The custom air conditioning (AC) lines market has experienced steady expansion, driven by rising demand for energy-efficient HVAC systems and increasing investments in smart building infrastructure. According to Grand View Research, the global HVAC market was valued at USD 179.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 8.4% from 2024 to 2030. A critical component within this ecosystem, custom AC lines are essential for seamless refrigerant flow in both residential and commercial applications, particularly in retrofitting and specialized installations. As system complexity increases and sustainability standards tighten, manufacturers capable of delivering precision-engineered, application-specific refrigerant lines are gaining strategic importance. This demand has paved the way for a competitive landscape of specialized producers focusing on quality, customization, and compliance with evolving environmental regulations. Based on industry reach, product innovation, and manufacturing capabilities, the following nine companies represent the leading custom AC lines manufacturers shaping the future of HVAC performance and reliability.

Top 9 Custom Ac Lines Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mestek

Domain Est. 1995

Website: mestek.com

Key Highlights: We specialize in systems for manufacturers involved in Roll Forming, Coil Processing, HVAC Fabrication and Tube and Pipe Production and Fabrication. We also ……

#2 Baldor.com

Domain Est. 1995

Website: baldor.com

Key Highlights: ABB is the world’s number-one manufacturer of NEMA motors, and we’re proud to support you locally with the Baldor-Reliance product brand….

#3 Sager Electronics

Domain Est. 1995

Website: sager.com

Key Highlights: Specializing in the design and manufacture of modular and custom power supplies, battery packs and assemblies, and thermal management solutions….

#4 Vintage Air

Domain Est. 1996

Website: vintageair.com

Key Highlights: Our Builder Series offers a wide variety of fully customizable solutions for classic cars and trucks, street rods, and custom vehicles. From our advanced Gen 5 ……

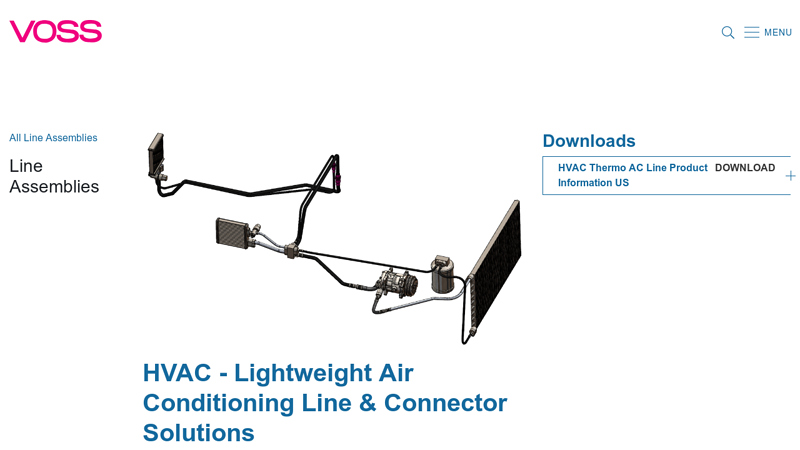

#5 HVAC

Domain Est. 2002

Website: vossusa.com

Key Highlights: VOSS provides a variety of air conditioning line solutions, including our cutting-edge polymer lines, designed to interconnect all components within your air ……

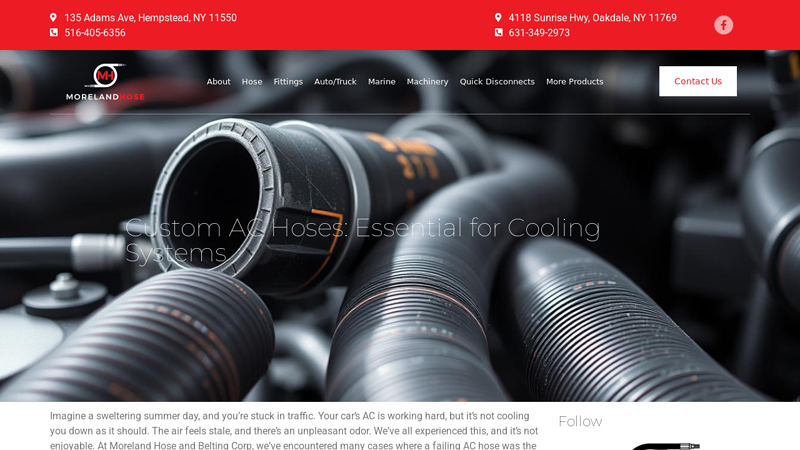

#6 Custom AC Hoses for Auto & HVAC Systems

Domain Est. 2003

Website: morelandhose.com

Key Highlights: Custom-crimped AC hoses for any vehicle or cooling system. All fitting types in stock. Walk-in service at Hempstead & Oakdale locations….

#7 Premier Custom Thermal Management Solutions Company

Domain Est. 2003

Website: 1-act.com

Key Highlights: Advanced Cooling Technologies, a leading thermal management solutions provider, specializes in thermal management solutions for spacecraft, electronics, ……

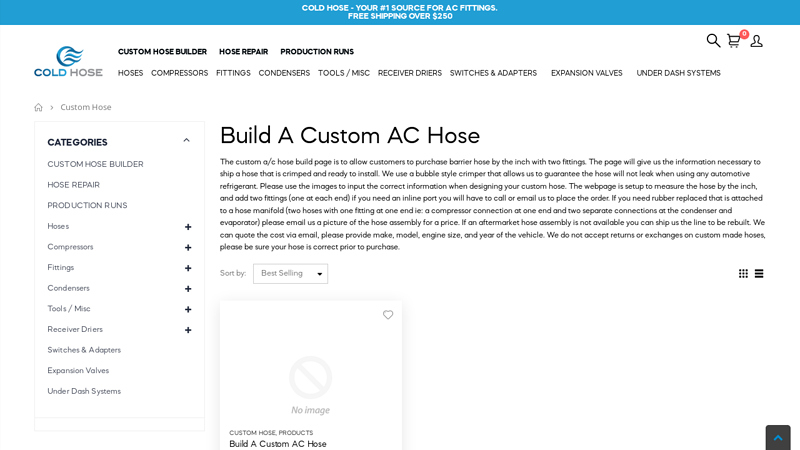

#8 Custom Hose

Domain Est. 2007

#9 Custom AC Hose Lines & Fittings – Made in USA

Domain Est. 2009

Website: autocoolingsolutions.com

Key Highlights: Custom Made AC Line Production. Off-Roaders, Resto-Mods, Coachbuilders, Fleet Managers We do production run custom line jobs….

Expert Sourcing Insights for Custom Ac Lines

2026 Market Trends for Custom AC Lines

The custom air conditioning (AC) lines market is poised for significant transformation by 2026, driven by technological advancements, regulatory shifts, and evolving consumer demands. Key trends shaping the industry include:

Rising Demand for Energy Efficiency and Sustainability

With global emphasis on reducing carbon emissions, HVAC systems are under increasing scrutiny. Custom AC lines are being optimized to minimize refrigerant leakage and improve thermal efficiency, directly contributing to lower energy consumption. The adoption of eco-friendly refrigerants like R-32 and R-454B, which require precise line sizing and installation, is accelerating demand for custom solutions over standardized options. Regulatory frameworks such as the AIM Act in the U.S. and F-Gas regulations in the EU are pushing manufacturers and installers toward sustainable practices, reinforcing the need for tailored AC line configurations.

Growth in Smart HVAC Integration

By 2026, smart HVAC systems are expected to dominate new residential and commercial installations. Custom AC lines are increasingly being designed to integrate seamlessly with IoT-enabled thermostats, sensors, and building management systems. These installations often require non-standard line lengths, bends, and routing to accommodate smart components and ensure optimal performance. The convergence of HVAC and home automation is creating a niche market for custom lines that support advanced diagnostics, predictive maintenance, and remote monitoring.

Expansion in Commercial and Industrial Applications

Urbanization and infrastructure development are fueling demand for customized HVAC solutions in commercial real estate, data centers, and industrial facilities. These environments often have unique cooling requirements, spatial constraints, and load profiles that off-the-shelf AC lines cannot meet. Custom AC lines offer the flexibility to adapt to complex architectural designs and high-capacity systems, making them essential for energy-efficient building operations. The push for LEED and other green building certifications further incentivizes the use of optimized, custom refrigerant lines.

Advancements in Materials and Manufacturing

Innovations in materials—such as corrosion-resistant copper alloys and flexible, insulated composite tubing—are enhancing the durability and performance of custom AC lines. Automated fabrication technologies, including CNC bending and laser measurement tools, are improving precision and reducing installation time. By 2026, digital twin technology and BIM (Building Information Modeling) are expected to become standard in planning custom AC line layouts, enabling accurate pre-fabrication and reducing on-site errors.

Labor Shortages and the Need for Precision

A persistent shortage of skilled HVAC technicians is increasing the importance of pre-engineered, custom AC lines. Factory-fabricated custom lines reduce on-site labor requirements, minimize refrigerant exposure during installation, and ensure compliance with safety standards. As training programs struggle to keep pace with industry demand, the reliance on precise, ready-to-install custom components will become a competitive advantage for contractors.

Regional Market Diversification

Emerging markets in Southeast Asia, the Middle East, and parts of Africa are experiencing rapid HVAC adoption due to rising temperatures and urban growth. These regions often require custom solutions to address extreme climates and non-standard building designs. Meanwhile, retrofitting older buildings in North America and Europe with modern, efficient HVAC systems is creating sustained demand for custom AC lines tailored to existing infrastructure.

In summary, the 2026 custom AC lines market will be defined by sustainability, digital integration, and precision engineering. Stakeholders who embrace innovation, comply with evolving regulations, and cater to sector-specific needs will be best positioned to capitalize on these dynamic trends.

Common Pitfalls When Sourcing Custom AC Lines (Quality, IP)

Sourcing custom air conditioning (AC) lines involves more than just finding a supplier who can fabricate tubes to your dimensions. Overlooking key aspects related to quality and intellectual property (IP) can lead to costly delays, product failures, or legal disputes. Here are the most common pitfalls to avoid:

Poor Material and Workmanship Standards

One of the biggest risks is receiving custom AC lines made from substandard materials or with inconsistent fabrication. Suppliers may use inferior-grade copper, improper wall thickness, or flawed brazing techniques that compromise performance and longevity. Always verify that the supplier adheres to industry standards (e.g., ASTM B280 for copper tubing) and conduct incoming quality inspections or request third-party testing reports.

Inadequate Pressure and Leak Testing

Custom AC lines must withstand high pressure and thermal cycling without failure. Some suppliers skimp on pressure testing or use inadequate methods, leading to leaks in the field. Ensure that every batch undergoes rigorous hydrostatic or pneumatic pressure testing and helium leak detection, with documented results provided for traceability.

Lack of Design Validation and Compatibility Testing

Custom lines must integrate seamlessly with your system’s compressors, condensers, and evaporators. A common mistake is assuming dimensional accuracy equals functional compatibility. Without proper flow testing, vibration analysis, or thermal cycling validation, lines may induce inefficiencies or premature wear. Require suppliers to collaborate on design validation and provide performance data under real-world conditions.

Ignoring Intellectual Property Risks

When you provide proprietary designs or engineering specifications to a supplier, you expose your IP to potential misuse. Unscrupulous vendors may replicate your design for competitors or claim partial ownership. Always establish clear IP ownership terms in contracts, use non-disclosure agreements (NDAs), and limit access to sensitive design data on a need-to-know basis.

Insufficient Documentation and Traceability

For compliance and warranty purposes, detailed documentation—including material certifications, test results, and batch traceability—is essential. Suppliers that fail to provide full documentation make it difficult to diagnose field failures or pass regulatory audits. Make comprehensive record-keeping a contractual requirement.

Overlooking Long-Term Supply Chain Reliability

Even with high initial quality, relying on a supplier without proven scalability or continuity plans can backfire. If the supplier lacks capacity or goes out of business, your production may halt. Evaluate the supplier’s financial health, redundancy plans, and ability to scale before finalizing agreements.

Failure to Define Tolerances and Acceptance Criteria

Vague specifications lead to inconsistent output. Without clearly defined dimensional tolerances, surface finish requirements, and acceptance criteria, suppliers may deliver parts that technically meet loose specs but fail in application. Provide detailed engineering drawings and quality control checklists to avoid disputes.

By proactively addressing these pitfalls, companies can secure reliable, high-quality custom AC lines while protecting their intellectual property and ensuring long-term supply chain stability.

Logistics & Compliance Guide for Custom AC Lines

Overview

Custom air conditioning (AC) lines are specialized components used in HVAC systems to connect indoor and outdoor units, facilitating refrigerant flow. Due to their custom nature—varying in length, diameter, material, and configuration—shipping and compliance requirements demand careful planning. This guide outlines key logistics and compliance considerations to ensure safe, timely, and regulation-compliant delivery of custom AC lines.

Material and Packaging Requirements

Custom AC lines are typically made from copper or aluminum and often arrive pre-charged with nitrogen to prevent oxidation. Proper packaging is critical to avoid contamination and physical damage during transit.

– Use protective end caps and sealed nitrogen plugs.

– Coil lines on sturdy reels or spools to prevent kinking.

– Wrap in moisture-resistant, puncture-proof material.

– Clearly label packages with handling instructions (e.g., “Fragile,” “Do Not Bend”).

– Include product specifications and nitrogen charge status on external labels.

Domestic and International Shipping Regulations

When shipping custom AC lines, especially across borders, compliance with transportation regulations is essential.

– Domestic (e.g., within the U.S.): Follow DOT (Department of Transportation) guidelines for non-hazardous freight. Ensure load securement and proper documentation.

– International: Comply with IATA (air), IMDG (sea), or ADR (road) regulations, even if lines are nitrogen-purged and non-hazardous. Always verify with carriers.

– Include a commercial invoice, packing list, and certificate of conformity.

– Confirm local import standards (e.g., CE marking in Europe, CCC in China).

Environmental and Safety Compliance

Custom AC lines may be part of systems using regulated refrigerants. Even if shipped empty, compliance with environmental standards is necessary.

– Adhere to EPA Section 608 regulations (U.S.) for refrigerant handling and disposal.

– Ensure production and packaging meet RoHS (Restriction of Hazardous Substances) and REACH (EU) requirements.

– Avoid using ozone-depleting substances in manufacturing or testing.

– Provide Material Safety Data Sheets (MSDS/SDS) upon request.

Customs Documentation and Duties

Accurate customs documentation prevents delays and penalties.

– Classify products correctly under the Harmonized System (HS Code). Example: 7411.21 or 7411.22 for copper tubing.

– Declare accurate values for customs duties and taxes.

– Include a detailed description: “Custom-length copper refrigerant lines for HVAC systems, nitrogen-purged.”

– Prepare for potential inspections; maintain records for audit purposes.

Carrier Selection and Freight Handling

Choose freight partners experienced in handling HVAC components.

– Use carriers with climate-controlled or dry van options to prevent condensation.

– Opt for tracking-enabled services for real-time visibility.

– Require liftgate service if delivery sites lack loading docks.

– Confirm insurance coverage for high-value custom orders.

Quality Assurance and Traceability

Maintain traceability throughout the supply chain.

– Assign unique batch or serial numbers to each custom line set.

– Retain production and inspection records for at least 3–5 years.

– Conduct pre-shipment quality checks for integrity, cleanliness, and correct dimensions.

Conclusion

Shipping custom AC lines requires a coordinated approach to logistics and compliance. By adhering to packaging standards, regulatory requirements, and documentation best practices, businesses can ensure reliable delivery while minimizing risk of damage, delays, or non-compliance penalties. Regular training and audits help maintain consistent performance across the supply chain.

In conclusion, sourcing custom AC lines requires careful consideration of specifications, material quality, compatibility, and supplier reliability. It is essential to partner with experienced manufacturers or suppliers who can deliver precision-engineered lines that meet industry standards and specific application requirements. Proper documentation, clear communication, and adherence to lead times and testing protocols will help ensure consistent performance, system efficiency, and long-term durability. By taking a strategic and informed approach, businesses can successfully source custom AC lines that support optimal operational outcomes while minimizing risks and downtime.