The global cotton harvesting machinery market is experiencing robust growth, driven by rising demand for mechanized agriculture, labor shortages, and the need for higher operational efficiency in cotton production. According to a report by Mordor Intelligence, the agricultural machinery market—encompassing cotton harvesters—is projected to grow at a CAGR of over 5.2% from 2024 to 2029. Cotton, being one of the most widely cultivated non-food crops, accounts for a significant share of this expansion, particularly in key producing regions such as the United States, India, China, and Brazil. Grand View Research further highlights that the global cotton harvesting equipment market is expected to benefit from increasing farm consolidation and advancements in precision farming technologies, including GPS-guided systems and automated controls. In this evolving landscape, a select group of manufacturers lead innovation, production volume, and technological integration. Here are the top six cotton harvesting machine manufacturers shaping the future of cotton farming worldwide.

Top 6 Cotton Harvesting Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cotton

Domain Est. 1990

Website: deere.com

Key Highlights: Learn about cotton pickers and strippers from John Deere and discover larger capacity, integrated technology, and improved productivity….

#2 From Field to Fabric

Domain Est. 1994

Website: cotton.org

Key Highlights: Cotton is machine harvested in the US, beginning in July in south Texas and in October in more northern areas of the Belt….

#3 Harvesting Equipment

Domain Est. 1995

Website: caseih.com

Key Highlights: Equipment built to perform with the speed and efficiency that farmers demand for a successful harvest. With the Axial-Flow® range and a wide choice of headers….

#4 Stripper Harvesting

Domain Est. 1996

Website: cottoninc.com

Key Highlights: Stripper-type harvesters were developed as a cost-effective alternative to hand pulling for harvesting cotton with short plant heights, relatively low yield ……

#5 Harvesting

Domain Est. 1996

Website: agcocorp.com

Key Highlights: AGCO’s combine harvesters are designed with three critical features in mind: efficiency, visibility and comfort. Easy to use and extremely durable, ……

#6 Orchard Machinery Corporation

Domain Est. 1997

Website: shakermaker.com

Key Highlights: OMC offers a full line of tree shakers, shuttles, carts, and tree nut and fruit harvesting solutions to meet the needs of modern growers around the world….

Expert Sourcing Insights for Cotton Harvesting Machine

Cotton Harvesting Machine Market Trends in 2026

Rising Demand Driven by Agricultural Mechanization

The global cotton harvesting machine market is projected to experience significant growth by 2026, primarily fueled by the increasing mechanization of agriculture. As labor costs rise and the availability of skilled farm labor declines—especially in major cotton-producing countries like India, the United States, and China—farmers are turning toward mechanized harvesting solutions to maintain productivity and efficiency. Cotton harvesting machines, including spindle pickers and brush-roll strippers, offer faster harvest cycles, reduced crop loss, and improved fiber quality compared to manual picking. This shift is particularly evident in developing economies where government subsidies and agricultural modernization programs are accelerating the adoption of advanced machinery.

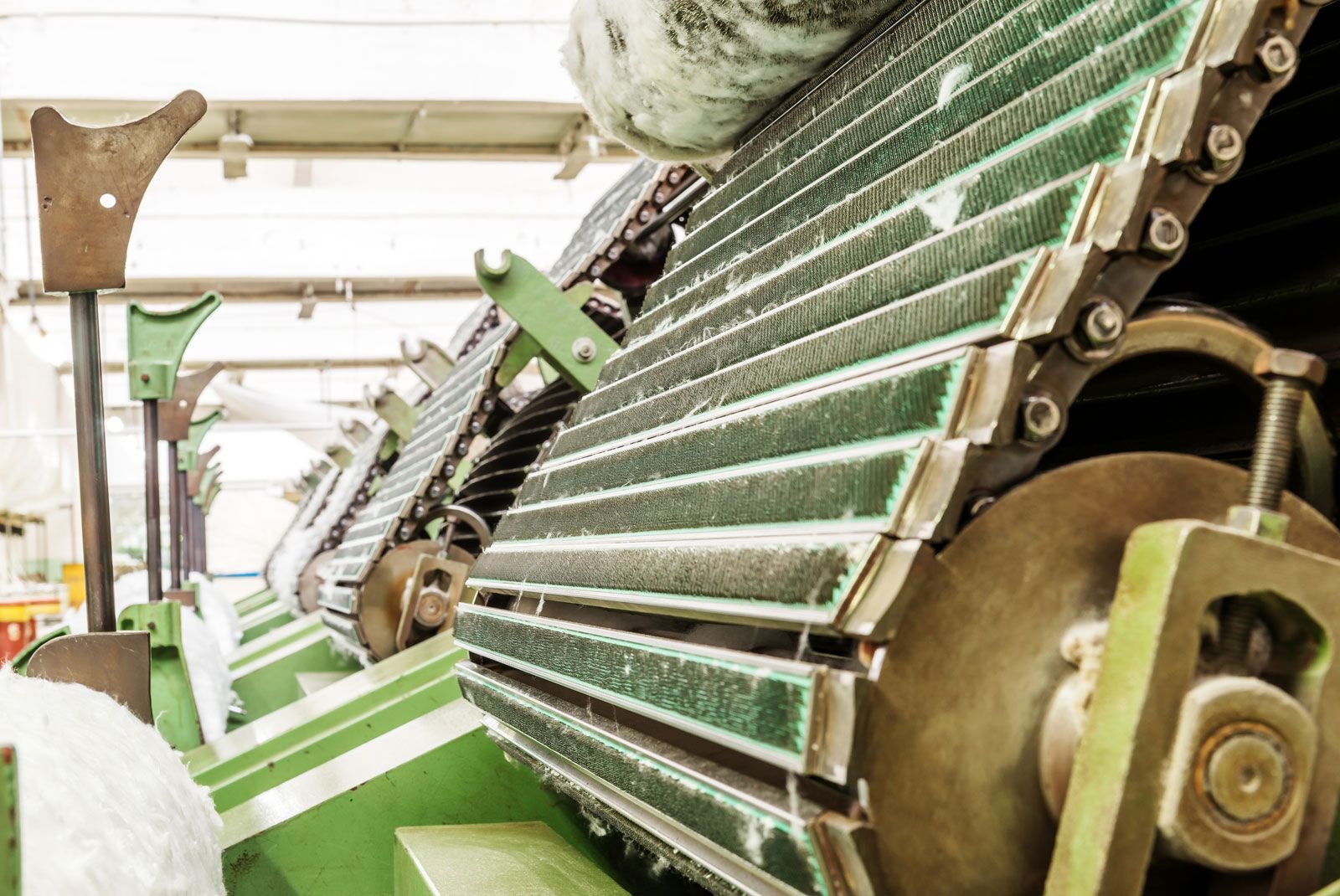

Technological Advancements and Automation

By 2026, technological innovation is expected to play a pivotal role in shaping the cotton harvesting machine market. Manufacturers are integrating automation, GPS-guided navigation, real-time yield monitoring, and IoT-enabled diagnostics into modern harvesters. These features enhance precision farming, allowing operators to optimize harvesting routes, monitor crop health, and minimize field overlap. Additionally, the development of electric and hybrid-powered harvesters is gaining momentum as sustainability becomes a priority in agriculture. Companies such as John Deere, Case IH, and CLAAS are leading the charge with smart harvesting systems that sync with farm management software, enabling data-driven decisions and improved operational efficiency.

Regional Growth Dynamics

The market growth in 2026 will vary significantly by region. North America, particularly the U.S., will continue to dominate due to large-scale cotton farms and high mechanization rates. Meanwhile, Asia-Pacific—especially India and China—is expected to witness the fastest growth, driven by rising farm incomes, government support for mechanization, and increasing pressure to boost cotton yields. In Africa, countries like Sudan and Tanzania are beginning to adopt mechanized cotton harvesting, supported by international development programs focused on agricultural productivity. Latin America, led by Brazil, will also contribute to market expansion as cotton cultivation areas grow and farmers seek cost-effective harvesting solutions.

Sustainability and Environmental Considerations

Environmental concerns are shaping the design and deployment of cotton harvesting machines in 2026. There is a growing emphasis on fuel-efficient engines, reduced soil compaction through improved machine design, and lower emissions. Additionally, precision harvesting technologies help minimize waste and over-harvesting, supporting sustainable cotton production. Certifications like the Better Cotton Initiative (BCI) are influencing machinery manufacturers to develop equipment that aligns with sustainable farming practices, thereby appealing to eco-conscious buyers and global supply chains.

Challenges and Market Barriers

Despite the positive outlook, several challenges could hinder market growth. High initial investment costs remain a barrier, especially for smallholder farmers in developing nations. Limited access to financing and lack of technical training for operating advanced machinery also restrict widespread adoption. Moreover, regional variations in farm size, cotton variety, and field conditions require customized machine solutions, complicating mass production and scalability. Addressing these issues through affordable leasing models, government incentives, and localized support services will be critical for market penetration.

Conclusion

By 2026, the cotton harvesting machine market is poised for transformation, driven by technological innovation, rising mechanization, and sustainability imperatives. While challenges remain, especially in emerging markets, strategic investments and policy support are expected to unlock new growth opportunities. As cotton producers worldwide strive for higher efficiency and lower environmental impact, advanced harvesting machinery will become an indispensable component of modern agriculture.

Common Pitfalls When Sourcing Cotton Harvesting Machines (Quality and Intellectual Property)

Sourcing cotton harvesting machines, especially from international or unfamiliar suppliers, presents several risks related to both machine quality and intellectual property (IP) rights. Being aware of these pitfalls can help avoid costly mistakes and operational disruptions.

Poor Build Quality and Substandard Components

One of the most frequent issues is receiving machines constructed with inferior materials or substandard components. Low-quality steel, weak hydraulics, or poorly engineered picking mechanisms can lead to frequent breakdowns, reduced harvesting efficiency, and higher maintenance costs. Machines not built to withstand harsh field conditions may fail prematurely, disrupting harvest schedules and increasing total cost of ownership.

Inaccurate or Inflated Performance Specifications

Suppliers may exaggerate machine performance metrics such as harvesting speed, capacity, or fuel efficiency. Without independent verification or third-party testing data, buyers risk acquiring equipment that underperforms in real-world conditions. This can result in missed harvest windows, lower yields, and financial losses.

Lack of Compliance with Safety and Emissions Standards

Cotton harvesters must comply with regional safety and environmental regulations (e.g., EPA in the U.S., CE in Europe). Sourcing machines that do not meet these standards can lead to legal penalties, import restrictions, or operational shutdowns. Buyers should verify certification documentation and ensure that the machines are approved for use in their target market.

Counterfeit or Copycat Equipment Infringing IP Rights

A significant IP-related risk is purchasing machines that replicate patented designs, technologies, or brand elements without authorization. These counterfeit or clone machines may mimic well-known brands but lack proper licensing. Using such equipment can expose the buyer to legal liability, including cease-and-desist orders, fines, or seizure of assets, especially if the original IP holder takes enforcement action.

Use of Unauthorized Proprietary Technology

Some suppliers incorporate proprietary harvesting mechanisms, automation software, or sensor systems protected by patents or trade secrets. If a machine uses such technology without proper licensing, the end-user may become entangled in intellectual property disputes. This is particularly common with advanced features like GPS-guided harvesting or automated cotton module building.

Inadequate Documentation and Lack of Traceability

Poor or missing technical documentation—such as assembly manuals, parts lists, or IP disclaimers—can signal that the machine is built without proper authorization. A lack of traceability in the supply chain increases the risk of unknowingly purchasing equipment that infringes on existing patents or trademarks.

Limited After-Sales Support and Spare Parts Availability

Even if a machine initially appears high-quality, sourcing from disreputable suppliers often means limited access to genuine spare parts, technical support, or service networks. This can lead to extended downtime during critical harvest periods. Additionally, using non-OEM parts may void warranties and further compromise machine integrity.

Failure to Conduct Due Diligence on Supplier IP Status

Buyers often overlook verifying whether the supplier holds legitimate rights to manufacture and sell the equipment. Conducting IP due diligence—such as checking patent databases, trademark registries, and supplier credentials—can prevent legal entanglements and ensure long-term operational security.

Avoiding these pitfalls requires thorough supplier vetting, independent quality inspections, and legal review of IP rights before finalizing procurement.

Logistics & Compliance Guide for Cotton Harvesting Machine

Overview

This guide outlines the essential logistics and compliance considerations for the international shipment and operation of cotton harvesting machines. These large agricultural equipment units require careful planning to ensure timely delivery, regulatory adherence, and operational readiness.

Classification & Documentation

Cotton harvesting machines are typically classified under the Harmonized System (HS) code 8433.51 (Harvesting or threshing machinery, for agricultural use). Accurate classification is crucial for customs clearance, duty calculation, and import/export compliance. Required documentation includes:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Import/Export Licenses (if applicable)

– Equipment Conformity Certificates (e.g., CE, EPA, or equivalent)

Export Controls & Regulations

Ensure compliance with export control regulations such as the U.S. Export Administration Regulations (EAR) or equivalent in your jurisdiction. While cotton harvesters are generally not controlled for national security reasons, verify if any embedded technology (e.g., GPS, automation systems) requires licensing. Screen end-users against denied party lists.

Transportation Logistics

Due to size and weight, cotton harvesting machines are typically shipped via:

– Breakbulk or Ro-Ro (Roll-on/Roll-off) vessels for international ocean freight

– Flatbed or lowboy trailers for domestic overland transport

Proper securing, route planning (avoiding low bridges, weight-restricted roads), and permits for oversized loads are mandatory. Pre-shipment inspection for roadworthiness is recommended.

Import Compliance

Importing countries may impose:

– Import tariffs based on HS code 8433.51

– Agricultural equipment standards (e.g., safety, emissions)

– Phytosanitary or customs inspections to prevent soil or plant material transfer

Consult local agricultural or customs authorities to confirm requirements in the destination country.

Assembly & Field Preparation

Machines are often shipped in disassembled or folded configurations. Follow manufacturer guidelines for reassembly, safety checks, and pre-harvest testing. Ensure trained technicians are available for setup and operator training.

Environmental & Safety Compliance

Adhere to environmental regulations regarding:

– Fuel and hydraulic fluid handling

– Noise emissions (OSHA or local standards)

– Operator safety standards (e.g., roll-over protection, emergency stops)

Verify compliance with destination country’s machinery safety directives (e.g., EU Machinery Directive 2006/42/EC).

Maintenance & Spare Parts Logistics

Establish a supply chain for spare parts and maintenance support. Include critical components in initial shipments and maintain an inventory plan aligned with harvesting cycles. Provide multilingual service manuals and technical support access.

Conclusion

Successfully managing the logistics and compliance of cotton harvesting machines requires coordination across shipping, customs, regulatory, and operational domains. Early planning, accurate documentation, and adherence to international and local standards are essential for smooth deployment and legal operation.

In conclusion, sourcing a cotton harvesting machine is a strategic investment that can significantly enhance operational efficiency, reduce labor dependency, and improve the overall productivity of cotton farming operations. The decision should be based on a thorough evaluation of factors such as farm size, budget, terrain conditions, and the level of automation required. Whether opting for a spindle picker, brush-roll harvester, or stripper-type machine, it is essential to select a model that aligns with specific agricultural needs and local growing conditions.

Additionally, considering the long-term benefits—such as reduced harvesting time, lower operational costs, and improved cotton quality—justifies the initial capital outlay. Sourcing from reputable manufacturers or suppliers with reliable after-sales support, spare parts availability, and service networks ensures the longevity and optimal performance of the machinery.

Furthermore, exploring government subsidies, financing options, and potential collaborations with agricultural cooperatives can make the acquisition more feasible for small to medium-scale farmers. Ultimately, adopting mechanized cotton harvesting not only supports sustainable farming practices but also positions producers competitively in the evolving global cotton market.