The global corrugated plastic sheets market, commonly referred to as coroplast sheets, has experienced steady expansion in recent years, driven by increasing demand across industries such as packaging, construction, signage, and automotive. According to Grand View Research, the global corrugated plastic packaging market was valued at USD 33.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. This growth is fueled by the material’s lightweight nature, durability, recyclability, and cost-effectiveness—qualities that make 4×8-foot coroplast sheets especially popular for custom fabrication and industrial applications. As demand rises, particularly in North America and Asia-Pacific, manufacturers are scaling production and innovating in material composition and sustainability. In this competitive landscape, six key players have emerged as leading producers of high-quality 4×8 coroplast sheets, setting industry benchmarks in consistency, performance, and supply chain reliability.

Top 6 Coroplast Sheets 4X8 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Coroplast Manufacturer, Supplier, Wholesaler

Domain Est. 2015

Website: polyreflex.com

Key Highlights: Polyreflex is a Professional China Manufacturer and Supplier of Coroplast, We Provide Custom Wholeslae Coroplast factory, Private Label Coroplast and ……

#2

Domain Est. 1996

Website: coroplast.com

Key Highlights: Coroplast is North America’s market share leader and largest manufacturer of corrugated plastic sheet for signs and re-usable packaging….

#3 1

Domain Est. 2021

Website: polyflute.com

Key Highlights: We are a Top 5 corrugated PP Sheets manufacturer in China with 17 years of export experience, we can provide all kinds of high-quality corrugated plastics at ……

#4 Corrugated Plastic Panels

Domain Est. 1996

Website: grimco.com

Key Highlights: Rating 4.2 (64) · Free delivery · 30-day returnsCoroplast is a fluted polypropylene substrate, great for those looking for an economical material for digital and screen print …

#5 Corrugated Plastic Sheet Stock 4×8 & Custom Sizes

Domain Est. 2012

Website: coolsealusa.com

Key Highlights: Our inventory includes corrugated plastic sheets in standard dimensions of 48” x 96”, available in thicknesses from 2mm to 10mm, and in colors White, Blue, and ……

#6 Black Coroplast Sheets 4×8

Domain Est. 2021

Website: corrugatedplasticproduct.com

Key Highlights: Black Coroplast sheets 4×8 are plastic corrugated boards that measure 4 feet by 8 feet and are designed for a wide range of applications….

Expert Sourcing Insights for Coroplast Sheets 4X8

H2: Projected Market Trends for Coroplast Sheets 4×8 in 2026

The market for Coroplast sheets (4×8 feet), a lightweight and durable polypropylene-based plastic sheeting, is poised for notable shifts and growth by 2026. Driven by evolving industrial demands, sustainability mandates, and technological advancements, the Coroplast sector is expected to expand across multiple application domains.

-

Increased Demand in Signage and Advertising

The signage industry will remain a dominant consumer of 4×8 Coroplast sheets. With the rise of political campaigns, real estate promotions, and event marketing, especially in North America and Europe, demand is projected to grow steadily. The reusability and weather resistance of Coroplast make it ideal for short-term outdoor use. By 2026, digital printing advancements will further enhance customization, driving adoption among small businesses and municipalities. -

Sustainability and Recyclability Focus

Environmental regulations are tightening globally, prompting manufacturers to shift toward recyclable and eco-friendly materials. Coroplast, being 100% recyclable (classified as #5 polypropylene), aligns well with circular economy goals. In 2026, expect increased adoption of closed-loop recycling programs and product innovations focused on biodegradable additives or recycled-content Coroplast sheets to meet ESG (Environmental, Social, and Governance) standards. -

Expansion in Packaging and Industrial Applications

Coroplast sheets are increasingly being used in reusable packaging, protective liners, and custom pallets due to their durability and cost-efficiency. The logistics and e-commerce sectors are leveraging Coroplast for lightweight, stackable packaging solutions. This trend is expected to accelerate through 2026 as companies seek alternatives to wood and corrugated fiberboard to reduce shipping weight and environmental impact. -

Geographic Market Shifts

While North America remains a key market, Asia-Pacific—particularly India and Southeast Asia—is projected to experience rapid growth. Urbanization, infrastructure development, and rising advertising spend will drive regional demand. Local manufacturing capabilities and lower production costs will further support market penetration in emerging economies. -

Price Volatility and Raw Material Challenges

The price of Coroplast is closely tied to polypropylene feedstock, which is influenced by crude oil prices. In 2026, ongoing geopolitical tensions and supply chain dynamics may lead to price fluctuations. However, advancements in alternative feedstocks and production efficiency are expected to mitigate some cost pressures. -

Technological and Product Innovations

Anticipated innovations include UV-resistant coatings, flame-retardant variants, and enhanced print surfaces for high-resolution graphics. Additionally, smart Coroplast with embedded QR codes or RFID tags for tracking in logistics is an emerging niche by 2026, particularly in industrial and retail sectors.

In summary, the Coroplast Sheets 4×8 market in 2026 will be shaped by sustainability trends, digital integration, and diversification of applications. Stakeholders who invest in eco-friendly production, recycling infrastructure, and value-added features are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Coroplast Sheets 4×8 (Quality & IP)

Sourcing Coroplast (corrugated polypropylene) sheets in standard 4×8-foot sizes is common for signage, prototyping, and packaging. However, buyers often encounter issues related to quality inconsistencies and intellectual property (IP) concerns. Being aware of these pitfalls can help ensure you receive reliable, compliant materials.

Inconsistent Material Quality

One of the biggest challenges when sourcing Coroplast is inconsistent quality across suppliers. Sheets may vary in thickness, weight, color accuracy, and structural integrity. Low-cost suppliers might use recycled or substandard polypropylene, leading to warping, brittleness, or poor print adhesion. Always request physical samples and verify specifications such as caliper (thickness), tensile strength, and UV resistance—especially if the material will be used outdoors.

Lack of UV and Weather Resistance

Not all Coroplast is created equal when exposed to sunlight or moisture. Some suppliers market their sheets as “outdoor suitable” without proper UV stabilizers. This can result in rapid fading, yellowing, or degradation within weeks. Ensure the product is explicitly rated for outdoor use and confirm UV inhibitor content, especially for signage applications requiring long-term durability.

Tolerances and Dimensional Accuracy

Inaccurate sheet dimensions or uneven corrugation can affect fit and finish, particularly in precision applications like displays or machine guards. Cheaper manufacturers may cut corners on production tolerances. Specify dimensional tolerances (e.g., ±1/16 inch) in your order and verify incoming shipments to avoid assembly or mounting issues.

Misrepresentation of Recyclability and Eco-Friendliness

Many suppliers claim their Coroplast is “eco-friendly” or “100% recyclable” without clarifying the percentage of post-consumer recycled content or regional recycling capabilities. Be cautious of greenwashing; request documentation on material composition and recycling guidelines. True sustainability requires transparency about sourcing and end-of-life recyclability.

Intellectual Property (IP) Infringement Risks

Using Coroplast for custom designs, branded signage, or patented products can pose IP risks. Some suppliers may offer molds or design services that unknowingly replicate protected patterns or inventions. Always ensure that your use of custom-cut or printed Coroplast does not infringe on existing trademarks, copyrights, or utility patents—especially if producing for resale.

Unauthorized Use of Branded Materials

If sourcing Coroplast for use in branded environments (e.g., retail displays for major corporations), ensure compliance with brand guidelines and material specifications. Unauthorized substitution of materials—even if functionally similar—can lead to contract violations or rejection of deliverables. Confirm material certifications if required by the end client.

Counterfeit or Grey-Market Products

Deals that seem too good to be true may involve counterfeit or grey-market Coroplast sheets falsely branded as premium manufacturers (e.g., Everplast, Coroplast USA). These products may lack quality control and technical support. Source from authorized distributors and verify authenticity through manufacturer certifications or batch traces.

Inadequate Supplier Support and Documentation

Reliable suppliers provide material data sheets (MSDS), spec sheets, and technical support. Many low-cost vendors lack these resources, making it difficult to troubleshoot issues or meet compliance requirements. Ensure your supplier can provide full documentation, especially for industrial or regulated applications.

Avoiding these pitfalls requires due diligence—request samples, verify claims, and work with reputable suppliers who prioritize transparency in both quality and intellectual property compliance.

Logistics & Compliance Guide for Coroplast Sheets 4×8

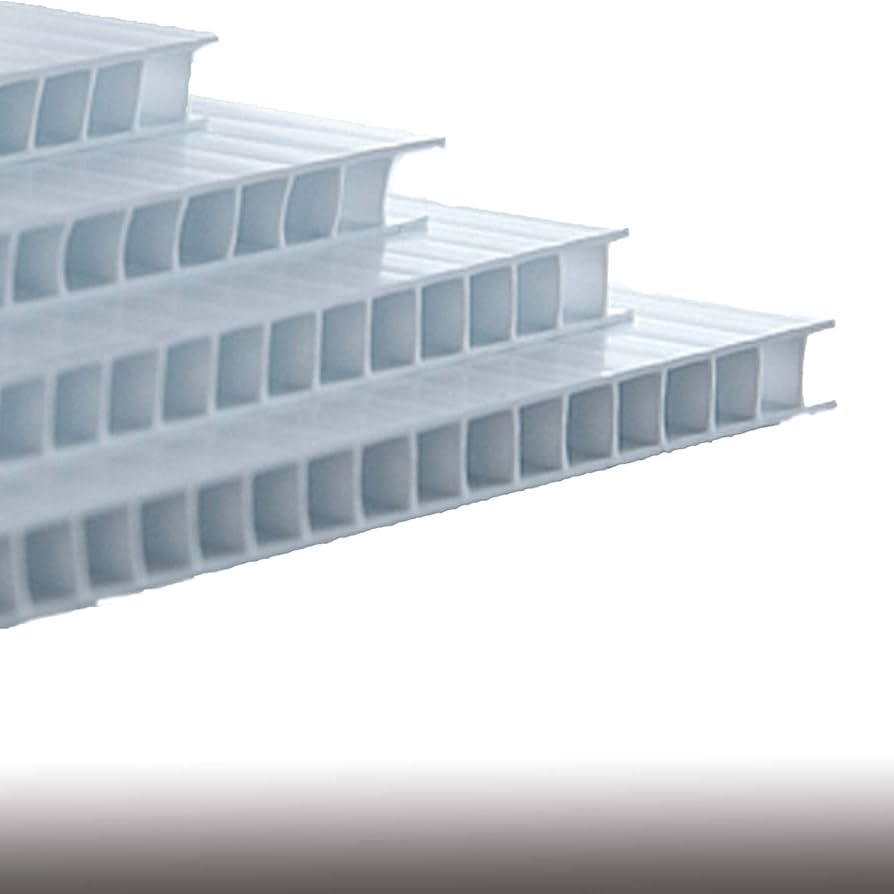

Product Overview

Coroplast (corrugated plastic) sheets, typically measuring 4 feet by 8 feet, are lightweight, durable, and commonly used in signage, packaging, and temporary structures. Made from polypropylene (PP), they are recyclable and resistant to moisture and chemicals. Proper logistics and compliance handling ensure safe transport, regulatory adherence, and environmental responsibility.

Packaging & Handling

Coroplast sheets should be stacked flat and secured to prevent warping or surface damage. Use edge protectors and banding or shrink-wrapping to stabilize bundles. Avoid placing heavy items on top during storage or transit. Handle with clean gloves to prevent dirt or oil transfer, especially for printed or coated sheets.

Storage Requirements

Store Coroplast sheets indoors in a dry, temperature-controlled environment away from direct sunlight to prevent UV degradation. Ideal storage temperature ranges between 50°F and 80°F (10°C to 27°C). Keep stacks off the floor using pallets to prevent moisture absorption and ensure air circulation.

Transportation Guidelines

Transport Coroplast sheets on enclosed trucks or containers to protect from weather and debris. Secure loads with straps or load bars to prevent shifting. Overhang should not exceed local regulations (typically 2–3 feet beyond the vehicle). Due to their lightweight nature, ensure aerodynamic stability to avoid wind lift during transit.

Regulatory Compliance

Coroplast sheets are generally exempt from hazardous material regulations under DOT, IATA, and IMDG when shipped in standard forms. However, they must comply with the following:

– REACH & RoHS: Confirm absence of restricted substances if intended for EU or electronic applications.

– Proposition 65 (California): Ensure compliance if products are distributed in California.

– Recycling Labeling: Include recycling code “5” (PP) where applicable.

Environmental & Recycling Considerations

Coroplast is recyclable through facilities that accept polypropylene (resin identification code #5). Encourage customers to return scrap material for proper recycling. Avoid contamination with adhesives, inks, or laminates that may hinder recyclability. Consider take-back programs to support circular economy practices.

Import/Export Documentation

When shipping internationally, provide accurate Harmonized System (HS) codes—typically 3923.90 for plastic sheets. Include commercial invoices, packing lists, and certificates of origin as needed. Verify destination country regulations on plastic imports, especially regarding recycling mandates or single-use plastic restrictions.

Safety Data & MSDS

Although Coroplast is non-toxic and non-hazardous under normal conditions, a Safety Data Sheet (SDS) should be available per OSHA’s HazCom Standard (29 CFR 1910.1200). The SDS should confirm stability, non-reactivity, and safe handling procedures, particularly during cutting or thermoforming operations.

Quality Assurance & Inspection

Inspect sheets upon receipt for dents, scratches, or warping. Verify dimensions (48” x 96”), thickness (commonly 2mm to 6mm), and color consistency. Maintain batch records for traceability, especially for large commercial or government contracts requiring material certification.

Disposal Guidelines

Dispose of waste Coroplast through licensed plastic recyclers. Landfilling should be a last resort due to environmental impact. Never incinerate without proper emissions controls, as burning polypropylene can release harmful fumes.

Conclusion for Sourcing Coroplast Sheets (4’x8′)

After evaluating various suppliers, pricing structures, material quality, and logistical considerations, sourcing 4’x8′ Coroplast sheets can be optimized by balancing cost, durability, and delivery efficiency. Key suppliers—ranging from online retailers like Amazon and Global Industrial to local plastics distributors and manufacturers such as Polygal or ABC Polymer—offer competitive pricing and varied material specifications (e.g., thickness from 2mm to 6mm, UV resistance, color options). Bulk ordering typically reduces per-sheet costs and improves long-term value, especially for commercial, signage, or prototyping applications.

Local suppliers provide faster turnaround and reduced shipping costs, while larger national vendors offer consistency and volume discounts. When selecting a source, factors such as sheet gauge, environmental resistance, and intended use (indoor vs. outdoor) should guide the decision. Additionally, requesting samples before large orders helps confirm quality and suitability.

In conclusion, the best sourcing strategy involves identifying reliable suppliers that meet specific project requirements in terms of quality, budget, and delivery timelines. Establishing relationships with one or two trusted vendors ensures consistent supply and potential for negotiated pricing, making Coroplast a cost-effective and versatile material solution.