

Expert Sourcing Insights for Custom Harley Davidson Parts

2026 Market Trends for Custom Harley-Davidson Parts

As the motorcycle customization industry evolves, the market for Custom Harley-Davidson parts is poised for significant transformation by 2026. Driven by shifting consumer preferences, technological advancements, and an expanding global enthusiast base, the demand for personalized and high-performance components continues to grow. This analysis explores key trends shaping the Custom Harley-Davidson parts market in 2026.

Rising Demand for Personalization and Aesthetic Customization

By 2026, personalization remains a dominant force in the motorcycle aftermarket. Harley-Davidson riders increasingly seek unique, one-of-a-kind builds that reflect individual identity and style. This trend fuels demand for custom paint finishes, handcrafted accessories, and bespoke chrome or billet aluminum components. Aftermarket manufacturers are responding with modular customization kits, limited-edition collaborations with artists, and digital design tools that allow riders to preview custom builds online before purchasing.

Integration of Smart Technology and Connectivity

A notable shift in 2026 is the integration of smart technology into custom parts. Riders are adopting aftermarket components with embedded sensors, Bluetooth connectivity, and app-controlled lighting or performance tuning. Custom handlebars with integrated navigation displays, LED lighting systems synchronized via smartphone apps, and performance exhausts with adjustable sound profiles are becoming increasingly common. These tech-enhanced parts cater to a younger, tech-savvy demographic seeking both style and functionality.

Sustainability and Eco-Conscious Customization

Environmental awareness is influencing the custom parts market. By 2026, more manufacturers are adopting sustainable practices, such as using recycled metals, low-VOC powder coatings, and energy-efficient production methods. There is also growing interest in electric or hybrid conversion kits for classic Harley-Davidson models, allowing riders to maintain vintage aesthetics while reducing emissions. This eco-conscious trend appeals to environmentally aware consumers without compromising the brand’s rugged image.

Expansion of the Global Enthusiast Community

The Harley-Davidson custom culture is no longer limited to North America. By 2026, emerging markets in Europe, Southeast Asia, and Latin America are experiencing a surge in custom bike popularity. Social media platforms and international motorcycle events are amplifying global interest, encouraging local artisans and aftermarket brands to develop region-specific parts that blend Harley-Davidson heritage with cultural design elements. This globalization is diversifying product offerings and expanding market reach.

Growth of E-Commerce and Direct-to-Consumer Models

Online retail continues to dominate the distribution of custom Harley-Davidson parts. In 2026, specialized e-commerce platforms offer immersive 3D product views, AR-based fitment tools, and direct manufacturer sales, reducing reliance on traditional dealerships. Subscription boxes for custom accessories and loyalty programs through branded online stores further enhance customer engagement and retention.

Conclusion

The 2026 market for Custom Harley-Davidson parts is characterized by innovation, personalization, and global expansion. As riders demand greater style, performance, and sustainability, manufacturers must adapt by embracing technology, eco-friendly practices, and digital engagement strategies. The future of customization lies at the intersection of tradition and modernity—honoring Harley-Davidson’s legacy while pushing the boundaries of what’s possible on two wheels.

Common Pitfalls When Sourcing Custom Harley Davidson Parts: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Custom Harley-Davidson Parts

Understanding Regulatory Requirements

Custom Harley-Davidson parts must comply with federal, state, and local regulations to ensure safety, environmental standards, and road legality. Key areas include:

- DOT (Department of Transportation) Compliance: Any parts affecting vehicle safety—such as lighting, mirrors, exhaust systems, or braking components—must meet DOT standards. Look for DOT certification marks on applicable components.

- EPA Regulations: Aftermarket exhaust systems and engine modifications may be subject to Environmental Protection Agency (EPA) rules, particularly regarding emissions. In the U.S., tampering with emissions controls is prohibited under the Clean Air Act.

- State-Specific Laws: States like California enforce additional regulations through the California Air Resources Board (CARB). CARB Executive Orders (EOs) are required for legal sale and installation of certain performance parts in the state.

- Motorcycle Noise Ordinances: Many localities regulate exhaust noise levels. Custom exhaust systems must comply with decibel limits to avoid fines or installation bans.

Intellectual Property & Brand Use

Harley-Davidson is a registered trademark, and unauthorized use of logos, insignias, or proprietary designs can lead to legal action.

- Trademark Licensing: Third-party manufacturers must obtain proper licensing from Harley-Davidson Motor Company to use its name, logos, or model-specific branding on parts or packaging.

- Part Authenticity Claims: Avoid implying that custom parts are “official” or “genuine Harley-Davidson” unless certified. Use disclaimers such as “Compatible with Harley-Davidson® models” instead.

- Design Patents: Be mindful of patented designs in Harley-Davidson components. Replicating protected elements may violate intellectual property rights.

Supply Chain & Inventory Management

Efficient logistics depend on clear sourcing, inventory tracking, and fulfillment processes.

- Supplier Vetting: Ensure all component suppliers are reliable and provide compliance documentation (e.g., material safety data sheets, test certifications).

- Inventory Labeling: Clearly label parts with part numbers, compatibility models, and compliance status (e.g., “CARB Certified,” “DOT Approved”) to prevent misshipping.

- Drop Shipping Compliance: If using third-party logistics (3PL) or drop shipping, verify partners understand compliance labels and packaging requirements.

Import/Export Considerations

For international shipment of custom parts:

- HS Code Classification: Accurately classify parts using Harmonized System (HS) codes to determine tariffs and duties. For example, motorcycle handlebars might fall under 8714.19, while custom lighting may be 8512.20.

- Customs Documentation: Prepare commercial invoices, packing lists, and certificates of origin. Include detailed descriptions to prevent delays.

- Import Restrictions: Some countries restrict modifications to vehicle emissions or safety systems. Research destination country regulations before shipping.

Packaging & Labeling Standards

Proper packaging ensures product integrity and regulatory adherence.

- Compliance Labels: Affix required labels (e.g., DOT, CARB, CE for Europe) visibly on the product or packaging.

- User Instructions: Include installation guidelines and compliance statements, especially for parts requiring professional installation.

- Hazard Communication: If shipping parts containing hazardous materials (e.g., certain coatings or fluids), comply with IATA, IMDG, or 49 CFR regulations.

Warranty & Liability Management

- Clear Warranty Terms: Define warranty coverage for custom parts, especially when modifications may void the original Harley-Davidson warranty.

- Liability Disclaimers: Include disclaimers stating that improper installation or non-compliant use may result in safety risks or legal issues.

Best Practices Summary

- Verify all parts meet DOT, EPA, and CARB standards where applicable.

- Never use Harley-Davidson trademarks without proper licensing.

- Maintain detailed compliance documentation for audits.

- Train logistics staff on handling and shipping requirements.

- Regularly review federal and state regulatory updates affecting aftermarket motorcycle parts.

Adhering to this guide ensures smooth operations, minimizes legal risk, and builds trust with customers in the custom Harley-Davidson marketplace.

In conclusion, sourcing custom Harley-Davidson parts requires careful consideration of quality, compatibility, and reputation. Whether purchasing from OEM suppliers, authorized dealers, specialty aftermarket manufacturers, or online marketplaces, it is essential to verify the authenticity and durability of components to ensure both performance and safety. Customization should enhance the riding experience while maintaining the integrity of the motorcycle. By researching reliable vendors, reading customer reviews, and consulting with Harley-Davidson specialists or experienced builders, riders can make informed decisions that reflect their personal style and mechanical needs. Ultimately, investing time and effort into sourcing the right custom parts allows Harley enthusiasts to create a truly unique and high-performing machine that stands out on the road.