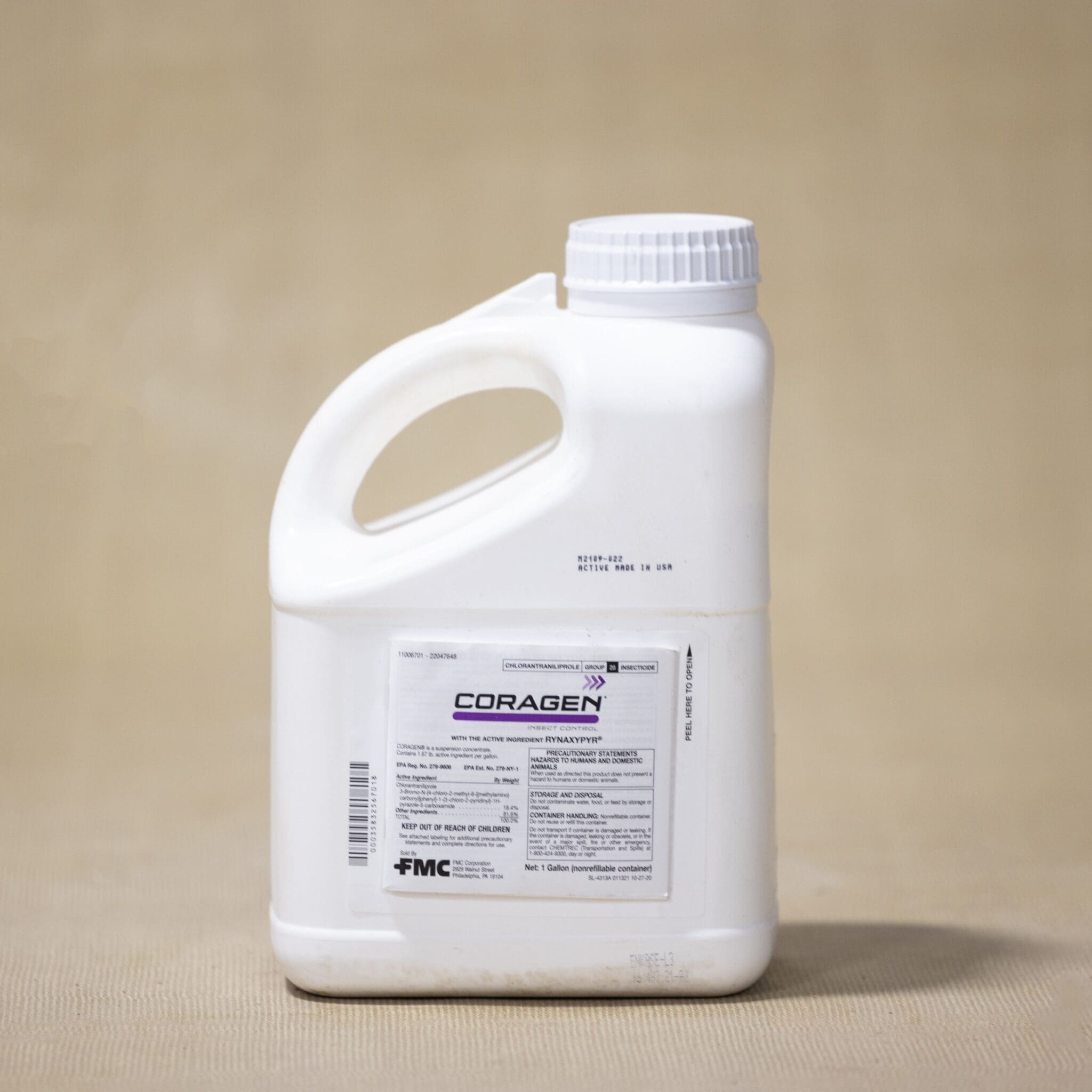

The global insecticide market is witnessing steady expansion, driven by increasing agricultural intensification and rising demand for crop protection solutions. According to Mordor Intelligence, the global insecticides market was valued at USD 17.42 billion in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2029. A key contributor to this trend is the adoption of advanced active ingredients like chlorantraniliprole, the primary component in Coragen®. As one of the most effective insecticides for controlling lepidopteran pests, Coragen has set industry benchmarks for performance and sustainability. With growing regulatory and environmental scrutiny on older chemistries, manufacturers producing chlorantraniliprole-based formulations—including Coragen and its equivalents—are gaining prominence. Below are the top three manufacturers leading innovation, quality, and market penetration in the Coragen insecticide space.

Top 3 Coragen Insecticide Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Coragen® eVo Insect Control

Domain Est. 1986

Website: ag.fmc.com

Key Highlights: Coragen® eVo insect control powered by Rynaxypyr® active offers fast acting long lasting protection against key pests….

#2 Coragen Insect Control

Domain Est. 1997

Website: greenbook.net

Key Highlights: View the product label for Coragen Insect Control from FMC Corporation. See active ingredients, product application, restrictions, and more at Greenbook….

#3 Chlorantraniliprole (Coragen® 20% SC) exposure induced …

Domain Est. 1997

Website: pmc.ncbi.nlm.nih.gov

Key Highlights: The reproductive toxicity of coragen, a modified ryanodine receptor-targeting insecticide with chlorantraniliprole concentrations of 20%, was examined in male ……

Expert Sourcing Insights for Coragen Insecticide

H2: Market Trends for Coragen Insecticide in 2026

As we approach 2026, the market dynamics for Coragen® insecticide—a leading chlorantraniliprole-based product developed by Corteva Agriscience—are being shaped by a confluence of regulatory, agricultural, and environmental factors. Coragen has established itself as a key player in integrated pest management (IPM) systems due to its broad-spectrum efficacy against lepidopteran pests, strong crop safety profile, and favorable environmental characteristics. The following trends are expected to define Coragen’s market trajectory in 2026:

1. Expansion in Global Crop Protection Demand

With rising global food demand driven by population growth and shifting dietary patterns, there is increasing pressure on farmers to maximize yields. Coragen’s proven performance in high-value crops such as fruits, vegetables, soybeans, and cotton positions it well for continued adoption. Emerging markets in Asia-Pacific, Latin America, and Sub-Saharan Africa are expected to contribute significantly to volume growth, especially as awareness of modern IPM practices increases.

2. Regulatory and Sustainability Pressures

Regulatory scrutiny on older, broad-spectrum insecticides (e.g., organophosphates and pyrethroids) continues to intensify due to environmental and health concerns. Coragen benefits from its lower mammalian toxicity and reduced impact on non-target organisms, aligning with global sustainability goals. In 2026, regulatory tailwinds—especially in the EU and North America—will likely favor reduced-risk insecticides like Coragen, further solidifying its role in compliant pest control programs.

3. Resistance Management and Stewardship Programs

The threat of insecticide resistance remains a critical concern. Corteva’s stewardship initiatives, including label restrictions and partnerships promoting mode-of-action rotation, are helping to preserve Coragen’s efficacy. By 2026, integrated resistance management strategies—where Coragen is used in rotation with biologicals and other chemistry groups—are expected to become standard practice, enhancing its long-term market viability.

4. Rise of Precision Agriculture and Digital Integration

Digital farming tools are gaining adoption, enabling targeted pesticide applications. In 2026, Coragen is increasingly being integrated into precision agriculture platforms, where data-driven scouting and predictive analytics optimize spray timing and dosage. Corteva’s collaboration with digital ag providers enhances Coragen’s value proposition by improving cost-efficiency and environmental performance.

5. Competition and Market Differentiation

While newer chemistries and biological alternatives are entering the market, Coragen maintains a competitive edge due to its residual activity, systemic properties, and crop versatility. However, increasing competition from generics of chlorantraniliprole (following patent expirations in certain regions) may pressure pricing. Corteva’s focus on brand integrity, technical support, and bundled solutions (e.g., seed treatments and digital tools) will be key to maintaining premium positioning.

6. Climate Change and Pest Pressure Shifts

Changing climate patterns are expanding the geographic range and lifecycle intensity of key lepidopteran pests (e.g., fall armyworm, corn earworm). This increased pest pressure is driving demand for reliable, long-lasting control solutions. Coragen’s performance under variable climatic conditions reinforces its relevance, particularly in regions experiencing more frequent pest outbreaks.

Conclusion

By 2026, Coragen insecticide is poised to remain a cornerstone product in modern agriculture, supported by strong science, regulatory alignment, and evolving farming practices. While market challenges such as generic competition and resistance risks persist, strategic innovation and sustainability leadership will enable Coragen to maintain a dominant share in the insecticide segment, especially within high-value and export-oriented crop systems.

Common Pitfalls When Sourcing Coragen Insecticide (Quality & Intellectual Property)

Sourcing Coragen® insecticide, a branded product containing the active ingredient chlorantraniliprole developed by Corteva Agriscience, involves significant risks related to quality and intellectual property (IP). Avoiding these common pitfalls is crucial for ensuring product efficacy, regulatory compliance, and legal safety.

1. Falling for Counterfeit or Substandard Products

One of the most prevalent risks is inadvertently purchasing counterfeit or low-quality generics misrepresented as genuine Coragen. These products may contain incorrect concentrations of chlorantraniliprole, impurities, or entirely different active ingredients. This compromises pest control effectiveness, risks crop damage, and may leave illegal chemical residues on produce. Visual similarity of packaging does not guarantee authenticity—counterfeiters often replicate labels closely.

2. Ignoring Regulatory and Registration Compliance

Coragen is a registered pesticide with stringent regional and national regulations. Sourcing from unauthorized suppliers—especially outside regulated distribution channels—increases the likelihood of acquiring unregistered or non-compliant products. Using such products may violate local agricultural laws, result in fines, and disqualify crops from entering regulated markets (e.g., export to the EU or U.S.).

3. Overlooking Intellectual Property Infringement

Coragen is a trademarked brand protected by intellectual property laws. Sourcing products labeled as “Coragen” from unauthorized manufacturers constitutes trademark infringement. Even if a product contains chlorantraniliprole, using the Coragen name without authorization exposes buyers and distributors to legal liability. Be cautious of products labeled as “generic Coragen” or using similar branding, as these often infringe on Corteva’s IP rights.

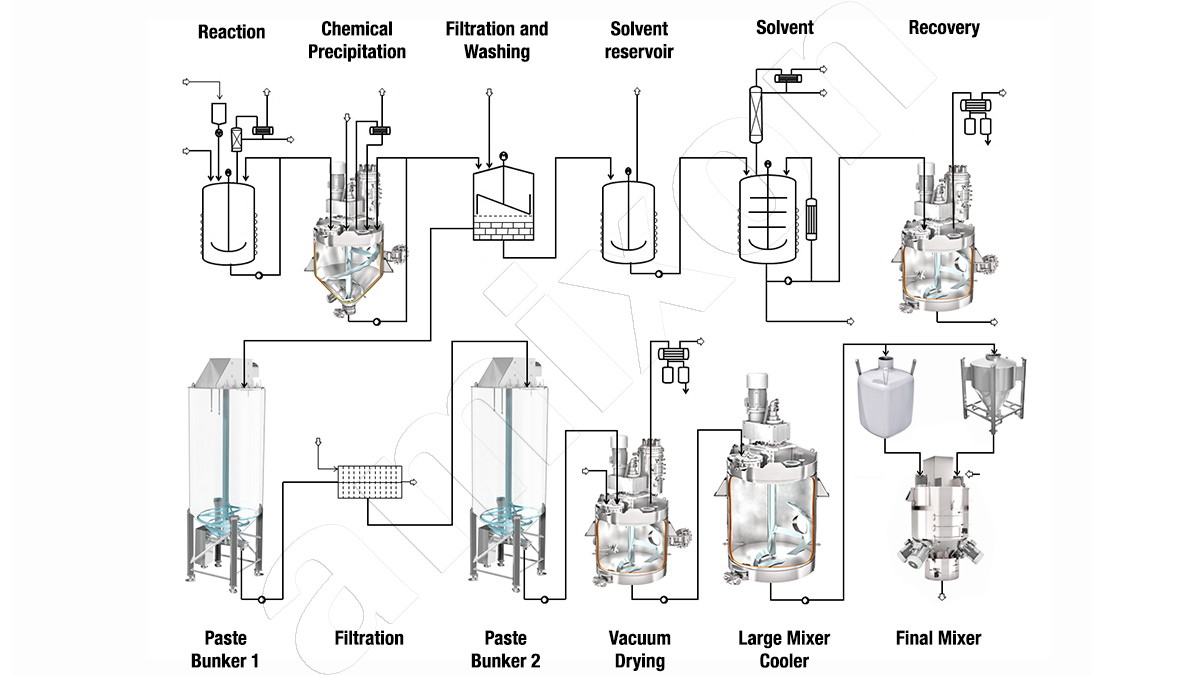

4. Assuming All Chlorantraniliprole Products Are Equivalent

While chlorantraniliprole is the active ingredient in Coragen, formulation matters. Corteva’s proprietary formulation ensures optimal stability, dispersion, and biological performance. Generic versions may use different adjuvants or manufacturing processes that reduce field performance or compatibility with other agrochemicals. Assuming chemical equivalence without field testing can lead to unexpected control failures.

5. Procuring Through Unverified or Illicit Supply Chains

Purchasing Coragen through unofficial distributors, online marketplaces, or gray-market channels increases exposure to counterfeit goods and IP violations. These channels often lack traceability, making it difficult to verify product origin or obtain support in case of quality issues. Always source through authorized distributors or directly from Corteva-approved suppliers.

6. Lack of Documentation and Traceability

Reputable suppliers provide batch-specific certificates of analysis (CoA), safety data sheets (SDS), and proof of origin. Failing to obtain or verify these documents makes it difficult to confirm product quality or defend against regulatory scrutiny. In the event of a product failure or legal challenge, traceability becomes critical.

7. Underestimating Legal and Reputational Risks

Using counterfeit or IP-infringing products can result in legal action from Corteva Agriscience, including cease-and-desist orders, fines, or litigation. Additionally, farms or distributors found using fake pesticides may suffer reputational damage, loss of certification (e.g., GlobalG.A.P.), and exclusion from premium supply chains.

Conclusion:

To mitigate these risks, always verify the authenticity of Coragen by purchasing through official channels, checking for proper registration in your region, and requesting full product documentation. Prioritize compliance over cost savings—protecting your crops, business, and legal standing is far more valuable than a short-term price advantage.

H2: Logistics & Compliance Guide for Coragen® Insecticide

Proper logistics and regulatory compliance are essential for the safe, legal, and effective handling, storage, transportation, and use of Coragen® insecticide (active ingredient: Rynaxypyr®). This guide outlines key considerations for distributors, retailers, applicators, and agricultural operators to ensure adherence to federal, state, and local regulations, as well as manufacturer recommendations.

-

Regulatory Classification & Labeling

-

EPA Registration: Coragen® is registered with the U.S. Environmental Protection Agency (EPA Reg. No. 100-1450). Always use the product in accordance with the current EPA-approved label.

- Hazard Classification: Coragen® is classified as a General Use Pesticide. It is not classified as a Restricted Use Pesticide (RUP), meaning no special applicator certification is required at the federal level—though state-specific requirements may apply.

-

GHS Labeling: Follow Globally Harmonized System (GHS) standards where applicable. Coragen® labels include signal words (“Danger”), hazard statements, precautionary statements, and pictograms indicating acute toxicity and environmental hazards.

-

Storage Requirements

-

Temperature: Store in a cool, dry, well-ventilated area between 32°F (0°C) and 100°F (38°C). Avoid freezing and excessive heat.

- Container Integrity: Keep product in original, tightly sealed container. Do not transfer to unmarked or incompatible containers.

- Segregation: Store away from food, feed, fertilizers, and other agricultural chemicals, especially strong oxidizers or acids.

-

Secondary Containment: Use spill pallets or containment systems to prevent environmental contamination in case of leaks.

-

Transportation Guidelines

-

Ground Transport (U.S. DOT): Coragen® is generally not regulated as a hazardous material under Department of Transportation (DOT) regulations (49 CFR) when shipped in approved packaging. Confirm classification using the Safety Data Sheet (SDS).

- Packaging: Use UN-rated packaging if required. Ensure containers are leak-proof, impact-resistant, and properly labeled with product name, EPA number, net contents, and supplier information.

- Documentation: Maintain shipping papers, SDS, and purchase records. Retain manifests for traceability.

-

International Shipments: Comply with IMDG (sea), IATA (air), or other applicable regulations. Obtain import permits if shipping across borders (e.g., Canada, Mexico).

-

Handling & Personal Protection

-

PPE Requirements (per label): Applicators must wear:

- Chemical-resistant gloves

- Long-sleeved shirt and long pants

- Shoes plus socks

- Protective eyewear (if mixing/concentrate handling)

- Avoid skin contact and inhalation. Wash hands thoroughly after handling.

-

Never eat, drink, or smoke while handling Coragen®.

-

Environmental & Application Compliance

-

Application Rates: Follow label-specified rates by crop and pest. Do not exceed maximum seasonal application limits.

- Buffer Zones: Observe required buffer zones near water bodies to protect aquatic organisms. Coragen® is highly toxic to aquatic invertebrates.

- Runoff & Drift: Apply using methods that minimize spray drift and runoff. Avoid application during high wind or rain events.

-

Pollinator Protection: Coragen® has low toxicity to bees when dry; however, avoid direct application to blooming crops or weeds where bees are foraging.

-

Recordkeeping & Documentation

-

Maintain application records for a minimum of 2 years (or as required by state law), including:

- Date, time, and location of application

- Crop and pest targeted

- Rate and volume applied

- Applicator name and certification number (if required)

-

Keep copies of the current product label and SDS on file.

-

Spill Response & Emergency Procedures

-

Spill Kit: Equip handling areas with absorbents, containment tools, PPE, and disposal bags.

- Small Spills: Contain with absorbent material, collect in labeled container, and dispose of as hazardous waste.

- Large Spills: Evacuate area, notify authorities, and contact emergency response (e.g., CHEMTREC: 1-800-424-9300).

-

Report spills to appropriate state and federal agencies if they reach waterways or exceed reportable quantities.

-

Disposal & Waste Management

-

Triple-rinse empty containers and puncture to prevent reuse. Follow label instructions for rinsate application or disposal.

- Dispose of unused product and contaminated materials through authorized pesticide collection programs or hazardous waste facilities.

-

Never pour down drains, toilets, or into stormwater systems.

-

State & Local Compliance

-

Verify state-specific regulations (e.g., California’s DPR, New York’s DEC) regarding use restrictions, reporting, or permitting.

-

Some states may require notification prior to application near sensitive sites (schools, water bodies, residential areas).

-

Training & Certification

-

Ensure all personnel are trained in pesticide safety, spill response, and label compliance.

- Applicators should review the Coragen® label and SDS before each use.

- Access training resources through EPA, state departments of agriculture, or the manufacturer (Corteva Agriscience™).

For the most up-to-date information, always refer to the official Coragen® product label and Safety Data Sheet (SDS), available at: www.corteva.com

Note: This guide is informational and does not replace the legal requirements of the product label or regulatory authority directives.

Conclusion for Sourcing Coragen Insecticide:

After a thorough evaluation of the sourcing options for Coragen® insecticide, it is evident that effective procurement requires careful consideration of supplier reliability, regulatory compliance, product authenticity, cost-efficiency, and supply chain consistency. Coragen, a highly effective insecticide containing the active ingredient chlorantraniliprole, is essential for managing key insect pests in crops such as vegetables, fruits, and row crops, and its proper sourcing directly impacts agricultural productivity and crop protection outcomes.

Sourcing through authorized distributors or directly from the manufacturer, Corteva Agriscience, ensures product quality, access to technical support, and compliance with local and international regulations. While alternative suppliers may offer competitive pricing, the risks associated with counterfeit or substandard products cannot be overlooked. Furthermore, integrating sustainable and responsible sourcing practices—such as proper handling, storage, and adherence to integrated pest management (IPM) principles—enhances environmental stewardship and long-term efficacy.

In conclusion, the optimal sourcing strategy for Coragen insecticide balances cost, availability, and quality while prioritizing authorized channels and regulatory standards. Establishing long-term partnerships with certified suppliers and staying informed on label updates and application guidelines will ensure effective pest control, regulatory compliance, and sustainable agricultural practices.