The global construction caulking market is experiencing steady growth, driven by rising infrastructure development, residential renovations, and increasing demand for energy-efficient building solutions. According to a report by Grand View Research, the global sealants market—of which construction caulking is a major segment—was valued at USD 12.9 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. Growth is further bolstered by stricter building codes prioritizing weather resistance and thermal performance, particularly in regions such as North America and Europe. Additionally, Mordor Intelligence forecasts sustained momentum in the construction adhesives and sealants market, citing urbanization and green building initiatives as key catalysts. As demand rises, innovation in durability, sustainability, and application ease has positioned leading manufacturers to capitalize on evolving industry needs. In this competitive landscape, ten companies have emerged as dominant players, combining technological expertise, global distribution, and robust product portfolios to meet the demands of modern construction.

Top 10 Construction Caulking Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 DAP Global Inc.

Domain Est. 1995

Website: dap.com

Key Highlights: Founded in 1865, DAP is a leading manufacturer and supplier of caulks, sealants, foam, adhesives, and patch and repair products with a history of ……

#2 Caulks and Sealants

Domain Est. 1992

Website: dow.com

Key Highlights: Dow’s adhesive, bonding, and sealant formulations create reliable, long-lasting bonds for a wide range of substrates and applications….

#3 Construction Sealant Products

Domain Est. 1996

Website: bostik.com

Key Highlights: Bostik is one of the only manufacturers that offers a full line of sealant technologies—including acrylics, hybrids, polyurethanes, and silicones — perfect for ……

#4 Sikaflex® – The Leading Brand for Sealants and Adhesives

Domain Est. 1995

Website: sika.com

Key Highlights: Sikaflex is known as the world’s leading brand for elastic one-component adhesives and sealants based on polyurethane (PU) or silane-terminated polymer (STP)….

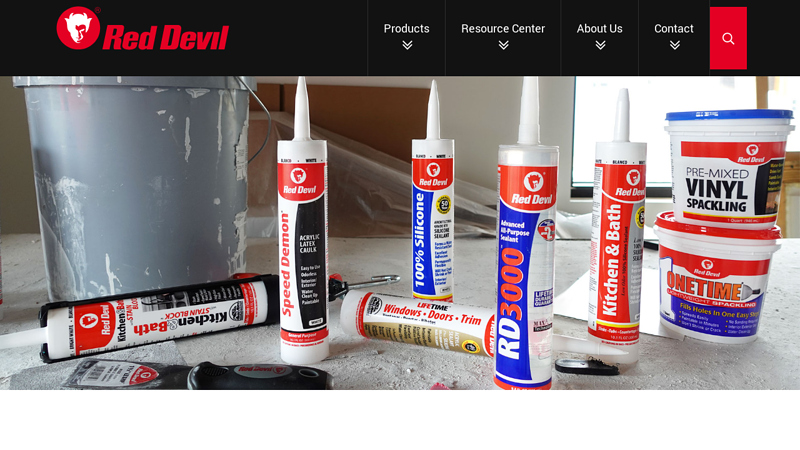

#5 Red Devil >

Domain Est. 1995

#6 Commercial Sealants & Waterproofing Products

Domain Est. 1996

Website: tremcosealants.com

Key Highlights: Securock® ExoAir® 430 (SE430). Pre-Applied Fluid Synthetic Air & Vapor Permeable Membrane to Gypsum Exterior Sheathing….

#7 Geocelusa

Domain Est. 1999

Website: geocelusa.com

Key Highlights: For over 40 years, our industry-leading roofing sealants have delivered on our promise to give Pro contractors and builders like you the confidence to get the ……

#8 SSI

Domain Est. 1999

Website: ssicm.com

Key Highlights: If It Seals It, We Sell It! SSI Online Ordering Is Now Available! Click the link below Your Source For ONLINE PAYMENT PORTAL IS NOW LIVE! SSI…

#9 OSI sealants

Domain Est. 2013

Website: ositough.com

Key Highlights: Adhesives. For superior adhesion, OSI got you covered. Our construction adhesives are expertly formulated and designed by pros, for pros….

#10 GE Sealants

Domain Est. 2016

Website: gesealants.com

Key Highlights: For more than 80 years, GE Sealants has led the caulk and sealants industry with a wide selection of hybrid, acrylic, and silicone caulk and sealants….

Expert Sourcing Insights for Construction Caulking

H2: 2026 Market Trends for Construction Caulking

The global construction caulking market is poised for steady growth and notable transformation by 2026, driven by evolving industry demands, technological advancements, and regulatory shifts. Key trends shaping the market include:

1. Surge in Sustainable and Low-VOC Products:

Environmental regulations and green building certifications (like LEED and BREEAM) are accelerating the demand for eco-friendly caulking solutions. In 2026, low-VOC (volatile organic compound), solvent-free, and bio-based sealants will dominate, especially in residential and commercial projects. Manufacturers are investing in R&D to improve the performance of sustainable formulations without compromising durability or adhesion.

2. Growth in Renovation and Retrofitting Activities:

As urban infrastructure ages and energy efficiency becomes a priority, renovation projects are outpacing new construction in many regions. Caulking plays a crucial role in sealing gaps, improving insulation, and reducing energy loss. By 2026, demand will be particularly strong in North America and Europe, where government incentives support energy-efficient retrofits.

3. Technological Advancements in Product Performance:

Innovations in hybrid polymers—such as MS (Modified Silane) polymers—are gaining traction due to their superior flexibility, adhesion, and weather resistance. These next-generation sealants offer faster curing times, easier application, and compatibility with diverse substrates, making them ideal for complex construction environments. Smart caulking solutions with moisture-sensing or self-healing properties are also emerging in niche markets.

4. Regional Market Expansion in Asia-Pacific:

The Asia-Pacific region, led by China, India, and Southeast Asia, will be a key growth driver in 2026. Rapid urbanization, government infrastructure initiatives, and rising disposable incomes are fueling construction activity. Local production and distribution networks are expanding to meet demand, with a growing preference for high-performance, cost-effective sealants.

5. Supply Chain Resilience and Raw Material Volatility:

Ongoing fluctuations in raw material prices (e.g., silicone, polyurethane feedstocks) and geopolitical factors continue to challenge the industry. By 2026, leading manufacturers will emphasize supply chain localization, strategic sourcing, and vertical integration to mitigate risks and maintain pricing stability.

6. Digitalization and BIM Integration:

Building Information Modeling (BIM) is influencing material selection, including caulking. In 2026, specifiers and contractors will increasingly rely on digital product data (e.g., environmental impact, performance specs) integrated into BIM platforms to make informed decisions, favoring transparent, traceable, and high-performance sealant brands.

Conclusion:

By 2026, the construction caulking market will be defined by sustainability, innovation, and regional diversification. Companies that prioritize eco-conscious product development, adapt to digital workflows, and strengthen supply chains will be best positioned to capture growth in an increasingly competitive and regulated landscape.

Common Pitfalls When Sourcing Construction Caulking (Quality and Intellectual Property)

Inadequate Quality Verification

One of the most frequent pitfalls is failing to thoroughly verify the quality of construction caulking materials. Buyers may rely solely on supplier claims or product data sheets without conducting independent testing or requesting third-party certifications. This can lead to the procurement of substandard products that fail prematurely, resulting in costly rework, water infiltration, and structural damage. It’s essential to verify performance characteristics such as adhesion, UV resistance, elongation, and durability under real-world conditions.

Overlooking Material Compatibility

Sourcing caulk without confirming compatibility with substrates (e.g., concrete, wood, metal, glass) and adjacent materials (e.g., sealants, adhesives, coatings) can compromise performance. Incompatible products may react chemically, cause staining, or fail to bond properly. Always ensure the caulk is specified for the intended application and environment.

Ignoring Environmental and Application Conditions

Caulking performance varies significantly with temperature, humidity, and exposure to weather. Selecting a product not suited for the project’s geographic or climatic conditions—such as using a standard silicone in high-movement joints or freezing environments—can lead to cracking, shrinking, or loss of adhesion.

Failing to Validate Intellectual Property Rights

A critical but often overlooked risk is the infringement of intellectual property (IP). Some suppliers, particularly offshore manufacturers, may produce caulk formulations that mimic patented chemistries or branding of established brands without licensing. Sourcing such products can expose contractors and developers to legal liability, supply chain disruptions, and reputational damage. Always verify that products are legally manufactured and do not infringe on trademarks, patents, or trade secrets.

Relying on Unverified Suppliers or Gray Market Goods

Purchasing from unqualified or unauthorized distributors increases the risk of receiving counterfeit, expired, or reformulated products. Gray market goods may not meet local building codes or regulatory standards (e.g., VOC content, fire ratings), posing compliance and safety risks.

Lack of Compliance with Local Standards and Codes

Construction caulking must meet regional building codes and environmental regulations (e.g., ASTM, ISO, LEED, VOC limits in California or the EU). Sourcing products without confirming compliance can lead to project delays, failed inspections, or penalties.

Insufficient Documentation and Traceability

Poor recordkeeping—missing batch numbers, material safety data sheets (MSDS), or test reports—hampers quality control and liability management. In the event of a failure, lack of traceability makes it difficult to identify the source and scope of the problem.

Prioritizing Cost Over Long-Term Performance

Choosing the lowest-cost option without considering lifecycle performance often results in higher long-term costs due to maintenance, repairs, and shortened service life. High-quality caulking may have a higher upfront cost but provides better durability and reduced risk.

Logistics & Compliance Guide for Construction Caulking

Product Classification and Regulatory Overview

Construction caulking products are typically classified under hazardous materials due to flammable solvents or volatile organic compounds (VOCs). These products are regulated by agencies such as OSHA (Occupational Safety and Health Administration), EPA (Environmental Protection Agency), and DOT (Department of Transportation). Understanding the specific chemical composition and compliance requirements—such as VOC content limits under EPA’s Clean Air Act or Cal/OSHA regulations in California—is essential for legal distribution and use.

Safety Data Sheets (SDS) and Labeling Requirements

All construction caulking products must be accompanied by a current Safety Data Sheet (SDS) compliant with OSHA’s Hazard Communication Standard (29 CFR 1910.1200). SDS must detail hazards, first aid measures, handling and storage instructions, and disposal considerations. Product containers must feature GHS-compliant labels with pictograms, signal words, hazard statements, and precautionary statements to ensure worker safety and regulatory compliance.

Transportation and Shipping Regulations

When transporting construction caulking, shippers must classify products according to DOT’s Hazardous Materials Regulations (49 CFR). Most solvent-based caulks fall under Hazard Class 3 (Flammable Liquids). Proper packaging, labeling (e.g., UN number, hazard class label), and documentation (e.g., shipping papers) are mandatory. Carriers must be trained and certified under DOT HAZMAT regulations. Non-compliance can lead to fines, shipment delays, or safety incidents.

Storage and Handling Protocols

Caulking materials should be stored in a cool, dry, well-ventilated area away from ignition sources and direct sunlight. Flammable caulks must be kept in approved flammable storage cabinets if volumes exceed safety thresholds. Containers should remain tightly sealed when not in use to prevent vapor release and contamination. Workers must be trained in proper handling procedures and emergency response, including spill containment using absorbent materials rated for chemical use.

Environmental and Disposal Compliance

Used or expired caulking products and contaminated materials (e.g., rags, applicators) may be classified as hazardous waste under RCRA (Resource Conservation and Recovery Act). Waste disposal must follow federal, state, and local regulations. Solvent-soaked wipes may qualify for the EPA’s Wipes Rule (40 CFR 261), allowing non-hazardous disposal if managed properly. Always consult a licensed waste disposal provider and maintain waste manifests for audit purposes.

International Trade Considerations

Exporting or importing construction caulks requires compliance with international standards such as REACH (EU), TSCA (USA), and local VOC regulations. Accurate Harmonized System (HS) codes must be assigned for customs declarations. Documentation such as certificates of analysis, non-objection letters, and import permits may be required. Ensure compliance with destination country labeling and registration requirements before shipment.

Recordkeeping and Audit Preparedness

Maintain comprehensive records including SDS archives, employee training logs, shipping documents, waste manifests, and regulatory registrations. These documents support compliance during inspections by OSHA, EPA, or DOT. Conduct regular internal audits to verify adherence to logistics and safety protocols, and update procedures in response to regulatory changes or product updates.

Conclusion for Sourcing Construction Caulking:

Sourcing the right construction caulking is a critical step in ensuring the durability, energy efficiency, and weather resistance of any building project. After evaluating various factors such as material type (silicone, acrylic, polyurethane), performance requirements (elasticity, adhesion, UV and moisture resistance), project specifications, and environmental conditions, it is clear that a tailored approach to supplier and product selection is essential. Prioritizing reputable manufacturers, verifying product certifications, and considering cost-efficiency without compromising quality will lead to optimal long-term performance. Additionally, establishing strong relationships with reliable suppliers ensures consistent material availability, technical support, and timely delivery. In conclusion, a strategic and informed sourcing process for construction caulking not only enhances structural integrity but also contributes to overall project success and client satisfaction.