The global demand for durable and efficient water storage solutions has fueled significant growth in the corrugated metal water tanks market, driven by increasing urbanization, agricultural needs, and infrastructure development across emerging economies. According to Grand View Research, the global water storage tank market was valued at USD 43.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Corrugated metal tanks, known for their strength, longevity, and resistance to environmental stress, are gaining traction in both residential and industrial applications. Their popularity is further amplified by rising concerns over water scarcity and the need for sustainable storage systems. As regional and global manufacturers scale production and innovate in coating technologies and corrosion resistance, the competitive landscape is evolving rapidly. Drawing on market insights and operational scale, the following eight manufacturers have emerged as key players in the corrugated metal water tanks sector, combining technological expertise with robust distribution networks to meet growing international demand.

Top 8 Corrugated Metal Water Tanks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Water Storage Tanks, Inc.

Domain Est. 2007

Website: waterstoragetanksinc.com

Key Highlights: CorGal Water Storage Tanks are made in the USA with US Steel, Liners and Hardware from US Suppliers. We offer an unprecedented 30-year structural warranty….

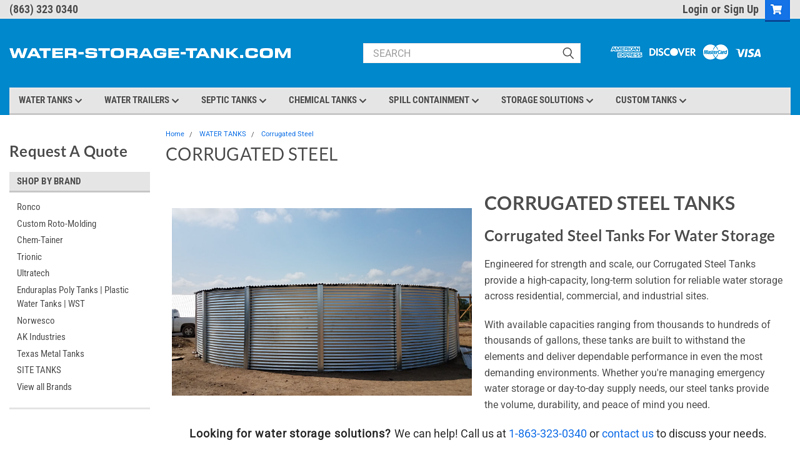

#2 Corrugated Steel

Domain Est. 2007

Website: water-storage-tank.com

Key Highlights: Our Corrugated Steel Tanks provide a high-capacity, long-term solution for reliable water storage across residential, commercial, and industrial sites….

#3 Corrugated Steel Storage Tanks

Domain Est. 1999

Website: tank-depot.com

Key Highlights: Shop certified high-capacity corrugated steel water storage tanks engineered for potable water, rainwater harvesting, fire protection, wastewater, and more….

#4 Galvanized Steel Water Tanks

Domain Est. 1999

Website: protank.com

Key Highlights: Protank offers some of the best galvanized steel water tanks available on the market today. Our tanks make top choices among water tanks in terms of their ……

#5 Advanced Drainage Systems

Domain Est. 2000

Website: adspipe.com

Key Highlights: Advanced Drainage Systems provides high-performing, durable pipe and innovative stormwater management solutions. Discover our industry-leading products ……

#6 Contain Water Systems

Domain Est. 2012

Website: containwatersystems.com

Key Highlights: Every Contain Water Systems tank is hand-crafted, custom built and assembled in the USA by highly-trained and experienced personnel….

#7 Corrugated Steel Tanks

Domain Est. 2019

Website: clarionmunicipal.com

Key Highlights: Corrugated steel water tanks provide a cost-effective storage solution for industry, processing, fire suppression and more. Install on site to your specs….

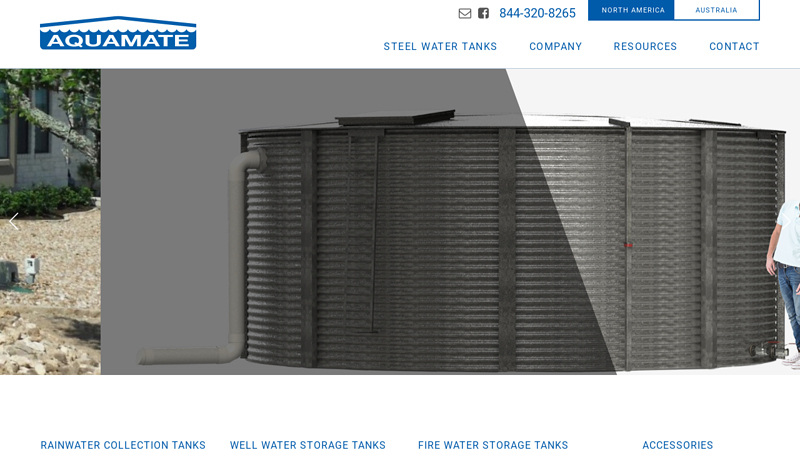

#8 Aquamate

Founded: 1986

Website: aquamatetanks.com

Key Highlights: Aquamate has been manufacturing galvanized water tanks since 1986. We engineer large water tanks from 5,000 to 102,000 gallons. Our steel water tanks are ……

Expert Sourcing Insights for Corrugated Metal Water Tanks

H2: 2026 Market Trends for Corrugated Metal Water Tanks

The global market for corrugated metal water tanks is poised for steady growth and transformation by 2026, driven by increasing water security concerns, infrastructure development, and technological advancements. Key trends shaping the market include:

1. Rising Demand for Water Security & Rainwater Harvesting:

Growing water scarcity, exacerbated by climate change and population growth, is a primary driver. Governments and individuals are increasingly investing in decentralized water storage solutions. Corrugated metal tanks, particularly galvanized steel (GI) and Colorbond® variants, are favored for rooftop rainwater harvesting systems in both urban and rural areas. By 2026, regulations promoting water conservation and incentives for rainwater collection are expected to further boost demand, especially in drought-prone regions like Australia, parts of Africa, the Middle East, and Western USA.

2. Infrastructure Development & Urbanization:

Rapid urbanization, especially in emerging economies (Asia-Pacific, Africa, Latin America), necessitates robust water storage infrastructure for municipal supply, construction sites, and industrial operations. Corrugated tanks offer a cost-effective, durable, and relatively quick-to-install solution for bulk water storage in expanding towns and cities. Large-capacity tanks for community water supply and agricultural irrigation projects will see significant demand.

3. Dominance of Galvanized Steel & Growth of Color-Coated Variants:

Galvanized iron (GI) tanks will remain the dominant material due to their proven durability, lower cost, and established manufacturing base. However, the market for pre-painted (Color-coated/Colorbond®) steel tanks is projected to grow faster. These offer superior corrosion resistance, longer lifespans (up to 20-30 years), minimal maintenance, and aesthetic appeal (available in various colors), making them attractive for residential and commercial applications where appearance matters. Zincalume® (aluminum-zinc coated) is also gaining traction for enhanced corrosion protection.

4. Focus on Durability, Longevity, and Sustainability:

End-users and regulators are demanding longer-lasting, low-maintenance solutions. This drives innovation in coatings (e.g., advanced multi-layer coatings, ceramic coatings) and improved manufacturing techniques (e.g., better sealing, reinforced joints). The inherent recyclability of steel aligns with growing sustainability concerns, giving metal tanks an advantage over plastic alternatives in terms of end-of-life environmental impact.

5. Technological Integration and Smart Features:

While basic tanks dominate, there’s a nascent trend towards “smart” water tanks. By 2026, integration of level sensors, remote monitoring systems (via IoT), and automated pump controls may become more common, especially in commercial and industrial applications, allowing for better water management and leak detection.

6. Regional Growth Disparities:

Asia-Pacific: Expected to be the fastest-growing region, driven by massive infrastructure projects, urbanization in India and Southeast Asia, and government water security initiatives.

* Africa & Middle East: High demand due to acute water scarcity, off-grid needs, and agricultural expansion. Cost-effectiveness of GI tanks is crucial here.

* North America & Europe:* Steady growth driven by residential rainwater harvesting (especially in drought-affected areas like California, Australia), replacement markets, and stringent water regulations. Demand leans towards higher-end Colorbond® tanks.

7. Competitive Landscape and Customization:

The market features both large multinational manufacturers and numerous regional players. Competition will intensify, focusing on price, quality, brand reputation, and service. Demand for customization (size, capacity, color, inlet/outlet configurations) is increasing to meet specific project requirements.

Conclusion:

By 2026, the corrugated metal water tank market will be characterized by sustained growth fueled by fundamental water security needs. While traditional GI tanks will maintain a strong presence, the shift towards higher-performing, longer-lasting Color-coated and Zincalume® variants will accelerate. Success will depend on manufacturers’ ability to offer durable, cost-effective, and increasingly sustainable solutions tailored to regional demands, with potential for integration of basic smart technologies in premium segments.

Common Pitfalls When Sourcing Corrugated Metal Water Tanks (Quality and Intellectual Property)

Poor Material Quality and Thickness

One of the most frequent issues when sourcing corrugated metal water tanks is receiving materials that do not meet the specified gauge or grade. Suppliers may use substandard galvanized steel or reduce the zinc coating, leading to premature rust and structural failure. Always verify the steel thickness (typically measured in gauge or mm) and zinc coating weight (e.g., Z275 or G60) against industry standards such as ASTM A653 or AS/NZS 2728.

Inadequate Corrosion Protection

Even if the base material is adequate, poor surface treatment or insufficient galvanization can drastically reduce tank lifespan. Be cautious of re-galvanized or recycled steel sheets, which may appear acceptable but degrade quickly. Ensure the supplier provides certified mill test reports and conducts salt spray testing to validate corrosion resistance.

Lack of Compliance with Regional Standards

Corrugated metal water tanks must comply with local water safety and construction regulations. Sourcing tanks that do not meet standards such as NSF/ANSI 61 (for potable water) or AS/NZS 3500 (plumbing and drainage) can result in legal and health issues. Always confirm compliance with applicable standards in your target market.

Intellectual Property Infringement

Many reputable tank designs are protected by patents, trademarks, or registered designs. Sourcing from manufacturers that copy proprietary profiles, connection systems, or branding exposes buyers to legal risk. For example, replicating patented bolt-together designs or using logos similar to established brands can lead to cease-and-desist orders or customs seizures.

Misrepresentation of Manufacturing Origin

Some suppliers falsely claim tanks are manufactured in countries known for quality (e.g., Australia, Germany, USA) when they are actually produced elsewhere with inferior processes. This misrepresentation affects both quality assurance and IP compliance. Request proof of origin, factory audits, or third-party verification to confirm manufacturing location.

Inconsistent Welding and Assembly

Poor weld quality or inconsistent corrugation depth can compromise structural integrity and water tightness. Inspect sample units for uniformity in seam strength, bolt hole alignment, and overall finish. Automated manufacturing lines typically offer better consistency than manual fabrication.

Absence of Technical Documentation and Support

Reputable suppliers provide detailed installation manuals, load specifications, and maintenance guidelines. A lack of documentation may indicate limited technical capability or copied designs. Ensure access to engineering support and warranty terms before finalizing procurement.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: audit suppliers, request material certifications, verify IP status, and test sample units. Partnering with established, transparent manufacturers reduces both quality and legal risks in sourcing corrugated metal water tanks.

Logistics & Compliance Guide for Corrugated Metal Water Tanks

Overview

Corrugated metal water tanks are widely used for water storage in agricultural, industrial, and residential applications. Due to their size, weight, and material composition, proper logistics planning and adherence to regulatory compliance are essential for safe and efficient delivery and installation. This guide outlines key considerations for transporting and deploying corrugated metal water tanks in accordance with industry standards and legal requirements.

Packaging and Handling

- Disassembled Packaging: Corrugated metal tanks are typically shipped in flat-pack configurations. Panels, fasteners, seals, and accessories should be securely bundled and labeled.

- Protective Measures: Use moisture-resistant wrapping and corner protectors to prevent corrosion and physical damage during transit.

- Weight Distribution: Ensure loads are evenly distributed on pallets or skids to prevent shifting. Individual panels should be stacked flat with spacers to avoid deformation.

- Handling Instructions: Clearly mark packages with “Fragile,” “This Side Up,” and “Do Not Stack” labels where applicable. Use appropriate lifting equipment (e.g., forklifts, cranes) during loading and unloading.

Transportation Requirements

- Vehicle Selection: Use flatbed trucks, curtain siders, or enclosed trailers based on tank size and weather conditions. Ensure the vehicle is rated for the total load weight.

- Securement: Secure loads using ratchet straps, load bars, or dunnage bags to prevent movement. Follow local transportation regulations (e.g., U.S. DOT, EU Directive 2014/47/EU) for cargo securement.

- Route Planning: Account for tank dimensions when planning routes—avoid low bridges, narrow roads, or weight-restricted zones. Oversize loads may require permits and pilot vehicles.

- International Shipments: For cross-border transport, comply with ISPM 15 for wooden packaging and provide accurate HS codes (e.g., 7308.90 for prefabricated steel structures).

Storage Guidelines

- Indoor vs. Outdoor: Store tanks indoors when possible. If stored outdoors, elevate packages off the ground and cover with UV-resistant, breathable tarps to prevent moisture buildup and rust.

- Ventilation: Ensure adequate airflow in storage areas to minimize condensation.

- Inventory Management: Organize by size and model number; use first-in, first-out (FIFO) rotation to prevent prolonged exposure to environmental factors.

Regulatory Compliance

- Material Standards: Ensure tanks meet recognized standards such as AS/NZS 3500.1 (Australia/New Zealand), NSF/ANSI 61 (U.S. potable water), or ISO 28560 (steel quality).

- Environmental Regulations: Comply with local environmental laws regarding coatings and galvanization (e.g., RoHS, REACH) if used in potable water applications.

- Import/Export Documentation: Provide commercial invoices, packing lists, certificates of origin, and conformity assessments (e.g., CE marking, ICC-ES reports) as required.

- Safety Data Sheets (SDS): Maintain SDS for any protective coatings or sealants used in tank manufacturing.

Installation and Site Compliance

- Foundation Requirements: Verify site preparation meets engineering specifications—level, compacted base with proper drainage.

- Assembly Standards: Follow manufacturer instructions and local building codes (e.g., IBC, NESC) during installation. Use certified personnel where required.

- Water Quality Compliance: For potable use, ensure tank linings and gaskets are non-toxic and certified to relevant health standards. Conduct pre-use flushing and testing.

- Permitting: Obtain necessary permits for tank placement, especially for large-capacity or elevated installations.

Documentation and Traceability

- Batch Tracking: Maintain records of batch numbers, manufacturing dates, and inspection reports for traceability.

- Delivery Verification: Require signed delivery receipts confirming quantity and condition upon arrival.

- Compliance Certificates: Provide clients with product conformity certificates, test reports, and installation manuals.

Emergency and Risk Management

- Damage Protocol: Establish procedures for inspecting and reporting damaged goods upon delivery. Retain photos and file claims promptly with carriers.

- Spill and Leak Response: For lined tanks, have spill kits and containment procedures ready during installation.

- Insurance: Ensure cargo is adequately insured during transit and storage against theft, damage, or environmental exposure.

Conclusion

Effective logistics and compliance management for corrugated metal water tanks ensures product integrity, regulatory adherence, and customer satisfaction. By following this guide, stakeholders can mitigate risks, streamline operations, and support safe, long-term performance of water storage systems.

In conclusion, sourcing corrugated metal water tanks offers a durable, cost-effective, and long-term solution for water storage needs, particularly in rural, agricultural, or off-grid settings. These tanks are known for their strength, resistance to harsh weather conditions, and ease of installation, making them a reliable choice in diverse environments. When sourcing, it is essential to consider factors such as tank size, gauge and quality of the metal, coating and galvanization for corrosion resistance, supplier reputation, and compliance with local standards. By working with reputable manufacturers or suppliers and ensuring proper installation and maintenance, buyers can maximize the lifespan and performance of corrugated metal water tanks. Overall, with careful selection and sourcing strategies, these tanks provide a sustainable and efficient storage solution that meets both immediate and long-term water management requirements.