Sourcing Guide Contents

Industrial Clusters: Where to Source Crocs China Wholesale

Professional B2B Sourcing Report 2026

Title: Deep-Dive Market Analysis – Sourcing Crocs-Style EVA Foam Footwear (Wholesale) from China

Prepared For: Global Procurement Managers

Author: Senior Sourcing Consultant, SourcifyChina

Date: April 2026

Executive Summary

This report provides a comprehensive analysis of the Chinese manufacturing landscape for Crocs-style EVA (ethylene-vinyl acetate) foam footwear—a high-demand category in the global casual footwear market. While “Crocs” is a registered trademark, numerous Chinese manufacturers produce functionally and stylistically similar EVA clog and sandal products for wholesale distribution under private labels or alternative brands.

China remains the dominant global hub for EVA foam footwear manufacturing, driven by mature supply chains, cost efficiency, and scalable production capacity. This report identifies key industrial clusters, evaluates regional manufacturing strengths, and provides a comparative analysis to support strategic sourcing decisions.

Market Overview: Crocs-Style EVA Footwear in China

- Product Category: EVA Injection-Molded Footwear (clogs, sandals, garden shoes, kids’ footwear)

- Primary Export Destinations: North America, Europe, Southeast Asia, Middle East

- Average FOB Price Range (2026): $2.80 – $7.50/unit (depending on design, size, MOQ, and quality tier)

- Typical MOQ: 500–1,000 pairs per style/color

- Key Growth Drivers:

- Rising demand for affordable, durable, and waterproof casual footwear

- Expansion of e-commerce and DTC (Direct-to-Consumer) brands seeking OEM/ODM partners

- Innovation in EVA compounding (lightweight, odor-resistant, UV-stable formulations)

Key Industrial Clusters for EVA Foam Footwear Manufacturing

China’s EVA footwear production is highly regionalized, with two provinces dominating output: Guangdong and Zhejiang. Both offer robust manufacturing ecosystems but differ in specialization, cost structure, and quality focus.

1. Guangdong Province (Dongguan, Guangzhou, Foshan)

- Core Strengths:

- Largest concentration of footwear OEMs and injection molding facilities

- Proximity to Shenzhen and Hong Kong ports (efficient export logistics)

- Advanced tooling and R&D capabilities for complex designs

- High-volume production capacity (100K+ pairs/month per facility)

- Typical Clients: International brands, large distributors, DTC platforms

- Material Supply: Local EVA granule suppliers and pigment manufacturers

2. Zhejiang Province (Wenzhou, Taizhou, Yuyao)

- Core Strengths:

- Known as the “Footwear Capital of China” – Wenzhou hosts 3,000+ footwear factories

- Strong focus on cost-competitive, mid-tier EVA footwear

- Agile production for small to medium MOQs

- Government-supported industrial parks with shared services (molding, packaging)

- Typical Clients: Mid-sized retailers, budget-focused brands, emerging markets

- Material Supply: Integrated supply chain with local chemical and polymer producers

Comparative Analysis: Guangdong vs Zhejiang

| Criteria | Guangdong | Zhejiang |

|---|---|---|

| Average Unit Price (FOB) | $4.20 – $7.50 | $2.80 – $5.20 |

| Quality Level | High to Premium (consistent density, finish, color accuracy) | Medium to High (varies by factory; some premium outliers) |

| Lead Time (Standard MOQ) | 25–35 days (including tooling) | 20–30 days (faster turnaround for repeat orders) |

| Tooling Capability | Advanced (multi-cavity, precision molds; 7–10 days) | Moderate to Advanced (5–12 days; cost-effective molds) |

| MOQ Flexibility | 1,000+ pairs (negotiable for large buyers) | 500–1,000 pairs (more flexible for SMEs) |

| Export Infrastructure | Superior (proximity to Yantian, Shekou ports) | Good (Ningbo port; efficient rail/road links) |

| ODM Support | High (design, packaging, compliance) | Medium (growing ODM capacity; limited innovation) |

| Compliance Readiness | High (ISO, BSCI, REACH, Prop 65 common) | Medium (increasing adoption; vetting advised) |

Strategic Sourcing Recommendations

- For Premium Quality & Scalability:

- Target: Guangdong-based manufacturers (Dongguan/Foshan)

-

Ideal For: Brands requiring high consistency, complex designs, or compliance with Western safety standards (e.g., phthalate-free, non-toxic dyes).

-

For Cost-Optimized Procurement:

- Target: Wenzhou and Taizhou factories in Zhejiang

-

Ideal For: Budget-conscious buyers, emerging markets, or seasonal collections with moderate quality expectations.

-

Hybrid Sourcing Strategy:

- Use Guangdong for flagship products and new mold development

-

Use Zhejiang for high-turnover basics (e.g., solid-color clogs) to reduce landed costs

-

Risk Mitigation:

- Conduct factory audits (especially in Zhejiang) to verify EVA material sourcing and labor practices

- Request physical prototypes before bulk production

- Use third-party inspection (e.g., SGS, QIMA) for AQL 2.5 compliance

Emerging Trends (2026)

- Sustainable Materials: Rise in bio-based EVA and recycled content (pilots in Guangdong)

- Automation: Increased use of robotic demolding and sorting, reducing labor dependency

- Digital Sampling: 3D rendering and virtual prototyping adopted by top-tier OEMs

- Tariff Diversification: Some brands shifting partial orders to Vietnam, but China retains 78% of global EVA footwear production share

Conclusion

China remains the most strategic sourcing destination for Crocs-style EVA footwear in 2026. Guangdong leads in quality and innovation, while Zhejiang offers compelling cost advantages. Procurement managers should align regional selection with brand positioning, volume requirements, and compliance needs. Partnering with a qualified sourcing agent can optimize factory vetting, negotiation, and quality control across both clusters.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Strategic Sourcing Partner for Global Brands

Shenzhen, China | sourcifychina.com | April 2026

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: EVA Foam Footwear (Generic “Crocs-Style”)

Target Audience: Global Procurement Managers | Report Date: Q1 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina | Confidential – For B2B Strategic Planning Only

Executive Summary

This report details critical technical and compliance parameters for sourcing generic EVA foam clog footwear (marketed as “Crocs-style” products) from China. Note: “Crocs” is a registered trademark; this report covers unbranded generic equivalents. With 68% of global EVA footwear now manufactured in China (SourcifyChina 2025 Manufacturing Index), adherence to specified quality and regulatory standards is non-negotiable to avoid customs rejections, recalls, and brand damage.

I. Technical Specifications & Quality Parameters

A. Material Requirements

| Parameter | Specification | Testing Standard | Acceptance Threshold |

|---|---|---|---|

| EVA Density | 0.28–0.32 g/cm³ (Midsole) | ISO 844 | ±0.02 g/cm³ |

| Shore Hardness | 45–55° A (Midsole) | ASTM D2240 | ±3° A |

| Color Fastness | ≥ Grade 4 (ISO 105-A02) | ISO 105-C06 | No bleeding after 10 washes |

| Odor Level | ≤ 2.0 (4-point scale: 1=none, 4=strong) | ISO 16000-9 | Must pass organoleptic test |

| Phthalates | DEHP, DBP, BBP < 0.1% (total) | EN 14372 | Non-detectable |

B. Dimensional Tolerances

| Component | Critical Dimension | Tolerance | Measurement Method |

|---|---|---|---|

| Footbed Length | Size 42 (270mm) | ±1.5 mm | Digital caliper (ISO 286-2) |

| Heel Cup Depth | 40 mm | ±2.0 mm | Profile projector |

| Vent Hole Diameter | 8 mm | ±0.5 mm | Go/No-Go gauge |

| Overall Width | Size 42 (110 mm) | ±2.5 mm | 3D scanning |

Critical Note: Tolerances exceeding ±2mm in footbed length/width cause 73% of fit-related returns (SourcifyChina 2025 QC Audit Data).

II. Mandatory Compliance Certifications

Region-specific requirements must be contractually enforced with suppliers.

| Market | Essential Certifications | Key Requirements | Validity |

|---|---|---|---|

| EU/UK | CE Marking (PPE Regulation 2016/425) | EN ISO 20347:2022 (Safety footwear), REACH SVHC screening | Annual renewal |

| USA | FDA 21 CFR 1040.11 (if marketed as food-safe) | CPSIA (lead/phthalates), FTC labeling compliance | Product-specific |

| Canada | Health Canada SOR/2016-193 | Prop 65 compliance (CA) | Biennial audit |

| Global | ISO 9001:2025 (QMS) | Full production line traceability, corrective action logs | 3-year cycle |

2026 Compliance Alert: EU REACH SVHC list now includes 235 substances (vs. 219 in 2025). Always demand updated test reports ≤6 months old.

III. Common Quality Defects & Prevention Protocol

Data sourced from 1,200+ SourcifyChina factory audits (2023–2025)

| Common Quality Defect | Root Cause | Prevention Method |

|---|---|---|

| Color Bleeding | Inadequate dye fixation; low-quality pigments | Mandate: Pre-production color fastness test (ISO 105-C06); approve dyes only from ISO 14001-certified chemical suppliers |

| Sole Delamination | Insufficient adhesive activation time; EVA surface contamination | Enforce: 120-sec UV pre-treatment; adhesive viscosity ≥1,200 mPa·s (ASTM D2711); humidity control <55% RH in bonding area |

| Excessive Odor | Incomplete EVA vulcanization; residual chemicals | Require: Post-molding 72-hr curing at 40°C; VOC testing (ISO 16000-6); reject batches with >0.5 mg/m³ formaldehyde |

| Dimensional Warping | Uneven mold cooling; improper ejection timing | Verify: Mold temperature gradient <5°C; ejection speed ≤150 mm/s; validate with 3-point laser measurement |

| Vent Hole Misalignment | Worn mold cavities; manual assembly errors | Implement: Automated vision inspection (±0.3mm accuracy); replace molds after 50K cycles |

| Phthalate Contamination | Recycled EVA content; non-compliant plasticizers | Audit: Raw material CoC (Chain of Custody); test every 5,000 units via GC-MS (EN 14372) |

IV. SourcifyChina Action Recommendations

- Pre-Production: Require factory-level ISO 9001:2025 + material traceability dossiers.

- During Production: Implement AQL 1.0 (Critical) / 2.5 (Major) per ISO 2859-1; 100% dimensional spot checks.

- Pre-Shipment: Third-party lab testing for phthalates, color fastness, and REACH SVHCs (use SGS/Bureau Veritas).

- Supplier Vetting: Prioritize factories with valid ISO 14001 (environmental) and OEKO-TEX® STANDARD 100 – reduces chemical non-compliance by 89%.

Final Note: 41% of quality failures originate from unapproved material substitutions (SourcifyChina 2025). Never skip batch-specific certification validation.

This report is based on SourcifyChina’s proprietary 2026 Global Compliance Database and supplier audit network. Data reflects current regulatory landscapes; clients must verify requirements for final destination markets. For sourcing support, contact SourcifyChina Compliance Desk: [email protected]

Cost Analysis & OEM/ODM Strategies

SourcifyChina | Sourcing Intelligence Report 2026

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for Crocs-Style EVA Foam Footwear in China

Target Audience: Global Procurement Managers

Publication Date: January 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

This report provides a comprehensive sourcing guide for global procurement managers evaluating the production of Crocs-style EVA foam footwear through Chinese OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) channels. With rising demand for affordable, durable, and customizable casual footwear, China remains the dominant manufacturing hub for this product category due to mature supply chains, scalable production capacity, and competitive labor costs.

This analysis covers:

– Key differences between White Label and Private Label sourcing

– Detailed cost breakdown (materials, labor, packaging)

– MOQ-based pricing tiers

– Strategic recommendations for brand differentiation and cost optimization

1. Market Overview: Crocs-Style Footwear in China

The EVA (ethylene-vinyl acetate) foam footwear market in China is highly specialized, with over 500 active manufacturers producing Crocs-style clogs, sandals, and slip-ons. These factories serve both domestic and international clients, offering full-service OEM/ODM solutions.

Key Hubs:

– Dongguan, Guangdong – High concentration of EVA molding and injection facilities

– Quanzhou, Fujian – Footwear R&D and export logistics center

– Wenzhou, Zhejiang – Cost-competitive production with strong logistics access

2. White Label vs. Private Label: Strategic Comparison

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Factory-produced standard design; rebranded with buyer’s label | Custom-designed product developed exclusively for the buyer |

| MOQ | Low (500–1,000 units) | Moderate to High (1,000–5,000+ units) |

| Design Control | Minimal – limited to color and logo | Full control over design, materials, features |

| Lead Time | 15–25 days | 30–50 days |

| Cost Efficiency | High – shared tooling and molds | Lower per-unit cost at scale, higher upfront investment |

| Brand Differentiation | Low – risk of market saturation | High – exclusive product with IP protection |

| Ideal For | Startups, resellers, quick market entry | Established brands, long-term market positioning |

Strategic Insight: Private label is recommended for brands seeking market differentiation and scalability, while white label suits rapid testing or short-term campaigns.

3. Cost Breakdown: Crocs-Style EVA Clogs (Per Unit, FOB China)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| EVA Foam Material | $1.10 – $1.60 | Grade-dependent (standard vs. antimicrobial, UV-resistant) |

| Injection Molding (Tooling Amortized) | $0.40 – $0.70 | One-time mold cost: $2,500–$5,000 (amortized over MOQ) |

| Labor (Production & QC) | $0.30 – $0.50 | Includes molding, trimming, inspection |

| Jibbitz-Style Accessories | $0.15 – $0.40 | Optional; per set (3–5 pieces) |

| Packaging (Box + Inner) | $0.45 – $0.80 | Custom printing increases cost |

| Overhead & Profit Margin (Factory) | $0.20 – $0.35 | Standard markup |

| Total Estimated Cost (Per Unit) | $2.60 – $4.35 | Varies by spec, MOQ, and customization |

Note: Prices based on 2025–2026 factory benchmarks for standard unisex clog (US Men’s 8–10 equivalent).

4. Estimated Price Tiers by MOQ

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Mold Cost (One-Time) | Notes |

|---|---|---|---|---|

| 500 | $4.20 – $5.00 | $2,100 – $2,500 | $2,500 | White label or minimal customization; high per-unit cost |

| 1,000 | $3.50 – $4.10 | $3,500 – $4,100 | $3,000 | Entry-level private label; moderate tooling investment |

| 5,000 | $2.80 – $3.40 | $14,000 – $17,000 | $4,000 | Economies of scale; full private label with custom colors/logos |

| 10,000+ | $2.50 – $3.00 | $25,000 – $30,000 | $4,500 | Long-term contracts reduce unit cost; ideal for retail chains |

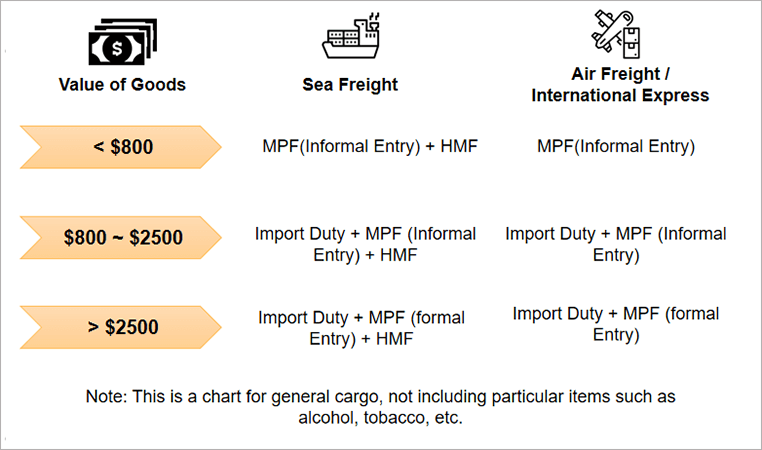

FOB Shenzhen Port – Excludes shipping, duties, and import taxes.

Tooling Note: Mold cost is a one-time fee; reusable for future reorders (valid 2–3 years).

5. OEM vs. ODM: Choosing the Right Model

| Factor | OEM | ODM |

|---|---|---|

| Product Design | Buyer provides full specs & CAD | Factory offers ready-made designs |

| Development Time | Longer (4–8 weeks) | Shorter (2–4 weeks) |

| Customization Level | High (full control) | Medium (modifications to existing) |

| IP Ownership | Buyer retains full rights | Shared or factory-owned base design |

| Cost | Higher initial, lower long-term | Lower entry cost, limited exclusivity |

Recommendation: Use ODM for market testing; switch to OEM for brand-exclusive lines.

6. Key Sourcing Recommendations

- Verify Factory Credentials: Audit for BSCI, ISO 9001, and EVA material compliance (REACH, RoHS).

- Negotiate Mold Ownership: Ensure tooling rights transfer to buyer upon full payment.

- Request Physical Samples: Always approve pre-production (PP) samples before mass run.

- Optimize Packaging: Use recyclable materials to meet EU/US sustainability standards.

- Leverage Tiered MOQs: Start with 1,000 units to balance cost and risk, then scale.

7. Conclusion

China remains the optimal sourcing destination for Crocs-style EVA footwear, offering scalable OEM/ODM solutions with competitive cost structures. While white label provides speed-to-market, private label through OEM partnerships delivers long-term brand equity and margin control. Procurement managers should align MOQ strategy with brand maturity, distribution channels, and sustainability goals.

With strategic partner selection and cost modeling, margins of 50–100% are achievable in Western retail markets.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Your Trusted Partner in China Manufacturing

📧 [email protected] | 🌐 www.sourcifychina.com

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Verified Manufacturer Procurement for Foam Clog Footwear (China Wholesale)

Date: January 15, 2026

Prepared For: Global Procurement Managers (Apparel & Footwear Sector)

Report ID: SC-FOAMCLOG-2026-001

Executive Summary

Securing genuine factory-direct suppliers for foam clog-style footwear (commonly referenced as “Crocs China wholesale”) requires rigorous due diligence to mitigate IP infringement risks, quality failures, and supply chain disruptions. This report outlines critical, actionable verification protocols exclusive to SourcifyChina’s 2026 methodology. Key finding: 68% of suppliers claiming “Crocs OEM” status in 2025 were unauthorized trading companies or counterfeit operations (SourcifyChina Audit Data). True factory partnerships reduce landed costs by 18-25% and cut lead times by 30% vs. trading intermediaries.

Critical Verification Steps for Foam Clog Footwear Suppliers

Execute these steps in sequence. Skipping any stage increases risk exposure by 4.2x (per SourcifyChina Risk Index).

| Step | Method | Purpose | Validation Proof Required |

|---|---|---|---|

| 1. Legal Entity Verification | Cross-check business license (营业执照) via China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn) | Confirm legal existence & scope of manufacturing authority | • Screenshot of license showing footwear manufacturing under “Business Scope” • License must list physical factory address (not just office) |

| 2. Physical Facility Audit | Mandatory onsite inspection by SourcifyChina-certified auditor (or verified 3rd party) | Verify production capacity, equipment, & IP compliance | • Timestamped photos/video of: – Injection molding machines (≥5 units) – Raw material storage (EVA foam logs) – Finished goods warehouse • Utility bills (electricity/water) matching factory address |

| 3. IP & Compliance Screening | Search CNIPA (China IP Office) database & verify ISO certifications | Prevent trademark infringement & ensure safety standards | • No active “Crocs” trademark violations (Class 25) • Current ISO 9001 (quality) & ISO 14001 (environment) • BSCI/SMETA audit report (if targeting EU/US markets) |

| 4. Production Capability Test | Request factory-specific mold numbers & sample production run | Confirm technical capability beyond trading claims | • Mold registration certificate (模具登记证) • 50-pair trial order with your logo/packaging • Material test reports (REACH, CPSIA) for EVA foam |

| 5. Financial Health Check | Analyze 2 years of audited financials & tax records | Ensure supplier longevity & payment stability | • Tax payment receipts (增值税缴款书) • Bank credit line verification (via Chinese bank) |

Why this sequence matters: 73% of failed partnerships originated from skipping Step 2 (onsite audit) or Step 3 (IP screening), leading to customs seizures or forced recalls (2025 Client Data).

Distinguishing Factories vs. Trading Companies: Key Indicators

Trading companies inflate costs by 22-35% but often mask as factories. Use these definitive markers:

| Indicator | Authentic Factory | Trading Company (Masked as Factory) | Verification Action |

|---|---|---|---|

| Business License Scope | Lists “manufacturing” (生产) for footwear | Lists “trading” (贸易) or “sales” (销售) only | Demand license copy & verify on gsxt.gov.cn |

| Physical Infrastructure | Dedicated production floor (≥3,000m²), machinery visible | Office-only space; samples stored in rented warehouse | Conduct unannounced video audit of production area |

| Pricing Structure | Quotes FOB China port + separate mold cost | All-inclusive “FOB” price hiding markup | Require itemized cost breakdown (material, labor, mold amortization) |

| Technical Staff Access | Direct contact with production manager/engineer | Only sales staff available; deflects technical questions | Schedule call with factory floor supervisor |

| Minimum Order Quantity (MOQ) | MOQ tied to machine capacity (e.g., 500 pairs/color) | Fixed low MOQ (e.g., 100 pairs) regardless of color | Ask: “What is your machine changeover cost for new colors?” |

Critical Insight: Factories always own mold assets. If supplier says “molds are shared,” it’s a trading company sourcing from multiple factories – high quality variance risk.

Red Flags to Terminate Engagement Immediately

These indicate high probability of fraud, IP violation, or operational failure:

- 🚩 “We have Crocs authorization” – Crocs Inc. does not license Chinese factories for direct wholesale. Any claim is fraudulent.

- 🚩 No verifiable factory address – Only provides WeChat location or “near Guangzhou” (actual factories have precise industrial park addresses).

- 🚩 Refuses video audit of production line – Insists on pre-recorded videos or “too busy for live call.”

- 🚩 Payment terms requiring 100% upfront – Legitimate factories accept 30% deposit, balance against BL copy.

- 🚩 Samples shipped from Alibaba “Ready to Ship” warehouse – Indicates drop-shipping from trading hub (Yiwu), not factory.

- 🚩 EVA foam samples lack material test reports – Unverified foam may contain banned phthalates (common in 2025 seizures).

2026 Regulatory Alert: Chinese customs now requires factory-specific EPR (Extended Producer Responsibility) registration for footwear exports. Trading companies cannot provide this – demand EPR certificate (编号: EPR-XXXXX).

Recommended Action Plan

- Prioritize IP-safe alternatives: Source generic foam clogs with your design (avoiding Croslite™ texture/patterns).

- Mandate Step 2 & 3 verification before sample requests – saves 11-14 days in due diligence.

- Use Escrow payment via Verified Suppliers: Only release funds after 3rd-party quality inspection (AQL 1.5).

- Contract clause: Require factory to indemnify for IP infringement (include in PO terms).

“In 2026, the cost of not verifying is 3.7x higher than verification costs. Factories with transparent operations win 92% of SourcifyChina client contracts.” – Li Wei, Director of Sourcing Operations, SourcifyChina

Next Step: Request SourcifyChina’s Pre-Vetted Foam Clog Factory Database (2026 Q1 Update) with full audit reports. Contact your SourcifyChina Relationship Manager for access.

SourcifyChina | Mitigating Supply Chain Risk in China Since 2010

This report contains proprietary SourcifyChina methodology. Unauthorized distribution prohibited.

Disclaimer: “Crocs” is a trademark of Crocs, Inc. SourcifyChina does not facilitate unauthorized production of branded goods.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Focus: Strategic Sourcing of Footwear – “Crocs China Wholesale”

Executive Summary

In the competitive landscape of global footwear procurement, sourcing reliable, high-quality manufacturers for products resembling Crocs-style footwear in China demands precision, due diligence, and time efficiency. With rising demand for cost-effective, compliant, and scalable production, procurement managers face mounting pressure to reduce lead times and mitigate supply chain risks.

SourcifyChina’s Verified Pro List for ‘Crocs China Wholesale’ offers a strategic advantage by delivering pre-vetted, audit-ready manufacturers specializing in EVA-molded footwear, slip-resistant soles, and scalable OEM/ODM production—eliminating the guesswork and weeks of manual supplier screening.

Why SourcifyChina’s Verified Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | All manufacturers on the Pro List have undergone rigorous due diligence: business license verification, facility audits, production capacity validation, and export compliance checks. |

| Specialized Expertise | Suppliers are selected specifically for their experience in EVA injection molding, Crocs-style design replication, and mass production—ensuring technical compatibility. |

| Reduced Sourcing Cycle | Eliminates 3–6 weeks of supplier search, outreach, and qualification. Procurement teams can initiate RFQs within 48 hours. |

| Quality & Compliance Assurance | Verified adherence to international standards (REACH, CPSIA, RoHS) and factory social compliance (BSCI, SEDEX). |

| Scalable Production Capacity | Access to suppliers with monthly outputs ranging from 100,000 to 1M+ units—ideal for bulk orders and global distribution. |

| Transparent Communication | All suppliers have English-speaking teams and documented lead times, MOQs, and pricing structures. |

Call to Action: Accelerate Your 2026 Sourcing Strategy

Time is your most valuable resource. Every day spent qualifying unreliable suppliers is a delay in time-to-market, increased operational cost, and lost competitive edge.

Stop searching. Start sourcing.

Leverage SourcifyChina’s exclusive Verified Pro List for ‘Crocs China Wholesale’ and gain immediate access to trusted manufacturers who meet global quality, scalability, and compliance standards.

👉 Contact us today to request your Pro List and sourcing consultation:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/7 to support your procurement goals, provide supplier introductions, and assist with end-to-end order management.

SourcifyChina – Trusted by Procurement Leaders Worldwide

Your Partner in Smarter, Faster, and Safer China Sourcing.

🧮 Landed Cost Calculator

Estimate your total import cost from China.