The global welding equipment market is experiencing steady growth, driven by rising industrialization, infrastructure development, and increased demand across automotive, construction, and manufacturing sectors. According to a report by Mordor Intelligence, the global welding equipment market was valued at USD 22.7 billion in 2023 and is projected to grow at a CAGR of 5.8% from 2024 to 2029. A key segment within this market is personal protective equipment (PPE), particularly auto-darkening welding helmets, which are seeing increased adoption due to enhanced safety regulations and technological advancements. Grand View Research further underscores this trend, noting that the growing emphasis on worker safety and the integration of smart features—such as solar-powered sensors, adjustable sensitivity, and improved response times—are accelerating demand for custom auto-darkening helmets. As manufacturers focus on innovation, comfort, and customization to meet diverse user needs, the competitive landscape has expanded globally. Below are the top 10 custom auto-darkening welding helmet manufacturers shaping this evolving market.

Top 10 Custom Auto Darkening Welding Helmet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Auto-Darkening Welding Helmets

Domain Est. 1999

Website: hobartwelders.com

Key Highlights: Our comprehensive auto-darkening welding helmet line is designed with the latest LCD lens technology for best-in-class eye protection….

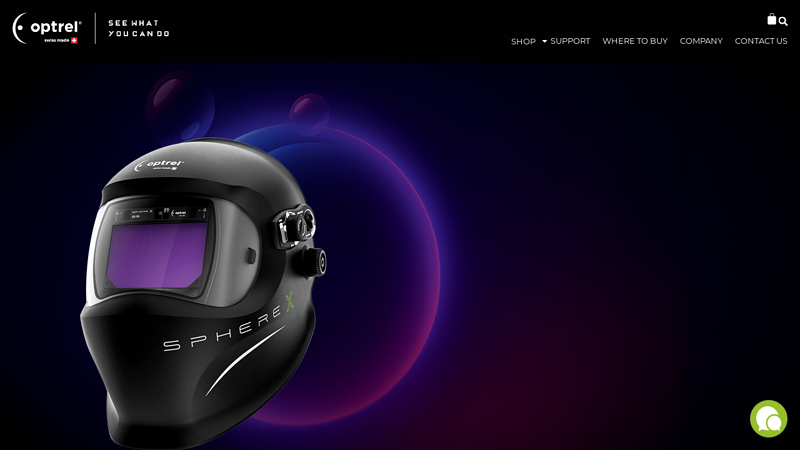

#2 Optrel USA

Domain Est. 2020

Website: optrel.us

Key Highlights: As one of the first inventors of auto-darkening technology for the welding industry, our safety equipment product line began with a focus on welding helmets….

#3 Custom Auto Darkening Welding Helmet Supplier, Factories

Domain Est. 2024

Website: chengdualpha.com

Key Highlights: Looking for a reliable auto darkening welding helmet? Check out Chengdu Alpha Welding & Cutting Equipment Co., Ltd. for top-quality helmets perfect for your ……

#4 Buy Online Auto

Domain Est. 1995

#5 Welding Helmets (Auto Darkening / Adjustable Shade)

Domain Est. 1995

#6 Digital Elite™, Forged in Freedom™, ClearLight 4x

Domain Est. 1996

Website: millerwelds.com

Key Highlights: Rating 4.7 (699) · Free deliveryAutomatically sets the helmet sensitivity by sensing your welding environment. Ideal for weld operators who frequently adjust their settings for…

#7 Welding Helmets

Domain Est. 1996

Website: lincolnelectric.com

Key Highlights: Lone Star Welding Helmet K4134-1 Lone star welding helmet is a solar-powered, auto-darkening hood for safety and protection….

#8 Auto

Domain Est. 2003

Website: weldfabulous.com

Key Highlights: Our auto-darkening welding helmets automatically adjust to the brightness of the welding arc, providing optimal protection and comfort….

#9 Powered Air Purifying Respirator

Domain Est. 2004 | Founded: 2001

Website: shine-xunan.com

Key Highlights: We have become the world’s largest R&D and manufacturing centre of auto darkening welding helmets and PAPRs. 20Year. Professional welding protection since 2001….

#10 Welding Hoods

Domain Est. 2012

Website: outlawleather.com

Key Highlights: 30-day returnsGet your own personalized welding helmet with your name or preferred design. These awesome helmets offer superior eye protection and are made of genuine cowhide ……

Expert Sourcing Insights for Custom Auto Darkening Welding Helmet

H2: 2026 Market Trends for Custom Auto Darkening Welding Helmets

The market for custom auto darkening welding helmets (CADWHs) is poised for significant evolution by 2026, driven by technological advancements, shifting industry demands, and evolving user expectations. Key trends shaping this landscape include:

1. Hyper-Personalization and Modularity: The concept of “custom” is moving beyond basic engraving. Expect a surge in modular helmet systems allowing welders to easily swap components (lenses, headgear, sensors, communication modules, battery packs) to tailor performance, comfort, and functionality to specific tasks (e.g., switching from a standard grind guard to a specialized one for confined space work). Customizable software settings via apps (shade ranges, sensitivity, delay times, sensitivity profiles) stored in the helmet or cloud will become standard.

2. Advanced Sensor Fusion and AI Integration: Helmets will leverage multiple sensors (beyond just arc detection) – including motion tracking, ambient light sensors, temperature sensors, and even proximity sensors. AI algorithms will analyze this data in real-time to:

* Predictive Darkening: Anticipate arc strike based on torch movement, enabling near-instantaneous (sub-millisecond) darkening for safer starts.

* Adaptive Performance: Automatically optimize lens parameters (sensitivity, delay) based on welding process (MIG, TIG, Stick), material, and environment (bright sunlight vs. indoor).

* Weld Quality Feedback: Provide basic real-time feedback on weld consistency or potential defects via visual/audible alerts.

3. Enhanced Ergonomics and Connectivity (Industry 4.0):

* Lightweight, Balanced Designs: Continued focus on reducing weight (using advanced composites) and improving weight distribution to minimize neck strain during long shifts.

* Integrated Communication & AR: Helmets will increasingly integrate Bluetooth/Wi-Fi for seamless connection to:

* Smart Devices: Receiving work instructions, schematics, or safety alerts via heads-up displays (HUD) using augmented reality (AR) overlays within the lens.

* Team Communication: Built-in noise-canceling microphones and speakers for clear communication in noisy environments without removing the helmet.

* IoT & Fleet Management: Data on usage hours, weld parameters, and environmental conditions can be transmitted for maintenance scheduling, productivity tracking, and safety compliance monitoring.

4. Superior Optical Performance and Comfort:

* Larger, Ultra-Wide Viewing Areas: Demand for panoramic lenses (100+ sq. in.) offering near 360-degree visibility will grow, improving situational awareness and reducing head movement.

* Higher Optical Clarity (Shade 5): Wider adoption of premium lenses offering true color perception in the light state (Shade 5) for better pre-weld inspection and reduced eye fatigue.

* Advanced Comfort Features: Improved suspension systems (auto-adjusting, multi-point), enhanced sweat management, better ventilation (active or passive), and hypoallergenic materials will be key differentiators.

5. Sustainability and Durability Focus:

* Longer Lifespans & Repairability: Manufacturers will emphasize durability and offer modular repair options (replacing sensors, electronics, or headgear) to extend product life and reduce waste.

* Sustainable Materials: Increased use of recycled plastics and bio-based materials in construction.

* Energy Efficiency: Longer-lasting, swappable, or even solar-assisted batteries to reduce downtime and environmental impact.

6. Market Expansion and Competitive Dynamics:

* Emerging Markets Growth: Significant demand growth expected in developing economies (Asia-Pacific, Latin America) driven by industrialization and infrastructure projects.

* Consolidation & Niche Players: Larger players may acquire innovators, while specialized niche brands focusing on specific technologies (e.g., AR integration, ultra-light design) will emerge.

* Price Stratification: A clear market split will solidify between high-end, feature-rich “smart helmets” and more affordable, reliable models for basic auto-darkening needs.

In summary, by 2026, the custom auto darkening welding helmet market will be defined by intelligent, connected, highly personalized, and ergonomically superior solutions. The focus will shift from being merely a protective device to becoming an integrated, data-driven component of the modern welder’s digital toolkit, enhancing not only safety but also productivity, quality, and overall work experience.

Common Pitfalls When Sourcing Custom Auto Darkening Welding Helmets (Quality and IP)

Sourcing custom auto darkening welding helmets presents unique challenges, especially when balancing quality, compliance, and intellectual property (IP) protection. Falling into common traps can lead to safety risks, legal issues, and financial losses. Here are key pitfalls to avoid:

Overlooking Compliance and Certification Standards

One of the most critical mistakes is assuming that all auto darkening helmets meet safety requirements. Sourcing non-compliant helmets—especially those lacking certifications like ANSI Z87.1 (U.S.) or EN 379 (Europe)—endangers end users and exposes your brand to liability. Custom helmets must undergo rigorous testing for optical clarity, response time, UV/IR protection, and durability. Always verify that suppliers provide up-to-date, authentic test reports and certifications from accredited third parties.

Ignoring Lens Performance Specifications

The auto-darkening lens is the core component, yet many buyers focus only on price or appearance. Key lens specifications—such as switching speed (typically <1/20,000 sec), shade range (e.g., 9–13), sensitivity adjustment, and delay control—are often compromised in lower-quality units. Substandard lenses may fail under high-heat conditions or have inconsistent darkening, increasing the risk of arc eye or flash burns. Ensure your supplier specifies lens performance metrics and provides sample testing data.

Failing to Protect Intellectual Property

When designing a custom helmet (e.g., unique shell design, ergonomic features, or interface layout), failing to secure IP rights is a major risk. Without proper agreements, suppliers in manufacturing regions may replicate or sell your design to competitors. Always establish clear non-disclosure agreements (NDAs), register design patents where applicable, and include IP ownership clauses in contracts. Conduct due diligence on suppliers’ track records regarding IP confidentiality.

Compromising on Build Quality and Materials

To meet low price points, some suppliers use inferior plastics, weak headgear mechanisms, or poor seals. This leads to helmets that crack under impact, fail in extreme temperatures, or provide inadequate head protection. Insist on material specifications (e.g., high-impact thermoplastics) and request physical samples for drop, heat, and wear testing. Avoid suppliers unwilling to provide material safety data sheets (MSDS) or durability test results.

Underestimating Supply Chain and Quality Control Risks

Relying solely on supplier claims without independent quality audits is risky. Inconsistent production batches, poor workmanship, and lack of in-process inspections can result in defective units reaching customers. Implement a third-party inspection protocol (e.g., pre-shipment inspections) and consider unannounced factory audits. Build quality checkpoints into your sourcing agreement, including acceptable quality limits (AQL) standards.

Neglecting After-Sales Support and Spare Parts Availability

Custom helmets often require replacement lenses, batteries, or headgear components. Sourcing from suppliers who don’t guarantee long-term spare parts availability can damage your brand reputation. Confirm that the supplier commits to supporting your product line for a defined period (e.g., 5–10 years) and has a reliable logistics network for parts distribution.

By proactively addressing these pitfalls—prioritizing compliance, lens performance, IP protection, material quality, supply chain oversight, and after-sales support—you can source custom auto darkening welding helmets that are safe, reliable, and legally protected.

Logistics & Compliance Guide for Custom Auto Darkening Welding Helmet

Product Classification & Regulatory Requirements

Auto darkening welding helmets are classified as personal protective equipment (PPE) under international safety standards. Compliance with regional regulations is mandatory for legal import, sale, and use.

- United States (OSHA & ANSI): Helmets must meet ANSI Z87.1-2020 standards for impact and optical clarity. OSHA 29 CFR 1910.135 requires head protection in hazardous environments. Ensure all units carry the appropriate ANSI marking.

- European Union (CE Marking & PPE Regulation (EU) 2016/425): Classify the helmet as Category III PPE (complex design). A Notified Body must perform type examination (Module B). Full quality assurance (Module D) or product verification (Module F) may also be required. Technical documentation and EU Declaration of Conformity are mandatory.

- Canada (CSA Z94.1): Helmets must be certified to CSA Z94.1 standard by an accredited body. Marking must include CSA certification logo.

- Australia & New Zealand (AS/NZS 1337.1): Compliance with AS/NZS 1337.1 for eye protection devices is required. SAA or other recognized certification bodies provide approval.

- Other Markets (e.g., UK, China, Brazil): Verify local standards (e.g., UKCA marking post-Brexit, GB standards in China, INMETRO in Brazil). Local representative or agent may be required.

Ensure all custom branding or modifications do not compromise certification. Any change to lens type, sensor configuration, or shell material may require re-certification.

Packaging & Labeling Standards

Proper packaging and labeling are essential for compliance, safe handling, and user information.

- Primary Packaging: Use durable, crush-resistant packaging to protect helmet during transit. Include protective film on lens and clear instruction manual in local language(s).

- Labeling Requirements:

- Safety certifications (e.g., ANSI, CE, CSA)

- Manufacturer/importer name and address

- Model number and serial number (if applicable)

- Warning labels (e.g., “Protects against UV/IR radiation,” “Do not use without certification verification”)

- Battery safety warnings (for lithium-powered models)

- Compliance with GHS if batteries are included

- User Instructions: Must include setup, operation, maintenance, limitations, and battery replacement steps. Include pictograms where required (e.g., CE directives).

- Custom Branding: Ensure logos and colors do not obscure safety labels or certification marks. Verify ink and material compliance with REACH and RoHS if applicable.

Shipping & Import Logistics

Efficient and compliant shipping ensures timely delivery and avoids customs delays.

- Harmonized System (HS) Code: Use appropriate HS code (e.g., 6506.10.0030 for protective helmets in the U.S., 6506.10.00 for EU). Confirm country-specific codes to ensure accurate duty assessment.

- Battery Regulations (If Applicable): Lithium batteries are regulated under IATA/IMDG/ICAO. Shipments must comply with:

- Proper packaging (UN38.3 tested)

- Marking and labeling (e.g., “Lithium Battery” handling label)

- Documentation (Shipper’s Declaration for Dangerous Goods, if required)

- Customs Documentation: Prepare commercial invoice, packing list, bill of lading/air waybill, and certificates of compliance. Include product classification, value, and country of origin.

- Import Duties & Taxes: Research duty rates and VAT/GST requirements in destination country. Consider bonded warehouses or duty-free programs if eligible.

- Freight Options: Choose air freight for speed or ocean freight for cost efficiency. Consider FOB, CIF, or DDP terms based on control and liability preferences.

Quality Control & Post-Market Compliance

Maintain product integrity and address compliance throughout the product lifecycle.

- Pre-Shipment Inspection (PSI): Conduct quality checks on sample units for:

- Functionality of auto-darkening feature

- Sensor response time (typically <1/20,000 sec)

- Shade range (e.g., 9–13)

- Build quality and structural integrity

- Correct labeling and documentation

- Traceability: Maintain batch or serial number records for recall readiness. Implement a system for tracking custom orders.

- Post-Market Surveillance: Monitor customer feedback, warranty claims, and incident reports. Report serious incidents to relevant authorities (e.g., EU RAPEX, U.S. CPSC).

- Recall Preparedness: Establish a recall plan aligned with regional requirements. Ensure ability to notify distributors and end-users rapidly.

Environmental & End-of-Life Compliance

Address environmental responsibilities for sustainable operations.

- WEEE Compliance (EU): Register with national WEEE authorities if selling in EU. Provide information on take-back and recycling options.

- Battery Disposal: Include disposal instructions for lithium batteries. Comply with local e-waste regulations.

- Material Restrictions: Ensure helmet components comply with RoHS (EU), Prop 65 (California), and other chemical restriction laws.

Adhering to this guide ensures safe, legal, and efficient distribution of custom auto darkening welding helmets across global markets.

In conclusion, sourcing a custom auto-darkening welding helmet requires careful consideration of several key factors, including optical quality, switching speed, shade range, comfort, durability, and compliance with safety standards such as ANSI and EN. By identifying reputable suppliers or manufacturers—preferably those with proven experience in producing reliable welding protection gear—businesses can ensure they receive a high-performance product tailored to their specific needs. Customization options, such as logo branding, color schemes, or enhanced features like solar power with battery backup, add value and reinforce brand identity. Ultimately, investing in a quality custom auto-darkening welding helmet not only enhances welder safety and productivity but also demonstrates a commitment to workplace safety and professional standards. Conducting thorough research, requesting samples, and evaluating after-sales support are essential final steps to making a strategic and cost-effective sourcing decision.