The global cotton textile market continues to expand, driven by rising consumer demand for breathable, sustainable, and comfortable apparel. According to a report by Mordor Intelligence, the global cotton fabric market was valued at USD 5.87 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2029. This growth is fueled by increasing investments in sustainable cotton production and advancements in fabric finishing technologies, particularly in the apparel sector. As shirts remain a staple in both formal and casual wardrobes, manufacturers specializing in high-quality cotton materials are playing a pivotal role in meeting evolving market needs. From combed and ring-spun cotton to organic and blended variants, innovation in fabric construction has become a key differentiator among leading suppliers. This landscape has given rise to a select group of manufacturers who combine scale, sustainability, and technical expertise to dominate the shirt fabric segment. Below, we explore the top nine cotton material manufacturers for shirts that are shaping the future of textile innovation and garment performance.

Top 9 Cotton Material For Shirts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

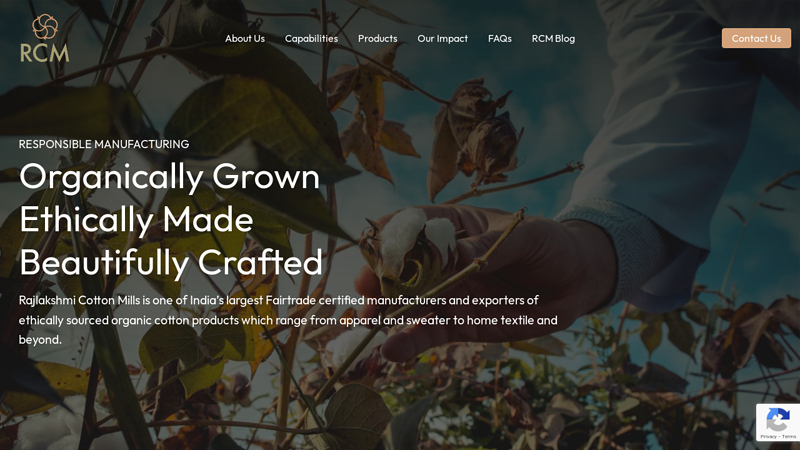

#1 Rajlakshmi Cotton Mills Pvt Ltd

Domain Est. 2018

Website: rcm-organic.co

Key Highlights: Rajlakshmi Cotton Mills is one of India’s largest Fairtrade certified manufacturers and exporters of ethically sourced organic cotton products….

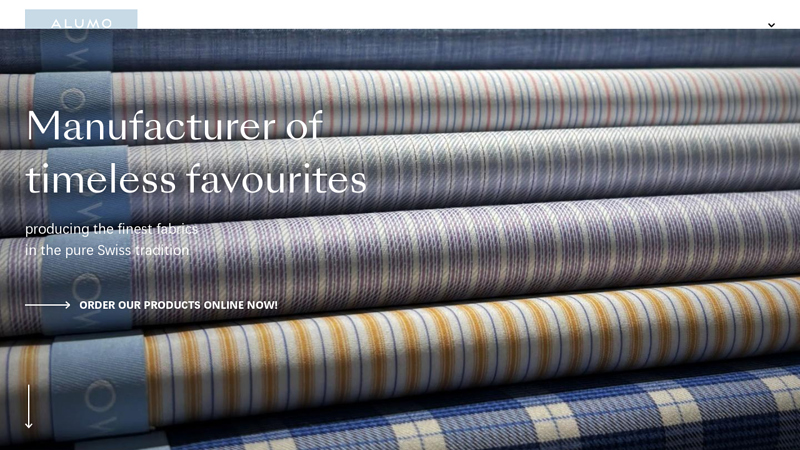

#2 ALUMO

Website: alumo.ch

Key Highlights: Based in Switzerland, ALUMO is a leading manufacturer of quality cotton shirting fabrics, inspiring tailors and brands worldwide through its unique art of ……

#3 Cotton Incorporated

Domain Est. 1996

Website: cottoninc.com

Key Highlights: Cotton Incorporated is the research and marketing company representing US upland cotton, funded by US cotton growers and importers of cotton ……

#4 U.S. Cotton – The Cotton the World Trusts

Domain Est. 1996

Website: cottonusa.org

Key Highlights: US cotton is proof. High quality. Constant innovation. The most rigorous product standards in the industry. Sustainable. Premium. And backed with programs, ……

#5 Robert Kaufman Fabrics

Domain Est. 1997 | Founded: 1942

Website: robertkaufman.com

Key Highlights: Wholesale supplier of quality textiles and fabrics for quilting, fashion and manufacturing since 1942….

#6 Spiritex USA Made Organic Cotton Fabric

Domain Est. 2003

Website: spiritex.net

Key Highlights: WHERE IS YOUR FABRIC MADE? Our fabric is spun, knit, and finished by various mills all located within 150 miles of our Asheville, NC headquarters….

#7 Elliott Berman Textiles: High

Domain Est. 2008

Website: elliottbermantextiles.com

Key Highlights: Free delivery 15-day returnsElliott Berman Textiles is your destination for exclusive, high-end apparel fabrics from Italy and France … WOVEN COTTON FABRICS · DESIGNER FABRICS….

#8 Wholesale Clothing Distributors

Domain Est. 2011

Website: bellacanvas.com

Key Highlights: Free delivery over $200 7-day returnsWholesale blank tee shirts perfect for custom printing. T- Shirts, tanks, polo shirts, hoodies, fleece, tri blend, and Heathers in all popular …

#9 CottonWorks™

Domain Est. 1997

Website: cottonworks.com

Key Highlights: CottonWorks™ by Cotton Incorporated is dedicated to increasing the demand for and profitability of cotton through research and promotion. CottonWorks™ serves as ……

Expert Sourcing Insights for Cotton Material For Shirts

2026 Market Trends for Cotton Material for Shirts

The cotton fabric market for shirts is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and increasing emphasis on sustainability. Here are the key trends shaping the industry:

Rising Demand for Sustainable and Organic Cotton

By 2026, sustainability will be a dominant force in the cotton shirt market. Consumers are increasingly favoring eco-conscious apparel, leading to a surge in demand for organic cotton, which is grown without synthetic pesticides or fertilizers. Certifications like GOTS (Global Organic Textile Standard) will become critical differentiators. Brands are expected to increase their use of recycled cotton and invest in regenerative agriculture practices to reduce environmental impact and meet corporate ESG goals.

Innovation in Cotton Blends and Performance Fabrics

To enhance functionality, manufacturers are integrating cotton with performance fibers such as TENCEL™, modal, and recycled polyester. These blends improve moisture-wicking, wrinkle resistance, and durability—features highly valued in both casual and workwear shirts. By 2026, smart cotton blends with antimicrobial or temperature-regulating properties are anticipated to gain traction, especially in the premium and athleisure-inspired shirt segments.

Digitalization and Supply Chain Transparency

Blockchain and digital traceability tools will play a crucial role by 2026 in verifying cotton origins and ethical sourcing. Consumers and retailers alike will demand transparent supply chains, pushing brands to adopt technologies that provide real-time tracking from farm to finished garment. This shift enhances trust and supports compliance with upcoming regulations on forced labor and environmental disclosures.

Regional Shifts in Production and Sourcing

Geopolitical dynamics and supply chain resilience concerns will influence cotton sourcing strategies. While India and China remain key producers, countries like Turkey, Bangladesh, and Vietnam are investing in sustainable cotton processing. Nearshoring and regional sourcing models will grow, especially for Western brands aiming to reduce lead times and carbon footprints.

Price Volatility and Climate Change Impact

Cotton prices are expected to remain volatile due to climate change affecting crop yields in major producing regions. Droughts, floods, and shifting weather patterns may constrain supply, prompting investment in climate-resilient cotton varieties and improved irrigation techniques. Brands will likely adopt hedging strategies and long-term sourcing contracts to manage cost fluctuations.

Growth of Direct-to-Consumer and Customization

The rise of DTC (Direct-to-Consumer) fashion brands will continue to influence cotton shirt demand, with an emphasis on high-quality, customizable basics. By 2026, digital platforms enabling personalized fit, fabric choice, and design will drive demand for flexible, small-batch cotton fabric production, favoring agile manufacturers and digital textile printers.

In conclusion, the 2026 cotton shirt material market will be defined by sustainability, innovation, and transparency. Success will depend on adaptability, ethical sourcing, and the ability to meet increasingly sophisticated consumer expectations.

Common Pitfalls Sourcing Cotton Material for Shirts (Quality, IP)

Sourcing cotton fabric for shirts involves navigating several challenges that can impact both product quality and intellectual property (IP) protection. Avoiding these common pitfalls is essential for maintaining brand reputation, ensuring customer satisfaction, and safeguarding business interests.

Quality Inconsistencies

One of the most frequent issues in cotton sourcing is inconsistent fabric quality across batches. Factors such as variations in cotton fiber length (staple), yarn count, dyeing processes, and finishing treatments can lead to differences in softness, shrinkage, color fastness, and durability. Sourcing from suppliers without strict quality control systems often results in garments that appear or feel different from one production run to the next, undermining brand consistency.

Misrepresentation of Cotton Type

Suppliers may falsely advertise cotton as premium varieties such as Egyptian, Pima, or Supima®—which are known for superior softness and strength—when in reality, the fabric is made from lower-grade cotton. This mislabeling not only affects shirt performance and customer satisfaction but can also lead to legal and reputational risks, especially if marketing claims are proven false.

Lack of Traceability and Certification

Without clear traceability and third-party certifications (e.g., Organic Content Standard, BCI, GOTS), brands risk sourcing cotton from unethical or environmentally harmful supply chains. This lack of transparency can lead to consumer backlash, especially as sustainability becomes a growing concern. Moreover, undefined sourcing paths make it difficult to verify quality claims or respond to audits.

Poor Shrinkage and Wrinkle Resistance

Some cotton fabrics, particularly those with low thread counts or inferior finishing, are prone to excessive shrinkage or wrinkling after washing. This affects the garment’s fit and appearance over time. Buyers who overlook technical specifications such as shrinkage tolerance (typically 3–5%) or wrinkle recovery ratings may end up with shirts that disappoint customers post-purchase.

Intellectual Property (IP) Risks in Fabric Design

When sourcing patterned or branded cotton fabrics (e.g., unique prints, jacquards, or licensed designs), there’s a risk of inadvertently using protected designs. Suppliers may offer “inspired” versions of well-known patterns, which could infringe on trademarks or copyrights. Brands may face legal action or be forced to destroy inventory if IP violations are discovered, leading to financial losses and damage to credibility.

Unverified Supplier Claims

Suppliers may make unsubstantiated claims about fabric performance, such as “anti-microbial,” “moisture-wicking,” or “UV-protective,” without providing test reports or certifications. These functional claims often require chemical treatments or specialized weaves. Without proper verification, brands risk false advertising and non-compliance with consumer protection regulations.

Hidden Costs from Minimum Order Quantities (MOQs)

Suppliers may offer attractive per-meter prices but enforce high MOQs that lead to overstocking or financial strain, especially for small or emerging brands. Additionally, low initial pricing may be tied to lower-quality cotton or outdated inventory, resulting in compromised shirt quality.

Inadequate Testing and Sampling Protocols

Skipping or rushing fabric sampling and lab testing increases the risk of quality failures. Without proper testing for colorfastness, pilling, tensile strength, and fabric weight, brands may not discover defects until after mass production, resulting in costly reworks or recalls.

Avoiding these pitfalls requires due diligence: vetting suppliers thoroughly, demanding certifications, conducting independent lab tests, ensuring IP compliance, and building long-term relationships based on transparency and accountability.

Logistics & Compliance Guide for Cotton Material for Shirts

Overview of Cotton Material in Apparel Supply Chain

Cotton is one of the most widely used natural fibers in the apparel industry, especially for manufacturing shirts due to its comfort, breathability, and durability. However, the logistics and compliance aspects of sourcing, transporting, and processing cotton involve multiple regulatory, environmental, and operational considerations. This guide outlines key steps and requirements for managing cotton material logistics and ensuring compliance across the supply chain.

Sourcing and Procurement Compliance

Ethical and Sustainable Sourcing

Ensure cotton is sourced from farms and suppliers that adhere to ethical labor practices and environmental sustainability standards. Preferred certifications include:

– Organic Content Standard (OCS)

– Global Organic Textile Standard (GOTS)

– Better Cotton Initiative (BCI)

– Fair Trade Certified

These certifications help verify that cotton is grown without harmful pesticides, with fair wages, and in environmentally responsible conditions.

Supplier Due Diligence

Conduct audits and assessments of cotton suppliers to confirm compliance with:

– Local and international labor laws

– Environmental regulations

– Anti-dumping and forced labor prohibitions (e.g., UFLPA for imports from Xinjiang, China)

Maintain documentation such as supplier agreements, certificates of origin, and audit reports.

International Trade Regulations and Documentation

Import/Export Documentation

Key documents required for cross-border movement of cotton material:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Phytosanitary Certificate (if required by destination country)

– Import licenses or permits (e.g., USDA regulations for U.S. imports)

Tariff Classification and Duties

Cotton fabric and yarn are classified under the Harmonized System (HS Code). Common codes include:

– 5208: Woven fabrics of cotton, in the piece

– 5209: Woven fabrics of cotton, of a weight > 200 g/m²

Check applicable tariffs, trade agreements (e.g., USMCA, EU GSP), and rules of origin to optimize duty costs.

Compliance with Forced Labor Laws

Many countries, including the United States, have strict regulations against importing goods made with forced labor:

– Uyghur Forced Labor Prevention Act (UFLPA): Presumes cotton from Xinjiang, China, is made with forced labor. Importers must provide clear and convincing evidence to rebut this presumption.

– Maintain full traceability from farm to fabric through supply chain mapping and third-party verification.

Logistics and Transportation

Mode of Transport

Depending on volume and urgency, cotton fabric can be transported via:

– Sea Freight: Cost-effective for large volumes; use 20’ or 40’ dry containers.

– Air Freight: For urgent shipments of sample materials or small batches.

– Land Freight: For regional movement (e.g., within North America or Europe).

Ensure proper packaging to prevent moisture, contamination, and physical damage.

Storage and Handling

- Store cotton fabric in dry, temperature-controlled warehouses to prevent mildew and fiber degradation.

- Use pallets and protective wrapping to avoid contamination.

- Implement FIFO (First In, First Out) inventory practices.

Lead Times and Planning

Account for:

– Harvesting and ginning cycles (typically 6–8 months from planting to fabric)

– Spinning and weaving lead times (4–12 weeks)

– Shipping durations (2–6 weeks by sea)

Plan procurement cycles accordingly to avoid production delays.

Quality Control and Testing

Pre-Shipment Inspections

Conduct quality checks for:

– Fabric weight (g/m²)

– Thread count and weave density

– Color fastness and shrinkage

– Pilling resistance and tensile strength

Use third-party inspection agencies (e.g., SGS, Bureau Veritas) for validation.

Compliance Testing

Ensure cotton materials meet:

– REACH (EU regulation on chemicals)

– OEKO-TEX Standard 100 (harmful substance testing)

– FDA guidelines (for products in contact with skin in the U.S.)

Retain test reports for audits and customs clearance.

Environmental and Sustainability Compliance

Carbon Footprint and Water Usage

Cotton farming is water-intensive. Encourage suppliers to adopt:

– Water-efficient irrigation (e.g., drip systems)

– Rainwater harvesting

– Water recycling in processing

Monitor and report environmental impact metrics as part of ESG (Environmental, Social, Governance) reporting.

Waste Management and Recycling

Ensure fabric scraps and production waste are:

– Collected and recycled where possible

– Disposed of in compliance with local environmental laws

Promote circular economy practices such as using recycled cotton blends.

Labeling and Traceability

Fiber Content Labeling

Comply with textile labeling regulations in target markets:

– U.S. (FTC): Requires disclosure of fiber composition and country of origin.

– EU (Textile Regulation (EU) No 1007/2011): Mandates accurate fiber names and percentages.

– UK, Canada, Australia: Similar requirements with specific language rules.

Supply Chain Traceability

Implement systems (e.g., blockchain, QR codes) to track cotton from farm to finished shirt. This supports:

– Consumer transparency

– Regulatory compliance

– Rapid response to recalls or audits

Risk Mitigation Strategies

Diversify Supply Sources

Avoid overreliance on single regions to reduce risks from climate, political instability, or trade restrictions.

Monitor Regulatory Changes

Subscribe to trade alerts and work with customs brokers to stay updated on:

– New import bans

– Tariff adjustments

– Environmental regulations

Maintain Compliance Records

Keep a centralized digital repository of:

– Certifications

– Test reports

– Customs filings

– Audit results

Essential for due diligence defense and corporate compliance programs.

Conclusion

Managing the logistics and compliance of cotton material for shirts requires a proactive, well-documented approach across sourcing, transportation, regulatory adherence, and sustainability. By investing in certified suppliers, robust logistics planning, and transparent traceability systems, apparel brands can ensure high-quality production while meeting global compliance standards and consumer expectations.

In conclusion, sourcing cotton material for shirts requires a careful balance between quality, sustainability, cost, and supply chain reliability. High-quality cotton, such as Egyptian, Pima, or organic cotton, enhances the comfort, durability, and overall appeal of the shirts, contributing to customer satisfaction and brand reputation. Sustainable and ethically sourced cotton not only supports environmental conservation but also meets the growing consumer demand for responsible fashion. Establishing strong relationships with reputable suppliers, conducting regular quality assessments, and considering certifications like GOTS or BCI can ensure transparency and consistency in the sourcing process. Ultimately, a strategic and responsible cotton sourcing approach positions the brand for long-term success in a competitive market while aligning with environmental and ethical standards.