The global CPVC pipe cutters market is experiencing steady growth, driven by rising demand in residential, commercial, and industrial plumbing applications. According to a report by Mordor Intelligence, the global CPVC pipes and fittings market—closely linked to the demand for specialized cutting tools—was valued at USD 3.6 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This expansion is fueled by increased construction activity, infrastructure development, and the adoption of corrosion-resistant plumbing solutions, particularly in emerging economies. As CPVC usage grows, so does the need for precision cutting tools that ensure clean, burr-free joints essential for system integrity. Leading manufacturers are responding with innovative, durable CPVC pipe cutters tailored for efficiency and reliability. In this evolving landscape, identifying the top seven CPVC pipe cutter manufacturers provides critical insight for contractors, distributors, and procurement professionals seeking high-performance tools aligned with market demands.

Top 7 Cpvc Pipe Cutter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Quick

Domain Est. 1995

Website: ridgid.com

Key Highlights: Rating 4.5 (19) Quick-Acting Tubing Cutters have ergonomic design, I-beam construction, durable surfaces & thrust bearing slide assemblies for easy use. Shop here….

#2 RAPTOR®

Domain Est. 1996

#3 Reed Manufacturing

Domain Est. 1997

Website: reedmfgco.com

Key Highlights: Reed Universal Pipe Cutter (UPC) makes the in-ditch cut for a municipal water project. The UPC handles tough cuts in the trench, underwater or aboveground….

#4 MCC CPVC Plastic Pipe Cutter 1/2″ to 1

Domain Est. 1997

#5 MCC

Domain Est. 2003

Website: mccusainc.com

Key Highlights: MCC Plastic Pipe Cutter makes cutting job much easier by highly efficient leverage mechanism and ergonomic handle….

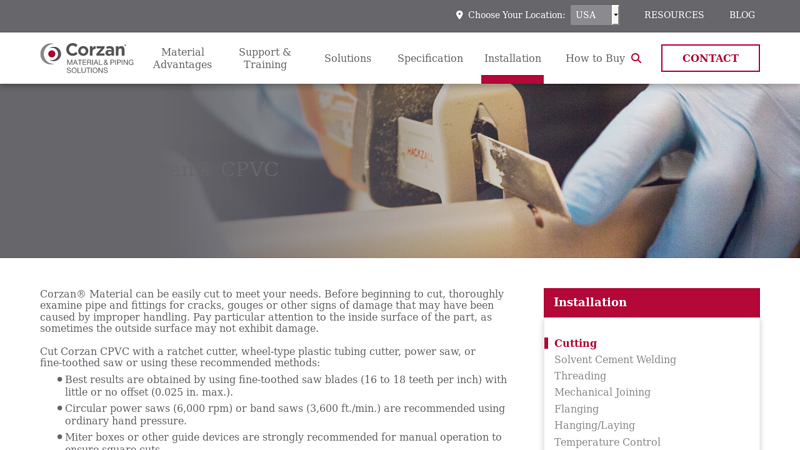

#6 Corzan® CPVC Installation

Domain Est. 2012

Website: corzan.com

Key Highlights: Cut Corzan CPVC with a ratchet cutter, wheel-type plastic tubing cutter, power saw, or fine-toothed saw or using these recommended methods….

#7 Pipe Cutters

Domain Est. 2017

Website: cutwithlenox.com

Key Highlights: Pipe Cutters ; Copper / Plastic Cutting Tubing Cutters. 21013TC258 ; Copper Cutting Tubing Cutters. 21008TC58 ; S2 CPVC Tubing Cutters. 12122S2 ; S1 Pex Tubing ……

Expert Sourcing Insights for Cpvc Pipe Cutter

2026 Market Trends for CPVC Pipe Cutter

The CPVC (Chlorinated Polyvinyl Chloride) pipe cutter market is poised for continued growth and technological evolution by 2026, driven by increasing adoption of CPVC piping systems in construction, plumbing, and industrial applications. Key trends shaping the market include advancements in tool design, rising demand in emerging economies, a focus on efficiency and safety, and the integration of smart technologies.

Growing Demand in Construction and Infrastructure

The global construction boom, particularly in residential, commercial, and industrial sectors across Asia-Pacific, the Middle East, and Africa, is fueling demand for CPVC piping due to its corrosion resistance, ease of installation, and cost-effectiveness. As CPVC replaces traditional materials like copper and galvanized steel, the need for reliable and precise CPVC-specific pipe cutters is increasing. Governments’ investments in infrastructure and water management projects further amplify this trend, directly boosting the market for compatible cutting tools.

Technological Advancements and Tool Innovation

By 2026, CPVC pipe cutters are expected to feature enhanced ergonomics, improved blade materials, and greater durability. Manufacturers are focusing on developing lightweight, one-handed cutters that reduce user fatigue and improve precision. Innovations such as self-adjusting cutting wheels, quick-release mechanisms, and ratcheting designs will become more prevalent, enabling faster and cleaner cuts with minimal burr formation—critical for ensuring leak-free joints in CPVC systems.

Emphasis on Safety and Efficiency

Workplace safety standards are becoming stricter, driving demand for tools that minimize injury risks. CPVC pipe cutters with enclosed blade mechanisms, non-slip grips, and controlled cutting action are gaining favor among professional plumbers and contractors. Additionally, time efficiency remains a priority; tools that deliver consistent, high-speed performance will be preferred, particularly in large-scale installations where labor costs are significant.

Expansion of Smart and Connected Tools

While still in early stages, the integration of smart technologies such as digital measurement guides, Bluetooth connectivity for usage tracking, and IoT-enabled maintenance alerts is emerging. By 2026, premium CPVC cutter models may offer data logging features to support quality control and training, especially in industrial and commercial settings where compliance and documentation are essential.

Regional Market Growth and Competitive Landscape

Asia-Pacific is expected to be the fastest-growing region due to rapid urbanization and expanding construction activities in countries like India, China, and Indonesia. North America and Europe will maintain steady demand, supported by renovation projects and green building initiatives that favor CPVC’s environmental benefits. The competitive landscape will see increased participation from both established tool manufacturers and regional players, leading to product diversification and pricing strategies aimed at different market segments.

In conclusion, the 2026 CPVC pipe cutter market will be characterized by innovation, regional expansion, and a strong alignment with the needs of modern construction and plumbing industries. Stakeholders who prioritize precision, safety, and efficiency in their tool offerings are likely to gain a competitive edge.

Common Pitfalls When Sourcing CPVC Pipe Cutters (Quality and IP)

Sourcing CPVC pipe cutters involves more than just finding a low price—overlooking critical quality and intellectual property (IP) factors can lead to poor performance, safety risks, and legal complications. Below are key pitfalls to avoid:

Poor Build Quality and Material Selection

Many low-cost CPVC pipe cutters use substandard materials such as brittle plastics or low-grade alloys that wear quickly or fracture under pressure. This leads to inconsistent cuts, deformation of the pipe, and shortened tool lifespan. Always verify that the cutter is made from durable materials like hardened steel blades and reinforced housings designed specifically for CPVC’s rigidity.

Inconsistent Cutting Performance

Inferior cutters often fail to produce clean, square cuts, which are essential for proper solvent welding in CPVC systems. Misaligned blades or weak ratcheting mechanisms can cause jagged edges or ovaling, increasing the risk of joint leaks. Ensure the cutter model is tested and certified for CPVC applications and delivers repeatable precision.

Lack of Compliance with Industry Standards

Reputable CPVC pipe cutters should comply with relevant standards such as ASTM D2846 or manufacturer specifications (e.g., ASTM F2160 for plastic pipe tools). Sourcing non-compliant tools may void warranties on CPVC systems and fail inspection during regulatory audits. Verify certifications and performance testing data before procurement.

Intellectual Property (IP) Infringement Risks

Many high-quality CPVC cutters are patented designs from established brands (e.g., Hilmor, Ridgid, or Oatey). Sourcing counterfeit or knockoff tools not only compromises quality but also exposes buyers to legal risks associated with IP violations. These copies often mimic branding and packaging but lack the engineering integrity of genuine products.

Inadequate Supplier Verification

Working with unverified suppliers—especially on open marketplaces—increases exposure to counterfeit goods and supply chain inconsistencies. Always vet suppliers for authenticity, request proof of authorization from original manufacturers, and conduct sample testing before large-scale orders.

Overlooking Ergonomics and Safety Features

Low-quality cutters may lack ergonomic handles or safety guards, increasing user fatigue and accident risk during prolonged use. Poor design can also compromise cutting accuracy. Choose tools designed with user comfort and operational safety in mind.

By focusing on verified quality, adherence to standards, and legitimate IP, buyers can avoid performance failures and legal exposure while ensuring reliable, long-term performance in CPVC installations.

Logistics & Compliance Guide for CPVC Pipe Cutter

Product Classification & Regulatory Requirements

CPVC pipe cutters are typically classified as hand tools used in plumbing and HVAC applications. While the tool itself is not a regulated product like the piping or fittings, compliance considerations include adherence to general safety standards such as those set by OSHA (Occupational Safety and Health Administration) in the U.S. and CE marking requirements in the European Union for mechanical and electrical safety (if applicable). Manufacturers should ensure tools meet ISO 9001 quality management standards and provide clear instructions for safe operation. Additionally, products exported internationally must comply with destination country regulations, including labeling in local languages and adherence to import standards.

Packaging & Labeling Standards

Proper packaging is essential to prevent damage during transit and ensure compliance with shipping regulations. CPVC pipe cuters should be securely packaged in durable materials with cushioning to protect cutting blades and moving parts. Labels must include product identification (model and SKU), manufacturer information, country of origin, safety warnings, and applicable certifications (e.g., CE, UKCA, or ANSI). If shipping to multiple regions, multilingual labeling may be required. Barcodes and SKU labels should be clearly visible for inventory and customs tracking.

Shipping & Transportation Guidelines

When shipping CPVC pipe cutters, standard ground or air freight methods are suitable, depending on urgency and volume. Since these tools are non-hazardous and non-restricted, they can be transported via most carriers (e.g., FedEx, UPS, DHL, or freight services). For international shipments, ensure accurate customs declarations using the appropriate HS Code—typically under 8205 (Other hand tools) or 8203 (Pliers and similar tools), depending on design. Include a commercial invoice, packing list, and bill of lading or air waybill. Declare the correct value, weight, and quantity to avoid delays.

Import & Export Compliance

Exporters and importers must comply with trade regulations in both origin and destination countries. Required documentation typically includes a commercial invoice, certificate of origin, and packing list. Some countries may require import permits or conformity assessments. Ensure compliance with U.S. Export Administration Regulations (EAR) or equivalent in other jurisdictions, although CPVC pipe cutters generally fall under low-risk categories. Sanctions screening and adherence to anti-boycott provisions are also recommended.

Storage & Inventory Management

Store CPVC pipe cutters in a dry, temperature-controlled environment to prevent corrosion or damage to cutting blades. Organize inventory using a first-in, first-out (FIFO) system to maintain product quality. Use barcode or RFID systems for accurate tracking. Ensure warehouse staff are trained in handling procedures to avoid accidental damage. Regularly audit stock levels and reconcile with digital inventory records to support efficient order fulfillment.

End-of-Life & Environmental Considerations

While CPVC pipe cutters are durable, end-of-life disposal should follow local e-waste or metal recycling guidelines if the tool contains electronic components. For manual-only models, metal parts can typically be recycled through scrap metal programs. Provide end-users with disposal recommendations in product documentation. Manufacturers are encouraged to design for disassembly and recyclability to support sustainability goals and comply with extended producer responsibility (EPR) regulations in certain regions.

Conclusion for Sourcing CPVC Pipe Cutter:

Sourcing a reliable and efficient CPVC pipe cutter is essential for ensuring clean, precise cuts and maintaining the integrity of CPVC piping systems, especially in plumbing and industrial applications. After evaluating various options, it is clear that selecting the right tool involves considering factors such as cutting capacity, durability, ease of use, and cost-effectiveness. Manual ratchet cutters offer affordability and portability for light-duty tasks, while heavy-duty rotary or chain cutters are preferable for larger-scale or commercial projects. It is recommended to source from reputable suppliers or manufacturers that offer quality certifications, warranty support, and compatibility with standard CPVC pipe sizes. Additionally, prioritizing ergonomic design and safety features enhances user experience and reduces the risk of injury. Ultimately, investing in a high-quality CPVC pipe cutter not only improves work efficiency but also contributes to long-term project success and system reliability.