The global power tools market is experiencing steady expansion, driven by rising construction activity, infrastructural development, and increasing demand from industrial and DIY consumers. According to a report by Mordor Intelligence, the global power tools market was valued at USD 40.56 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. Corded drill power tools, in particular, remain a cornerstone of this sector due to their consistent performance, durability, and widespread use in professional settings. With North America and Europe maintaining strong market shares and the Asia-Pacific region witnessing accelerated growth due to urbanization and manufacturing growth, leading manufacturers are investing in innovation, energy efficiency, and ergonomic design to capture expanding opportunities. This evolving landscape underscores the importance of identifying the top players shaping the corded drill segment—companies that combine engineering excellence with global reach and technological advancement.

Top 10 Corded Drill Power Tools Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 FEIN Power Tools, Inc.

Domain Est. 1995

Website: fein.com

Key Highlights: As a power tool specialist, FEIN is a strong partner in demanding metalworking and woodworking applications, representing the highest quality around the world….

#2 CORDED DRILLS & FASTENING

Domain Est. 1995

Website: makitatools.com

Key Highlights: Makita USA: The Leader In Cordless with 18V LXT Lithium-Ion. The best in class for cordless power tool technology. A leader in power tool technology for the ……

#3 Milwaukee® Tool

Domain Est. 2000

Website: milwaukeetool.com

Key Highlights: Milwaukee Tool is the most respected manufacturer of heavy-duty power tools, hand tools, instruments, and accessories….

#4 Corded Power Tools

Domain Est. 1995

Website: ridgid.com

Key Highlights: Corded Power Tools · Corded Drills. Get the reliable power you need for those time consuming projects. · Circular Saws · Reciprocating Saws · Hand Sanders · Routers….

#5 Metabo

Domain Est. 1997

Website: metabo.com

Key Highlights: Metabo manufactures both corded and cordless power tools, as well as a full line of abrasives and accessories for metalworking, concrete and many other ……

#6 Power Tools

Domain Est. 1998

Website: craftsman.com

Key Highlights: From drills to saws, experience precision and power for both DIY and advanced DIY tasks. Equip yourself with reliable tools that deliver exceptional results….

#7 Power tools for professional craftsmen

Domain Est. 1999

Website: flex-tools.com

Key Highlights: FLEX power tools ✚ accessories for professional craftsmen. System solutions for: Renovation, refurbishment & modernising, metalworking, automotive, ……

#8 Power Tools

Domain Est. 1999

Website: ryobitools.com

Key Highlights: Our collection includes versatile Power Tool Combo Kits, Drilling, Nailers, and more, designed for superior performance and versatility….

#9 Ingersoll Rand Cordless & Air Power Tools

Domain Est. 2001

Website: powertools.ingersollrand.com

Key Highlights: Explore Ingersoll Rand power tools, expertly crafted to handle a variety of tasks including drilling, fastening, cutting, grinding, sanding, and much more….

#10 Drills

Domain Est. 2019

Expert Sourcing Insights for Corded Drill Power Tools

H2: Projected 2026 Market Trends for Corded Drill Power Tools

The corded drill power tools market is poised for measured evolution by 2026, shaped by industrial demand, technological refinements, and competitive dynamics with cordless alternatives. While cordless drills continue to dominate consumer and light-duty applications due to advancements in battery technology, corded drills maintain a strategic foothold in professional and heavy-duty sectors. This analysis outlines key trends expected to influence the corded drill segment through 2026.

-

Stable Demand in Industrial and Commercial Sectors

Corded drills are expected to retain strong demand in construction, manufacturing, and industrial maintenance where continuous operation, high torque, and reliability are critical. Their uninterrupted power supply makes them ideal for extended use on job sites with reliable electrical infrastructure. As global infrastructure projects increase—particularly in emerging markets—demand for durable, cost-effective corded models is projected to remain steady. -

Price Sensitivity and Cost Efficiency Driving Adoption

Corded drills typically offer a lower upfront cost compared to high-end cordless models with advanced battery systems. In markets where budget constraints are paramount—such as small contracting firms and DIY users in developing economies—this cost advantage will support continued adoption. By 2026, manufacturers may focus on value-engineered models that deliver performance without premium pricing. -

Technological Integration and Efficiency Improvements

Although innovation in corded drills lags behind cordless tools, advancements in motor efficiency, variable speed controls, and ergonomic design will persist. Brushless motor technology, once exclusive to cordless tools, is beginning to appear in high-end corded models, improving energy efficiency and lifespan. Integration with smart features (e.g., overload protection, electronic torque control) may also increase, enhancing user safety and performance. -

Environmental and Regulatory Pressures

Energy efficiency standards and environmental regulations in regions like the EU and North America may push manufacturers to develop more energy-efficient motors and reduce the carbon footprint of production. While corded tools rely on grid power (which may not always be green), their lack of battery waste presents a sustainability advantage over cordless tools with lithium-ion disposal issues. -

Competition with Cordless Tools Restraining Growth

The rapid improvement in cordless drill performance—especially in battery life, power output, and charging speed—continues to erode the traditional advantages of corded models. By 2026, corded drills are expected to occupy a niche segment, primarily in fixed workstations or continuous-use environments, rather than general-purpose applications. -

Regional Market Disparities

In developed markets (North America, Western Europe), corded drill sales are expected to plateau or slightly decline due to the preference for cordless versatility. However, in regions with expanding construction industries and lower adoption of high-cost cordless systems—such as parts of Asia-Pacific, Latin America, and Africa—corded drills will likely see sustained or growing demand. -

Consolidation and Brand Positioning

Major power tool manufacturers (e.g., Bosch, DeWalt, Makita) are anticipated to streamline their corded drill offerings, focusing on professional-grade lines while shifting R&D investments toward cordless and hybrid systems. Niche and regional brands may fill the gap with affordable, reliable corded models targeting price-sensitive users.

Conclusion

By 2026, the corded drill power tools market will persist as a specialized segment within the broader power tool industry. While overall market share may shrink relative to cordless tools, corded drills will remain indispensable in applications requiring constant power, durability, and cost efficiency. Success for manufacturers will depend on optimizing performance, reducing operational costs, and clearly differentiating corded tools’ value proposition in a rapidly evolving market landscape.

Common Pitfalls When Sourcing Corded Drill Power Tools (Quality and IP)

Sourcing corded drill power tools involves navigating several potential challenges, especially concerning product quality and intellectual property (IP) risks. Overlooking these pitfalls can lead to supply chain disruptions, legal liabilities, and damage to brand reputation. Here are key areas to watch:

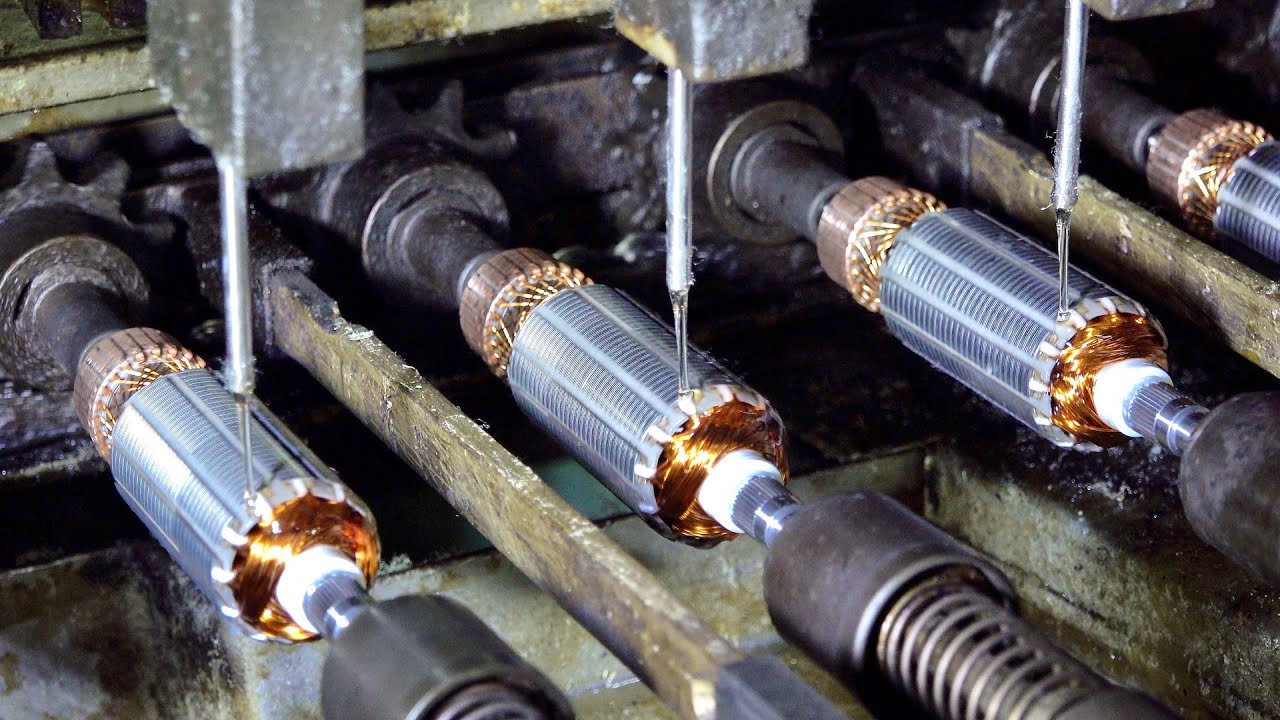

Quality Inconsistencies and Substandard Components

One of the most frequent issues when sourcing corded drills—particularly from low-cost manufacturers—is inconsistent build quality. Suppliers may use inferior materials such as low-grade motor windings, weak gearbox components, or subpar plastic housings, which reduce tool lifespan and performance. Tools may also lack proper quality control processes, leading to high failure rates during or after use. Always verify certifications (e.g., CE, UL), conduct factory audits, and require sample testing under real-world conditions to mitigate this risk.

Misrepresentation of IP Ownership and Design Infringement

Many suppliers, especially in manufacturing hubs, offer corded drills that closely resemble branded models. This raises serious IP red flags—these tools may be counterfeit, unauthorized clones, or violate design patents. Sourcing such products exposes buyers to legal action, customs seizures, and reputational harm. Always confirm that the supplier owns or has licensed the designs and request documentation of IP rights. Conduct due diligence through third-party IP searches to avoid unknowingly distributing infringing products.

Inaccurate or Inflated Performance Specifications

Suppliers may exaggerate key performance metrics like motor power (e.g., stating peak instead of sustained watts), torque output, or no-load speed. These misleading specs can result in tools underperforming in actual applications. Additionally, some manufacturers falsely claim IP (Ingress Protection) ratings—such as IP54 or IP55—for dust and water resistance without proper testing. Always validate claims through independent lab testing and request certified test reports.

Lack of Compliance with Regional Safety Standards

Corded power tools must meet region-specific electrical and safety regulations (e.g., OSHA in the US, IEC standards in Europe). Sourcing non-compliant tools can result in product recalls or import denials. Ensure your supplier provides full compliance documentation and understands the target market’s requirements to avoid costly delays.

Supply Chain and After-Sales Support Gaps

Even if the initial quality is acceptable, unreliable suppliers may lack the infrastructure for consistent production, spare parts availability, or technical support. This becomes critical when warranty claims arise or repairs are needed. Evaluate the supplier’s service capabilities and establish clear service-level agreements (SLAs) before committing.

By proactively addressing these pitfalls—focusing on verified quality, authentic IP, accurate specifications, regulatory compliance, and reliable support—buyers can significantly reduce risks and ensure a sustainable, legal, and high-performing product supply.

Logistics & Compliance Guide for Corded Drill Power Tools

Product Classification and HS Codes

Corded drill power tools are typically classified under the Harmonized System (HS) for international trade. The most common HS code is 8467.21.00, which covers electrically operated hand tools with self-contained electric motors, specifically drilling and hammering tools. However, classification may vary by country, so verification with local customs authorities or a licensed customs broker is essential prior to shipment.

Import/Export Regulations

Exporters and importers must comply with regulations in both origin and destination countries. Key considerations include:

– Export Controls: Ensure compliance with export control laws (e.g., U.S. Export Administration Regulations, or EAR) if components have dual-use applications.

– Restricted Destinations: Be aware of sanctioned countries or regions where shipments may be prohibited.

– Documentation: Prepare accurate commercial invoices, packing lists, and bills of lading. Include full product descriptions, quantities, weights, values, and HS codes.

Electrical Safety and Certification Requirements

Corded drills must meet electrical safety standards in the target market. Common certifications include:

– North America: UL (Underwriters Laboratories) or ETL certification to UL 62841 (Hand-Held Motor-Operated Electric Tools Safety Standard).

– European Union: CE marking under the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive. Compliance with EN 62841 series is required.

– United Kingdom: UKCA marking (post-Brexit), with conformity to BS EN 62841.

– Australia/New Zealand: RCM (Regulatory Compliance Mark) under AS/NZS 62841.

– Other Markets: Local certifications such as CCC (China), KC (South Korea), or PSE (Japan) may apply.

Packaging and Marking Requirements

Proper packaging ensures product safety during transit and compliance with regulations:

– Packaging: Use sturdy, recyclable materials to prevent damage. Include internal cushioning and secure fastening.

– Labeling: Clearly display:

– Product name and model number

– Voltage, frequency, and power rating (e.g., 120V~, 60Hz, 750W)

– Manufacturer/importer details

– Safety warnings and symbols

– Certification marks (e.g., CE, UL, RCM)

– Multilingual Labels: Required in some regions (e.g., EU, Canada); include safety instructions and warnings in local languages.

Battery and Motor Compliance (if applicable)

While corded drills do not use batteries, their motors and electrical components must comply with RoHS (Restriction of Hazardous Substances) directives in the EU and similar regulations globally, limiting lead, mercury, cadmium, and other hazardous materials.

Transportation and Logistics

- Shipping Mode: Ocean freight is typical for bulk shipments; air freight may be used for urgent or low-volume orders.

- Hazard Classification: Corded drills are generally non-hazardous (UN 3481 may apply if batteries are included, but not relevant for purely corded models).

- Palletization: Unitize shipments on standard pallets (e.g., 48″x40″ in North America) with stretch wrapping. Label each pallet with handling instructions and shipping marks.

- Temperature and Humidity: Store and transport in dry, climate-controlled environments to prevent corrosion or damage.

Customs Clearance and Duties

- Duty Rates: Vary by country and HS code. For example, U.S. import duty on corded drills under 8467.21.00 is typically 3.7%.

- Valuation: Customs value must include cost, insurance, and freight (CIF). Transfer pricing and related-party transactions must be documented.

- De Minimis Thresholds: Small shipments below a certain value may be exempt from duties and taxes (e.g., $800 in the U.S. under Section 321).

Environmental and End-of-Life Compliance

- WEEE Directive (EU): Producers must register and provide take-back options for waste electrical equipment. Include WEEE symbol on packaging or product.

- Producer Responsibility: In several countries, importers are considered producers and must comply with recycling and reporting obligations.

Recordkeeping and Documentation Retention

Maintain records for a minimum of:

– 5 years (U.S. CBP)

– 10 years (EU customs)

Records should include:

– Test reports and certification documents

– Technical files and conformity declarations

– Shipping and customs documentation

– Supplier compliance statements

Best Practices for Compliance

- Partner with certified testing laboratories for product evaluations.

- Regularly audit suppliers for component compliance.

- Stay updated on regulatory changes via government websites and trade associations.

- Use a customs broker or trade compliance specialist for complex shipments.

Adhering to this guide ensures smooth international logistics and regulatory compliance for corded drill power tools, minimizing delays, penalties, and product recalls.

In conclusion, sourcing corded drill power tools requires a strategic approach that balances performance, durability, cost-efficiency, and supplier reliability. Corded drills offer consistent power and uninterrupted operation, making them ideal for heavy-duty and continuous use in construction, manufacturing, and industrial applications. When selecting suppliers, it is essential to evaluate product quality, compliance with safety standards, warranty support, and after-sales service. Establishing relationships with reputable manufacturers or distributors can ensure access to reliable tools that enhance productivity and reduce long-term maintenance costs. Additionally, considering factors such as energy efficiency, ergonomics, and compatibility with existing tool systems contributes to smarter sourcing decisions. Ultimately, a well-informed procurement strategy for corded drill power tools supports operational efficiency, worker safety, and overall project success.