The global plastic extrusion market is experiencing steady expansion, driven by increasing demand across construction, automotive, and packaging industries. According to a 2023 report by Grand View Research, the market was valued at USD 37.93 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by innovations in material efficiency, sustainability initiatives, and rising infrastructure development. Within this competitive landscape, Chaska, Minnesota, has emerged as a hub for high-precision extrusion manufacturing, with Crown Extrusions standing out as a key regional player. As demand for custom thermoplastic solutions continues to rise, particularly in technical and industrial applications, the performance and specialization of manufacturers like those in Chaska are becoming increasingly critical to supply chain resilience and product innovation. Here’s a look at the top six Crown Extrusions-affiliated manufacturers in Chaska, MN, shaping the future of polymer-based manufacturing.

Top 6 Crown Extrusions Chaska Mn Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Crown Extrusions Inc.

Domain Est. 1995

Website: members.aec.org

Key Highlights: Crown Extrusions Inc. 4035 Norex Dr Chaska · Minnesota 55318-3043 United States [ Map ], 952 448-3533 (Phone) 952 448-5328 (Fax) Visit Website »….

#2 Aluminum Extrusions

Domain Est. 2000 | Founded: 1968

Website: crownextrusions.com

Key Highlights: Since 1968, Crown Extrusions has functioned primarily as a custom extruder with a diverse customer base. We have invested in the most advanced technology ……

#3 Crown Extrusions Inc. Company Overview, Contact Details …

Domain Est. 2009

Website: leadiq.com

Key Highlights: Crown Extrusions Inc. is a mining & metals company based out of 122 Columbia Ct N, Chaska, MN, United States. Sign up for free to view info. Email Format…

#4 Crown Extrusions Inc, 4035 Norex Dr, Chaska, MN 55318, US

Domain Est. 1996 | Founded: 1968

Website: mapquest.com

Key Highlights: Crown Extrusions Inc, established in 1968, is a family-owned business based in Chaska, Minnesota, specializing in custom aluminum extrusions….

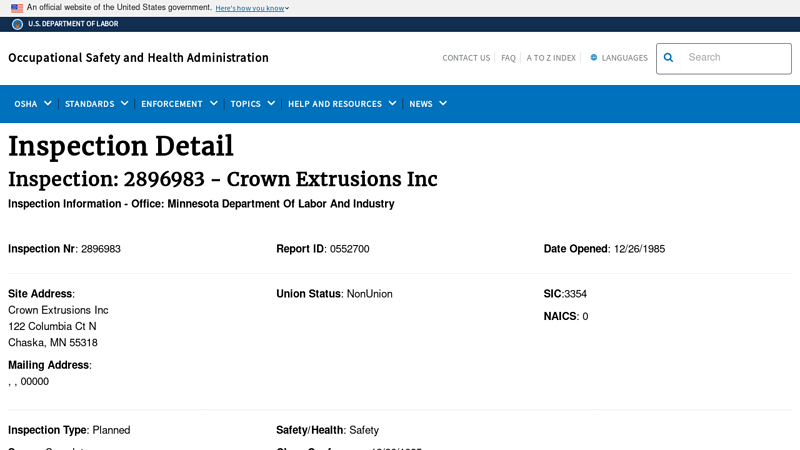

#5 Inspection Detail

Domain Est. 1997

Website: osha.gov

Key Highlights: Inspection: 2896983 – Crown Extrusions Inc ; Site Address: Crown Extrusions Inc 122 Columbia Ct N · Chaska, MN 55318 ; Mailing Address: , , 00000….

#6 Crown Extrusions

Domain Est. 2005

Website: cience.com

Key Highlights: What is Crown Extrusions’s official website? Answer: Crown Extrusions’s official website is https://crownextrusions.com. What is Crown Extrusions’s Revenue?…

Expert Sourcing Insights for Crown Extrusions Chaska Mn

H2: 2026 Market Trends Forecast for Crown Extrusions, Chaska, MN

As Crown Extrusions in Chaska, Minnesota, looks toward 2026, several key market trends are expected to shape its operational landscape, customer demand, and strategic direction. These trends are driven by broader industry shifts in manufacturing, sustainability, supply chain resilience, and material innovation—particularly within the plastics and custom extrusion sectors.

1. Increased Demand for Sustainable and Recyclable Materials

By 2026, regulatory pressures and consumer preferences are pushing manufacturers toward environmentally responsible practices. Crown Extrusions is likely to see growing demand for bio-based polymers, recyclable resins, and closed-loop recycling solutions. With states like Minnesota advancing clean energy and circular economy goals, the company may invest in material science partnerships or recycling infrastructure to meet green procurement standards in construction, medical, and consumer goods markets.

2. Growth in Medical and Healthcare Extrusion Applications

The healthcare sector continues to be a high-growth area for precision plastic extrusion. By 2026, Crown Extrusions may expand its capabilities in producing medical-grade tubing, catheter components, and single-use devices. Stringent FDA compliance and the localization of medical supply chains post-pandemic will favor domestic manufacturers like Crown, especially with nearshoring trends accelerating.

3. Automation and Smart Manufacturing Integration

To remain competitive and address labor constraints, Crown Extrusions is expected to further adopt Industry 4.0 technologies—such as IoT-enabled extrusion lines, predictive maintenance systems, and AI-driven quality control—by 2026. These advancements will improve production efficiency, reduce waste, and support just-in-time delivery models that clients increasingly require.

4. Supply Chain Localization and Resilience

Global supply chain disruptions have prompted many OEMs to reshore production. By 2026, Crown Extrusions is likely to benefit from regional supply chain reconfiguration, especially in the Midwest’s industrial corridor. Proximity to automotive, agricultural equipment, and appliance manufacturers in Minnesota, Wisconsin, and Iowa positions Crown as a reliable domestic supplier less vulnerable to international logistics delays.

5. Customization and Niche Market Expansion

Clients are demanding more customized profiles, multi-material co-extrusions, and rapid prototyping. Crown may focus on high-mix, low-volume production for specialty applications in renewable energy (e.g., solar panel components), electric vehicles (wire and cable insulation), and smart building systems. This shift supports higher margin contracts and long-term partnerships.

6. Workforce Development and Technical Talent

As automation grows, so does the need for skilled technicians and engineers. Crown Extrusions may deepen collaborations with local technical colleges—such as Ridgewater College or Normandale Community College—to develop training programs that ensure a pipeline of talent equipped for advanced manufacturing roles.

Conclusion

By 2026, Crown Extrusions is poised to leverage macro trends in sustainability, healthcare, and supply chain localization to strengthen its market position. Strategic investments in technology, materials innovation, and workforce development will be critical to maintaining agility and meeting evolving customer needs in a competitive extrusion landscape.

Common Pitfalls When Sourcing from Crown Extrusions in Chaska, MN (Quality and Intellectual Property)

Sourcing aluminum extrusions from Crown Extrusions in Chaska, MN, can offer significant benefits in terms of material quality and manufacturing expertise. However, businesses must be aware of potential pitfalls related to product quality and intellectual property (IP) protection to ensure a successful partnership.

Quality-Related Pitfalls

One major risk in sourcing from any extrusion supplier, including Crown Extrusions, is inconsistent product quality. While Crown Extrusions is known for high standards, variations in alloy composition, dimensional tolerances, or surface finish can occur due to changes in production batches or equipment calibration. Buyers may also face challenges if specifications are not clearly communicated or documented. Without robust quality assurance processes—such as incoming inspections, material certifications (e.g., mill test reports), and routine audits—companies may receive components that fail to meet design or regulatory requirements, leading to production delays or rework.

Additionally, lead time variability and supply chain disruptions can indirectly impact quality. Rush orders may push the supplier to expedite production at the expense of thorough quality checks. Ensuring alignment on quality expectations through detailed specifications and quality control agreements is essential to mitigate these risks.

Intellectual Property (IP) Concerns

Another critical area involves the protection of intellectual property. When sourcing custom extrusion profiles, especially proprietary designs, companies risk exposing sensitive engineering data. Crown Extrusions, like many contract manufacturers, may require CAD files or detailed drawings to produce custom dies and profiles. Without proper legal safeguards—such as non-disclosure agreements (NDAs) and clear ownership clauses in supply contracts—there is potential for misuse or unauthorized replication of designs.

Furthermore, if tooling (e.g., extrusion dies) is funded by the buyer but retained or managed by the supplier, disputes over IP ownership and reuse can arise. It is crucial to define in writing who owns the tooling, whether Crown Extrusions can use the designs for other customers, and how design data is stored and protected.

To avoid these pitfalls, businesses should conduct due diligence, establish clear contractual terms, and maintain ongoing communication with Crown Extrusions to align on both quality standards and IP protections.

Logistics & Compliance Guide for Crown Extrusions – Chaska, MN

Overview

This guide outlines the key logistics procedures and compliance requirements for operations at Crown Extrusions’ facility in Chaska, Minnesota. Adherence to these standards ensures efficient material flow, regulatory compliance, and continued safety and quality in manufacturing.

Shipping & Receiving Procedures

All inbound and outbound shipments must follow documented protocols to maintain inventory accuracy and supply chain continuity. Receiving staff verify purchase order numbers, material specifications, and quantities against delivery manifests. Shipments with discrepancies are documented and reported immediately. Outbound orders are palletized and labeled per customer requirements, including barcodes, lot numbers, and destination details.

Transportation Management

Crown Extrusions works with pre-approved carriers that meet safety, reliability, and insurance standards. Freight is scheduled using the company’s transportation management system (TMS), optimizing load efficiency and delivery timelines. Temperature-controlled and time-sensitive shipments are prioritized and tracked in real time. All drivers must comply with site access rules, including check-in at the security desk and adherence to designated traffic routes.

Inventory Control & Warehouse Operations

The Chaska warehouse operates under a FIFO (First-In, First-Out) system to manage raw materials and finished goods. Inventory counts are conducted weekly, with annual physical audits. All materials are stored according to compatibility and safety guidelines—flammable resins are segregated, and high-value items are secured in restricted access zones. Bin locations are updated in the ERP system immediately after movement.

Regulatory Compliance

Crown Extrusions complies with federal, state, and local regulations, including OSHA, EPA, and DOT standards. Documentation for hazardous materials (if applicable) follows 49 CFR requirements. SDS (Safety Data Sheets) are maintained and accessible. The facility is registered with the Minnesota Department of Health and Pollution Control Agency for applicable environmental permits. Annual compliance training is mandatory for all logistics and operations personnel.

Customs & International Trade (If Applicable)

For international shipments, Crown Extrusions ensures all export documentation, including commercial invoices, packing lists, and certificates of origin, are accurate and compliant with U.S. Customs and Border Protection (CBP) and Harmonized Tariff Schedule (HTS) classifications. The facility utilizes AES (Automated Export System) filings through an authorized freight forwarder. Import activities follow FDA and CBP guidelines for resin and packaging materials.

Quality Assurance & Traceability

Each production lot is traceable from raw material intake through extrusion, finishing, and shipment. Quality checks are performed at receiving and prior to dispatch. Non-conforming materials are quarantined and dispositioned per internal QA procedures. Documentation, including inspection reports and certifications, is archived digitally for a minimum of seven years.

Sustainability & Waste Management

Crown Extrusions follows a zero-landfill initiative at the Chaska location. Scrap materials are recycled in-house or through certified vendors. Waste streams are segregated—plastic regrind, packaging, and hazardous waste are handled according to Minnesota Pollution Control Agency (MPCA) regulations. Monthly waste audits ensure compliance and identify improvement opportunities.

Emergency Preparedness

The facility maintains an updated emergency response plan covering fire, chemical spills, and natural disasters. Spill kits, fire extinguishers, and eyewash stations are inspected monthly. Evacuation routes and assembly points are clearly marked. Logistics personnel participate in biannual emergency drills coordinated with the safety team.

Contact Information & Reporting

For logistics inquiries, contact the Chaska Shipping & Receiving Supervisor at (952) XXX-XXXX or [email protected]. Compliance concerns should be reported to the EHS Manager via the internal compliance portal or hotline. All incidents and near-misses must be documented within 24 hours using the company’s incident reporting system.

In conclusion, sourcing crown extrusions in Chaska, MN offers several advantages, including access to reputable manufacturers, high-quality aluminum extrusion capabilities, and proximity to regional distribution networks. The local industrial infrastructure, skilled workforce, and support for custom fabrication make Chaska a strategic location for businesses seeking reliable and efficient crown molding extrusion solutions. Whether for architectural, residential, or commercial applications, partnering with trusted extruders in Chaska ensures precision, durability, and timely delivery. Conducting thorough supplier evaluations and leveraging local expertise can ultimately enhance product quality and reduce supply chain complexity.