The global floor molding market is experiencing steady expansion, driven by rising construction activities and growing demand for aesthetic interior finishes in residential and commercial spaces. According to a report by Mordor Intelligence, the global floor trim and molding market was valued at approximately USD 8.7 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.8% from 2024 to 2029. This growth is bolstered by increasing renovation projects and the popularity of seamless flooring transitions, where corner floor molding plays a critical functional and decorative role. As demand for durable, design-forward architectural finishes climbs, manufacturers are innovating with moisture-resistant, low-maintenance materials suited for diverse applications. In this evolving market landscape, identifying leading corner floor molding manufacturers becomes essential for contractors, designers, and distributors aiming to partner with reliable, high-quality suppliers. Based on production scale, material innovation, global reach, and customer reviews, the following ten companies stand out as the top performers in the corner floor molding industry.

Top 10 Corner Floor Molding Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Metrie Moulding, Trim & Doors

Domain Est. 2003

Website: metrie.com

Key Highlights: For over 100 years, Metrie has been North America’s trusted millwork partner—largest manufacturer of solid wood and composite moulding, trim, and doors….

#2 Newmouldings

Domain Est. 2012

Website: newmouldings.com

Key Highlights: Free deliveryFrom Base board casing to Crown Browse our online collections of in stock Hard Wood Moldings and Trim Most orders ship the same day with Free Shipping …Missing: flo…

#3 MDF Moldings, base, quarter rounds, base shoe, risers …

Domain Est. 1996

Website: galleher.com

Key Highlights: We offer a broad range of simple to ornate moldings. All profiles are offered in standard 16′ long Ultralight MDF as well as flex trim and corners….

#4 High

Domain Est. 2001

Website: framerica.com

Key Highlights: Framerica offers a broad selection of transition moldings designed to cater to various flooring types, including laminate, vinyl, tile, and carpet….

#5 Quality Molding and Trim

Domain Est. 2003

Website: randallmanufacturing.com

Key Highlights: Free delivery over $200At Randall Manufacturing, our high-quality molding and trim products will give your room the touch it needs. Browse our catalog today for the perfect fit….

#6 The Moulding Company

Domain Est. 2003

Website: themouldingcompany.com

Key Highlights: The Moulding Company serves Sacramento, Santa Clara, Concord, and San Francisco with baseboards, flexible moulding, backband, casing, and more!…

#7 VersaFlex Corner Molding

Domain Est. 2004

Website: versatrim.com

Key Highlights: Versatrim manufactures, sells, and distributes a complete line of custom coordinated floor moldings and trims for laminate and vinyl flooring….

#8 Flex Corner Mold

Domain Est. 2006

Website: flexiblemillwork.com

Key Highlights: 30-day returnsOur flexible corner molding can be ordered as straight flexible pieces and easily bend around a curve as tight as a normal sized paint can – about a 7″ (inch) ……

#9 Moulding Blocks & Corners

Domain Est. 2009

#10 Royal® Mouldings

Domain Est. 2013

Website: royalbuildingsolutions.com

Key Highlights: Royal® 100% cellular PVC mouldings do way more than decorate. They insulate and protect while ramping up the curb appeal of any window, eave or doorway….

Expert Sourcing Insights for Corner Floor Molding

H2: Projected Market Trends for Corner Floor Molding in 2026

By 2026, the corner floor molding market is expected to experience steady growth driven by evolving construction trends, rising demand for aesthetic interior finishes, and advancements in material technology. Key trends shaping the market include:

-

Increased Demand in Residential Renovations

As homeowners continue to prioritize home improvement projects—spurred by remote work setups and the desire for enhanced living spaces—corner floor molding remains a popular choice for seamless transitions between flooring and walls. The trend toward DIY renovations is also boosting demand for easy-to-install, pre-finished molding products. -

Growth in Commercial and Multifamily Construction

The expansion of multifamily housing, hospitality sectors, and office renovations, particularly in urban centers, is contributing to higher adoption of corner floor molding. These products offer durability, clean aesthetics, and protection against wear in high-traffic areas. -

Shift Toward Sustainable and Low-VOC Materials

Environmental awareness is pushing manufacturers to develop eco-friendly corner molding options using recycled composites, sustainably sourced wood, and low-VOC adhesives. By 2026, green building certifications such as LEED and WELL are expected to influence product selection, favoring non-toxic, recyclable materials. -

Innovation in Material and Design

Traditional wood molding is being complemented by alternatives like PVC, polyurethane, and hybrid composites that offer moisture resistance, dimensional stability, and easier maintenance. These materials are especially popular in bathrooms, kitchens, and basements. Additionally, customizable profiles and color-matched finishes are gaining traction to meet diverse design preferences. -

Regional Market Expansion

While North America and Europe remain dominant markets due to mature construction industries, Asia-Pacific is expected to see the fastest growth, fueled by urbanization and rising disposable incomes. Countries like China, India, and Vietnam are witnessing increased adoption of Western-style interior finishes, including decorative floor molding. -

E-Commerce and Direct-to-Consumer Sales Growth

Online platforms are becoming a primary channel for purchasing corner floor molding, especially for DIY consumers. Companies are investing in augmented reality (AR) tools that allow customers to visualize molding in their spaces before buying, enhancing the online shopping experience. -

Integration with Flooring Systems

Major flooring brands are increasingly offering corner molding as part of coordinated product lines (e.g., matching laminate, LVT, or hardwood). This bundling strategy simplifies installation and ensures design consistency, driving demand within integrated flooring solutions.

In conclusion, the corner floor molding market in 2026 will be shaped by aesthetic preferences, sustainability goals, and technological innovation. With rising construction activity and consumer focus on home value, the market is poised for moderate but consistent growth across residential and commercial sectors.

Common Pitfalls Sourcing Corner Floor Molding (Quality, IP)

Poor Material Quality and Durability

One of the most frequent issues when sourcing corner floor molding is receiving products made from substandard materials. Low-quality molding may warp, crack, or discolor quickly due to exposure to moisture, foot traffic, or UV light. Inferior plastics or composites can become brittle over time, leading to chipping at impact points. Always verify material specifications—such as UV resistance, impact strength, and dimensional stability—and request samples to assess real-world performance before large-scale procurement.

Inconsistent Profile and Dimensional Accuracy

Inconsistent extrusion profiles or imprecise corner angles (e.g., not exactly 90° or 135°) result in visible gaps and uneven installation. This not only compromises aesthetics but also reduces protection at floor-wall junctions. Suppliers with outdated or poorly maintained tooling often produce molding with variable thickness or curvature. To avoid this, insist on tight tolerance specifications and conduct first-article inspections to confirm dimensional consistency across batches.

Lack of Intellectual Property (IP) Protection and Design Infringement

Sourcing from manufacturers in regions with weak IP enforcement increases the risk of inadvertently procuring molding that infringes on patented designs or registered profiles. Using such products can expose your company to legal action, product recalls, or brand damage. Always verify that the supplier owns the rights to the molding design or has proper licensing. Request IP documentation and consider working with suppliers who offer proprietary, non-infringing profiles.

Inadequate Surface Finish and Color Matching

Poor surface finishes—such as visible seams, rough textures, or inconsistent gloss levels—can detract from the overall appearance of a space. Additionally, color variations between batches make it difficult to maintain uniformity across large installations. Ensure the supplier uses high-quality pigments and consistent manufacturing processes, and request color samples with batch-specific lot numbers to verify match accuracy.

Insufficient UV and Weather Resistance for Intended Use

When used in sunlit areas or outdoor applications, some corner floor moldings degrade rapidly due to inadequate UV stabilizers. This leads to fading, yellowing, or embrittlement. Confirm that the material is specifically formulated for the intended environment—indoor, outdoor, or high-exposure areas—and request test data on UV resistance and weathering performance.

Misaligned Supplier Capabilities and Project Requirements

Some suppliers may promise custom profiles or colors but lack the tooling or process control to deliver reliably. This results in extended lead times, cost overruns, or failure to meet technical specs. Conduct thorough due diligence on the supplier’s manufacturing capabilities, quality control processes, and track record with similar projects to ensure alignment with your quality and IP needs.

Logistics & Compliance Guide for Corner Floor Molding

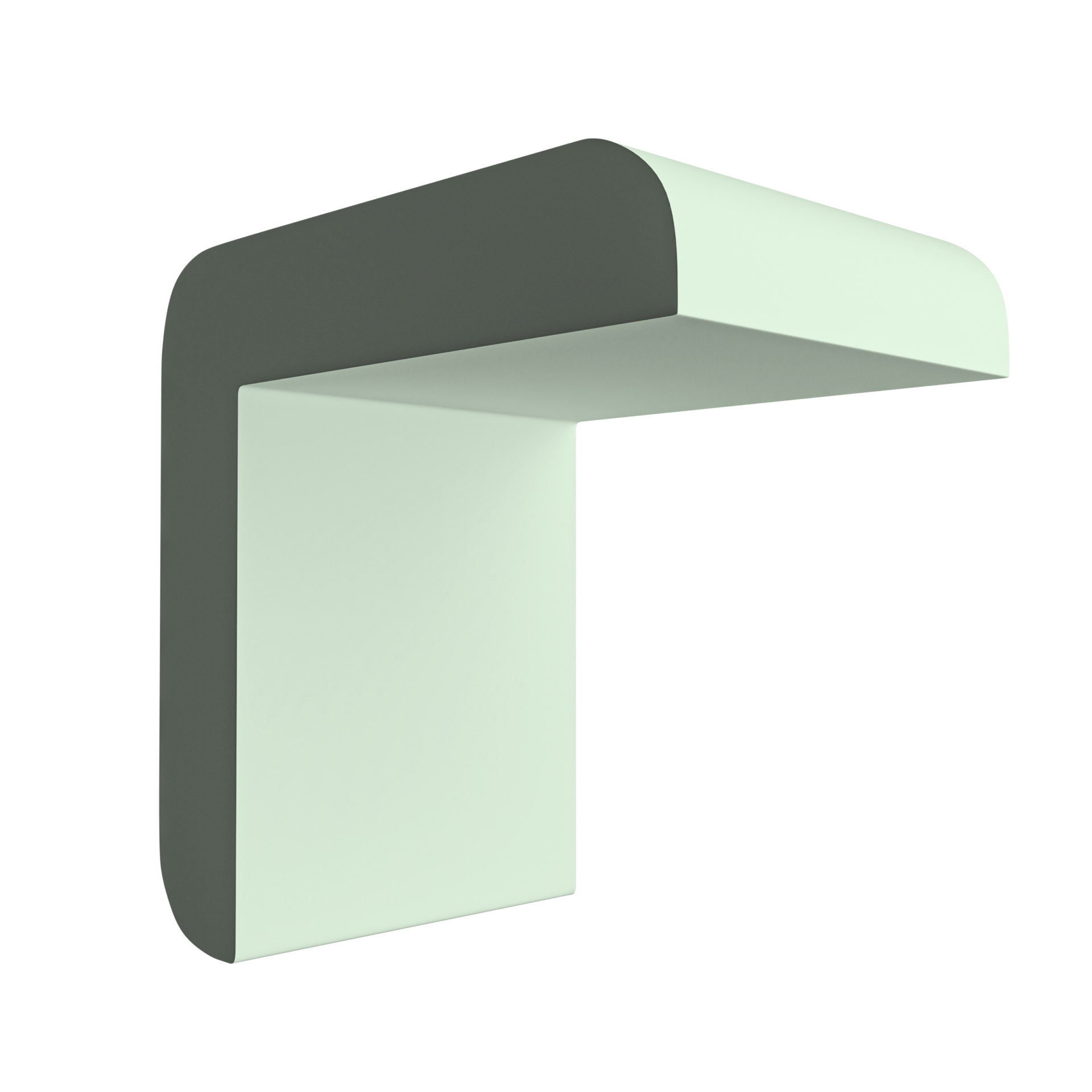

Product Overview

Corner floor molding, also known as base corner molding or floor cove molding, is a trim component used to create a seamless transition between baseboards and flooring at inside or outside corners. It enhances aesthetics and provides protection against moisture and impact. This guide outlines key logistics and compliance considerations for handling, shipping, storing, and installing this product.

Material Composition & Environmental Compliance

Corner floor molding is typically manufactured from PVC, wood composites, or rubber. Ensure compliance with regional environmental and safety regulations:

– REACH & RoHS (EU): Verify that the product contains no restricted substances such as lead, phthalates, or hazardous flame retardants.

– LEED & Indoor Air Quality (USA): Select low-VOC or no-added-formaldehyde options to support green building certifications. Products should comply with CA 01350 or similar standards for indoor air quality.

– FSC Certification (if wood-based): Confirm sustainable sourcing if the molding contains wood fibers or components.

Packaging & Labeling Requirements

Proper packaging ensures product integrity during transit and compliance with shipping regulations:

– Use moisture-resistant wrapping to prevent warping or mold growth, especially for wood-based or composite materials.

– Clearly label packages with:

– Product type (e.g., “PVC Corner Floor Molding – 2.5m Length”)

– Batch/lot number and manufacturing date

– Handling symbols (e.g., “This Way Up,” “Protect from Moisture”)

– Compliance marks (e.g., CE, UL, or country-specific certifications)

– Include multilingual labeling if shipped internationally.

Transportation & Handling

Follow best practices to minimize damage and ensure safe delivery:

– Stacking: Do not exceed recommended stack heights to avoid crushing lower layers.

– Climate Control: Avoid exposure to extreme temperatures or humidity during transit, particularly for PVC and composite products.

– Loading/Unloading: Use mechanical aids (pallet jacks, forklifts) to prevent bending or cracking. Avoid dragging bundles across rough surfaces.

Storage Conditions

Store corner floor molding in a controlled environment:

– Indoor Storage Only: Keep in a dry, well-ventilated area, off the ground on pallets.

– Temperature Range: Maintain between 10°C and 30°C (50°F–86°F).

– Avoid Direct Sunlight: Prolonged UV exposure can degrade PVC and cause discoloration.

– Maximum Stack Height: Adhere to manufacturer recommendations—typically no more than 1.5 meters (5 feet).

Import/Export Compliance

For international shipments, ensure adherence to destination country regulations:

– HS Code Classification: Use appropriate Harmonized System code (e.g., 3925.30 for PVC moldings or 4418.79 for wood moldings).

– Customs Documentation: Include commercial invoice, packing list, bill of lading, and certificates of origin.

– Product-Specific Regulations: Some countries may require fire safety testing (e.g., flame spread index) or phthalate content declarations.

Installation & Safety Compliance

Ensure end-users follow safety and performance standards:

– Provide installation guidelines with product, including recommended adhesives and fasteners.

– Comply with local building codes regarding trim materials in commercial or residential spaces.

– For commercial applications, verify fire resistance ratings if required (e.g., ASTM E84 for surface burning characteristics).

Disposal & Recycling

Promote sustainable end-of-life management:

– PVC moldings may be recyclable through designated plastic recycling programs.

– Provide disposal guidance based on local waste regulations.

– Encourage recycling where facilities exist; label recyclability per ISO 14021 (environmental labels and declarations).

Documentation & Recordkeeping

Maintain records to support compliance and traceability:

– Keep copies of material safety data sheets (MSDS/SDS), test reports, and supplier certifications.

– Track lot numbers and shipment details for recall readiness.

– Store compliance documentation for a minimum of 5 years, or per regional legal requirements.

By following this logistics and compliance guide, distributors, contractors, and end-users can ensure the safe, legal, and sustainable handling of corner floor molding throughout its supply chain lifecycle.

Conclusion for Sourcing Corner Floor Molding:

After evaluating various suppliers, materials, installation methods, and cost considerations, sourcing corner floor molding requires a balanced approach that prioritizes quality, compatibility, and value. The ideal choice depends on the specific application—whether for interior or exterior corners, residential or commercial use—and the aesthetic and functional requirements of the space. Flexible vinyl and rubber moldings offer durability and ease of installation for irregular corners, while wood and MDF provide a classic look suitable for traditional interiors. Sourcing from reputable suppliers ensures consistent product quality, proper material certifications, and timely delivery. Additionally, considering availability, lead times, and sustainability can further enhance the effectiveness of the procurement process. Ultimately, selecting the right corner floor molding involves aligning product performance with design intent and long-term maintenance needs, resulting in a professional, finished appearance that protects flooring edges and enhances interior aesthetics.