The global cryogenic labeling market is experiencing robust expansion, driven by increasing demand for reliable sample identification in life sciences, biobanking, and pharmaceutical research. According to a 2023 report by Mordor Intelligence, the global cryogenic labels market was valued at approximately USD 540 million in 2022 and is projected to grow at a CAGR of 7.8% through 2028. This growth is fueled by the rising need for long-term biological sample storage at ultra-low temperatures, particularly in academic research institutions, contract research organizations (CROs), and clinical diagnostic labs. As storage environments become more complex—spanning liquid nitrogen, vapor phase, and -80°C freezers—labels must maintain adhesion, legibility, and barcode integrity under extreme conditions. This performance imperative has elevated the importance of specialized manufacturers capable of delivering chemically resistant, durable labeling solutions. In this landscape, the top 10 cryogenic labels manufacturers have emerged as key players, combining advanced materials science with rigorous testing protocols to meet stringent industry standards. From ISO-certified production to innovations in thermal and cryo-resistant adhesives, these companies are shaping the reliability and scalability of cold chain sample tracking worldwide.

Top 10 Cryogenic Labels Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

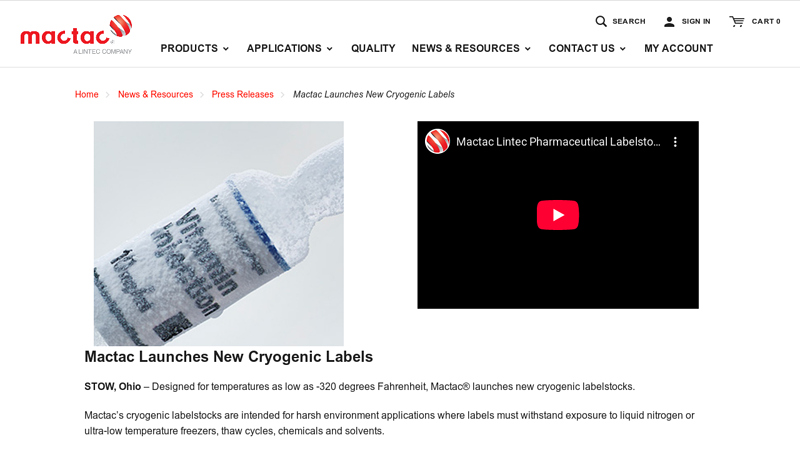

#1 Mactac Launches New Cryogenic Labels

Domain Est. 1997

Website: mactac.com

Key Highlights: Mactac’s new cryogenic labels feature an aggressive advanced-technology high-tack acrylic pressure-sensitive adhesive and other unique characteristics….

#2 Cryo-Tags® & Tough-Spots®

Domain Est. 1997

Website: divbio.com

Key Highlights: Cryo-Clear Laser Labels 1.28″ x 0.50″ 1,700/pk … 1.28 in. 0.50 in. … Price $76$76.00. Out of stock….

#3 Cryogenic Labels

Domain Est. 1996

Website: emsdiasum.com

Key Highlights: Browse our durable cryogenic labels for efficient sample identification. EMS offers top-notch solutions ensuring accuracy in your cryopreservation process….

#4 Cryogenic Storage Labels

Domain Est. 1996

#5 Cryogenic Labels

Domain Est. 1998

Website: bradyid.com

Key Highlights: 1-day deliverySick of your labels not sticking to your frozen tubes? Shop our cryogenic labels. Backed by over 100 years of labeling innovation….

#6 Cryogenic Labels

Domain Est. 1998

Website: gmplabeling.com

Key Highlights: $13.75 delivery Free 365-day returnsWe have 9 different cryogenic label designs in stock and can ship them with same day service, or can manufacture any custom cryogenic label you …

#7 Cryogenic Labels for Laboratories

Domain Est. 1999

Website: computype.com

Key Highlights: Explore cryogenic label kits built for frozen surfaces, racks, and vials. Resistant to chemicals and liquid nitrogen, and compatible with automation….

#8 Cryogenic Labels

Domain Est. 2003

Website: labtag.com

Key Highlights: These cryogenic laser labels are designed to withstand long-term storage in liquid nitrogen (-196°C), freezers, and dry ice. They are supplied in letter and A4 ……

#9 LabelTac® Cryogenic Label Supply

Domain Est. 2010

#10 Cryogenic Labels Solutions

Domain Est. 2015

Website: cclhealthcare.com

Key Highlights: CCL Healthcare offers a comprehensive range of cryogenic packaging solutions that are rigorously tested and made with top-quality materials, adhesives, inks, ……

Expert Sourcing Insights for Cryogenic Labels

H2: 2026 Market Trends for Cryogenic Labels

The global cryogenic label market is poised for significant evolution and expansion by 2026, driven by increasing demand in life sciences, biobanking, pharmaceuticals, and advanced materials research. Key trends shaping the market in the H2 of 2026 include:

1. Accelerated Adoption in Biobanking and Cell & Gene Therapy:

Biobanks and regenerative medicine facilities are expanding rapidly to support personalized medicine and clinical trials. This drives demand for cryogenic labels capable of long-term stability (often 10+ years) at ultra-low temperatures (-80°C to -196°C). Labels must maintain adhesion, print legibility, and resistance to thermal shock during repeated freeze-thaw cycles. By 2026, the integration of cryo-labels with digital tracking systems (e.g., barcodes, RFID) becomes standard practice to ensure sample integrity and compliance with regulatory standards (e.g., 21 CFR Part 11).

2. Technological Advancements in Materials and Adhesives:

Innovations in substrate materials—such as enhanced polyesters, polyimides, and specialty coated papers—are improving durability and chemical resistance. Next-gen adhesives formulated for extreme cold environments ensure reliable bonding even on frosted or condensation-prone surfaces. By H2 2026, self-laminating and tamper-evident cryogenic labels gain traction, offering added protection against environmental degradation and unauthorized access.

3. Growth in Automation and High-Throughput Environments:

Laboratories and biorepositories are increasingly adopting automated storage and retrieval systems (ASRS). This necessitates cryogenic labels with superior print quality for machine readability, consistent dimensions for robotic handling, and resistance to mechanical stress. Demand rises for labels compatible with thermal transfer and direct thermal printers used in high-volume labeling workflows.

4. Sustainability and Eco-Conscious Procurement:

Environmental concerns are influencing procurement decisions. By 2026, suppliers offering recyclable substrates, reduced plastic content, and non-toxic adhesives gain competitive advantage. Life cycle assessments (LCAs) of labeling materials become a differentiator, especially among research institutions and pharmaceutical companies with strong ESG commitments.

5. Regional Market Expansion and Supply Chain Resilience:

Asia-Pacific, particularly China and India, emerges as a high-growth region due to expanding healthcare infrastructure and biotech investment. In response, global suppliers localize production and distribution to ensure supply chain resilience and reduce lead times. Trade dynamics and geopolitical factors continue to influence raw material costs and logistics strategies.

6. Integration with Digital Lab Ecosystems:

Cryogenic labels are increasingly embedded within broader laboratory information management systems (LIMS) and cloud-based sample tracking platforms. By H2 2026, demand grows for labels with encoded data (e.g., QR codes, NFC) enabling real-time sample location tracking, audit trails, and integration with AI-driven inventory management tools.

Conclusion:

By the second half of 2026, the cryogenic label market is characterized by innovation, digital integration, and sustainability. Suppliers who offer high-performance, compliant, and digitally compatible labeling solutions tailored to the evolving needs of life science and industrial applications will lead the market. The convergence of material science, automation, and digital traceability defines the competitive landscape, positioning cryogenic labels as critical components in the future of cold-chain sample management.

Common Pitfalls Sourcing Cryogenic Labels: Quality and Intellectual Property (IP) Concerns

Sourcing cryogenic labels—designed to withstand extreme low temperatures such as those in liquid nitrogen (-196°C) or dry ice (-78.5°C)—involves unique challenges. Poor decisions can lead to sample misidentification, data loss, regulatory non-compliance, and even intellectual property (IP) exposure. Below are key pitfalls related to quality and IP that organizations should avoid.

Quality-Related Pitfalls

1. Inadequate Adhesive Performance at Low Temperatures

A common mistake is selecting labels based on room-temperature performance without verifying cryogenic adhesion. Many standard adhesives become brittle and lose tack at ultra-low temperatures, leading to label detachment. This can result in unidentifiable samples, costly errors, and potential safety issues. Always demand cryogenic-specific adhesive data, including peel strength after thermal cycling and long-term immersion testing.

2. Substrate Embrittlement and Cracking

Not all label face materials remain flexible when frozen. Paper and some plastics may crack or disintegrate upon exposure to cryogenic conditions, especially during thermal shock (rapid temperature changes). Suppliers may offer “cryo-compatible” labels that fail under real-world handling. Ensure the substrate material (e.g., polyester, polyimide) is proven to resist cracking and maintain integrity after repeated freeze-thaw cycles.

3. Poor Print Legibility and Durability

Standard thermal transfer or direct thermal printing may fade or smudge after cryogenic exposure. Ink can delaminate or become unreadable due to condensation, frost, or solvent exposure (e.g., during sample retrieval). Verify that the print method and ribbon/ink are specifically rated for cryogenic use and resistant to abrasion, moisture, and common lab solvents.

4. Lack of Standardized Testing and Certifications

Some suppliers provide anecdotal evidence rather than certified test results. Relying on unverified claims increases risk. Always request independent test data (e.g., ASTM standards for cryogenic performance), ISO certifications (e.g., ISO 15198 for specimen labeling), and compliance with regulatory frameworks like FDA 21 CFR Part 11 if used in clinical or pharmaceutical settings.

5. Inconsistent Batch-to-Batch Quality

Cryogenic label performance must be consistent across production batches. Sourcing from suppliers without robust quality control systems can introduce variability—some labels may hold while others fail. Evaluate the supplier’s quality management system (e.g., ISO 9001) and request batch-specific certificates of conformance.

Intellectual Property (IP)-Related Pitfalls

1. Use of Proprietary Label Designs Without Licensing

Many high-performance cryogenic labels incorporate patented materials, adhesive formulations, or application technologies. Sourcing generic or counterfeit alternatives may infringe on IP rights, leading to legal action, supply chain disruption, or forced product recalls. Always verify that the supplier owns or is licensed to use the technology, and request documentation to confirm IP compliance.

2. Reverse Engineering and Unauthorized Replication

Some buyers attempt to reverse engineer successful label designs to cut costs. This poses significant legal risks and often results in inferior products that fail under cryogenic stress. Engaging in or enabling reverse engineering can lead to patent or trade secret infringement claims, damaging reputation and incurring financial penalties.

3. Lack of IP Clarity in Custom Label Development

When co-developing custom cryogenic labels with a supplier, ownership of the resulting IP may be unclear. Without a written agreement, the supplier may retain rights to the design or materials, limiting your freedom to use or modify the label. Always establish clear IP ownership terms in contracts—preferably assigning rights to your organization for custom-developed solutions.

4. Exposure of Sensitive Information During Sourcing

Disclosing detailed application requirements (e.g., specific storage conditions, sample types, or internal workflows) to multiple vendors increases the risk of sensitive operational or research data being exposed. Use non-disclosure agreements (NDAs) and limit information sharing to what is strictly necessary during the sourcing process.

5. Counterfeit or Gray Market Labels

Purchasing from unauthorized distributors or low-cost online marketplaces increases the risk of receiving counterfeit labels that mimic reputable brands but lack performance and IP legitimacy. These labels may not meet safety or regulatory standards and could expose your organization to liability. Source only through authorized channels and verify authenticity with the manufacturer.

Conclusion

Avoiding these pitfalls requires due diligence in both technical validation and legal compliance. Prioritize suppliers with proven cryogenic performance data, robust quality systems, and transparent IP practices. Conduct thorough audits, insist on certifications, and protect your organization through clear contracts and confidentiality measures. Doing so ensures reliable sample identification and safeguards your operational and intellectual assets.

H2: Logistics & Compliance Guide for Cryogenic Labels

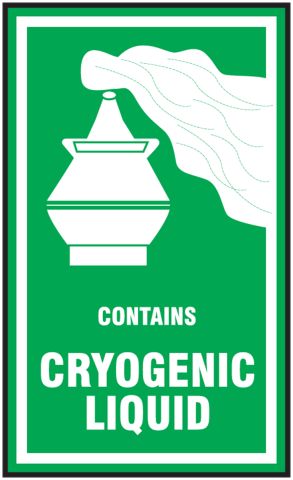

Cryogenic labels are critical components in the safe, compliant, and efficient handling of materials stored at ultra-low temperatures (typically below -150°C / -238°F), such as liquid nitrogen, liquid helium, biological samples, and certain pharmaceuticals. Proper labeling ensures traceability, safety, and regulatory adherence throughout the logistics chain.

1. Storage and Handling Prior to Application

- Temperature Control: Store cryogenic labels only at recommended ambient or refrigerated temperatures (usually 15-25°C / 59-77°F and 30-55% RH). Never pre-store labels in freezers or cryogenic environments before use, as this can compromise adhesive activation and cause premature failure.

- Packaging: Keep labels in their original, sealed packaging until ready for use to prevent moisture absorption and contamination.

- Acclimatization: Allow sealed label rolls or sheets to acclimate to room temperature for several hours (consult manufacturer specs, often 24 hours) before opening the packaging. Opening cold packages can cause condensation, damaging labels.

- Clean Application Surface: Ensure containers (vials, cryo-tubes, cans, Dewars) are clean, dry, and free of frost, oil, or residue before labeling. Isopropyl alcohol wipe-down is common.

2. Application Procedures

- Timing: Apply labels at ambient temperature before placing the container into cryogenic storage. Application directly in the cold environment is ineffective.

- Surface Prep: Wipe the application area with isopropyl alcohol and allow it to dry completely.

- Firm Pressure: Apply firm, even pressure across the entire label surface, especially the edges, using a squeegee or roller. This ensures maximum adhesive contact and minimizes air pockets. Pay extra attention to corners and edges.

- Avoid Moisture: Never apply labels to wet, frosty, or condensing surfaces.

- Label Orientation: Ensure critical information (sample ID, date, hazard symbols) is clearly visible and oriented for easy reading after freezing.

3. Cryogenic Storage & Transportation

- Temperature Stability: Maintain consistent cryogenic temperatures during storage (e.g., liquid nitrogen vapor phase: -150°C to -190°C; liquid phase: ~-196°C). Fluctuations can stress the label.

- Physical Protection: Protect labeled containers from physical impact, abrasion, and crushing within storage racks or transport containers. Use protective sleeves or racks where possible.

- Moisture & Frost: Minimize exposure to ambient air during retrieval to prevent rapid frosting/icing, which can exert shear forces on labels. Use tongs and work quickly. Consider secondary containment (e.g., labeled plastic bags) for added protection.

- Transportation: When transporting cryogenic materials (e.g., dry shippers):

- Ensure the primary container is securely labeled.

- Use robust, UN-rated packaging designed for cryogenic transport.

- Apply additional durable outer labels on the shipping container with essential information (UN number, proper shipping name, hazard class, sender/recipient details).

- Comply with IATA DGR, IMDG Code, or ADR regulations as applicable.

4. Regulatory Compliance

- GHS/CLP: Labels must comply with Globally Harmonized System (GHS) or Classification, Labelling and Packaging (CLP) regulations where applicable for hazardous materials. Include:

- Product Identifier

- Signal Word (e.g., “Danger”)

- Hazard Pictograms (e.g., Gas under pressure, Health Hazard, Cryogenic gas symbol)

- Hazard Statements (e.g., “May cause frostbite”, “Contains gas under pressure; may explode if heated”)

- Precautionary Statements (e.g., “Wear cold insulating gloves”, “Use only outdoors or in a well-ventilated area”)

- Supplier Information

- Biological/Clinical Samples: Adhere to specific regulations (e.g., HIPAA for PHI in the US, GDPR in EU). Labels must support traceability (unique IDs, barcodes/QR codes) without compromising patient privacy. Follow institutional biosafety protocols.

- Pharmaceuticals: Comply with cGMP requirements for labeling accuracy, permanence, and traceability (including lot numbers, expiry dates). 2D barcodes (e.g., Data Matrix) are often mandated.

- Transport Regulations (IATA, IMDG, ADR): Ensure outer packaging labels meet the strict requirements for shipping dangerous goods, including proper class/division (2.2 – Non-flammable, non-toxic gas), UN number (e.g., UN 1005 for Nitrogen, refrigerated liquid), proper shipping name, and orientation arrows. Cryogenic labels themselves need to survive transport conditions.

- Industry Standards: Follow relevant standards (e.g., ISO 15198 for in vitro diagnostic medical devices, specific biorepository standards).

5. Label Performance & Verification

- Material Suitability: Use labels specifically engineered for cryogenic temperatures with adhesives (e.g., modified acrylics) and facestocks (e.g., durable polyimide, polyester) that remain flexible and adherent after thermal shock.

- Print Durability: Ensure printed text/barcodes use inks resistant to cryogenic temperatures, moisture, solvents (e.g., isopropanol wipes), and abrasion. Thermal transfer printing is common for durability.

- Testing: Conduct qualification testing per ASTM F1640 (Standard Guide for Packaging Materials for Foods to be Irradiated) or internal protocols, including:

- Thermal cycling (repeated immersion in LN2 and room temp)

- Adhesion testing after cryogenic exposure

- Legibility and barcode scan verification after cycling

- Audit & Traceability: Maintain records of label specifications, lot numbers, application procedures, and testing results. Regularly audit label legibility and adhesion in storage.

6. Best Practices Summary

- Plan: Select the right cryogenic label (material, adhesive, print method) for your specific temperature, duration, and regulatory needs.

- Prepare: Store labels correctly, acclimatize, and clean surfaces meticulously.

- Apply: Apply firmly at room temperature before freezing.

- Protect: Shield labeled items from physical damage and moisture ingress.

- Comply: Integrate GHS, transport, and industry-specific labeling requirements.

- Verify: Test performance and audit labels regularly.

By adhering to this guide, organizations can ensure the integrity, safety, and regulatory compliance of their cryogenic operations through reliable and durable labeling. Always consult the specific label manufacturer’s instructions and relevant regulatory authorities for the most up-to-date requirements.

Conclusion for Sourcing Cryogenic Labels

In conclusion, sourcing cryogenic labels requires a careful evaluation of material durability, adhesive performance, and compatibility with extreme low-temperature environments such as liquid nitrogen, dry ice, and ultra-low freezers. The selected labels must maintain legibility, adhesion, and resistance to moisture, chemicals, and mechanical abrasion to ensure long-term integrity and sample traceability. It is essential to prioritize suppliers offering validated, tested products that meet industry standards (e.g., ISO, GHS) and provide batch traceability and regulatory compliance documentation. Additionally, considerations such as barcode compatibility, printing method (thermal transfer vs. direct thermal), and labeling workflows should align with laboratory or operational requirements. By conducting thorough vendor assessments, performing real-world testing, and selecting labels tailored to specific storage and handling conditions, organizations can ensure reliable sample identification, reduce errors, and maintain compliance in critical cryogenic applications.