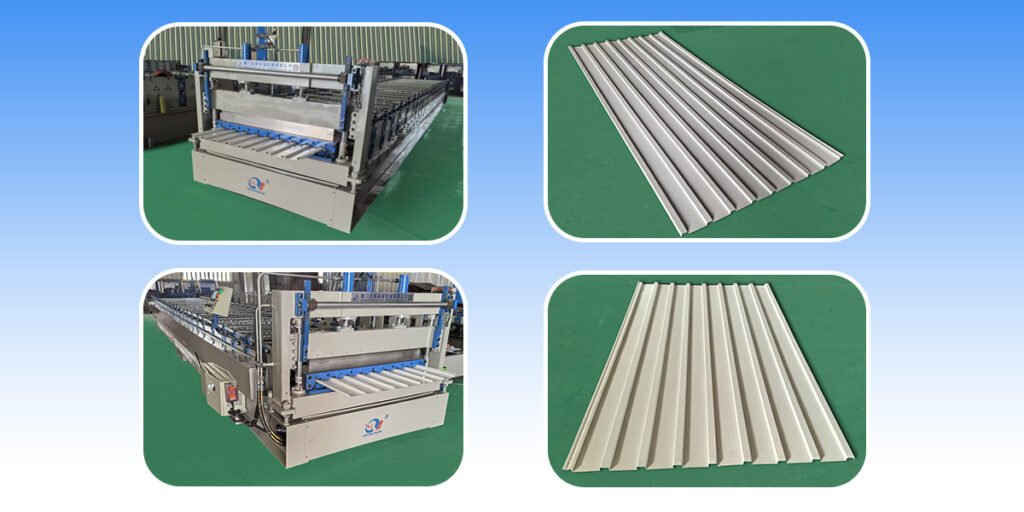

The global corrugated metal roofing market is experiencing steady growth, driven by rising demand for durable, cost-effective, and low-maintenance roofing solutions across residential, commercial, and industrial sectors. According to a 2023 report by Mordor Intelligence, the global metal roofing market was valued at USD 25.3 billion and is projected to grow at a CAGR of 6.2% from 2023 to 2028. A critical yet often overlooked component of metal roofing systems is flashing—especially for corrugated metal roofs—where proper installation prevents leaks, enhances longevity, and maintains structural integrity. As the construction industry prioritizes weather resilience and energy efficiency, the demand for high-performance flashing solutions has surged. This growing need has elevated the role of specialized manufacturers who combine engineering precision with corrosion-resistant materials. In this context, we spotlight the top nine corrugated metal roof flashing manufacturers leading innovation, scalability, and quality assurance in a competitive and expanding market.

Top 9 Corrugated Metal Roof Flashing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Berridge Manufacturing Co.

Domain Est. 1996

Website: berridge.com

Key Highlights: For over 50 years Berridge has worked to set the standard by designing, developing and manufacturing superior architectural metal products and technology….

#2 Corrugated Metal Roofing and Siding Manufacturers

Domain Est. 2000

Website: corrugated-metals.com

Key Highlights: Explore Corrugated Metals, Inc.’s extensive range as a metal roofing and siding manufacturers, including custom roll forming services. Contact us today!…

#3 Metal Roofing Manufacturer

Domain Est. 1997

Website: mbci.com

Key Highlights: MBCI manufactures the highest quality metal roofing & wall panels to meet your project’s aesthetic & structural standards. Request a quote today!…

#4 Metal Roofing Manufacturers

Domain Est. 1999

Website: unioncorrugating.com

Key Highlights: Union Corrugating Company provides commercial and residential metal roofing to fit your requirements. To learn more about our metal roofing manufacturers ……

#5 Metal Roofing Panel Manufacturers/Suppliers

Domain Est. 1999

Website: metalroofingsystems.com

Key Highlights: Metal Roofing Systems manufactures complete systems for metal roof, wall, and soffit applications. We manufacture all of our flashing and roof drainage ……

#6 Construction Metal Products

Domain Est. 2003

Website: cmpmetalsystems.com

Key Highlights: Construction Metal Products is the Carolinas’ leading metal roofing manufacturer of metal roofing, metal walls, and custom sheet metal fabrication products….

#7 Drexel Metals

Domain Est. 1996 | Founded: 1985

Website: drexmet.com

Key Highlights: Founded in 1985, Drexel Metals Corporation grew to become a leader in the distribution of painted metal for the roofing, architectural sheet metal, military and…

#8 Prefabricated Roof Flashings

Domain Est. 2003

Website: flashco.com

Key Highlights: FlashCo helps roofing contractors save time with high quality prefabricated accessories. Install flashings up to 5 times faster. Save labor costs….

#9 Trim and Flashing for Metal Roofing and Wall Panels

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: Use our trim and metal flashing center to find the metal roof trim option that’s best for your roof or wall panel. Dimensions, details, and installation videos ……

Expert Sourcing Insights for Corrugated Metal Roof Flashing

H2: Market Trends for Corrugated Metal Roof Flashing in 2026

-

Increased Demand in Residential and Commercial Construction

By 2026, the global construction sector is expected to experience steady growth, driven by urbanization and infrastructure development, particularly in emerging economies. Corrugated metal roof flashing, valued for its durability and weather resistance, will see heightened demand in both residential roofing renovations and new commercial builds. The trend toward long-span metal roofing systems will further amplify the need for compatible flashing solutions. -

Sustainability and Recyclability Driving Adoption

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are influencing material choices in construction. Corrugated metal flashing, often made from galvanized steel, aluminum, or zinc-coated alloys, is fully recyclable and energy-efficient over its lifecycle. By 2026, eco-conscious builders and developers are expected to favor metal flashing over asphalt-based or plastic alternatives, accelerating market growth. -

Technological Advancements in Coatings and Corrosion Resistance

Innovation in protective coatings—such as advanced galvalume (aluminum-zinc alloy) and polymer-based finishes—will enhance the longevity and performance of corrugated metal roof flashing in harsh climates. These improvements reduce maintenance costs and increase product lifespan, making them attractive in coastal, high-humidity, and industrial zones. Smart coatings with self-healing properties may begin entering niche markets by 2026. -

Rise of Prefabricated and Modular Construction

The growing popularity of prefabricated and modular buildings will drive demand for standardized, easy-to-install flashing components. Corrugated metal roof flashing is well-suited for integration into modular roofing systems due to its lightweight nature and compatibility with panelized designs. Manufacturers are expected to expand product lines to include pre-cut, pre-formed flashing kits tailored for off-site assembly. -

Regional Market Shifts and Supply Chain Localization

Asia-Pacific, particularly China, India, and Southeast Asia, will dominate market growth due to rapid urbanization and government-led housing initiatives. Meanwhile, North America and Europe will focus on retrofitting aging infrastructure, boosting replacement demand. To mitigate supply chain disruptions, manufacturers are increasingly localizing production, which will improve delivery times and reduce costs for corrugated flashing products. -

Digital Integration and BIM Adoption

Building Information Modeling (BIM) is becoming standard in architectural and construction planning. By 2026, manufacturers of corrugated metal flashing are expected to offer BIM-compatible product libraries, enabling seamless integration into digital construction workflows. This enhances precision in flashing design and installation, reducing waste and on-site errors. -

Price Volatility and Raw Material Challenges

Fluctuations in steel and aluminum prices—driven by geopolitical tensions and energy costs—could impact production margins. However, long-term contracts and investment in alternative alloys (e.g., aluminum-magnesium) may help stabilize costs. Recycling initiatives and circular economy models will play a key role in mitigating raw material risks.

In summary, the 2026 market for corrugated metal roof flashing will be shaped by sustainability imperatives, construction innovation, and regional development dynamics. Companies that invest in high-performance materials, digital tools, and localized supply chains will be best positioned for growth.

Common Pitfalls Sourcing Corrugated Metal Roof Flashing (Quality, IP)

Sourcing corrugated metal roof flashing involves navigating several potential pitfalls that can compromise both the quality of the materials and the integrity of the installation. Being aware of these issues helps ensure a durable, watertight roofing system.

Poor Material Quality

One of the most frequent issues is receiving flashing made from substandard metal. Low-grade steel or aluminum may lack the necessary thickness (gauge), leading to premature corrosion, warping, or damage during installation. Inferior coatings—such as insufficient galvanization or poor-quality paint finishes—reduce weather resistance and shorten the lifespan of the flashing. Always verify material specifications, including metal type, thickness (e.g., 26 or 29 gauge), and coating standards (e.g., G90 galvanized or Kynar 500® finish).

Inaccurate Profile Matching

Corrugated flashing must precisely match the profile of the existing roofing panels, including wave pitch, amplitude, and curvature. Suppliers may provide generic or incorrectly profiled flashing, resulting in gaps, poor fit, and water infiltration. Custom fabrication based on actual roofing samples is often necessary but can be overlooked to cut costs or lead times. Always confirm the profile match using a physical sample or detailed manufacturer specs before ordering.

Inadequate Weather Sealing and IP Rating

Improper sealing mechanisms can undermine the flashing’s ability to maintain weatherproof integrity. Flashings without integrated drip edges, proper sealant channels, or compatible closure strips may not meet required Ingress Protection (IP) standards for moisture resistance. For exposed or high-wind areas, the flashing must contribute to a system that prevents water ingress under pressure (e.g., equivalent to IPX4 or higher). Overlooking these design features can lead to leaks and failed inspections.

Lack of Certified Coatings and Corrosion Resistance

In coastal or high-humidity environments, corrosion is a major concern. Sourcing flashing without appropriate corrosion-resistant coatings—such as zinc-aluminum alloys (e.g., Galvalume®) or pre-painted finishes with proven warranties—can lead to early failure. Request test certifications (e.g., ASTM B117 salt spray testing) and ensure compatibility with other roofing materials to avoid galvanic corrosion.

Insufficient Supplier Expertise

Many suppliers lack specialized knowledge in metal roofing components and may offer off-the-shelf solutions ill-suited for corrugated systems. This can result in incorrect recommendations, delayed delivery, or lack of technical support. Partner with suppliers experienced in industrial or architectural metal roofing who can provide engineering support, shop drawings, and installation guidance.

Non-Compliance with Building Codes and Standards

Flashing must meet local building codes, wind uplift requirements, and fire safety standards. Sourcing products without proper certification (e.g., UL, ICC-ES) or regional approvals can lead to failed inspections and costly rework. Always confirm that the flashing complies with applicable codes such as the International Building Code (IBC) or Australian Standard AS/NZS 2909.

Avoiding these pitfalls requires due diligence in material selection, supplier vetting, and attention to technical details—ensuring long-term performance and weather resistance of the roofing system.

Logistics & Compliance Guide for Corrugated Metal Roof Flashing

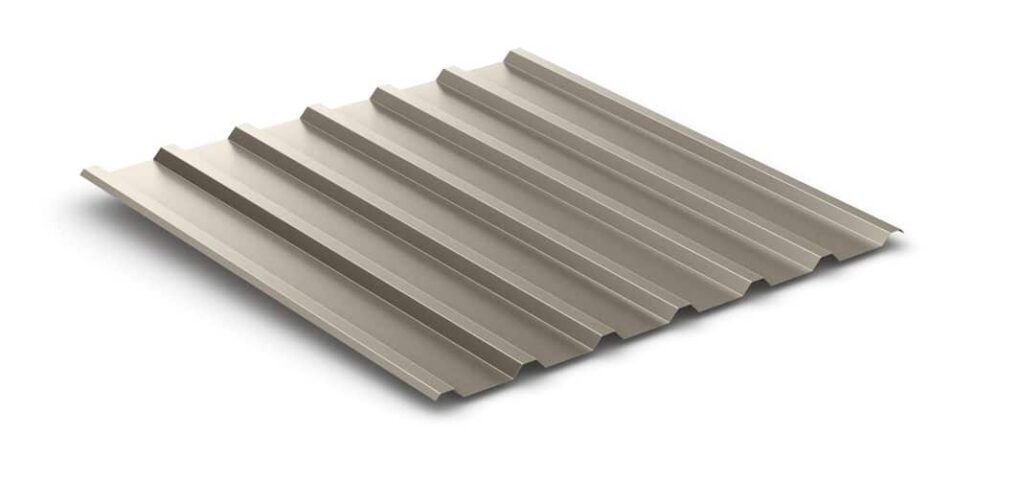

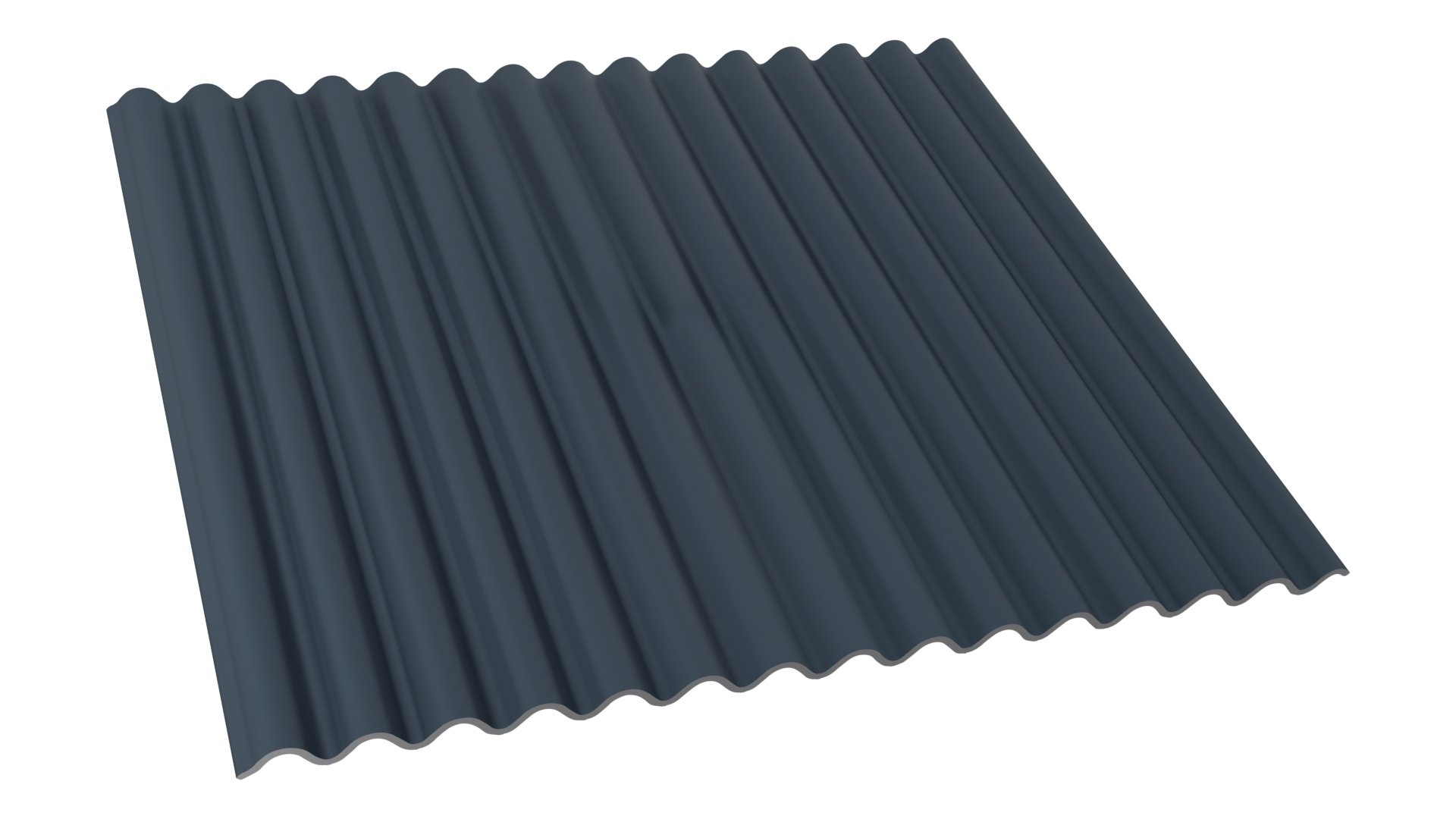

Product Overview and Definition

Corrugated metal roof flashing is a critical roofing component designed to prevent water infiltration at joints, edges, and penetrations in corrugated metal roofs. Typically made from galvanized steel, aluminum, or stainless steel, these flashing components are manufactured to match the profile of corrugated roofing panels. They are used around chimneys, vents, skylights, and eaves to ensure long-term weather resistance and structural integrity.

Material Specifications and Standards

Corrugated metal roof flashing must comply with relevant material standards to ensure durability and corrosion resistance. Common standards include:

– ASTM A653/A653M: Standard specification for steel sheet, zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) by the hot-dip process.

– ASTM B209: Standard specification for aluminum and aluminum-alloy sheet and plate.

– ASTM A240/A240M: Standard specification for chromium and chromium-nickel stainless steel plate, sheet, and strip for pressure vessels and general applications.

Materials should be certified to meet these standards, with documentation provided by suppliers.

Manufacturing and Quality Control

Manufacturers must adhere to strict quality control procedures to ensure dimensional accuracy, proper corrugation match, and coating integrity. Quality assurance includes:

– Dimensional verification against project specifications

– Coating thickness testing (e.g., zinc coating weight for galvanized products)

– Visual inspection for surface defects, warping, or coating damage

– Batch traceability and test certifications (e.g., mill test reports)

Packaging and Handling Requirements

To prevent damage during transport and storage, corrugated metal flashing must be:

– Bundled securely with protective edge guards and moisture-resistant wrapping

– Stacked flat on pallets to avoid bending or deformation

– Stored under cover in a dry, well-ventilated area, off the ground

– Labeled clearly with product type, dimensions, material grade, and batch number

Handling should utilize appropriate lifting equipment to avoid scratching or denting.

Transportation and Shipping Logistics

Shipping must ensure product integrity through:

– Use of enclosed or covered trucks to prevent exposure to rain and debris

– Secure strapping to prevent shifting during transit

– Compliance with regional weight and dimension regulations for oversized loads, if applicable

– Documentation including packing lists, material certifications, and shipping manifests

Import/Export and Customs Compliance

For international shipments:

– Ensure Harmonized System (HS) code accuracy (e.g., 7308.90 for structural elements of iron or steel)

– Provide commercial invoices, packing lists, and certificates of origin

– Comply with destination country import regulations, including anti-dumping duties if applicable

– Confirm RoHS or REACH compliance for shipments to the European Union, if relevant

Building Code and Regulatory Compliance

Installation must meet local and national building codes, including:

– International Building Code (IBC) and International Residential Code (IRC) requirements for roof flashing

– Wind uplift and weather resistance standards (e.g., ASTM E331 for water penetration resistance)

– Local amendments and climate-specific requirements (e.g., snow load, hurricane zones)

Designers and installers should verify compliance with these codes during specification and installation.

Environmental and Sustainability Considerations

Environmental compliance includes:

– Use of recyclable materials (steel and aluminum are highly recyclable)

– Minimization of volatile organic compounds (VOCs) in coatings

– Adherence to environmental regulations during manufacturing (e.g., EPA standards in the U.S.)

– Availability of Environmental Product Declarations (EPDs) for green building certifications (e.g., LEED)

Installation Best Practices and Compliance

To ensure long-term performance:

– Follow manufacturer’s installation guidelines precisely

– Use compatible fasteners (e.g., stainless steel or coated screws) to prevent galvanic corrosion

– Seal joints and overlaps with appropriate roofing sealants

– Inspect completed installations for proper fit, alignment, and sealing

Proper installation is essential for maintaining product warranties and compliance with roofing system certifications.

Warranty and Documentation

Suppliers should provide:

– Product warranty covering material defects and coating performance

– Installation instructions and technical data sheets

– Compliance documentation (e.g., test reports, certifications)

Maintaining these records supports warranty claims and regulatory audits.

Conclusion

Effective logistics and compliance for corrugated metal roof flashing require attention to material standards, proper handling, regulatory requirements, and installation practices. Adhering to this guide ensures product performance, regulatory compliance, and long-term durability in roofing applications.

In conclusion, sourcing corrugated metal roof flashing requires careful consideration of material compatibility, durability, proper fit, and supplier reliability. Choosing the right flashing—typically made from galvanized steel, aluminum, or other corrosion-resistant metals—ensures effective water diversion and long-term protection of vulnerable roof areas such as valleys, eaves, and penetrations. It is essential to match the flashing profile precisely to the corrugated roofing panels to maintain weather-tight integrity. Working with reputable suppliers who provide quality-certified products and accurate specifications helps prevent installation issues and future leaks. Ultimately, investing time and resources into sourcing high-quality, correctly profiled corrugated metal flashing contributes significantly to the overall performance, efficiency, and lifespan of the roofing system.