The industrial automation sector in the United States has seen robust expansion, with the conveyor and drive systems market playing a pivotal role in modern material handling operations. According to Grand View Research, the global conveyor system market size was valued at $6.7 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth is driven by increasing demand for efficient logistics solutions across manufacturing, automotive, food and beverage, and e-commerce sectors—industries with a strong presence in Georgia. Atlanta, in particular, has emerged as a Southeastern hub for industrial innovation and supply chain infrastructure, supported by its strategic location, skilled workforce, and advanced manufacturing ecosystem. As automation adoption accelerates, local manufacturers of conveyors and drives are well-positioned to meet rising regional demand. Based on production output, technological integration, and market reach, the following four companies represent the leading conveyor and drive manufacturers in Atlanta, GA.

Top 4 Conveyors And Drives Atlanta Ga Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Conveyors & Drives, Inc. Information

Domain Est. 2013 | Founded: 1969

Website: signalhire.com

Key Highlights: Established in 1969, Conveyors & Drives is the premier boutique material handling automation integration firm serving middle-market manufacturers, ……

#2 Conveyors & Drives, Inc.

Domain Est. 2010

Website: georgiamanufacturingalliance.com

Key Highlights: Conveyors & Drives, Inc. is a recognized leader and provider of material handling solutions across the nation. Headquartered in Atlanta, Georgia, ……

#3 Conveyors & Drives, Inc.

Website: conveyorcompanies.com

Key Highlights: At Conveyors & Drives, Inc., we have a profound commitment to delivering high-quality conveyor systems and a wide range of associated products, services, ….

#4 Our Products

Domain Est. 1998

Website: condrives.com

Key Highlights: We offer a variety of material handling products including new and used conveyors, automatic guided vehicles and more….

Expert Sourcing Insights for Conveyors And Drives Atlanta Ga

H2: 2026 Market Trends for Conveyors and Drives in Atlanta, GA

As the industrial and manufacturing landscape continues to evolve, Atlanta, Georgia, is poised to become an even more critical hub for conveyors and drives technology by 2026. Several key trends are expected to shape the market, driven by technological innovation, regional economic growth, and shifts in supply chain dynamics.

1. Increased Automation Across Key Industries

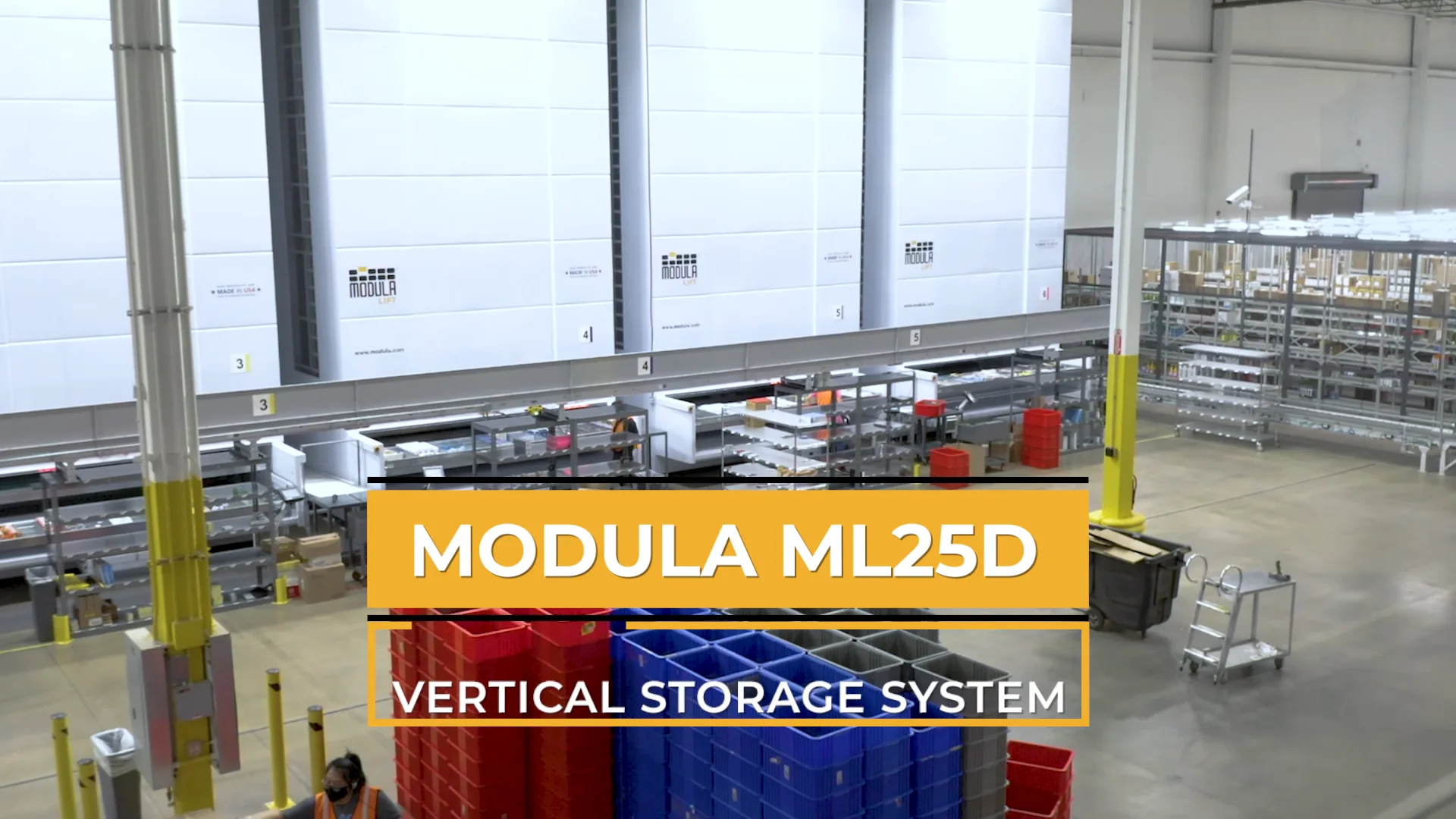

Atlanta’s robust presence in logistics, e-commerce, food and beverage, and automotive manufacturing is accelerating the demand for automated material handling systems. By 2026, companies will increasingly adopt smart conveyors and precision drives integrated with IoT sensors and predictive maintenance capabilities. This shift aims to improve operational efficiency, reduce downtime, and support just-in-time manufacturing and fulfillment models.

2. Growth in E-Commerce and Last-Mile Distribution

With major distribution centers from Amazon, UPS, and other logistics firms located in or near Atlanta, the region’s conveyor and drive market will benefit from continued investment in high-speed sorting systems and automated packaging lines. Conveyors designed for flexibility, scalability, and integration with robotics will see heightened demand to meet the needs of rapid order fulfillment.

3. Emphasis on Energy Efficiency and Sustainable Solutions

Environmental regulations and corporate sustainability goals are pushing manufacturers and logistics providers to adopt energy-efficient drives and regenerative conveyor systems. Variable frequency drives (VFDs) and servo-driven conveyors that reduce energy consumption will be in higher demand. Local suppliers and integrators in Atlanta will increasingly offer green-certified or energy-optimized solutions to meet compliance and cost-saving objectives.

4. Rise of Smart Manufacturing and Industry 4.0 Integration

By 2026, Atlanta’s industrial sector will see broader adoption of Industry 4.0 principles. Conveyors and drives will increasingly be embedded with real-time monitoring, data analytics, and connectivity to centralized control systems like SCADA and MES. This digital transformation will enable better asset tracking, throughput optimization, and seamless integration with warehouse management systems (WMS).

5. Skilled Labor Shortages Driving Demand for Low-Maintenance Systems

As the manufacturing and logistics industries face ongoing labor challenges, there will be a growing preference for conveyors and drives that require minimal maintenance and offer plug-and-play installation. Atlanta-based providers will respond with modular designs, remote diagnostics, and augmented reality (AR)-assisted servicing to reduce dependency on specialized technicians.

6. Expansion of Local Supply Chain and Onshoring Trends

With a national push toward supply chain resilience, more companies are reshoring production to the U.S. Southeast. Atlanta’s strategic location, transportation infrastructure, and business-friendly climate make it an attractive location for new manufacturing facilities. This industrial growth will directly increase demand for conveyor systems and industrial drives, benefiting local distributors, integrators, and service providers.

7. Technological Innovation in Drive Systems

Advancements in motor efficiency, compact drive designs, and integration with AI-driven controls will redefine drive performance. Servo and stepper drive technologies will gain traction in precision applications, while decentralized drive architectures will support modular automation in Atlanta’s growing smart factories.

Conclusion

By 2026, the conveyors and drives market in Atlanta, GA, will be defined by digitalization, sustainability, and scalability. Companies that invest in smart, flexible, and energy-efficient systems will lead the market, supported by the region’s expanding industrial base and strategic logistics role. Local businesses must adapt quickly to these trends to remain competitive and meet the evolving demands of modern manufacturing and distribution.

Common Pitfalls When Sourcing Conveyors and Drives in Atlanta, GA (Quality and IP Considerations)

Sourcing conveyors and drives in Atlanta, GA, offers access to a robust industrial supply chain and technical expertise. However, businesses often encounter pitfalls related to quality assurance and intellectual property (IP) protection. Being aware of these issues can help avoid costly delays, performance issues, and legal complications.

Inconsistent Quality Standards

One of the most common challenges is variability in product quality among suppliers. Not all manufacturers or distributors adhere to the same quality control processes. Some may use substandard materials or outdated engineering practices, leading to premature equipment failure, increased maintenance costs, and safety hazards.

Lack of Certifications and Compliance

Many conveyors and drive systems must meet industry-specific standards (e.g., ANSI, ISO, OSHA, or CE). Sourcing from vendors who cannot provide proper certifications may result in non-compliant installations, which can lead to operational shutdowns or regulatory fines.

Inadequate Testing and Validation

Some suppliers may skip rigorous testing protocols, especially for custom-engineered systems. Without proper load testing, environmental stress testing, or performance validation, the equipment may not function as expected under real-world conditions.

Poor Documentation and Traceability

Incomplete or missing documentation—such as schematics, operation manuals, or material certifications—can hinder maintenance, troubleshooting, and future upgrades. This lack of traceability also makes it difficult to verify quality claims or track component origins.

Intellectual Property Risks with Custom Designs

When working with local manufacturers on custom conveyor or drive solutions, companies often share proprietary designs, control logic, or integration specifications. Without proper legal agreements (e.g., NDAs or IP assignment clauses), there’s a risk the supplier could reuse or resell your design to competitors.

Use of Counterfeit or Reverse-Engineered Components

Some suppliers may unknowingly—or deliberately—source counterfeit drives, motors, or control modules. These components can compromise system reliability and pose significant IP infringement risks, especially if they mimic patented technology from well-known brands.

Weak Contracts and Warranty Terms

Vague or limited warranty coverage can leave buyers exposed if components fail prematurely. Additionally, contracts that don’t clearly define IP ownership or usage rights can lead to disputes down the line, particularly when software or custom engineering is involved.

Overlooking Service and Support Capabilities

Even high-quality equipment requires ongoing support. Choosing a supplier based solely on price without evaluating their service network, response time, or technical expertise can result in extended downtime and higher lifecycle costs.

Final Recommendation

To mitigate these risks, businesses should:

– Vet suppliers thoroughly, including audits and reference checks.

– Require certifications and detailed technical documentation.

– Use strong contracts that protect IP and define quality expectations.

– Partner with reputable, established providers in the Atlanta industrial sector.

By proactively addressing quality and IP concerns, companies can ensure reliable, compliant, and legally secure conveyor and drive systems.

Logistics & Compliance Guide for Conveyors and Drives – Atlanta, GA

Overview

Conveyors and Drives, based in Atlanta, Georgia, operates in a dynamic industrial environment that demands strict adherence to logistics efficiency and regulatory compliance. This guide outlines key considerations for managing the transportation, warehousing, installation, and regulatory requirements associated with conveyor systems and industrial drive components in the Atlanta metro area.

Transportation & Distribution

Atlanta’s strategic location as a Southeast transportation hub provides Conveyors and Drives with access to major highways (I-75, I-85, I-20), Hartsfield-Jackson International Airport, and Class I rail lines (CSX, Norfolk Southern). This enables efficient inbound shipping of components and outbound delivery of systems.

– Utilize regional freight carriers and logistics partners experienced in oversized industrial equipment.

– Coordinate just-in-time (JIT) deliveries to minimize on-site storage and support lean manufacturing clients.

– Ensure proper crating, labeling, and securement for fragile or heavy drive components during transit.

Warehousing & Inventory Management

Maintaining an organized warehouse in the Atlanta area supports rapid fulfillment and responsive customer service.

– Implement inventory tracking systems (e.g., barcode/RFID) to monitor stock levels of motors, belts, rollers, and controls.

– Designate climate-controlled zones for sensitive electronic drives and variable frequency drives (VFDs).

– Comply with OSHA standards for material handling, stacking heights, and forklift operations.

Regulatory Compliance

Conveyors and Drives must adhere to federal, state, and local regulations in Georgia.

– OSHA Standards: All installed systems must meet OSHA 29 CFR 1910.219 (guarding of moving parts) and electrical safety standards (NFPA 70E).

– Environmental Regulations: Proper disposal of lubricants and packaging materials in accordance with Georgia Environmental Protection Division (EPD) guidelines.

– DOT Compliance: For company-operated vehicles, maintain FMCSA compliance including vehicle inspections, driver logs, and hazardous materials training if applicable.

Import/Export Considerations

If sourcing components internationally, ensure compliance with U.S. Customs and Border Protection (CBP) and Harmonized Tariff Schedule (HTS) classifications.

– Accurately classify drive motors, gearboxes, and control panels to avoid duty overpayments.

– Maintain records for FDA/FTC if any components contain restricted substances.

– Leverage Atlanta’s Foreign Trade Zone (FTZ #22) for deferred customs duties and streamlined processing.

Installation & Field Service Compliance

On-site installations must follow engineering specifications and safety codes.

– Technicians must be trained and certified in lockout/tagout (LOTO), electrical safety, and fall protection.

– Submit as-built drawings and compliance documentation to clients, including NEC (NFPA 70) and ANSI/ASME B20.1 safety standards.

– Maintain liability and workers’ compensation insurance as required by Georgia law.

Customer Documentation & Certification

Provide clients with comprehensive compliance and operation packages.

– Include equipment manuals, CE/UL certification marks (if applicable), and warranty information.

– Offer training sessions to ensure safe and compliant operation of conveyor and drive systems.

Emergency Response & Risk Management

Prepare for logistical disruptions such as severe weather or supply chain delays common in the Southeast.

– Develop a business continuity plan with backup suppliers and alternative transport routes.

– Maintain spill kits and fire extinguishers in vehicles and warehouse per NFPA standards.

Conclusion

By aligning logistics operations with federal and state compliance requirements, Conveyors and Drives can ensure reliable service, mitigate legal risk, and maintain a strong reputation across the Atlanta industrial market. Regular audits, employee training, and partnerships with certified logistics providers are essential to long-term success.

In conclusion, sourcing conveyors and drives in Atlanta, GA offers numerous advantages due to the region’s strong industrial infrastructure, strategic transportation access, and concentration of specialized suppliers and distributors. With a wide range of local vendors, manufacturers, and service providers, businesses can find reliable, high-quality conveyor systems and drive components tailored to their specific operational needs. Additionally, the availability of expert installation, maintenance, and technical support within the area ensures long-term system efficiency and uptime. By leveraging Atlanta’s robust industrial supply network, companies can streamline operations, reduce lead times, and benefit from cost-effective solutions—making Atlanta a prime location for sourcing material handling equipment.