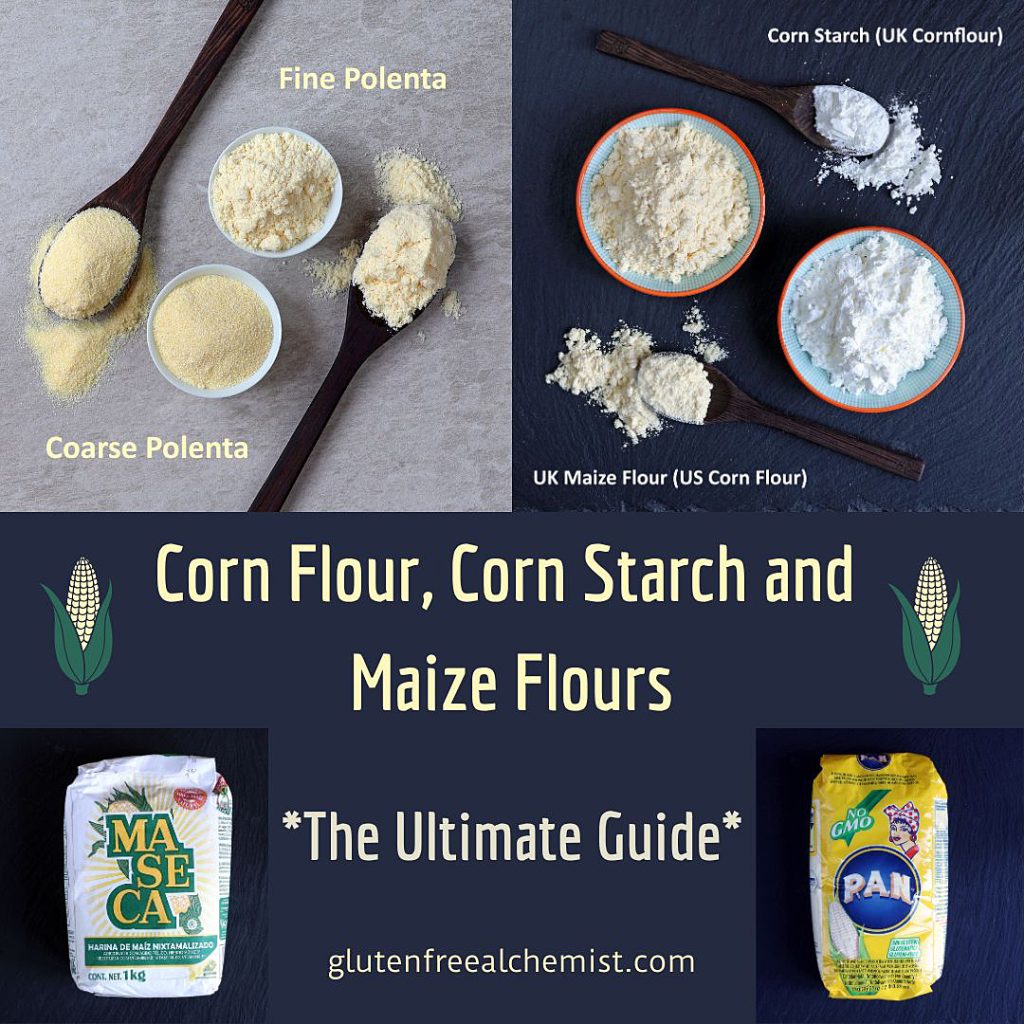

The global corn flour powder market is experiencing steady growth, driven by rising demand in the food processing industry, increasing consumer preference for gluten-free products, and expanding applications in bakery, snacks, and infant foods. According to Grand View Research, the global corn starch market—of which corn flour is a key derivative—was valued at USD 77.3 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 4.8% from 2024 to 2030. Mordor Intelligence further supports this trajectory, highlighting that increasing urbanization and the proliferation of ready-to-eat foods are significantly propelling demand for processed corn-based ingredients across both developed and emerging economies. As supply chains evolve and manufacturers scale production to meet quality and volume demands, identifying leading corn flour powder producers becomes critical for food manufacturers seeking reliable, high-performance ingredients. The following list highlights the top nine manufacturers shaping the global corn flour landscape through innovation, capacity, and market reach.

Top 9 Corn Flour Powder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mittal Cornezza: Corn Flour Manufacturer

Domain Est. 2022

Website: mittalcornezza.com

Key Highlights: Mittal Cornezza is a leading corn Grits & corn flour manufacturer and trusted supplier in India, offering top-quality corn products like grits, germ, ……

#2 Yellow Corn Flour

Domain Est. 1996

Website: grainmillers.com

Key Highlights: Grain Millers is a supplier of yellow corn flour. Yellow corn flour is a clean label ingredient that is available in Non-GMO and gluten free….

#3 Corn Flour

Domain Est. 1999

Website: icpmill.com

Key Highlights: Iowa Corn Processors’ Corn Flour is a finely milled, versatile ingredient ideal for food manufacturing, blending, and custom applications….

#4 Corn Flour

Domain Est. 2005

Website: safaagro.com

Key Highlights: Corn Flour is a fine powder made by grinding whole corn kernels into a smooth, pale-yellow flour. Naturally gluten-free and rich in carbohydrates, ……

#5 Flour, Corn Meal & Breading

Domain Est. 2006

Website: wrmills.com

Key Highlights: Wilkins Rogers Mills produces Indian Head Corn Meal, Washington Flour, Cross White Corn Meal, Washington Chicken and Seafood Breadings as well as other ……

#6 Alpha Corn Flour (Pregel Flour)

Domain Est. 2012

Website: grainspan.com

Key Highlights: GrainSpain provides the finest quality Alpha Corn Flour (Pregel Flour), which is made from 100% natural corn and dry-milled with no preservatives….

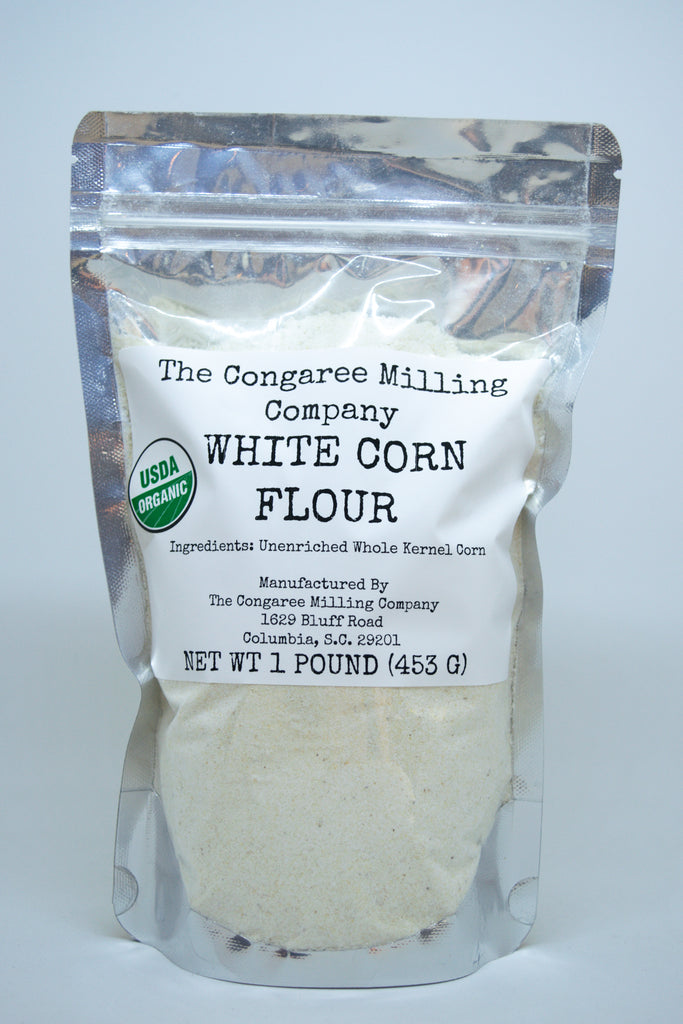

#7 White Corn Flour

Domain Est. 2013

Website: thecongareemillingcompany.com

Key Highlights: 6–9 day deliveryOur line of USDA Certified Organic stone-ground corn flour is gluten-free. At The Congaree Milling Company, we don’t process any wheat, barley, or rye….

#8 Corn Flour Flours, Meals and Powder Bob’s Red Mill Distributor …

Domain Est. 2015

Website: ballun.n.my

Key Highlights: We mill our Whole Grain Corn Flour from whole yellow corn kernels with all the natural nutrients intact‚Äîthe germ, bran and endosperm….

#9 Corn Flour Yellow

Domain Est. 2016

Website: aivaproducts.com

Key Highlights: Free deliveryNaturally Sourced & Pure – Made from yellow corn, just pure corn flour you can trust for wholesome cooking. Smooth Texture, Bold Flavor – Finely milled for a ……

Expert Sourcing Insights for Corn Flour Powder

H2: 2026 Market Trends for Corn Flour Powder

-

Rising Demand in Food Processing Industry

By 2026, corn flour powder is expected to see increased demand from the global food processing sector, driven by its extensive use in ready-to-eat meals, snacks, and bakery products. As consumers continue to favor convenience foods, manufacturers are leveraging corn flour for its functional properties—such as thickening, binding, and texture enhancement—making it a staple ingredient in frozen meals, sauces, and gluten-free baked goods. -

Growth in Gluten-Free and Health-Conscious Consumer Segments

The surge in gluten-free diets due to rising celiac disease diagnoses and health awareness is propelling the corn flour market. Corn flour, being naturally gluten-free, serves as a viable alternative to wheat flour. In 2026, this trend is expected to intensify, particularly in North America and Europe, where product innovation in gluten-free pasta, bread, and snacks will drive corn flour adoption. -

Expansion in Plant-Based and Alternative Food Products

With the plant-based food movement gaining momentum, corn flour powder is increasingly used as a base or filler in meat analogs, dairy alternatives, and vegan snacks. By 2026, continued investment in plant-based product development is likely to elevate the demand for corn flour as a cost-effective and neutral-flavored ingredient. -

Sustainability and Non-GMO Preferences Shaping Sourcing

Consumers and manufacturers are placing greater emphasis on sustainable and non-GMO agricultural practices. In response, suppliers are expected to offer certified non-GMO and sustainably produced corn flour by 2026. Traceability, eco-friendly packaging, and carbon footprint reduction will be key differentiators in the competitive landscape. -

Emerging Market Growth in Asia-Pacific and Africa

Regions such as India, China, Nigeria, and Kenya are witnessing rapid urbanization and dietary shifts, increasing the use of processed foods that incorporate corn flour. Government support for maize farming and food security initiatives in these regions will further bolster production and domestic consumption, positioning Asia-Pacific and Africa as high-growth markets by 2026. -

Price Volatility and Supply Chain Resilience

Climate change and geopolitical factors may continue to affect corn yields and prices through 2026. As a result, manufacturers are investing in diversified sourcing strategies and vertical integration to mitigate supply chain risks. Enhanced logistics and digital monitoring tools are expected to improve market resilience. -

Technological Advancements in Processing and Product Innovation

Innovations in milling, drying, and micronization technologies are enabling the production of finer, more consistent corn flour powders with improved solubility and functionality. These advancements support new applications in beverages, infant nutrition, and sports foods—segments expected to grow by 2026.

Conclusion

The global corn flour powder market in 2026 will be shaped by health trends, technological progress, sustainability demands, and expanding applications across food sectors. With strong growth potential in both developed and emerging economies, stakeholders who adapt to evolving consumer preferences and supply chain challenges will be best positioned for success.

Common Pitfalls Sourcing Corn Flour Powder (Quality, IP)

Sourcing corn flour powder effectively requires careful attention to both quality specifications and intellectual property (IP) considerations. Overlooking these aspects can lead to product failures, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Inadequate Quality Specifications

One of the most frequent issues in sourcing corn flour powder is failing to define and verify precise quality parameters. Buyers often assume “corn flour” is standard, but variations in processing and origin significantly impact performance.

- Unverified Purity and Contaminants: Sourced corn flour may contain undeclared additives, allergens (like gluten from cross-contamination), or mycotoxins (e.g., aflatoxins). Without rigorous third-party testing and certificates of analysis (CoA), these contaminants can compromise food safety and compliance.

- Inconsistent Particle Size and Moisture Content: Variability in grind fineness and moisture levels affects flowability, solubility, and shelf life. Suppliers may not control these parameters tightly, leading to batch-to-batch inconsistencies in manufacturing processes.

- Starch Modification Misrepresentation: Some suppliers market modified starches as plain corn flour. If not properly labeled, this can affect functionality in end products (e.g., texture, viscosity) and violate labeling regulations.

Intellectual Property (IP) Risks

Corn flour powder, especially when derived from proprietary corn varieties or processing methods, can be protected by patents, trademarks, or trade secrets. Ignoring IP rights exposes buyers to legal liability.

- Unauthorized Use of Patented Corn Varieties: Certain genetically modified (GM) or high-amylose corn strains are patented. Sourcing flour from such corn without proper licensing—even unknowingly—can lead to infringement claims, particularly in regions with strict IP enforcement (e.g., the U.S., EU).

- Misuse of Branded or Certified Products: Suppliers may falsely claim their corn flour meets certifications like Non-GMO Project Verified, Organic (USDA/EU), or Kosher/Halal. Using such misrepresented products can damage brand integrity and lead to recalls or legal action.

- Lack of Supply Chain Transparency: Without traceability from farm to mill, it’s difficult to verify whether IP rights have been respected throughout the supply chain. This opacity increases the risk of inadvertently sourcing infringing material.

Mitigation Strategies

To avoid these pitfalls:

– Define detailed technical specifications (e.g., particle size, moisture, starch content, GM status) in procurement contracts.

– Require regular CoAs and conduct independent batch testing.

– Conduct due diligence on suppliers’ certifications and audit their facilities.

– Consult legal experts to review IP rights related to corn varieties and processing technologies, especially when sourcing from international markets.

Proactive management of quality and IP issues ensures reliable supply, regulatory compliance, and protection against legal and operational risks.

H2: Logistics & Compliance Guide for Corn Flour Powder

This guide outlines key logistical and compliance considerations for the safe and legal international shipment and handling of corn flour powder. Adherence to these guidelines ensures product integrity, regulatory compliance, and supply chain efficiency.

H2: 1. Classification & Regulatory Framework

- HS Code: Identify the correct Harmonized System (HS) code (e.g., 1102.20.00 in many jurisdictions) for accurate customs declaration and tariff application. Verify the specific code required by the destination country.

- Regulatory Bodies: Comply with regulations from relevant authorities:

- Food Safety: FDA (USA), EFSA/EU Food Law (Europe), CFIA (Canada), FSSAI (India), etc.

- Phytosanitary: National Plant Protection Organizations (NPPOs) under IPPC guidelines.

- Customs: Relevant national customs authorities (e.g., CBP in USA, HMRC in UK).

- Transport Safety: Competent Authorities for ADR (road, Europe), IMDG Code (sea), IATA DGR (air) – Note: Corn flour powder is generally NOT classified as dangerous goods for transport, but specific conditions like dust explosion risk may have implications.

- Food Safety Standards: Adhere to HACCP principles and relevant GFSI-recognized standards (e.g., BRCGS, SQF, FSSC 22000) if required by the buyer or market.

H2: 2. Packaging & Containment

- Material: Use food-grade packaging (e.g., multi-wall paper bags with polyethylene liner, woven polypropylene bags with PE liner, bulk totes/bags (FIBCs) with food-grade lining). Ensure materials are clean, dry, and free from contaminants.

- Sealing: Employ secure, hermetic sealing methods (heat sealing, stitching with adhesive tape) to prevent moisture ingress, contamination, and spillage.

- Moisture Protection: Include desiccants if necessary and ensure packaging has low moisture vapor transmission rate (MVTR). Maintain packaging integrity throughout transit.

- Dust Control: Minimize dust generation during filling, handling, and transport to prevent respiratory hazards and explosion risks (ATEX/DSEAR compliance in workplaces may apply). Use dust extraction systems during processing/packaging.

- Labeling: Apply clear, legible, and durable labels including:

- Product name (“Corn Flour,” “Cornstarch,” “Maize Flour”)

- Net weight

- Batch/Lot number

- Best before/Use by date

- Storage instructions (“Store in a cool, dry place”)

- Manufacturer/Supplier name and address

- Country of origin

- Ingredients (if applicable, e.g., “100% Corn”)

- Allergen statement (e.g., “Contains: None” or warnings for potential cross-contamination if applicable)

- HS Code

- Handling symbols (e.g., “Keep Dry,” “Fragile,” “Do Not Stack” if applicable)

H2: 3. Storage Requirements

- Environment: Store in a clean, dry, cool, well-ventilated area.

- Temperature: Maintain ambient temperatures (typically 15°C – 25°C / 59°F – 77°F is ideal). Avoid excessive heat.

- Humidity: Keep relative humidity low (<60%) to prevent caking, clumping, and microbial growth. Use dehumidifiers if necessary.

- Palletizing: Stack on clean, dry pallets. Ensure stable stacking patterns appropriate for the packaging type (e.g., do not exceed recommended stacking heights for bags). Use edge protectors for paper bags.

- Separation: Store away from walls and floors (allow airflow), and segregate from non-food items, strong-smelling goods, and potential contaminants (chemicals, pesticides). Implement FIFO (First-In, First-Out) inventory management.

- Pest Control: Implement and document a robust Integrated Pest Management (IPM) program.

H2: 4. Transportation & Handling

- Vehicle Condition: Use clean, dry, odor-free, and pest-free transport vehicles (trucks, containers). Vehicles must be suitable for food-grade cargo (“Food Grade Certified” or equivalent declaration often required). Inspect for cleanliness and damage before loading.

- Container Standards: For sea freight, use clean, dry, fumigated (if required by destination), and well-ventilated containers (e.g., “Clean, Dry, Odor-Free” declaration). Consider ventilation to manage humidity.

- Loading/Unloading: Handle packages carefully to avoid punctures, tears, or crushing. Use appropriate equipment (forklifts, pallet jacks). Minimize dust generation. Ensure loads are secured to prevent shifting.

- Transit Conditions: Protect cargo from direct sunlight, rain, snow, and extreme temperatures. Avoid routes or methods prone to excessive vibration or moisture exposure.

- Documentation: Ensure all transport documents (Bill of Lading, Air Waybill) accurately reflect the cargo description, quantity, weight, and packaging.

- Dust Explosion Risk: Be aware that fine organic dust like corn flour can be explosible when suspended in air within confined spaces. Follow safety protocols during bulk handling (avoid dust clouds, eliminate ignition sources, use appropriate equipment).

H2: 5. Documentation & Compliance

- Commercial Invoice: Detailed invoice with seller/buyer info, description (Corn Flour Powder), HS code, quantity, unit price, total value, currency, Incoterms® rule.

- Packing List: Itemizes contents per package/shipment (number of bags, net/gross weight per bag, total weight, dimensions, marks & numbers).

- Bill of Lading (Sea) / Air Waybill (Air): Contract of carriage and receipt of goods.

- Certificate of Origin: Required by many countries for tariff determination and trade agreements. Can be generic or preferential (e.g., EUR.1, Form A).

- Phytosanitary Certificate: Often required for plant-based products. Issued by the NPPO of the exporting country, certifying the consignment is free from specified pests and meets the importing country’s phytosanitary requirements. Crucial for market access.

- Certificate of Analysis (CoA): Provided by the manufacturer/supplier, detailing results of quality and safety tests (e.g., moisture content, ash content, microbial limits – Total Plate Count, E. coli, Salmonella, yeast & mold, gluten-free if claimed, heavy metals). Often required by importers and regulators.

- Food Safety Certificate: May be required (e.g., FDA Prior Notice for US imports, EC Health Certificate for certain EU imports).

- Import Permits/Licenses: Verify if the destination country requires specific import permits for corn flour.

- Labeling Compliance: Ensure final product labeling meets all requirements of the destination market (language, mandatory information, nutritional claims).

H2: 6. Key Compliance Considerations

- Allergens: Corn is a common allergen. Labeling must comply with destination country regulations (e.g., clear declaration in ingredient list, potential “may contain” statements for cross-contact if validated).

- Genetically Modified Organisms (GMO): Declare if the corn flour is derived from GMO sources. Many countries have strict labeling and/or approval requirements for GMOs.

- Gluten-Free Claims: If marketed as “gluten-free,” ensure rigorous testing and controls are in place to prevent cross-contamination from gluten-containing grains (wheat, barley, rye) and meet the regulatory threshold for the target market (e.g., <20 ppm in Codex/US/EU).

- Additives: Declare any permitted additives (e.g., anti-caking agents like silicon dioxide) according to regulations.

- Traceability: Implement a system to trace the product from raw material (corn lot) to finished goods batch and through the supply chain (one-up, one-down).

- Incoterms®: Clearly define responsibilities (costs, risks, documentation) between buyer and seller using the appropriate Incoterms® 2020 rule (e.g., FOB, CIF, DAP).

Disclaimer: This guide provides general information. Regulations and requirements vary significantly by country, specific product formulation, and intended use. Always consult with legal counsel, regulatory experts, and the relevant authorities in both the exporting and importing countries for definitive and up-to-date compliance requirements before shipping.

In conclusion, sourcing corn flour powder requires a careful evaluation of several key factors to ensure quality, consistency, and cost-effectiveness. Identifying reliable suppliers with strong certifications, adherence to food safety standards, and transparent sourcing practices is essential. Considerations such as moisture content, granulation size, gluten-free status, and intended application (e.g., food manufacturing, baking, or industrial use) should guide supplier selection. Additionally, building long-term relationships with suppliers, negotiating favorable terms, and conducting regular quality audits can enhance supply chain reliability. By prioritizing quality, sustainability, and scalability, businesses can secure a consistent supply of corn flour powder that meets both production needs and consumer expectations.